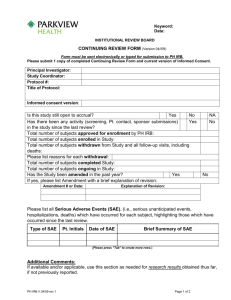

Helsinki University of Technology Internal Combustion Engine Laboratory

Helsinki University of Technology

Internal Combustion Engine Laboratory

Internal Combustion Engine Laboratory

– Located in the Department of Mechanical

Engineering and in the Group of Vehicle

Engineering

– The only university level research and education unit for advanced engine technology in Finland

– Personnel in 2006: 7+8+5

Courses 2007-2008

· Experimental Methods (BSc) 5 cr

· Internal Combustion Engine Fundamentals (MSc) 5 cr

· Piston Engine Technology (MSc)

·

·

Simulation of Internal Combustion (MSc)

Laboratory Exersizes (MSc)

5 cr

5 cr

5 cr

· Advanced Spray Combustion Modeling (PhD) 10 cr

· Engine Combustion Diagnostics (PhD)

· Post Graduate Seminar (PhD)

10 cr

5 cr

Internal Combustion Engine Laboratory

Main research interests

· In-cylinder physical phenomena: spray, combustion and emission formation, computational and experimental research

· Engine performance development, computational and experimental research

· Piston technology, thermal load, tribology computational and experimental research

Diesel Combustion and

John Dec’s conceptual model

Performance Simulation,

1D-fluid mechanics, turbocharging

Combustion Modeling with CFD,

3-d fluid mechanics with spray, combustion and emission sub-models

Optical Diagnostics,

PIV/LIF measurements in HUT

Double-pulse Nd-Yag laser and high speed camcorders and analyzing software

Optical access in engine

New Unique Research Engine, EVE

IEA Combustion Agreement

Meeting in Helsinki 2004

Polttoainesuihkun dynamiikka

2004-2006

· Yhteistyöhanke ja tutkijanvaihtoa

· Polttoainesuihkun fysiikka erityisesti lähellä suutinta

SAE Paper 2003-01-3231

Martti Larmi, Jukka Tiainen

Helsinki University of Technology

Diesel Spray Simulation and KH-RT Wave Model

Fuel Spray, exp. and simulated

KH-RT Wave Model

RD Wave Model

SAE 2003-01-3231

Dimensionless numbers

We

=

Oh

=

ρ g u r

2 r

σ

ρ

µ l l

σ r

Oh

=

We l

/ Re l

We l

Re l

=

=

ρ l u

σ r

2 r

ρ l u r r

µ l

SAE 2003-01-3231

Breakup Regimes

Breakup regime

Deformation and flattening

Bag breakup

Boundary layer or “shear” breakup

Weber number

…12

12…80

80…

Stretching and thinning

Catastrophic breakup

80…350

350…

Table from Lee and

Reitz, 2000

SAE 2003-01-3231

Bag Breakup

Picture from Lefebre:

Atomization and sprays, 1989

SAE 2003-01-3231

Streching and thinning

Picture from Lee and

Reitz, 2000

SAE 2003-01-3231

Catastrophic Breakup

Picture from Lee and

Reitz, 2000

SAE 2003-01-3231

350.0

300.0

250.0

200.0

KH-RT

RD

150.0

100.0

50.0

0.0

0.0 10.0 20.0 30.0 40.0 50.0 60.0 70.0

Distance downstream nozzle [mm]

SAE 2003-01-3231

SAE 2003-01-3231

80.0

70.0

60.0

50.0

KH-RT

RD

Experimental

40.0

30.0

20.0

10.0

0.0

0.0

2.0

4.0

6.0

8.0

10.0 12.0 14.0

Distance from spray axis [mm]

SAE 2003-01-3231

SAE Paper 2006-01-1390

Ville Vuorinen, Martti Larmi, Eero Antila, Ossi Kaario

Helsinki University of Technology

Essam El-Hannouny, Sreenath Gupta

Argonne National Laboratory

Near Nozzle Diesel Spray Modeling and X-Ray Measurements

Argonne National Laboratories,

X-Ray Measurements

SAE 2006-01-1390

Early Injection Phase Fuel Mass Distribution

SAE 2006-01-1390

2

1

0

−500

3

0

−500

Fuel Mass Distribution, X-Ray

3 3

2

−−=theory: round liquid tube z=0.20mm

(a) 0.4ms

z=0.80mm

z=2.00mm

z=10.00mm

1

2

1

(b) 0.8ms

0 y (

µ

m)

500

0

−500

3

(c) 1.5ms

2

0 y (

µ

m)

1

500

0

−500

0 y (

µ

m)

500

(d) 2.7ms

0 y (

µ

m)

500

SAE 2006-01-1390

Droplet SMD, CAB model

2

0.6

0.4

0.2

0

−0.5

2

80

µ m

60

40

20

(a) 75

µ

s

CAB

C

λ

=5.5

0 y (cm)

0.5

1.5

1

0.5

0

−0.5

2

0

(b) 0.15ms

0.5

1.5

1

0.5

0

−0.5

0

(c) 0.4ms

0.5

1.5

1

0.5

0

−0.5

0

(d) 1.2ms

0.5

SAE 2006-01-1390

Droplet SMD, KHRT

0.6

0.4

0.2

0

−0.5

2

80

µ

m

60

40

20

(a) 75

µ

s

KHRT

C

3

=4.0

0 y (cm)

0.5

1.5

1

0.5

0

−0.5

0

(c) 0.4ms

0.5

2

1.5

1

0.5

0

−0.5

2

1.5

1

0.5

0

−0.5

0

(b) 0.15ms

0.5

0

(d) 1.2ms

0.5

SAE 2006-01-1390

4

3.5

o− = CAB/C

λ

=5.5

.− = KHRT/C

3

=5.33

3

2.5

2

* = experimental peak values and errorbars by El−Hannouny et al.

SAE 2003−01−3150

1.5

1

0.5

0

−4 −3 −2 z

∼

0.5−1.0mm

z

∼

2.0−3.0mm

z

∼

10.0mm

−1 0 y (mm)

1 2 3 4

SAE 2006-01-1390