CONTROLLED COMBUSTION OF LOW-QUALITY GAS MIXTURES

advertisement

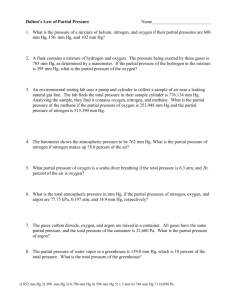

CONTROLLED COMBUSTION OF LOW-QUALITY GAS MIXTURES Malinen Kaisua; Järvinen Mikab, Saari Karib, Lampinen Markkub, Fogelholm Carl-Johanb, Riikonen Artoc a. Corresponding author. Helsinki University of Technology, Department of Energy Technology, P.O. Box 4400, Sähkömiehentie 4, 02015 HUT, Finland. Currently at ÅF-Consult Ltd. email: kaisu.malinen@afconsult.com, tel: +358 40 348 5372 b. Helsinki University of Technology, Department of Energy Technology, P.O. Box 4400, Sähkömiehentie 4, 02015 HUT, Finland. c. Gasum Oy, Miestentie 1, PL 21, 02151 ESPOO, Finland ABSTRACT The objective of this work was to experimentally determine the lowest levels of methane content in gas mixtures that would still enable controlled combustion using a commercial standard gas burner. A gas mixture is of low quality when it is uncertain whether the mixture will ignite or maintain stable combustion. Such low-quality gas mixtures can typically include refinery gas, coke oven gas, blast furnace gas and biogas. This work focused on studying and determining the properties of biogases. Biogas is a gas mixture comprised of 35-70 % methane. The rest of the biogas consists of various inert gases, including carbon dioxide, nitrogen, water vapour and sulphur compounds. The testing equipment included a water-cooled boiler and a gas burner. A well insulated cylinder with a glass window was built between the burner and the boiler for making possible to videotape the form and the behaviour of the flame. The composition of the flue gases were measured online. The oxygen level of the flue gas was kept on a range of 3,5-4,0 %. The tests were performed with eight different nozzle pressures between 530 Pa and 3000 Pa. Gas mixtures were composed by mixing natural gas with an inert gas, carbon dioxide or nitrogen prior to combustion. Combustion was considered to be controlled when the flame was stable, and the flue gases contained only small amounts of carbon monoxide and/or hydrocarbons. Tests of the carbon dioxide-methane gas mixtures revealed that combustion could still be controlled at methane concentrations of 52-56 %. When nitrogen was used as the inert gas, combustion was controlled until the methane content fell below 39-44 %. Keywords: Biogas, low-quality gas, controlled combustion, experimental study. INTRODUCTION A gas mixture is of low quality when it is uncertain whether the mixture will ignite or combustion will continue. Such low-quality gas mixtures can typically include refinery gas, coke oven gas, blast furnace gas and biogas (Raiko et al. 1995). This research focused on studying and determining the properties of biogases. Biogas is a gas mixture comprised of 35-70 % methane. The rest of the biogas consists of various inert gases, including carbon dioxide, nitrogen, water vapour and sulphur compounds. (Hagen et al. 2001, Kuittinen et al. 2006, ETSU 1996, Clementson 2007). Zabetakis presented the results of various flammability tests with combustible gas-inert gas-air mixtures. The tests revealed that the carbon dioxide-methane mixture was still flammable, when its methane concentration was 23,5% (7 % of CH4, 23 % of CO2, 70 % of air). When the inert gas was nitrogen, the mixture was flammable until the methane concentration went below 15 % (6,5 % CH4, 37 % N2, 56,5 % air). Tia et al. studied biogas combustion in a crater bed. Their research revealed that biogas containing methane down to 7 % can be steadily burned with stabilized flame in the crater bed due to its good heat circulation characteristics. According to Energy Technology Support Unit, gas turbines can operate with 28 % of methane and possibly less. Dual fuel engines are generally limited to about 35 % methane minimum. Spark ignition engines have been limited to about 30 % methane minimum but current developments may reduce this to 28 % with lean burn engines at λ = 1,75. In this study, the main goal was to determine the lowest levels of methane content in gas mixtures that would still enable controlled combustion without auxiliary fuel. Also, test results of controlled combustion of biogas with standard gas burner could not be found. Gas mixtures were composed by mixing natural gas with an inert gas, carbon dioxide or nitrogen prior to combustion. Combustion was considered to be controlled when the flame was stable (it did not flashback or blowoff), and the flue gases contained only small amounts of carbon monoxide and/or hydrocarbons. The tests were performed with different nozzle pressures when the oxygen level in the flue gases was kept on the range of 3,5-4,0 %. The inert gas level was increased in the gas mixture until the flame quenched. The flame was videotaped in order to observe the changes in the combustion through the form and the behaviour of the flame. The compositions of the flue gases were measured online with two analyzers. All the gas amounts presented are volume-% if not stated otherwise. METHODS The testing equipment, shown on Figure 1, included a water-cooled, 85 kW Jäspi T-85 tube boiler manufactured by Kaukora Oy and a 16–34 kW Junior 2 G35 gas burner manufactured by Oilon Oy. A well insulated cylinder with a glass window was built between the burner and the boiler for making possible to videotape the form and the behaviour of the flame. The composition of the flue gas was measured online with a Gasmet portable sampling unit, FTIR-analyzer by Temet Instruments Oy. The oxygen level of the flue gas was kept on a range of 3,5–4,0 % and it was monitored with PPM IPA-Pro analyzer manufactured by PPM Systems. The tests were performed with eight different nozzle pressures between 530 Pa and 3000 Pa. Gas mixtures were composed by mixing natural gas with an inert gas, carbon dioxide or nitrogen prior to combustion. Natural gas was provided to the system from the natural gas network. The pressure of the natural gas was reduced from 4 bar to 175 mbar. The flow rate of the gas was monitored mainly with two rotameters manufactured by Kytölä Oy, but there was also a separate gas flowmeter (0,06-10 m3/h) attached to the pipeline. Depending on the flow rate, the bigger, LA-NJ27-D (max. 180 l/min) rotameter or the smaller, NP-G26 (max. 40 l/min) was used. The type of the gas flowmeter was BK-G6 and it was manufactured by Elster Instroment. The inert gases, nitrogen and carbon dioxide, were in gas cylinders. The pipeline of the inert gas was connected to the natural gas pipeline before the gas burner in order to mix the two gases before the burner. The flow rate of the inert gas was monitored with two rotameters manufactured by Kytölä Oy, A-5AR (max. 150 l/min) and NP-G26 (max. 40 l/min). Figure 1. Testing equipment. The bigger rotameter used for natural gas was already calibrated to methane but the smaller rotameter and the rotameters used to measure the inert gas flow were calibrated to air in STP, 20 °C and 1,013 bar. Inlet and outlet temperature of the cooling water as well as the temperature of inert gas and the temperature of the flue gases were measured with K-type thermocouples and lead to datalogger. The signals from the flame electrode, cooling water flow and the oxygen level in the flue gases were delivered also to the datalogger. The values were measured in every 10 seconds by the datalogger and recorded to the computer. The composition of the flue gases was measured with FTIR-analyzer in every 30 seconds and recorded to computer. When measurements were executed with high rates of gas flow, the flow of the inert gas cooled the control valve of the gas cylinder so extensively that the operation of the control valve was impaired. Therefore the pipeline after the inert gas cylinder was heated occasionally with a warm air heating device. Figure 2. The window built between the burner and the boiler. The form and the behaviour of the flame was videotaped with a standard video camera through the window presented on Figure 2. Low flow rate of air was directed from two opposite points to the window glass for cooling the window and keeping it clear. The clock of the camera and the clocks of the two computers were calibrated for making possible to retrieve exactly the correct time period from the videotape afterwards. The pictures were generated from the videotape with an image processing program Pinnacle Studio™ that makes able to divide the film into multiple pictures in a second. For a safety procedure, there is a flame indicator electrode in the standard commercial burners. If the electrode did not receive a current between 3-100 µA DC at any time of the combustion it stopped the gas input. The flame indicator was bypassed temporary in order to ensure that the electrode did not influence the combustion tests. The bypass tests were executed several times and the results revealed that the indicator had no influence in flame quenching. RESULTS & DISCUSSION The tests were performed with eight different nozzle pressures between 530 Pa and 3000 Pa with gas mixtures of methane-nitrogen and methane-carbon dioxide. On the following chapters are presented the results of the five of the measurements performed with nozzle pressures of 530/600 Pa, 1000 Pa, 1500 Pa, 2000 Pa and 2500 Pa. Concentrations of various gases were measured from flue gases but the ones with most significant changes, carbon monoxide and methane, are presented below. Combustion of CH4-N2 mixtures Due to the combustion air control system of the burner, it was not possible to start the tests from the level of 0 % inert gas in the gas mixture when the nozzle pressure was 1500 Pa or higher. In the higher nozzle pressures the flow of the natural gas increased higher than the burner was designed and it was not able to deliver enough combustion air required. Due to the low air ratio in combustion, the flame quenched. The combustion air control system affected also the combustion tests performed with smaller nozzle pressures. When the nozzle pressure was 530-1000 Pa and the N2 content in the gas mixture increased approximately to 50 %, the oxygen amount in the flue gases started to increase substantially as the combustion air control system could not be adjusted low enough. In these tests the carbon monoxide and methane content in the flue gases increased significantly, together with the oxygen level. Figure 3 presents the pictures of the flame in different situations when the nozzle pressure is constant and the N2 concentration in the gas mixture increases. Figure 4 and Figure 5 are presenting the carbon monoxide and methane contents in the flue gases in corresponding situations. As shown on the flame pictures, we were able to start the tests with 100 % of CH4 / 0 % of N2 in the gas mixture with two of the lower nozzle pressures, 530 Pa and 1000 Pa. In these tests the shape of flame was about the same. It is clearly shown on the pictures, that when the level of nitrogen increased in the gas mixture, the flame shortened until it divided into two parts and finally quenched flashing back to the burner. When the nozzle pressure was 1500-2500 Pa, the combustion was possible to start when the nitrogen content in the gas mixture was 10-35 %. The flames were almost identical during these tests. The shape of the flame started to narrow in the middle when the nitrogen level reached 60 % and the flame blowoff happened when there was 64-65 % of nitrogen in the gas mixture. N2 Nozzle pressure Nozzle pressure Nozzle pressure Nozzle pressure Nozzle pressure 530 Pa 1000 Pa 1500 Pa 2000 Pa 2500 Pa *) *) *) 0% 20 % 40 % 60 % 64 65 % *) Could not be measured due to the combustion air control system of the burner Figure 3. The form of the flame when the nozzle pressure is constant and the N2 content in the gas mixture increases. 1500 1000 500 CO content in the flue gases, ppm 2000 3500 530 Pa 1000 Pa 1500 Pa 2000 Pa 2500 Pa 3000 2500 2000 1500 1000 500 0 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 N2 content in the gas mixture, % Figure 4. The content of the carbon monoxide in the flue gases with different nozzle pressures when the nitrogen content in the gas mixture increases. CH4 content in the flue gases, ppm 2500 530 Pa 1000 Pa 1500 Pa 2000 Pa 2500 Pa 0 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 N2 content in the gas mixture, % Figure 5. The content of the methane in the flue gases with different nozzle pressures when the nitrogen content in the gas mixture increases. The CO level in the flue gases started to increase at the nozzle pressure of 530 Pa, when there was about 25 % of nitrogen in the gas mixture. The content of the carbon monoxide started to increase exponentially when the content of the nitrogen in the gas mixture exceeded 45 %. At the nozzle pressures of 1000-2000 Pa the carbon monoxide level started to increase when there was about 35 % of nitrogen in the gas mixture. The CO content started to increase exponentially when there was 55-57 % of nitrogen in the gas mixture. On the highest nozzle pressure (2500 Pa) test the carbon monoxide content in the flue gases stayed under 500 ppm. In the tests executed with nozzle pressures of 1000-2500 Pa, the CO content in the flue gases stayed under 100 ppm until there was 45 % of nitrogen in the gas mixture. The figures of the methane content are accordant with the figures of CO content in the flue gases. When there was 46 % of nitrogen in the gas mixture, started the methane content to increase rapidly in the test performed with 530 Pa nozzle pressure. When there was 55 % of nitrogen in the gas mixture at the nozzle pressure of 1000 Pa, started the methane content increasing exponentially in the flue gases. In the measurements performed with higher nozzle pressures the methane content in the flue gases did not start to increase until the nitrogen content in the gas mixture exceeded 56-61 %. Combustion of CH4-CO2 mixtures At the end of the combustion tests the adiabatic combustion temperature of gas mixture of methane and carbon dioxide was 1500-1600 °C, almost 300 °C higher than in the combustion tests made with methane-nitrogen gas mixtures. Although the combustion temperature was higher, the flame quenched much earlier, on average of 15 % of smaller content of inert gas in the gas mixture than in the combustion tests performed with nitrogen. Figure 6 presents the pictures of the flame in different situations when the nozzle pressure is constant and the CO2 concentration in the gas mixture increases. Figures 7 and 8 present the carbon monoxide and methane compositions in the flue gases in corresponding situations. The combustion tests were possible to start with 0 % CO2 / 100 % of CH4 when the nozzle pressure was 600-1000 Pa. The form of the flame stayed at the same until there was 50 % of carbon dioxide in the gas mixture. When the amount of carbon dioxide reached 50 % in the gas mixture, started the flame get shorter in the test performed with 600 Pa nozzle pressure as the in the test performed with 1000 Pa nozzle pressure the diameter of the flame started to narrow. It is clearly seen that at the nozzle pressure of 600 Pa, the flame flashed back to the burner, in the 1000 Pa measurements the flame blew off. In the nozzle pressures of 1500-2500 Pa, it was possible to start the tests at the CO2 levels of 13-30 % in the gas mixture. There are no differences in the forms of the flames when the carbon dioxide content in the gas mixture stayed below 50 %. When the carbon dioxide level reached 50 %, the flame had already quenched at the nozzle pressure of 2500 Pa. At the same time the flame blew off at the nozzle pressure of 2000 Pa. When there was 51 % of carbon dioxide in the gas mixture, blew the flame off in the combustion performed at 1500 Pa nozzle pressure. CO2 Nozzle pressure Nozzle pressure Nozzle pressure Nozzle pressure Nozzle pressure 600 Pa 1000 Pa 1500 Pa 2000 Pa 2500 Pa *) *) 0% *) 20 % 40 % 50 % flame has quenched 51- flame has quenched 55 % *) Could not be measured due to the combustion air control system of the burner Figure 6. The form of the flame when the nozzle pressure is constant and the CO2 content in the gas mixture increases. 4000 1500 Pa 3500 2000 Pa 3000 2500 Pa 2500 2000 1500 1000 6000 600 Pa 1000 Pa 1500 Pa 2000 Pa 2500 Pa CO content in the flue gases, ppm 1000 Pa 5000 4000 3000 2000 1000 CH4 content in the flue gases, ppm 4500 600 Pa 500 0 0 0 5 10 15 20 25 30 35 40 45 50 55 60 CO2 content in the gas mixture, % Figure 7. The content of the carbon monoxide in the flue gases with different nozzle pressures when the carbon dioxide content in the gas mixture increases. 0 5 10 15 20 25 30 35 40 45 50 55 60 CO2 content in the gas mixture, % Figure 8. The content of the methane in the flue gases with different nozzle pressures when the carbon dioxide content in the gas mixture increases. Contrary to the methane-nitrogen combustion tests, the oxygen level in the flue gases did not increase as extremely. At the test performed with nozzle pressure of 530 Pa the oxygen content in the flue gases rose above the limit of 3,5-4,0 %, but only at the end of the tests, most of the measurement points are within the desired limits of O2. In the lowest nozzle pressure test (530 Pa) the carbon monoxide level started to increase already when there was only 20 % of CO2 in the gas mixture. The level of carbon monoxide started to grow exponentially, when carbon dioxide content was 36-40 % in the gas mixture. On the other tests performed with higher nozzle pressures, the CO content in the flue gases started to increase coherently, when there was 30 % of CO2 in the gas mixture. The CO level started to increase exponentially at the nozzle pressures of 1000-2000 Pa when the CO2 level was 42-47 %. In all of the tests the CO level rose at least to 500 ppm. At the nozzle pressure of 530 Pa, the methane content started to grow exponentially, much earlier than in the other measurements, when there was 36-40 % of carbon dioxide in the gas mixture. In the other tests the methane concentrations started to increase only after there was 43-48 % of carbon dioxide in the gas mixture. Because of the mixing could have been interferenced by the excess amount of the combustion air in the lower nozzle pressure levels, only the tests from 1000 Pa (CO2) and 1500 Pa (N2) can be truly considered as the results of controlled combustion due to the gas properties. When the amount of combustion air increased, the air-gas mixture diluted which meant that the combustion velocity became slower, the temperature of the flame reduced and the combustion became uncontrolled (as can be seen in the concentrations of the CO and CH4 in the flue gases). If the air amount could have been controlled, it is possible that controlled combustion with somewhat lower quality gas mixtures could have been achieved. SUMMARY AND CONCLUSIONS Tests of the carbon dioxide-methane gas mixtures revealed that combustion could still be controlled at methane concentrations of 52-56 %. When nitrogen was used as the inert gas, combustion was controlled until the methane content fell below 39-44 %. The flame quenched when there was less than 35-39 % of methane in the nitrogenmethane gas mixture. When the inert gas was carbon dioxide, the flame quenched at the methane concentrations of less than 45-54 %. Comparing to the flammability tests made by Zabetakis, the results seem to have excellent correspondence although the test equipment and method of measurement were different. In our tests the methane content in the methane-inert gas-air mixture was 6,6-6,7 % (6,5 % by Zabetakis) when the inert gas was nitrogen and 6,9-7,1 % (7,0 % by Zabetakis) when the inert gas was carbon dioxide. On the contrary, methane-inert gas compositions differ as the air ratio seems to have been λ = 0,9-1,05 at the measurements performed by Zabetakis. The air ratio in this study was fixed to λ = 1,28-1,29. With lower air ratio we could have achieved the exactly same results but methane and carbon dioxide emissions in the flue gases would have been even higher. The most important thing in defining controlled combustion is to monitor the content of carbon monoxide and hydrocarbons, such as methane, ethane and ethylene, in the flue gases. When the combustion is controlled, the gas will mix and combust normally and there should not be any above-mentioned gases found in the flue gases. In the test performed, it was clearly seen from the contents of the CO and CxHy in the flue gases when the combustion was not controlled anymore. Landfill gas has the lowest methane content amongst the biogases. For controlled combustion of landfill gas without auxiliary fuels, it is important that the methane content of a landfill gas does not fall below current levels. However, in the future, the methane content of landfill gases will certainly drop when the landfills are closed. One solution to keep these low-quality gas mixtures combustible in standard gas burners would be to upgrade or enrich the gas mixture with natural gas. ACKNOWLEDGEMENTS Gasum Oy is gratefully acknowledged for funding this work. We would also like to thank Pasi Miikkulainen and Ari Kankkunen for the advises on videotaping the flame and image processing, Loay Saeed for the guidance of using the FTIR flue gas analyzer and most of all Mika Ahlgren for building the testing equipment. REFERENCES CLEMENTSON M. (2007). SCG Rapport. Basic http://www.scg.se/Rapporter/Resources/BiogasfolderengA5.pdf data of Biogas – Sweden. ETSU (Energy Technology support unit). (1996). A technical survey of power generation from biogas. Report B/LF/00325/REP. 74 p. HAGEN M., POLMAN E., JENSEN J.K., MYKEN A., JÖNSSON O, DAHL, A. (2001). Adding gas from biomass to the gas grid. SCG report 118. Malmö. 142 p. ISSN 1102-7371. KUITTINEN V., HUTTUNEN M. J., LEINONEN S. (2006). Suomen biokaasulaitosrekisteri IX. Tiedot vuodelta 2005. Joensuun Yliopisto, Karjalan tutkimuslaitoksen raportteja N:o 3/2006. Joensuu. 77 p. ISBN 952-458-832-3. MALINEN, K. (2007). Huonolaatuisten kaasuseosten hallittu poltto. Diploma Thesis. Helsinki University of Technology, Department of Mechanical Engineering. Espoo. 108 p + 24 p. RAIKO, R. (ed.). (1995). Poltto ja palaminen. International Flame Research Foundation (IFRF). Jyväskylä. ISBN 951-666-604-3. pp. 109-138. TIA S., CHAIVATAMASATH P., JUMNONGPON V., MANOMAIWONG S. (1998). Biogas Combustion in a Crater Bed. RERIC International Energy Journal: Vol. 20, No. 1, June 1998. ZABETAKIS M. G. (1965). Flammability characteristics of combustible gases and vapors. U.S Bureau of Mines, Bulletin 627. Washington, USA. 121 p.