Regioselectively Functionalized Cellulose Ethers -Preparation, Characterization and Properties- Introduction

advertisement

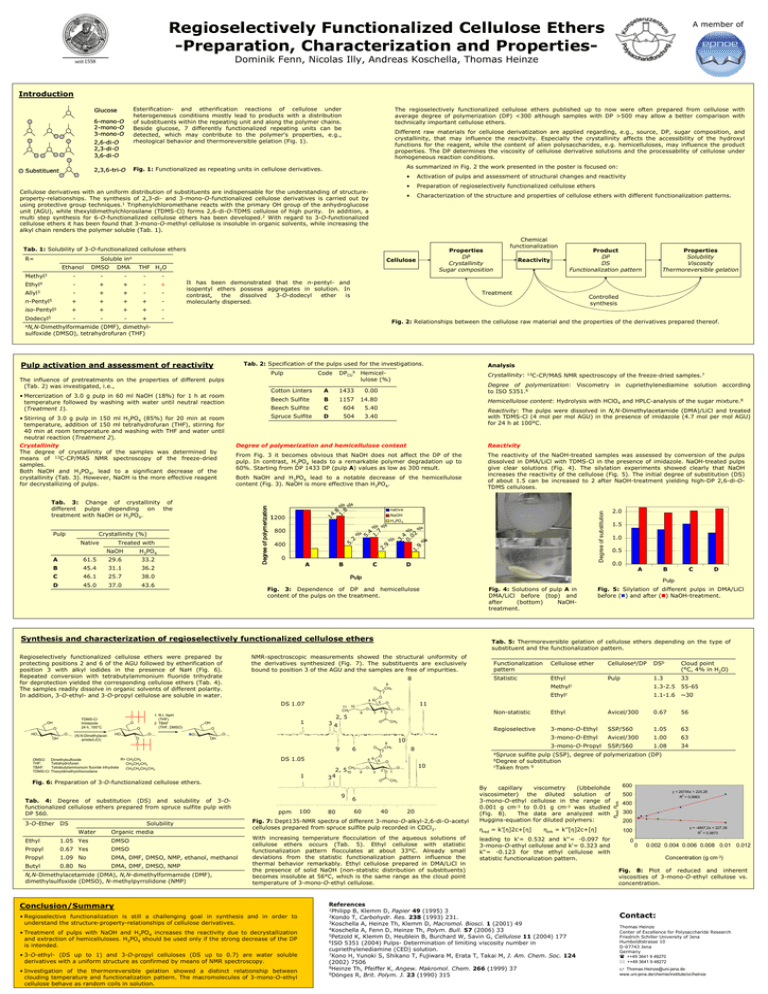

Regioselectively Functionalized Cellulose Ethers -Preparation, Characterization and Properties- A member of Dominik Fenn, Nicolas Illy, Andreas Koschella, Thomas Heinze Introduction Esterification- and etherification reactions of cellulose under heterogeneous conditions mostly lead to products with a distribution of substituents within the repeating unit and along the polymer chains. Beside glucose, 7 differently functionalized repeating units can be detected, which may contribute to the polymer's properties, e.g., rheological behavior and thermoreversible gelation (Fig. 1). As summarized in Fig. 2 the work presented in the poster is focused on: Fig. 1: Functionalized as repeating units in cellulose derivatives. 2,3,6-tri-O Substituent Different raw materials for cellulose derivatization are applied regarding, e.g., source, DP, sugar composition, and crystallinity, that may influence the reactivity. Especially the crystallinity affects the accessibility of the hydroxyl functions for the reagent, while the content of alien polysaccharides, e.g. hemicelluloses, may influence the product properties. The DP determines the viscosity of cellulose derivative solutions and the processability of cellulose under homogeneous reaction conditions. Cellulose derivatives with an uniform distribution of substituents are indispensable for the understanding of structureproperty-relationships. The synthesis of 2,3-di- and 3-mono-O-functionalized cellulose derivatives is carried out by using protective group techniques.1 Triphenylchloromethane reacts with the primary OH group of the anhydroglucose unit (AGU), while thexyldimethylchlorosilane (TDMS-Cl) forms 2,6-di-O-TDMS cellulose of high purity. In addition, a multi step synthesis for 6-O-functionalized cellulose ethers has been developed.2 With regard to 3-O-functionalized cellulose ethers it has been found that 3-mono-O-methyl cellulose is insoluble in organic solvents, while increasing the alkyl chain renders the polymer soluble (Tab. 1). • Activation of pulps and assessment of structural changes and reactivity • Preparation of regioselectively functionalized cellulose ethers • Characterization of the structure and properties of cellulose ethers with different functionalization patterns. Tab. 1: Solubility of 3-O-functionalized cellulose ethers Soluble ina DMA Cellulose Ethanol DMSO Methyl3 - - - THF H2O - - Ethyl4 - + + - + Allyl3 - + + - - n-Pentyl5 + + + + - iso-Pentyl5 + + + + - Dodecyl5 - - - + - It has been demonstrated that the n-pentyl- and isopentyl ethers possess aggregates in solution. In contrast, the dissolved 3-O-dodecyl ether is molecularly dispersed. Pulp activation and assessment of reactivity Tab. 2: Specification of the pulps used for the investigations. Code Pulp The influence of pretreatments on the properties of different pulps (Tab. 2) was investigated, i.e., • Mercerization of 3.0 g pulp in 60 ml NaOH (18%) for 1 h at room temperature followed by washing with water until neutral reaction (Treatment 1). • Stirring of 3.0 g pulp in 150 ml H3PO4 (85%) for 20 min at room temperature, addition of 150 ml tetrahydrofuran (THF), stirring for 40 min at room temperature and washing with THF and water until neutral reaction (Treatment 2). Crystallinity The degree of crystallinity of the samples was determined by means of 13C-CP/MAS NMR spectroscopy of the freeze-dried samples. Both NaOH and H3PO4, lead to a significant decrease of the crystallinity (Tab. 3). However, NaOH is the more effective reagent for decrystallizing of pulps. B 45.4 31.1 36.2 C 46.1 25.7 38.0 D 45.0 37.0 43.6 1433 0.00 B 1157 14.80 Beech Sulfite C 604 5.40 Spruce Sulfite D 504 3.40 ,.8 8% 11.,8 % 8% % Both NaOH and H3PO4 lead to a notable decrease of the hemicellulose content (Fig. 3). NaOH is more effective than H3PO4. native unbehandelt NaOH Phosphorsäure H 3PO 4 1144 1400 1200 1200 1000 800 800 600 400 400 200 00 A A B B C C D D O HO O OH 1. R-I, NaH (THF) 2. TBAF (THF, DMSO) O O HO (N,N-Dimethylacetamide/LiCl) O 8 4 6 1 O 11 10 CH3 2, 5 O 9 Fig. 4: Solutions of pulp A in DMA/LiCl before (top) and after (bottom) NaOHtreatment. 0.5 0.0 A B 3 O 5 O 2 O 1 O 34 Cellulosea/DP DSb Cloud point (°C, 4% in H2O) Statistic Ethyl Pulp 9 Solubility Organic media Ethyl 1.05 Yes DMSO Propyl 0.67 Yes DMSO Propyl 1.09 No DMA, DMF, DMSO, NMP, ethanol, methanol Butyl 0.80 No DMA, DMF, DMSO, NMP N,N-Dimethylacetamide (DMA), N,N-dimethylformamide (DMF), dimethylsulfoxide (DMSO), N-methylpyrrolidone (NMP) 4 6 CH3 1 Fig. 6: Preparation of 3-O-functionalized cellulose ethers. Tab. 4: Degree of substitution (DS) and solubility of 3-Ofunctionalized cellulose ethers prepared from spruce sulfite pulp with DP 560. 6 2, 510 34 9 ppm 100 80 O 9 3 8 2O 1 10 O • Treatment of pulps with NaOH and H3PO4 increases the reactivity due to decrystallization and extraction of hemicelluloses. H3PO4 should be used only if the strong decrease of the DP is intended. • 3-O-ethyl- (DS up to 1) and 3-O-propyl celluloses (DS up to 0.7) are water soluble derivatives with a uniform structure as confirmed by means of NMR spectroscopy. • Investigation of the thermoreversible gelation showed a distinct relationship between clouding temperature and functionalization pattern. The macromolecules of 3-mono-O-ethyl cellulose behave as random coils in solution. 1.1-1.6 ~30 Ethyl Avicel/300 0.67 56 Regioselective 3-mono-O-Ethyl SSP/560 1.05 63 3-mono-O-Ethyl Avicel/300 1.00 63 3-mono-O-Propyl SSP/560 1.08 34 6 40 sulfite pulp (SSP), degree of polymerization (DP) of substitution cTaken from 9 bDegree CH3 20 With increasing temperature flocculation of the aqueous solutions of cellulose ethers occurs (Tab. 5). Ethyl cellulose with statistic functionalization pattern flocculates at about 33°C. Already small deviations from the statistic functionalization pattern influence the thermal behavior remarkably. Ethyl cellulose prepared in DMA/LiCl in the presence of solid NaOH (non-statistic distribution of substituents) becomes insoluble at 56°C, which is the same range as the cloud point temperature of 3-mono-O-ethyl cellulose. • Regioselective functionalization is still a challenging goal in synthesis and in order to understand the structure-property-relationships of cellulose derivatives. 55-65 Ethylc aSpruce Fig. 7: Dept135-NMR spectra of different 3-mono-O-alkyl-2,6-di-O-acetyl celluloses prepared from spruce sulfite pulp recorded in CDCl3. Conclusion/Summary 33 1.3-2.5 Non-statistic 10 7 O 5 O O 60 1.3 Methylc CH3 8 CH3 O DS 1.05 Fig. 5: Silylation of different pulps in DMA/LiCl before () and after () NaOH-treatment. 11 O OH R= CH2CH3 DMSO: Dimethylsulfoxide THF: Tetrahydrofuran CH2CH2CH3 TBAF: Tetrabutylammonium fluoride trihydrate CH2CH2CH2CH3 TDMS-Cl: Thexyldimethylchlorosilane D Cellulose ether O RO C Functionalization pattern 8 CH3 7 O Si Water 1.0 Tab. 5: Thermoreversible gelation of cellulose ethers depending on the type of substituent and the functionalization pattern. NMR-spectroscopic measurements showed the structural uniformity of the derivatives synthesized (Fig. 7). The substituents are exclusively bound to position 3 of the AGU and the samples are free of impurities. OH O 3-O-Ether DS 1.5 Pulp Fig. 3: Dependence of DP and hemicellulose content of the pulps on the treatment. DS 1.07 OH 2.0 Pulp Regioselectively functionalized cellulose ethers were prepared by protecting positions 2 and 6 of the AGU followed by etherification of position 3 with alkyl iodides in the presence of NaH (Fig. 6). Repeated conversion with tetrabutylammonium fluoride trihydrate for deprotection yielded the corresponding cellulose ethers (Tab. 4). The samples readily dissolve in organic solvents of different polarity. In addition, 3-O-ethyl- and 3-O-propyl cellulose are soluble in water. Si NMR spectroscopy of the freeze-dried samples.7 Reactivity: The pulps were dissolved in N,N-Dimethylacetamide (DMA)/LiCl and treated with TDMS-Cl (4 mol per mol AGU) in the presence of imidazole (4.7 mol per mol AGU) for 24 h at 100°C. Synthesis and characterization of regioselectively functionalized cellulose ethers TDMS-Cl Imidazole 24 h, 100°C 13C-CP/MAS Degree of polymerization: Viscometry in cupriethylenediamine solution according to ISO 5351.6 Hemicellulose content: Hydrolysis with HClO4 and HPLC-analysis of the sugar mixture.8 55.,2 2% % 55.,4 4% 11.,7 % 7% 22.,9 % 9% % 33.2 A Beech Sulfite Crystallinity: The reactivity of the NaOH-treated samples was assessed by conversion of the pulps dissolved in DMA/LiCl with TDMS-Cl in the presence of imidazole. NaOH-treated pulps give clear solutions (Fig. 4). The silylation experiments showed clearly that NaOH increases the reactivity of the cellulose (Fig. 5). The initial degree of substitution (DS) of about 1.5 can be increased to 2 after NaOH-treatment yielding high-DP 2,6-di-OTDMS celluloses. Degree of polymerization H3PO4 29.6 Cotton Linters Analysis Reactivity Treated with NaOH DPCU6 Hemicellulose (%) From Fig. 3 it becomes obvious that NaOH does not affect the DP of the pulp. In contrast, H3PO4 leads to a remarkable polymer degradation up to 60%. Starting from DP 1433 DP (pulp A) values as low as 300 result. Crystallinity (%) 61.5 Controlled synthesis Degree of polymerization and hemicellulose content Tab. 3: Change of crystallinity of different pulps depending on the treatment with NaOH or H3PO4. A Properties Solubility Viscosity Thermoreversible gelation Fig. 2: Relationships between the cellulose raw material and the properties of the derivatives prepared thereof. (DMF), dimethylsulfoxide (DMSO), tetrahydrofuran (THF) Native Product DP DS Functionalization pattern Reactivity Treatment aN,N-Dimethylformamide Pulp Chemical functionalization 33.,4 4 00.,0 %% 022 11.,9 % % 9% % R= Properties DP Crystallinity Sugar composition By capillary viscometry (Ubbelohde viscosimeter) the diluted solution of 3-mono-O-ethyl cellulose in the range of 0.001 g cm-3 to 0.01 g cm-3 was studied (Fig. 8). The data are analyzed with Huggins-equation for diluted polymers: ηred = k’[η]2c+[η] ηinh = k’’[η]2c+[η] leading to k‘= 0.532 and k‘‘= -0.097 for 3-mono-O-ethyl cellulose and k‘= 0.323 and k‘‘= -0.123 for the ethyl cellulose with statistic functionalization pattern. References 1Philipp B, Klemm D, Papier 49 (1995) 3 2Kondo T, Carbohydr. Res. 238 (1993) 231. 3Koschella A, Heinze Th, Klemm D, Macromol. Biosci. 1 (2001) 49 4Koschella A, Fenn D, Heinze Th, Polym. Bull. 57 (2006) 33 5Petzold K, Klemm D, Heublein B, Burchard W, Savin G, Cellulose 11 (2004) 177 6ISO 5351 (2004) Pulps- Determination of limiting viscosity number in cupriethylenediamine (CED) solution. 7Kono H, Yunoki S, Shikano T, Fujiwara M, Erata T, Takai M, J. Am. Chem. Soc. 124 (2002) 7506 8Heinze Th, Pfeiffer K, Angew. Makromol. Chem. 266 (1999) 37 9Dönges R, Brit. Polym. J. 23 (1990) 315 600 y = 26745x + 224,28 2 R = 0,9963 500 ηred ηinh 2,6-di-O 2,3-di-O 3,6-di-O The regioselectively functionalized cellulose ethers published up to now were often prepared from cellulose with average degree of polymerization (DP) <300 although samples with DP >500 may allow a better comparison with technically important cellulose ethers. Degree of substitution Glucose 6-mono-O 2-mono-O 3-mono-O 400 300 200 y = -4867,2x + 227,39 2 R = 0,9873 100 0 0 0.002 0.004 0.006 0.008 0.01 0.012 Concentration (g cm-3) Fig. 8: Plot of reduced and inherent viscosities of 3-mono-O-ethyl cellulose vs. concentration. Contact: Thomas Heinze Center of Excellence for Polysaccharide Research Friedrich Schiller University of Jena Humboldtstrasse 10 D-07743 Jena Germany ++49 3641 9 48270 ++49 3641 9 48272 | Thomas.Heinze@uni-jena.de www.uni-jena.de/chemie/institute/oc/heinze