Electrochemical and Solid-State Letters, 4 共11兲 G85-G87 共2001兲

G85

1099-0062/2001/4共11兲/G85/3/$7.00 © The Electrochemical Society, Inc.

Work Function Engineering of Molybdenum Gate Electrodes

by Nitrogen Implantation

Pushkar Ranade,a,z Hideki Takeuchi,b Tsu-Jae King,b,* and Chenming Hub

a

Department of Materials Science and Engineering, bDepartment of Electrical Engineering and Computer

Sciences, University of California at Berkeley, Berkeley, California 94720, USA

The continued scaling of complementary metal oxide semiconductor 共CMOS兲 devices into the sub-70 nm regime will require a

fundamental change in transistor gate stack materials. Refractory metals and their metallic derivatives are among the few materials

other than poly-silicon suitable for use as metal oxide semiconductor field effect transistor gate electrodes. In this paper we report

the dependence of the Mo gate work function on nitrogen implant dose and energy. By implanting nitrogen into Mo/SiO2 /Si

stacks, the interfacial Mo work function can be controllably lowered from an initial 共unimplanted兲 value of ⬃5 eV. The ability

to engineer the Mo gate work function over the range of the Si energy bandgap makes it an attractive candidate for future bulk-Si

and ultrathin body silicon-on-insulator-CMOS gate electrodes.

© 2001 The Electrochemical Society. 关DOI: 10.1149/1.1402497兴 All rights reserved.

Manuscript submitted May 30, 2001; revised manuscript received June 21, 2001. Available electronically August 21, 2001.

As metal oxide semiconductor field effect transistors

共MOSFETs兲 are scaled in physical dimension beyond the 100 nm

technology node, the integration of high permittivity dielectrics and

metal gate electrodes into complementary metal oxide semiconductor 共CMOS兲 gate stacks will be required.1 Metal gate technology is

particularly attractive because it eliminates the poly-Si gate depletion effect and the associated degradation in transistor performance.

To achieve low and symmetrical threshold voltages for sub-70 nm

bulk-Si CMOS technology, it will be necessary to have gate electrodes with work functions differing by almost 1 V on the NMOS

and PMOS devices.2 While appropriate work functions are easy to

achieve with Si 共semiconductor兲 gate electrodes, this may not be

trivial with metal gate electrodes. Mo gate electrodes have been

successfully used in the fabrication of CMOS devices with high

permittivity gate dielectrics.3-5 Because Mo has been observed to be

thermally stable on a wide range of dielectrics 共SiO2, Si3N4, ZrO2,

HfO2兲 it appears to be a promising gate material for future CMOS

generations. In an earlier publication,6 nitrogen ion implantation into

Mo thin films was shown to be effective for adjusting the Mo work

function. In this paper, the dependence of the interfacial Mo work

function on the nitrogen implant dose and energy and post-implant

annealing conditions is examined.

Experimental

Results

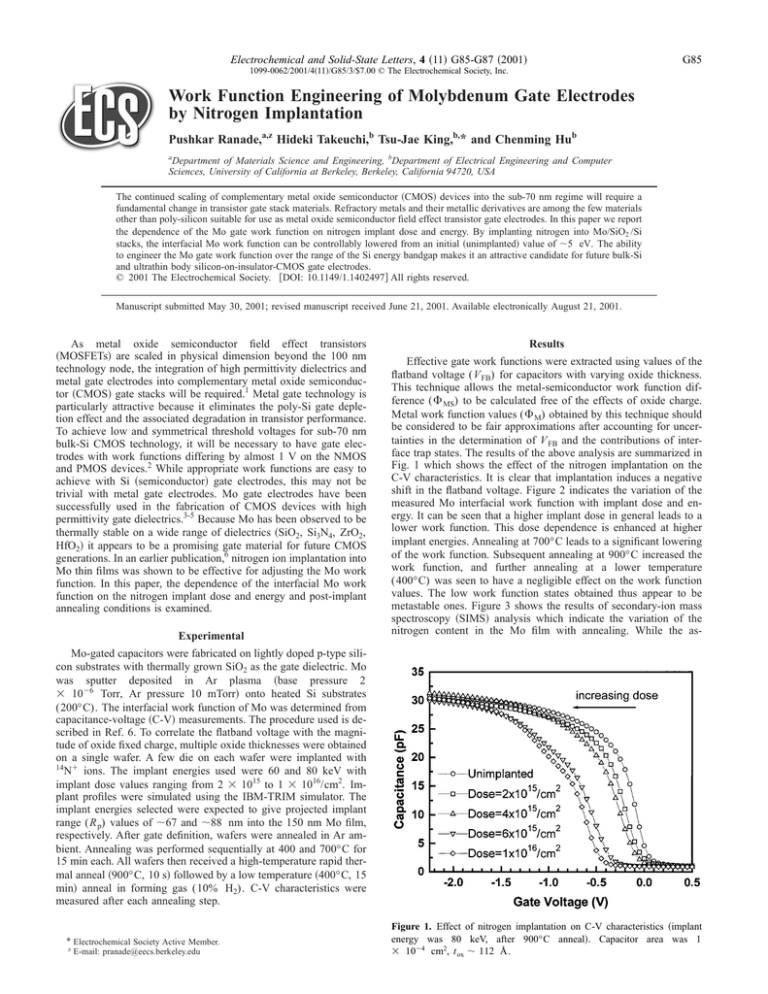

Effective gate work functions were extracted using values of the

flatband voltage (V FB) for capacitors with varying oxide thickness.

This technique allows the metal-semiconductor work function difference (⌽ MS) to be calculated free of the effects of oxide charge.

Metal work function values (⌽ M) obtained by this technique should

be considered to be fair approximations after accounting for uncertainties in the determination of V FB and the contributions of interface trap states. The results of the above analysis are summarized in

Fig. 1 which shows the effect of the nitrogen implantation on the

C-V characteristics. It is clear that implantation induces a negative

shift in the flatband voltage. Figure 2 indicates the variation of the

measured Mo interfacial work function with implant dose and energy. It can be seen that a higher implant dose in general leads to a

lower work function. This dose dependence is enhanced at higher

implant energies. Annealing at 700°C leads to a significant lowering

of the work function. Subsequent annealing at 900°C increased the

work function, and further annealing at a lower temperature

(400°C) was seen to have a negligible effect on the work function

values. The low work function states obtained thus appear to be

metastable ones. Figure 3 shows the results of secondary-ion mass

spectroscopy 共SIMS兲 analysis which indicate the variation of the

nitrogen content in the Mo film with annealing. While the as-

Mo-gated capacitors were fabricated on lightly doped p-type silicon substrates with thermally grown SiO2 as the gate dielectric. Mo

was sputter deposited in Ar plasma 共base pressure 2

⫻ 10⫺6 Torr, Ar pressure 10 mTorr兲 onto heated Si substrates

(200°C). The interfacial work function of Mo was determined from

capacitance-voltage 共C-V兲 measurements. The procedure used is described in Ref. 6. To correlate the flatband voltage with the magnitude of oxide fixed charge, multiple oxide thicknesses were obtained

on a single wafer. A few die on each wafer were implanted with

14 ⫹

N ions. The implant energies used were 60 and 80 keV with

implant dose values ranging from 2 ⫻ 1015 to 1 ⫻ 1016/cm2. Implant profiles were simulated using the IBM-TRIM simulator. The

implant energies selected were expected to give projected implant

range (R p) values of ⬃67 and ⬃88 nm into the 150 nm Mo film,

respectively. After gate definition, wafers were annealed in Ar ambient. Annealing was performed sequentially at 400 and 700°C for

15 min each. All wafers then received a high-temperature rapid thermal anneal 共900°C, 10 s兲 followed by a low temperature 共400°C, 15

min兲 anneal in forming gas (10% H2). C-V characteristics were

measured after each annealing step.

* Electrochemical Society Active Member.

z

E-mail: pranade@eecs.berkeley.edu

Figure 1. Effect of nitrogen implantation on C-V characteristics 共implant

energy was 80 keV, after 900°C anneal兲. Capacitor area was 1

⫻ 10⫺4 cm2, t ox ⬃ 112 Å.

G86

Electrochemical and Solid-State Letters, 4 共11兲 G85-G87 共2001兲

Figure 3. SIMS concentration-depth profiles for nitrogen, showing segregation at the Mo/SiO2 interface with annealing 共60 keV 14N⫹ implant, dose was

5 ⫻ 1015/cm2兲.

Figure 2. Variation of measured Mo work function with nitrogen implant

and annealing conditions. Also shown along the vertical axis are the positions of the conduction and valence bandedges of Si.

functions (⬃5 eV) observed from the unimplanted samples. The

work function lowering observed after 700°C annealing and the

subsequent increase in the work function after 900°C annealing can

be attributed to competing chemical changes 共nitrogen segregation兲

and structural changes 共improvement of crystalline quality兲 in the

film between these temperatures. The segregation of nitrogen at the

interface leads to an initial lowering of the work function 共annealing

at temperatures up to 700°C兲. While increasing the annealing temperature does increase the nitrogen concentration at the interface, it

also leads to an improvement in the crystalline quality of the film

and presumably increases the contribution of the 共110兲 Mo planes to

the work function. Thus, the subsequent increase in the work func-

implanted profile shows no distinct features, a significant pileup of

nitrogen is observed at the Mo/SiO2 interface after annealing at

700°C. This segregation effect is even more prominent after annealing at 900°C. Figure 4 shows the results of X-ray diffraction 共XRD兲

analysis performed on the Mo/SiO2 /Si stack after implantation. The

broad diffraction peak observed after implantation is indicative of

increased poly-crystallinity or nonuniform strain induced in the film.

Annealing at 700°C led to a fairly sharp and intense diffraction peak

and annealing at 900°C led to a further increase in the intensity of

the peak, indicating an improvement in the crystalline quality of the

film and the restoration of the predominantly 共110兲 texture of the

film.

Discussion

As seen in the cross-sectional SEM image of Fig. 5, the deposited Mo film has a columnar or fibrous morphology. XRD confirms

the predominantly 共110兲 texture 关共110兲 planes parallel to the surface兴

of this film. The various crystallographic planes of body-centered

cubic 共bcc兲 Mo crystals have vacuum work functions ranging from

4.3 to 4.95 eV.7 The 共110兲 Mo surfaces are the most densely packed

in the bcc system and possess the highest work functions. The columnar microstructure is thus crucial in obtaining the high work

Figure 4. XRD diffraction data showing evolution of Mo film morphology

after nitrogen implantation and annealing. The presence of a single diffraction peak at ⬃40.6° indicates a preferred 共110兲 texture to the Mo film.

Electrochemical and Solid-State Letters, 4 共11兲 G85-G87 共2001兲

G87

relatively straightforward technique to modulate the Mo work function over the range of the Si energy bandgap, so that Mo is an

attractive candidate gate electrode material for bulk-Si CMOS devices and also for ultrathin body SOI-CMOS devices.11

Conclusions

The effect of nitrogen implantation and thermal annealing on the

work function of Mo gate electrodes is presented. Nitrogen is observed to segregate at the Mo/SiO2 interface upon thermal annealing, lowering the interfacial Mo work function from a relatively

high value of ⬃5 eV. The ability to tailor the Mo work function

over a fairly wide range makes it an attractive candidate for future

CMOS technology generations.

References

Figure 5. Cross-sectional SEM image showing morphology of deposited

Mo film.

tion is observed to be dependent on the implant dose and energy and

the resulting crystalline damage induced by the implant. An optimization of the implant dose and energy will hence be necessary to

control the final work function.

Metal work functions at dielectric interfaces have been observed

to be dependent on the permittivity of the dielectric.8-10 While the

interfacial Mo work function does vary with the dielectric being

used,3-6 the variation is within 200 mV of the vacuum surface work

function of the 共110兲 crystallographic planes of Mo 共4.95eV兲.7 This

observation indicates the applicability of Mo as a bulk-Si PMOS

gate electrode. Selective nitrogen implantation into the Mo film is a

1. International Technology Roadmap for Semiconductors, Semiconductor Industry

Association, 1999.

2. I. De, D. Johri, A. Srivastava, and C. M. Osburn, Solid-State Electron., 44, 1077

共2000兲.

3. Q. Lu, R. Lin, P. Ranade, Y.-C. Yeo, X. Meng, H. Takeuchi, T.-J. King, C. Hu, H.-F.

Luan, S. Lee, W. Bai, C.-H. Lee, D.-L. Kwong, X. Guo, X. Wang, and T.-P. Ma,

Tech. Dig. Int. Electron Devices Meet., 2000, 641.

4. Y.-C. Yeo, Q. Lu, P. Ranade, H. Takeuchi, K. J. Yang, I. Polishchuk, T.-J. King, C.

Hu, S. C. Song, H. F. Luan, and D.-L. Kwong, IEEE Electron Device Lett., 22, 227

共2001兲.

5. Q. Lu, R. Lin, P. Ranade, T.-J. King, and C. Hu, in VLSI Technology Digest, p. 45,

IEEE, New York 共2001兲.

6. P. Ranade, Y.-C. Yeo, Q. Lu, H. Takeuchi, T.-J. King, C. Hu, in Gate Stack and

Silicide Issues in Silicon Processing, C3.2.1, MRS, Warrendale, PA 共2000兲.

7. H. B. Michaelson, J. Appl. Phys., 48, 4729 共1977兲.

8. Y.-C. Yeo, P. Ranade, Q. Lu, R. Lin, T.-J. King, and C. Hu, in VLSI Technology

Digest, p. 49, IEEE, New York 共2001兲.

9. R. C. Keller and C. R. Helms, J. Vac. Sci. Technol. A, 10, 775 共1992兲.

10. H. Matsuhashi and S. Nishikawa, Jpn. J. Appl. Phys., Part 1, 33, 1293 共1994兲.

11. L. Chang, S. Tang, T.-J. King, J. Bokor, and C. Hu, Tech. Dig. Int. Electron Devices

Meet., 719 共2000兲.