Signal Leakage Preventive Maintenance The Art of Locating Leaks Leakage Equipment Applications

advertisement

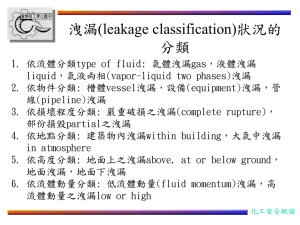

Signal Leakage Leakage Equipment Applications Preventive Maintenance Signal leakage, also called egress, occurs when RF signals escape from the HFC cable plant and radiate into the environment. In the 1970s, cable operators began putting channels into the ‘’mid-band,’’ a range of frequencies also used for aeronautical applications. To ensure air traffic safety, the FCC established rules strictly limiting the level of signal leakage at aeronautical frequencies. In March 1989, the rules were amended to require offset signals in the aeronautical band and to clarify the method by which cable systems report cumulative leakage index (CLl) to the FCC. Since its establishment as a legal obligation, leakage testing has also proven to be a powerful preventive maintenance technique. Active monitoring for leaks and prompt repair of their causes has been shown to improve overall system performance and to reduce the number of service calls. Leakage testing has also been useful for reducing the level of reverse path ingress. Sources of Signal Leakage Significant leaks occur most often where shielding effectiveness is low and signal levels are high. Both conditions must be present. For example, the shielding effectiveness of subscriber cabling is relatively weak, but subscriber signal levels are low, so home cabling usually radiates only lowlevel leaks. A high percentage of leaks are from within the home. Much stronger leaks are found in the distribution system because the signal levels are much higher, especially near amplifiers. The hardware used in distribution systems is designed for high shielding effectiveness so leaks only occur if there are workmanship problems, mechanical defects, or damage. Common causes include loose covers or connectors on passive devices or amplifiers, poorly made and defective connections, and bad splices. Damage to underground distribution cable may be caused by road construction, careless excavation, or sinking posts and power poles where cables are buried. 1 The Art of Locating Leaks Pinpointing sources of leakage is a blend of art and science. An “ideal” leak would behave like a point source, and the operator would only need to move his leakage receiver in the direction of increasing power to find it. However, real conditions are very different. RF leakage currents can run for considerable distances from their source down guide wires, the sheathing of hard line cable, and other metal structures connected to, or near, the source of the leak. The geometry of the leak site, including the location of surrounding metallic structures, can influence the apparent direction of the leak. Sometimes conditions and geometry will promote standing waves, which make leak strength rise and fall in a periodic way as the detecting vehicle drives by the source. Leakage radiation may also be reflected from buildings, changing the apparent direction of the source. Sometimes the leakage being detected is actually from two separate sources, or from a single source and a reflection of that source, again obscuring the direction of the leakage source. All of these effects create multiple signals that can appear stronger or weaker at the leakage detector, producing readings that rise and fall confusingly as the detector is moved. Systematic leak location procedures and technician training can reduce this confusion, but practical experience is also valuable. 800-344-2412 317-895-3600 www.trilithic.com Signal Leakage Leakage Equipment Applications The “Driveout” It is easy to survey large areas of an HFC system in a short amount of time by patrolling the system with a vehicle-mounted leakage receiver and a roof-mounted quarter-wave antenna. A driveout will quickly isolate the general area from which the leak is radiating and will give the operator a rough indication of signal strength. When preparing a vehicle for this use, consideration should be given to the placement of the monopole antenna on the vehicle’s roof, as the antenna requires a good, uncluttered ground plane for maximum sensitivity and even pattern of reception (Figure 1). The antenna should be situated as far as possible from metal ladders and other metallic obstructions that might block leakage signals or cause lobes or asymmetrical receiving patterns. 90 60 -4 30 -6 -8 -10 30 -20 B -30 -50 0 -40 0 Figure 1: Vertical-plane radiation pattern for a groundmounted quarter-wave vertical antenna. The solid line is the pattern for perfect earth. The shaded pattern shows how the response is modified over average earth. Standing Waves WEAKER READINGS Standing Waves While patrolling the cable system and monitoring for leakage, the operator may encounter a series of amplitude peaks at regular distances (Figure 2). Often, as the vehicle moves, the peaks will gradually rise in overall strength and merge until a steady tone is heard. This phenomenon is caused by standing waves distributed along metallic cables or similar structures that conduct leakage energy away from the source of the leak. Standing wave effects diminish with distance from the source as the energy is attenuated by conduction loss. The simplest way to deal with standing waves is to drive at a constant pace (to make the standing wave pattern recognizable) and observe the fluctuations until they reach their peak, then begin to decline in strength. The source of the leakage will be found near the point where the peak of the fluctuation was found. 2 60 -2 800-344-2412 STRONGEST READINGS Figure 2 317-895-3600 www.trilithic.com WEAKER READINGS Signal Leakage Leakage Equipment Applications Tracking Down the Source Once the general area of the leak is determined, it is necessary to pinpoint the location on foot using a hand-held leakage detector (The area that needs to be investigated on foot can be greatly reduced if the driveout data is analyzed first by Trilithic’s Leakage Analysis Workshop software). Finding the source of a leak can usually be done with the ''rubber duck'' antenna, affixed to the leakage detector. If the location of the leak cannot be determined by simply "walking it down,'' the operator may use a dipole antenna to triangulate the source. On foot, in the vicinity of the leakage source, the operator simply rotates the dipole antenna for peak leakage detector readings while noting the position of the dipole elements (Figure 3). Alternately, the operator may rotate for minimum detector readings; sometimes it is easier to establish a "null" than a “peak” reading. Moving to another spot parallel to, and 15 to 20 feet away from the cable plant, the operator takes a second bearing on the leak. The leakage source will be near the point where the bearings from the two measurements intersect. 30 0 -2 -6 -8 -10 60 60 -20 90 DIRECTION OF B -30 -40 -50 120 150 150 180 (A) Figure 3: Dipole antenna radiation pattern. 800-344-2412 90 DOUBLE ELEMENT 120 The procedure for making calibrated measurements for the Cumulative Leakage Index (CLI) calculation as prescribed by the FCC requires that the operator take his measurements using a horizontal dipole antenna, elevated three meters above the ground, and positioned three meters from the source of the leak. Procedures require the dipole antenna to be rotated in the horizontal plane to maximize the leakage signal, giving the highest reading on the calibrated leakage measurement receiver. 3 30 -4 Measuring the Leak For measuring the strength of a leak, a calibrated leakage receiver is required. Instruments such as the Trilithic Seeker Lite², Seeker, and Seeker GPS leakage detectors are equipped to read radiated fields directly in microvolts per meter (μV/m). A 317-895-3600 www.trilithic.com Signal Leakage Leakage Equipment Applications False Triggering and Noise Sources ‘’False triggering “of leakage detectors is caused by electrical noise and, in some cases, overbuilt HFC systems. Besides complicating leakage measurements, false triggering can obscure real leakage problems in the same area. False triggering caused by electrical noise can have many sources, including electric motors, faulty power line hardware, and even neon signs. Interference can also be generated by a vehicle’s electrical system, including those of the vehicle carrying the leakage detector. The operator can reduce noise from his own vehicle through improved grounding and shielding of suspect electronic devices and the use of resistor spark plugs to combat ignition noise. all kinds. This circuitry gives the Seeker series additional noise resistance, as compared to competitive leakage detectors. When Signal “Tagging’’ is the Answer… When leaks from overbuilt HFC systems or high local noise levels routinely cause the leakage detector to false alarm, the operator may want to consider signal tagging. A tag is a special lowfrequency modulation added to the carrier and used for leakage detection. This modulation has no effect on the channel’s video, but causes a distinctive response in Trilithic leakage receivers. The Seeker Lite², Seeker, Seeker GPS, and Seeker BB-2 have specialized circuits that detect the presence of carriers that have been tagged by Trilithic’s patented CT-2 channel tagging device. These leakage detectors break squelch only if a tagged signal is detected, making them more immune to false triggering. …And when it’s Not Some new digital terminals and baseband descrambling set tops are intolerant of tagging modulation. In those cases, the operator may wish to use another technique to improve noise immunity. The best choice is the to rely on the noise discriminating function of current detectors such as the Trilithic Seeker series, coupled with the CT-3 channel tagger. The Seeker leakage detectors contain additional circuitry to discriminate between signals and noise of 4 800-344-2412 317-895-3600 www.trilithic.com 062909-REV1

![Section 01669/Leakage Test of Hydraulic Structures [spec]](http://s3.studylib.net/store/data/007419897_1-1b5e9897de2aef63720e2aa5ff669e8a-300x300.png)