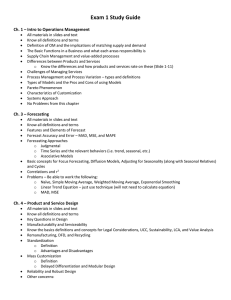

D Waiting-Line Models Quantitative Module Module

advertisement