Waste Treatment Infrastructure in North Rhine-Westphalia, Germany

advertisement

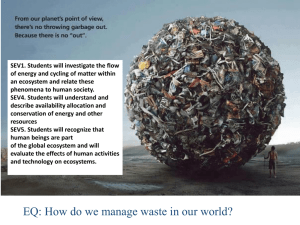

Waste Treatment Infrastructure in North Rhine-Westphalia, Germany Sibylle Morstadt (1), Karl-Heinz Striegel (2), (1) TAUW GmbH, Moers, (2) State Environmental Office/North Rhine-Westphalia, Essen, Germany Summary The description of the waste disposal and recovery infrastructure in the Federal State of North Rhine-Westphalia / Germany (18 mn inhabitants = 530 inh./km²) sets an example of a largely developed, highly differentiated and - to a large extent - privately organized commercial and industrial waste management sector. For the turn of the year 2001/2002, this infrastructure was the subject of the first of two status reports prepared by the State Environmental Office by order of the State Ministry of the Environment. This is · the report on waste treatment plants in North Rhine-Westphalia. With the publication of the Waste Disposal and Recovery Atlas in December 2001, the State Environmental Office succeeded in representing the complete disposal and recovery infrastructure of this highly industrialized and densely populated European region in a detailed way and for the very first time. Meanwhile, the data sheets for all waste disposal and recovery plants in North Rhine Westphalia as well as the text volume are available on the homepages of the State Ministry of the Environment (www.munlv.nrw.de) and of the State Environmental Office of NRW (www.lua.nrw.de). 1. Introduction, characteristics of waste management in North Rhine-Westphalia For many decades, waste treatment and disposal infrastructure developed without strong public incentives in North Rhine-Westphalia. Guided by Federal and European legal framework only and orientated towards rough State planning directives for hazardous waste, private operators took full responsibility and investment risk for appropriate waste management facilities. Favorable for the development of such a broad waste treatment infrastructure was the long industrial tradition of the chemical industry, steel production and hard coal mining. During several decades, North Rhine-Westphalia generated 30 to 40 % of German hazardous waste. These conditions led to an extreme variety of disposal and recycling activities, following all ups and downs of economic frame conditions, public pressure and legal development. While other German States decided to give State-owned monopolistic hazardous waste management and operation a try, North Rhine-Westphalia continued to be an open market for private engagement in waste management infrastructure. Planning, supervision and monitoring of such a wide range of participants on the wastehandling market are only possible with data based registers which are processed and administrated by State waste management boards. This waste disposal and recycling register has been existing and growing in number, complexity and diversification for 15 years now. With the Disposal and Recovery Atlas NRW published in December 2001, and the additional landfill report to be published soon, the State Environmental Office and the Ministry of the Environment of North Rhine Westphalia are presenting – for the first time and up to now unique in Germany – the complete disposal and recovery infrastructure of an economically important European region. This presentation gives rise to more founded research on the environmental impact of waste industry and on their efficiency in terms of elimination and isolation of hazardous substances. SARDINIA2003_2_Infrastructure.doc 1 2. Disposal and recovery options, an overview of waste treatment plants in operation in North Rhine-Westphalia ENADA, the waste disposal and recovery register currently identifies 3090 recycling and disposal plants in operation (Appendix 1, status June 2000). The disposal and recovery infrastructure of North Rhine-Westphalia consists of the following types of recycling and disposal plants: · · · · · · · · · Biological treatment plants for composting and anaerobic digestion above all of biowaste and green waste Biological treatment plants for contaminated soils Chemical-physical treatment plants of mainly fluid and pasty hazardous waste Mechanical re-processing and screening plants, mainly for domestic and commercial waste Thermal waste treatment plants, incinerators for domestic waste, hazardous waste and sewage sludge, including other thermal processes for waste treatment, e.g. for contaminated soils Waste-to-energy-processes in power stations, combustion plants and cement kilns Mechanical-biological treatment plants for domestic and commercial waste Landfills and Intermediate waste stocks and comparable transition and collection stations. Furthermore, industrial reutilization processes, e.g. for glass, paper and plastics are playing an important role in the material recycling of waste. The most important group is represented by the 692 mechanical reprocessing plants – 272 of which are mineral building rubble reprocessing plants. Landfills (461 plants) and screening plants (186) are the next important plant types. The number of biological treatment plants (100) increased a lot during the last few years due to the requirement of anaerobic digestion (15) and composting (85) of biowaste and green waste, sewage sludge and waste from food industry. The chemical-physical treatment plants (77) mostly for hazardous waste are an important disposal branch as well. Finally, thermal processes and incinerators (58) are to be mentioned. The recovery of waste in industrial processes (635 plants) as e.g. in combustion plants and power stations rapidly increased as well during the last few years. Their knowledge and recording have become indispensable for a complete view of waste streams. However, the legal distinction of what is waste and what is ‘non-waste’ sometimes becomes difficult in these cases. Landfills are still one of the most important waste disposal facilities in North RhineWestphalia - also as far as quantity is concerned: 282 landfills for inert material of landfill class DK I according to European directive (predominately former landfills for soil and building rubble), 89 landfills of the landfill class DK II (former landfills for mixed domestic and commercial waste or sewage sludge), 57 landfills for industrial and commercial waste (disposal class II or III) and 22 landfills for hazardous waste (DK III) are operated in North Rhine-Westphalia. Besides, the types of waste disposal and treatment plants mentioned above, there are some other types, as e.g. the 301 scrap vehicle demolishing facilities – nowadays progressively advancing to vehicle dismantling plants - and 407 intermediate waste stocks, transition and recollection stations. In addition, we depart from the fact that 87 asphalt mixing plants reprocessing road material and 154 active excavations with earth and other inert material backfills are existing – both beyond legal waste definition. The complete results of the investigations on waste disposal and recovery infrastructure are presented in Appendix 2 and in Chapter 8. The most important disposal and recovery options shall be discussed in detail now: SARDINIA2003_2_Infrastructure.doc 2 3. Biological treatment plants Composting plants: Composting plants and anaerobic digestion plants are favorable recycling facilities for biowaste, green waste, sewage sludge and several waste materials from food industries. Composting plants primarily aim at producing compost as fertilizer, whereas the digestion plants are producing not only compost, but also fluid fertilizers and biogas for heat generation. A comparison of the energy balance of the two options gives priority to biogas production instead of composting. At present, there are important development activities in the field of biogas technology for biodegradable waste. During the last decade, the biological waste treatment gained more and more importance. In total, 105 plants are operated in NRW. With a capacity of 1,6 and an input rate of 1,42 mn tons/a, North Rhine-Westphalia is playing a prime role in biological waste processing in Germany. Composting plants (90) still are the predominant biological treatment option. With the separate collection of all bio-degradable waste from North Rhine-Westphalian households, the system capacity for composting rapidly increased to 1.4 mn tons/a. The input rate in 2000 was 1.32 mn tons (resp. 73 kg / inhabitant a) – this represents three quarters of the biodegradable waste generation in North Rhine-Westphalian households. About 22 % of those 90 composting plants apply open composting. In terms of available system capacities, 9 % only are working with open composting. Half of all compost produced is used in agriculture, a quarter of it is used for recultivation purposes (mainly in mining areas) and the remaining 25 % are applied in horticulture and private gardening, on cemeteries as well as by road construction firms and earth factories. Anaerobic digestion plants In 15 anaerobic digestion plants, 100,000 tons/a of waste material are handled. The input rate is increasing rapidly. The range of capacity of these facilities varies between 1,000 and 40,000 tons/a. In total, the processing capacity comes up to 200,000 tons/a. These plants are producing 43 % of compost, 54 % of fluid fertilizers and only 3 % of obstructing material requiring incineration. Biogas rates amount to 10 up to 570 m³/h. This corresponds to a production rate of 70 to 120 m³/tons of waste. The methane content usually comes up to between 50 and 80 %. 4. Mechanical re-processing and screening plants Screening plants While mechanical reprocessing plants are using more sophisticated technical equipment for waste dissection, screening plants are low-technology plants destined for the positive or negative selection of waste compounds, traditionally by manual labor. Today, these plants constitute the first step in a chain of more complex recycling processes. 186 such screening plants are existing in North Rhine-Westphalia. Mixed commercial waste, residual domestic waste and mixed building rubble are favorable waste fractions. The capacity of the screening plants in NRW comes up to 10.5 mn tons/a; the input rate amounts to 5.1 mn tons/a. Relevant waste fractions which can be recycled are earth material (negative selection of obstructing material). In screening plants for paper/cardboard, wood, plastics and metals SARDINIA2003_2_Infrastructure.doc 3 with positive selection of reusable compounds, the residual fraction after screening can be quite high and may come up to 60 %. This residual fraction usually has to be disposed of in landfills and incinerators. Three main types of screening plants (respectively process lines within screening plants) can be distinguished in North Rhine-Westphalia. These are: · the paper sorting process lines (capacity 1,95 mn tons/a), · the sorting lines exclusively for packaging waste from DUALES SYSTEM DEUTSCHLAND (German dual waste management system – DSD (capacity 0,94 mn tons/a) and · the sorting-lines for mixed commercial waste and building rubble (capacity 7,61 mn tons/a). A comparison of the residual fraction after screening reveals surprising differences: The input material in paper sorting lines is almost completely recycled. The percentage of residual fraction in DSD sorting lines suitable for elimination in disposal plants is considerably higher (up to approx. 25 % ). The residual fraction of mixed commercial waste and building rubble appropriate for elimination in disposal plants can amount to approx. 40 %. As a consequence, it can be outlined that the applied sorting technique for the latter mentioned material has not yet been optimized. Mechanical re-processing plants Mechanical reprocessing plants are applied for material recovery from solid waste. In our opinion, they differ from screening plants, as they are providing further mechanical procedures as e.g. cutting, crushing and sieving, washing, mixing and solidifying with binding agents. In general, the destination of both systems is quite similar: disconnection and disintegration of relevant recyclable waste fractions from pollutants and obstructing fractions in order to make the reuse easier. Processes become more and more sophisticated in order to extract quantitatively more and qualitatively better (= purer) material. This group of treatment plants constitutes the largest group with 692 plants in total. They are representing a system capacity of more than 77 mn tons/a and an average input rate (between 1998 and 2000) of 28 mn tons/a (Table 1). They are uniformly distributed all over North Rhine-Westphalia. From these 692 mechanical-reprocessing plants, 395 plants are applied for the re-processing of mineral residues from road construction and building rubble. More than half of the mentioned capacity (43 mn tons/a) and half of the input (13 mn tons/a) refer to the recycling of mineral building material including asphalt recycling. Waste statistics of 1998 show that another 4.86 mn tons of mineral building waste and another 1.78 mn tons of mixed waste from construction sites have been disposed of in landfills and are still awaiting recycling. The remaining reprocessing plants specialize in a great number of different waste types using different types and combinations of mechanical aggregates (table: waste types with more than 1 mn tons/a). Waste type Building rubble, mineral residues from road construction Asphalt from road restoration Waste from heavy industry (Steel, ferrous and non-ferrous metals) Mixed waste from construction sites SARDINIA2003_2_Infrastructure.doc Number of process lines within plants 303 92 Licensed capacity [tons/a] 34.030.000 8.800.000 8.000.000 21 28 5.500.000 4 Ferrous metals Other mineral waste Bottom slag and ashes from incinerators Secondary combustibles from waste *) Wood Glass 5.430.000 3.770.000 2.000.000 65 13 8 1.330.000 23 1.210.000 1.080.000 23 9 *) = discussed in detail below) Table 1: Mechanical reprocessing plants in North Rhine-Westphalia, ordered according to capacity as far as waste types with more than 1 mn tons/a are concerned (status 06/2001) 5. Chemical-physical treatment plants Chemical-physical treatment is applied for fluid and pasty, mostly hazardous waste. Only few of these plants are processing certain types of solid waste material, as e.g. batteries. The plants are operated with the objective to remove organic and inorganic impurities, to separate solid fractions from liquid waste fractions, to split off relevant recyclable fractions (e.g. oil, solvents) and to obtain a sewage water which can be discharged into the public sewage system. The destruction or reduction of hazardous substances and properties is the result of chemical reactions (neutralization, oxidation, reduction, electrolysis) and/or physical processes (filtering, decantation, sedimentation). The result of this destruction and/or concentration of hazardous compounds is a solid output material which can be finally disposed of or incinerated. After filtration in buffer tanks and analytical control stations, the waste water from North Rhine-Westphalian chemical-physical treatment plants is finally discharged into the public sewage system and cleaned in public waste water treatment plants together with communal waste water. These 77 chemical-physical treatment plants are representing 8 % of the total number of plants operating in NRW. They are situated along the river Rhine and in the Ruhr District, where industrial and commercial activities are concentrated. The German technical regulation pertaining to hazardous waste requires a general separation of chemical physical treatment for inorganic waste and for organic waste. In June 2001, 37 plants accepted organic waste only, while 20 plants accepted inorganic waste only. In 16 plants both groups of waste were handled. Four plants carry out special types of chemical-physical processing. Here, batteries, transformers and septic hospital waste are mostly handled by means of distillation. Waste material Waste water/ drainage water from landfills etc. Hazardous waste (fluid / pasty) Sludge e.g. from separators and precipitators Oil-containing liquids / emulsions (service fluids) Waste oil Waste acids, spent acids Waste from colors /pigments/solvents Others Total of acceptance capacities SARDINIA2003_2_Infrastructure.doc Number of operating process lines 11 Licensed capacity in tons/a 1,221,960 25 29 514,600 359,440 15 300,000 4 6 7 33 131 222,400 216,080 130,360 215.307 3,180,147 5 Table 2: Licensed capacities of chemical-physical treatment in NRW, differentiated according to waste types (status 06/2001) The total licensed capacity of these chemical-physical treatment plants in NRW comes up to approx. 3.2 mn tons/a; the input rate in 1998/1999 was approx. 1.55 mn tons/a. Table 2 shows the distribution of the chemical-physical treatment plants and capacities with regard to different waste material. In 21 plants with a total capacity of approximately 754.000 tons/a, oil-containing liquids are treated by means of emulsion separation. Among these chemical-physical treatment plants, the distillation plants are constituting a group with technically well delimitable treatment technology. The distillation procedure is used for the recovery of solvents and other organic liquids, like antifreeze and brake fluids, Freon 12 and similar compounds. In North Rhine-Westphalia, 20 chemical-physical treatment plants of this type (with in total 26 process-lines) are operating. They are representing a licensed capacity of 340,000 tons/a. The average input rate of the last three years was 110,000 tons/a. 6. Thermal treatment plants The prime objectives of thermal waste treatment are the reduction of volume (necessary for landfills), the destruction of organic pollutants, the extraction of recyclable compounds and – last, but not least – the energy recovery from waste. Waste incinerators have different stove types depending on the waste type treated: pasty and fluid hazardous waste requires an other oven type than domestic and commercial waste or sewage sludge. Meanwhile, North Rhine-Westphalia disposes of a sufficient number of different types of incineration plants for mineralizing the total of residual waste generated. Most of the incinerators for hazardous waste are part of big production plants of chemical industries; they are situated along the river Rhine. On the other hand, sewage sludge and domestic waste incinerators - still operated and controlled by public enterprises - are distributed more uniformly all over NRW. Incineration plants In North Rhine-Westphalia, 36 waste incinerators are in operation. 15 of them are domestic waste incinerators, 6 are sewage sludge incinerators and 14 are hazardous waste incinerators. In addition, the RZR-Herten incineration plant provides both technologies - one for domestic waste and one for hazardous waste. The Bielefeld incineration plant for domestic waste operates three additional stoves for septic hospital waste. The capacity of waste incineration in North Rhine-Westphalia amounts to 6,2 mn tons/a (Table 3). Incinerators for Domestic waste, partly including sewage sludge Sewage sludge only (dry mass content) Hazardous waste Total 16 Capacity* Approved of [tons/a] 5,400,000 6 240,000 106,000 550,000 6,190,000 378,000 5,384,000 Number of plants 15 37** Input 1998/99 [tons/a] 4,900,000 Table 3: Number, capacities and input rates of waste incineration plants in NRW, (status 06/2001) * ** The approved capacity is higher than the realized capacity. RZR-Herten is mentioned twice due to it‘s subsystems for hazardous waste and for domestic waste. SARDINIA2003_2_Infrastructure.doc 6 Those 16 domestic waste incinerators are representing a total licensed capacity of 5.4 mn tons/a, respectively a realized capacity of approximately 5.24 mn tons/a, about 1 mn ton/a of which were realized within the last three years. In 1999, about 4.9 mn tons of domestic waste were treated. Beyond this, a total capacity of 240,000 tons/a is available in specialized sewage sludge incinerators. The six plants are either operated by waste water associations (3), by local public institutions (1) or by industrial production companies (2). Most of them are using the fluidized bed firing system. Sewage sludge can, however, also be treated in domestic waste incinerators. In total, 224,000 tons of sewage sludge (calculated as dry mass content) were treated in North Rhine-Westphalia in 1998. The 15 incineration plants for hazardous waste are mostly located within chemical industries and are therefore concentrated along the river Rhine. The licensed capacity of these plants amounts to 550,000 tons/a, the realized capacity to 470,000 tons/a. Almost all of them can be used by other waste generators as well. In 1998, 378,000 tons of waste were treated there. The transfer of hazardous waste from abroad, especially from Benelux increased from 5,000 to approx. 16,000 tons/a within 2 years. Other thermal treatment plants Besides these incineration plants, numerous other thermal processes with a wide range of waste recovery or disposal objectives are existing. There are burning places for pyrotechnical production residues, plants for the recovery of non-ferrous metals (Al, Ag), regeneration plants for used foundry sands or for loaded active carbon etc. The total capacity of these plants amounts to 508,000 tons/a, with individual capacities of 10,000 to 50,000 tons/a. Furthermore, there is a thermal treatment plant for contaminated soils in North Rhine-Westphalia, where organic pollutants are destroyed in a pyrolysis drum. 7. Power stations, cement kilns and blast furnaces Power stations, cement kilns and other energy intense production processes are contributing to the energetic use of waste as well. Waste oil, scrap tires, pre-conditioned combustibles from domestic residual waste and commercial waste are interesting waste types. Licenses for such energy-intensive production facilities continue to be adjusted to this increasing need for cheap energy sources. Waste input rates depend on the characteristics of the energy delivering process, the quality requirements of the product and the exhaust cleaning technique applied. Power stations 38 out of 170 power stations in North Rhine-Westphalia were provided with a permission for waste-to-energy reuse. Power stations at 31 sites used appreciable amounts of waste. Some of them are industrial facility owned power stations, reusing internal production residues only. Ten out of these 20 plants are located together with refineries or other chemical factories, while other seven plants are attributed to wood industries and paper production. In those facilities, 1.1 mn tons /a of waste can be reused. This is double the annual amount of waste transformed to energy (490,000 tons). Cement kilns Only 10 out of 21 sites for cement production in North Rhine-Westphalia are disposing of a permission for the use of waste for energy production and/or as secondary raw material. All of these ten works apply rotary kilns with cyclone preheater systems. SARDINIA2003_2_Infrastructure.doc 7 In nine of these ten cement kilns, 280,000 tons/a of combustibles were replaced by waste material (1998/1999). This amount could be more than duplicated as well, if the plant operators would actually make full use of the licensed capacities of 690,000 tons/a. In addition to the traditional waste types like scrap tires and waste oils, new combustibles reprocessed from domestic and commercial waste were used within the last two years in an order of 160,000 tons/a. At present, the average value of energy substitution in terms of calorific value for all ten cement kilns amounts to 53 %. Blast furnaces In another 12 plants at eight different industrial sites in North Rhine-Westphalia, the material and/or energetic reuse of waste is licensed: there are sintering plants (3), iron and steel production plants (2) and non-ferrous metal production plants (7). In none of them, however, the energetic reuse of waste was practiced during the last few years. 8. Conclusions and outlook The present waste treatment infrastructure in North Rhine-Westphalia can be described with the following characteristics: § § § § about 3000 plants in North Rhine-Westphalia are serving as waste disposal and recovery plants; about 100 mn tons of system capacity are legally licensed here (not considering the landfill capacity) about 42 mn tons of waste are handled in these facilities per year, out of which 4.25 mn tons were hazardous waste. These plants are specializing in more than 50 different material groups, partly with input quantities of more than 1 mn t/a. This highly developed recycling and disposal infrastructure forms an economic branch which has gained importance far beyond the limits of the state. Some of the plants can be designated as "specialists", as they are concentrating on dangerous pollutants e.g. PCB and are treating quantitatively small waste streams, while others "generalists" splitting up a wide range of waste materials into individual constituents, favorable for recycling. Anyway: Waste recycling requires more and more diversified reprocessing activities which can either be concentrated at one site (with one operator) or distributed over several plants at several sites with different operators. The disposal network covers the entire state; focal points are nearby industrial activities and those areas where the density of population is particularly high. Throughout the year of 1998, 73.58 mn tons of waste were treated and landfilled. This comes up to 4 tons per inhabitant and year. Almost two third of it, (47.14 mn tons) were recovered and only one third (26.44 mn tons) were eliminated in landfills and incinerators. Approximately 42 mn tons of waste were treated in “classical“ waste disposal and recovery plants (described in appendix 2). These plants correspond to a licensed treatment capacity of more than 100 mn t/a. Three quarters of these 42 mn tons of waste were treated in mechanical reprocessing and screening plants; nearly 90 % of the total capacity (100 mn tons) are to be found in the field of mechanical reprocessing and screening. The mineral construction waste (soils, building debris, road break-up including asphalt) constitutes a considerable part (13 mn tons) of these throughputs and capacities. Meanwhile, mechanical reprocessing represents 46 % and landfills 26 % only of all disposal and recovery options; within a couple of years, mechanical reprocessing took over the prime position (Figure 3). The direct material reuse in industrial processes (15 %) and the incineration (approx. 8 %) constitute important disposal possibilities as well. SARDINIA2003_2_Infrastructure.doc 8 Biological and combined mechanical-biological processing plants, chemical-physical treatment plants and waste-to-energy plants make up the remaining part of approx. 5 % only. Yet, this quantitative statement does not allow any conclusions concerning the environmental relevance and the economic importance of those individual disposal and recovery techniques. In such a technically oriented, more and more diversified and privately organized commercial and industrial waste management sector, small scale enterprises with a low technological standard will disappear more and more – replaced by economically powerful enterprises offering integrated disposal and recovery solutions for a multitude of different waste streams and used-up products - facilities that are disseminated all over the country. The further development strongly depends on european legislation and technical innovation potential: the German Technical Directive on municipal waste (1993) combined with the European Directive and the German Ordinance for Landfills (2002) of waste have progressively changed and will continue to change the infrastructure of waste treatment in Germany up to the threshold point of 2005, when landfills of organic waste will be completely forbidden. New incentives came from the greenhouse effect (waste-to-energy concepts) combined with waste-to–fertilizer concepts that brought forth a variety of new recycling options for waste in production processes. Material requirements for these input materials that substitute primary raw material and fossil combustibles created the necessity of more sophisticated reprocessing techniques for a large variety of waste materials (wood, papersludge, waste oil, residues from sorting plants etc.). waste-to-energy process without mechanical reprocessing 1 mn t, (1%) direct re-use without mechnical re-processing 11 mn t, (15 %) Landfilling 19,08 mn t, (26 %) Incineration 5,63 mn t, (8%) mechanical re-processing of construction debris, roads etc. 13,30 Mio.t, (18 %) ChemicalPhysical treatment 1,55 mn t, (2%) mechanical re-processing, others 20,03mn t, (28 %) Biological treatment 1,75 mn t, (2%) MechanicalBiological treatment 0,24 mn t, (<< 1 %) Figure 3 Distribution of disposal and recovery options in NRW (Status 2001: 73.6 mn tons) SARDINIA2003_2_Infrastructure.doc 9 Bibliography LUA NRW / MUNLV Entsorgungsatlas NRW – Statusbericht der Entsorgungsanlagen mit CD-ROM – Ministerium für Umwelt und Naturschutz, Landwirtschaft und Verbraucherschutz des Landes Nordrhein-Westfalen (Hrsg.), Düsseldorf 2001 (First Status Report on the complete infrastructure of waste disposal and recovery in North Rhine-Westphalia – text volume and CD-ROM, also available on the internet homepage: www.munlv.nrw.de /Arbeitsbereiche /Abfall /Entsorgungsatlas) Morstadt, S. Striegel, K.-H. Die Rolle der Sortier- und Aufbereitungsanlagen für die Entsorgung von gewerblichen und kommunalen Massenabfällen in Nordrhein-Westfalen, In: Gewässerschutz-Wasser-Abwasser, Bd. 177, 33. Essener Tagung für Wasserund Abfallwirtschaft, Institut für Siedlungswasserwirtschaft der RWTH Aachen (Hrsg.), Aachen 2000 (Publication on the role and function of sorting plants and mechanical re-processing facilities in NRW) SARDINIA2003_2_Infrastructure.doc 10 Appendix 1: Number and type of waste disposal and recovery facilities in North RhineWestphalia / Germany (June 2001) Biological treatment plants 100 Composting plants 85* Anaerobic digestion plants 15* Chemical-physical treatment in a broader sense 955 Chemical-physical treatment plants 77 Specialization: 30* Bio waste composting plants 49* Green waste composting plants 6* Sewage sludge composting plants 15 Bio-waste and comparable waste (excluding plants for agricultural digestion of mature only) Specialization: 37 For organic waste only 20 For inorganic waste only 16 For inorganic and organic waste 4 Sorting plants 186 38 For paper only 17 For packaging waste only (DUAL Refuse System Germany) 131 Mechanical reprocessing plants 692 Heat-controlled processes 58 Incineration plants 36 Other heat-controlled processes Combined mechanical-/ biological treatment plants Contaminated soil treatment plants 22 Other waste disposal facilities 862 SARDINIA2003_2_Infrastructure.doc from construction work 272 For mineral building debris and mineral street break-up debris 115 For mixed building rubbish and asphalt reprocessing plants 62 For iron and non-ferrous metals (s.a. wrecked car disassembly sites) 43 For industrial mineral waste (slag, ashes, sands, powders ) 41 For plastics 43 For electrical and electronic devices 15 For wood 20 For extraction of combustibles for waste-to-energy processes 19 For grease from food waste and animal carcasses 62 For further materials (a.o. cables, glass, paper, tires) Specialization: 22 For domestic waste and sewage sludge 14 For hazardous waste 10 Facilities for heat controlled extraction of chemicals 6 Facilities for heat controlled destruction of certain wastes 6 Melting, drying and heat-controlled dissociation processes 15 635 Total For commercial waste and mixed waste originating 4 Industrial production processes with waste recovery Landfills Other chemical-physical treatment plants 204 Material recycling in production processes 431 Waste-to-energy processes (power plants, cement kilns, etc.) 407 Stocks / collection and transition stations / intermediate deposit 301 Wrecked Car Disassembly Sites 154 Fill-up of trenches and ditches (no landfills in a legal sense) 282 For inert material - German Disposal Class (GDC) I 461 89 For other waste (GDC II ) 57 For certain industrial and commercial waste (GDC II/III) 22 For hazardous waste (GDC III) 11 Underground storage (reuse of waste for mining purposes) 3090 11 Appendix 2 Results of investigation on waste disposal and recovery infrastructure in June 2001 1) Type of treatment Facility type Waste treated Purpose of treatment Number of facilities Licensed capacity Annual input (1998, 1999, 2000) Biological treatment Specialization: Bio-degradable waste and yard waste from households and industries, sewage sludge Transformation of biodegradable waste into fertilizer and soil conditioner 90 1.4 mn t 1.32 mn t Bio-waste and yard waste, vegetable and animal residues from food production, grease and fat Extraction of biogas (methane) for energy recovery, transformation of biowaste into fertilizer 15 0.2 mn t 0.1 mn t 105 1.6 mn t 1.42 mn t Composting plants Anaerobic digestion plants In total: Biological treatment plants for contaminated soil Contaminated soil Destruction of organic pollutants in the soil 12 0.77 mn t 0.33 mn t Chemical-physical treatment Chemical-physical treatment plants Residual solvents, emulsions, other water/oil mixtures, acids and bases, industrial sewage sludge and other industrial sludge and liquids Chemical extraction of recyclable fractions (e.g. petroleum), destruction or extraction and concentration of pollutants, recovery of tolerable waste water concentrations, neutralization of acids, etc. 77 3.20 mn t 1.55 mn t Mechanical reprocessing Specialization: Solid waste from households and industries like papers, packaging material, construction debris and building rubble, Separation and extraction of recyclable and combustible waste fractions 186 10.5 mn t 5.09 mn t Solid waste from households and industries like packages, construction debris and building rubble, plastics, electronic devices and metals, slag and ashes Shredding and screening for recovery of recyclable materials and separation of pollutant substances, cleaning by washing, mixing and solidifying 692 34.83 mn t 14.94 mn t + 42.84 mn t constr. debris and asphalt + 13.3 mn t constr. debris and asphalt Contaminated soils Cleaning by washing, mechanical reprocessing 2 0.046 mn t 0.004 mn t 880 88.22 mn t 33.33 mn t 16 5.4 mn t 1) 4.9 mn t Sorting plants Mechanical reprocessing plants Washing plants for contaminated soils Subtotal Heat-controlled processes SARDINIA2003_2_Infrastructure.doc Specialization: Domestic waste i i t High calorific waste from households, public institutions and small industries Heat controlled destruction of organic pollutants, recovery of recyclable fractions (metals, 12 incinerators slag) energy recovery from waste volume reduction prior to application for landfills, Hazardous waste incinerators High calorific waste from industrial processes and hazardous products from households see above 14 0.55 mn t 0.378 mn t Sewage sludge incinerators Sewage sludge from public and industrial waste water purification plants see above 6 0.24 mn t 0.106 mn t (dried mass) Other heat-controlled processes Waste with organic pollutants (e.g. activated carbon, oilcontaminated metals, cables), metals, pyrotechnical residues Heat-controlled destruction of organic pollutants, recovery of recyclable fractions 22 0.508 mn t 0.2 mn t Heat-controlled treatment plants for contaminated soils Soil contaminated with organic compounds Heat-controlled destruction of organic pollutants, recovery of recyclable fractions 1 0.048 mn t 0.045 mn t 59 6.75 mn t 5.63 mn t 4 0.55 mn t 0.24 mn t 1137 101.09 mn t 42.50 mn t 880 of these are mech. reprocessing plants 88.22 mn t to be allocated to mech. reprocessing 33,33 mn t to be allocated to mech. reprocessing Subtotal Combined mechanical/biological treatment Combined mechanical/biological treatment plants Residual waste from households and industry Extraction of recyclable fractions and controlled degradation of organic substance within residual waste prior to landfill application Total in NRW 1) The licensed capacity of installations is higher than the installed capacity or even the effective capacity (considering interruption and maintenance periods). Political decisions may as well reduce the effective capacity of treatment plants. The effective capacity of domestic waste incinerators comes up to 4.93 mn t/a SARDINIA2003_2_Infrastructure.doc 13 14