Overview

advertisement

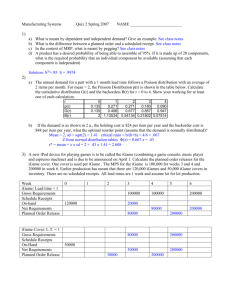

Overview • • • • Dependent demand Master production schedule Bill of materials MRP – Time-phased product structure – Gross material requirements plan – Net requirements plan • Lot-sizing techniques • Extensions of MRP Furniture Mfg. Master Production Schedule • Produces 3-types of chairs – Ladder-back chair – Kitchen chair – Desk chair April 1 2 May 3 4 5 6 7 8 Ladder-back chair Kitchen chair Desk chair Aggregate production plan for chair family Bill of Materials 670 Bill of Materials • List of components & quantities needed to make product • Provides product structure (tree) – Parents: Items above given level – Children: Items below given level Chapter 14 MRP 670 Back legs Front legs Back slats Seat cushion Leg supports Seat-frame boards A Ladder-back chair 1 Bill of Materials Dependent vs. Independent Demand A Ladder-back chair Back slats B (1) Ladder-back subassembly C (1) Seat subassembly G (4) Back slats H (1) Seat frame • Demand for chairs D (2) Front legs Seat cushion Leg supports F (2) Back legs Back legs Front legs J (4) Seat-frame boards I (1) Seat cushion E (4) Leg supports Seat-frame boards Dependent vs. Independent Demand Demand Source Material Type Method of Estimating Demand Planning Method • Demand for front legs – A component or subassembly – Depends on the demand for chairs (parent) A Ladder-back chair Materials With Independent Demand – A finished product – Independent Materials With Dependent Demand Requirements for Effective Use of Dependent Demand Inventory Models • master production schedule • specifications or bills-of-material Company Customers • inventory availability Finished Goods • purchase orders outstanding Forecast & Booked Customer Orders • lead times EOQ & POQ Cooperstown Cars, Inc. Cooperstown Cars, Inc. Bill of Materials for Toy Car • Produces toy • Demand for Toy Car in Week 8 is 100 Toy Car cars • Schedule production for: – Body Wheel Assembly(2) – Axles (2) Body – Wheels (4) Axle (1) Chapter 14 MRP Wheels (2) – – – – – Toy car assembly Wheel assembly Body Axle Wheels 2 Time-Phased Product Structure Gross Requirements Plan 1 2 3 Week 4 5 6 7 Toy Car Required Date Order release data Wheel assembly Required Date Order release data Body Required Date Order release data Axle Required Date Order release data Wheels Required Date Order release data 0 2 1 8 100 4 3 Time in Weeks More complexity/Scheduled receipts Net Requirements Plan 1 Toy Car Gross requirements Scheduled receipts Projected on-hand | 20 Planned order receipts Planned order releases 2 3 Week 4 5 Net Requirements Plan 6 7 8 100 Wheels 20 20 20 20 20 20 Lot-Sizing Rules 20 20 Gross requirements Scheduled receipts Projected on-hand | 30 Planned order receipts Planned order releases 1 150 2 Week 4 5 120 3 6 150 7 120 8 Lot-Sizing Rules: L4L L4L- order the amount needed to fulfill requirements When there is a net requirement, how much Net Requirements Plan should we order? •Lot-for-lot – L4L •Economic Order Quantity – EOQ Wheels Lead time = 1 week Gross requirements Scheduled receipts Projected on-hand | 30 Planned order receipts Planned order releases 1 150 200 80 2 3 80 80 Week 4 5 120 6 150 7 120 8 80 •Part Period Balancing - PPB •Wagner-Whitin Algorithm Chapter 14 MRP 3 Lot-Sizing Rules: L4L Lot-Sizing Rules: EOQ EOQ- order the EOQ Net Requirements Plan Net Requirements Plan Lead Time = 1 week Gross requirements Scheduled receipts Projected on-hand | 30 Planned order receipts Planned order releases Wheels 1 150 200 80 2 3 80 80 Week 4 5 120 80 40 40 0 150 Lead time = 1 week Gross requirements Scheduled receipts Projected on-hand | 30 Planned order receipts Planned order releases Wheels 6 150 7 120 0 150 120 0 120 8 S $100 H $1 / unit / week Q* MRP II 2 3 80 80 Week 4 5 120 6 150 7 120 8 80 $52 / unit / year D (150 120 150 120) / 8 67.5units / wk 2 DS H 1 150 200 80 3510units / year 2(3510)100 116 52 Extensions to MRP Enterprise Resource Planning Customer orders Forecasts Master production schedule Bills of materials Routings Time standards MRP explosion MRP II with ties to customers and suppliers Inventory records Inventory transactions Material requirements plan Cost and financial data Manufacturing resource plan Purchasing reports Financial/ accounting reports Sales and marketing reports Human resource reports Manufacturing reports MRP and ERP ERP @ BMW, Spartanburg Chapter 14 MRP 4 Product • BMW X5 sport activity vehicle • Application: mySAP™ Automotive • Goal: – Tight supplier network in order to ensure just-in-time production – Compress Customer Order Cycle – Improve Inventory Accuracy Key success factors in the Automotive Industry • Speed: speed in product development, speed in product assembly, and speed in product delivery to dealers and customers. • Manufacturers must closely manage armies of suppliers and partners to make certain that the correct systems and components are delivered where and when they are needed. • Collaboration among all the industry players -- suppliers, OEMs, dealers, and customers -- is essential. • Linking complex business processes into a logical flow, maximizing efficiency and satisfying customers' expectations. Business Benefits • Cost reduction of 3% to 6% per vehicle – by changing the supply chain from the traditional push paradigm – New level of collaboration and efficiency. • Groups processes and functions by market segments – OEMs, suppliers and aftermarket, or sales and service. Chapter 14 MRP Why use ERP • Automotive Industry is competitive • Global competition • Trend toward make-to-order manufacturing -- filling individual customer requirements rather than make-tostock new demands on manufacturers and dealers • Potential cost reduction • Customers want what they want, when they want it. Business Benefits • End-to-end integration of SAP and non-SAP products. • Offers a single data platform for – Engineering – Planning – supply chain management – Procurement – customer relationship management. How it works • mySAP™ Automotive generates delivery schedules to meet assembly-line planning and sequencing directives. • Long-horizon forecasts and short-horizon J-I-T delivery schedules are sent to suppliers. – Electronic Data Interchange (EDI) – mySAP™ Automotive Supplier Portal (Internet) 5 How it works • BMW gets an advance shipping notification – Exact information on part counts and delivery dates • Upon receipt parts are transferred directly to the line Chapter 14 MRP Additional benefits • Monitoring the production status in real time • Recording production confirmation and parts consumption every 3 minutes and adjustment of inventory • Costs are posted to calculate the value of work in progress • Seamless collaboration between business partners across the supply chain allows – Engineering – High-volume production – Highly customized products 6