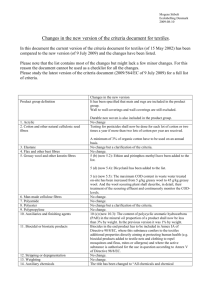

Non-Formaldehyde Nitrogen-Containing Fixing Agent For Direct Dyeing

advertisement

Non-Formaldehyde Nitrogen-Containing Fixing Agent For Direct Dyeing By Yiqi Yang, Edward F. Carman III Institute of Textile Technology, Charlottesville, VA This work was studied to determine if nitrogen based fixing agents imparted the same, or increased, fastness properties to direct dyes as a formaldehyde fixative. Also studied were the effects of the structures and concentrations of dyes and fixatives on color fastnesses of direct dyed cotton. The effect of the fixlng agents on the fastness properties of the direct dyed 100 percent cotton fabric was examined. Fastness properties tested were wash, crock, and light. Tensile and tear strengths of the fixed fabrics were also tested. Introduction Although direct dyes possess poor wet fastness properties, they are still widely used due to their ease of application, comparatively low cost, and good migration properties.’ in fact, direct dyes are second only to sulfur dyes in their textile usage worldwide, with vat and fiber reactive dyes well behind.’ The main disadvantage of direct dyes is their poor wash fastness. The sorption of direct dye by cotton is not a permanent irreversible process. The dye may be removed from the cotton fiber in successive washings with fresh Water. Darker shades can be reduced in depth quickly after only a few water Washings. How quickly the color change occurs depends mainly on the affinity of the dye to the fiber. Sulfonic acid groups are present on the direct dye molecule to impart aqueous solubility, thereby facilitating the application from the aqueous phase.3 Sulfonic groups, however, reduce the affinity of the dye towards the cellulosic substrate. This decreased affinity is due to two factors 1) both the cellulosic fiber and the direct dye have negative charges in the aqueous medium, and 2) the sulfonate group increases the dyeAmerican Dyestuff Reporter October 1996 water interaction and therefore decreases the dye-fiber attraction. The wet fastness characteristics of cellulosic textiles dyed with direct dyes are rather poor, and to improve the fastness properties of direct dyed fabrics an aftertreatment may be used. The aftertreatment follows the completion of the dyeing process. Although the improvement in fastness is occasionally an empirical observation, the aftertreatment process is related to the chemical constitution of the dye. To determine the optimal concentration of fixative required for good fastness properties, Etters4 researched the efficiency of five different fixatives as a function of the concentration. The efficiency of the fixative was calculated using the formula: E=D/MV where E is the efficiency, D is the percent decrease in dye desorption caused by the fixative, and MV is the money-value concentration of fixative. The money-value was calculated from the concentration of the fixative (%OWG, on the weight of goods) times the price per pound of the fixative in dollars. Efficiency is, therefore, the percent decrease in dye desorption that is obtained for one dollar’s worth of fixative per one hundred pounds of dyed material after-treated with a given concentration of fixative. Within many techniques of aftertreat- ing, the direct dyed fibers to improve the wash fastness, the application of formaldehyde, cationic, and metallic salts fixatives are the most common approaches. Formaldehyde improves colorfastness through crosslinking reactions. Improvement in the fastness properties occur during the reaction of two dye molecules with one molecule of formaldehyde through the formation of a methylene bridge.3 It is also possible that one formaldehyde molecule could react with one dye molecule and one hydroxyl group of cellulose. Both reactions could decrease the dye desorption from the fiber. Because of its high reactivity, formaldehyde is one of the most effective fixatives for direct dyes. However, because of the health problems associated with formaldehyde, there is a market demand for nonformaldehyde fixing agents. An alternative method utilizes nitrogen containing organic compounds that couple with the dye to increase the molecular weight and reduce solubility of the dye. The interaction between the dye and the fixative is mainly the ionic attraction from the positively charged nitrogen and the negatively charged dye ion.6 This salt linkage neutralizes the negative charge on the dye and decreases the water solubility of the dye. Enlargement of the dye molecule 39 inside the fiber also makes it more difficult for the dye to be released by the fiber. Another category of fixative that can be used to improve the wet fastness properties of direct dyes is metallic salts. One of the most common metals used as an aftertreatment is copper. The cupric cation, Cu2+, could behave like the organic nitrogen containing fixatives, forming insoluble copper salts with the anionic dye molecules. Direct dyes containing two hydroxyl groups in he ortho position, adjacent carbon posiions in a benzene ring, can react with copper salts to produce less-soluble metallic chelates. Copper salts are not environmentally desirable, but the aftertreatments can be tailored to improve both wash and light fastness properties of some direct dyes without producing enough free copper ion in the effluent to cause problems. Copper salts are used primarily with heavy browns, navy and black shades. Although the treated dyestuffs will have improved light fastness, blue shades will exhibit a green cast. Other approaches such as coupling with diazonium salts, forming metalcomplex with metals other than copper, or the treatment with potassium bichromate are also used for the improvement of colorfastness of direct dyed fabrics. The objectives of this article are to 40 determine the effect of the type and concentration of nitrogen containing dye fixing agents on the fastness properties of direct dyed cotton fabric, and the effect of the number of sulfonate groups a dye has on the fastness properties after fixation. A comparison of the effect of a formaldehyde condensate dye fixing agent to the non-formaldehyde dye fixing agents on the fastness properties of direct dyed cotton fabric is also given. Material Dyestuffs This work used three direct dyestuffs. The main criterion for selection of the dyestuffs was the solubility of the dyes. The sulphonate groups were varied from 2 to 4 while keeping a similar chemical structure. Table I summarizes the characteristics of the dyes selected. The dyestuffs were supplied by Aakash Chemicals & Dye-Stuffs, Inc. Fixatives Four different fixatives, donated by ICI Surfactants, were used for this experiment, for which three were nonformaldehyde: 1) polyamine condensate (poly), 2) quaternary polyimine (quat), 3) cationic polyamide (cat), and 4) formaldehyde condensate (form). The latter fixative was chosen for a comparison study between it and the three other non-formaldehyde agents. Fixatives were chosen for their varying chemistry, availability, and wide use in the commercial market. The abbreviations in the parentheses will be used later on for these four fixing agents. Fabric A 7.4 ounces/square yard, 100 percent cotton, 3/1 left-hand twill fabric was commercially scoured, bleached, and mercerized for use in this research. Twill fabric was chosen for its ease of dyeing. wide usage, and acceptance as a substrate in other direct dyeing experiments, such as the ones by Etters,4 and Bhattacharyya, et al. The fabric was donated by Milliken & Company. Methods Prescouring Five approximately 2 by 3 yard samples were washed in a Sears Kenmore Model 22631 washer set on high load and cotton/sturdy cycle at 130°F water temperature with 40 grams of AATCC detergent, without optical brightener. After that, the goods were rinsed in distilled water twice with a liquor ratio of 40: 1. The fabric was then air dried. Dyeing Ten grams of the fabric was dyed with a liquor ratio of 20: 1 at a pH of 7. The dye concentrations were 1 %, 2% and 4% on the weight of goods (owg) American Dyestuff Reporter October 1996 Am with 5% (owg) of NaCl in each bath. An Atlas Launderometer was used for dyeing with 25 steel balls in each can. The bath was heated to 100°F and held for S minutes, then the temperature was raised to 210°F and held for 30 minutes. The dyebaths were cooled to 70°F in about 40 minutes. The dye liquor was dropped, and samples were rinsed in cool water baths until color bleeding stopped. The fabric then was centrifuged, and was ready for fixation treatment. Fixing Six levels of concentrations, 0.5, 1 .O, 2.0, 3.0, 4.0, and 5.0 percent (owg), of each fixative were tested for each dyed sample with a liquor ratio of 20: 1. The experiment was performed in the Laundrometer, with 25 steel balls in each can. The temperature was elevated to 120°F and held for 20 minutes. Then the bath was cooled to 70°F and the fabric was removed from the cans, rinsed with distilled water, centrifuged, and air dried at ambient conditions. To minimize the processing error, three replicas for each test condition were run. The mean values were reported. Color Measurement The major concern for this work was the color change or color fastness under different conditions. The visual method used was the AATCC standard Gray Scales for Evaluating Staining and Change in Color. Both scales have assessment values from one to five, as Well as half values. The value of 5 means no shade difference between the control and the test sample. The smaller the value, the more the color difference or the fading. The instrumental measurement was Efmc2\8 on the BYK Gardner Spectrophotometer, using a 10 CIE Standard Observer and a D65 Illuminant. E FMC2 is a quantitative American Dyestuff Reporter October 1996 description of the total color difference between two substrates and a value of about 0.5 to 1 .O is detectable by the human eyes. The larger the value, the more the color difference or the fading. Co/or Fastness Tests Wash fastness tests were performed using the AATCC Test Method 61-1989, Test 2A. Crock fastness. both dry and wet, were examined according to the AATCC Test Method 8-1989. Light fastness tests were conducted at Ciba’s laboratory in Greensboro. NC. The 40 hour tests were conducted under the guidelines of AATCC Test Method 16E1987, using an Atlas Ci65 Weatherometer water-cooled Xenon-Arc light. All the tests are the standard tests from the Technical Manual of the Association of Textile Chemists and Colorists. Fabric Strength Tensile strength was tested using the Scott Tensile Tester according to ASTM D1 682-75. Tear strength was examined by Elmendorf Tear Tester based on ASTM D1424-83. Both methods were from the American Society for Testing and Materials. Results And Discussion To evaluate the effect of fixatives on wash fastness, the dyed and finished samples were washed and the color fadings were assessed by both the E FMC2 and gray scale Values. Figures 1, 2, and 3 presents the color fastness results of the fabrics dyed with 1.0% (owg) of Direct Red 83, Direct Red 62 and Direct Orange 26, respectively, and finished with all four fixatives at concentration levels from 0.5 to 5.O%(owg). As shown in the figures, the nonformaldehyde fixatives could achieve the same or better fixation results than a formaldehyde fixing agent. For Direct Red 83, the best nitrogen containing fixative was polyamine condensate. For Direct Red 62 and Orange 26, the best was cationic polyamide. Quaternary polyimine was always the least effective fixative for the dyes examined. Considering the dye characteristics listed in Table I, it is possible that polyamine condensate is better for dyes with high water solubility and cationic polyamide is better for those with lower solubility. Because of the charge neutralizing mechanism, the more positive charges a fixative has could more efficiently neutralize the negative charges on direct dyes and decrease the dye 42 solubility. However, if the fixative carries too many positive charges, the solubility in water of itself and the solubility of the dye-fixative complex after finishing will be high. This in turn will decrease the effectiveness of the fixative. Due to the limited size, a fixative could only cover certain number of dye molecules no matter how many charges it has. Therefore, if a fixative carries more charges than the charges of the dye molecule it could cover after fixation, some net positive charges will be left and, later, increase the solubility of the dye-fixative complex. Other factors, such as the similar distance between two charges of the fixative and that of the dye, are also important to the effectiveness of the fixatives. The results in Figures 1 to 3 also demonstrate that the most improvement of wash colorfastness are at fixative concentrations lower than 1%. Further increase of the fixative concentrations could not improve the wash fastness with the same proportion as it did at concentrations below 1%. A possible explanation is that at concentrations below l%, there are already enough fixative molecules on the fabric to neutralize most of the dyes. Increase of the fixative concentration would not further decrease the solubility of the dyes on the fabric. Staining of the color removed from dyed goods onto other textiles is also a major consideration of the wash colorfastness The relation between fixative and staining was consistent with that between fixative and wash fastness. An example of the staining onto cotton stop of the standard AATCC multifiber test fabric of polyamine condensate fixed fabric is illustrated in Figure 4. The best improvement was for the Direct Red 83 dyed fabric, about 3 gray scale classes. while both the Red 62 and Orange 26 were 1 class improved.This result was similar to the improvement of wash fastness by polyamine condensate presented in Figures 1 to 3, in which polyamine condensate improved colorfastness of Direct Red 83 dyed fabric about 2.5 classes but only 0.5 to 1 class for Direct Red 62 and Orange 26 dyed ones. No remarkable improvement in both dry and wet crock fastnesses was encountered for any of the three dyestuffs examined with any of the four fixatives. Figure 5 illustrated the charge of crock fastness of fabrics finished with polyamine condensate. Figure 6 shows the crock fastness of the fabric finished with all four fixatives. As shown in the figures, the maximum improvement was only 0.5 class based on the S-class American Dyestuff Reporter October 1996 gray scale for staining. This is probably because crock fastness examines the strength of the interaction between the dye and the fiber, not the affinity which is related to the relative attraction between dye-fiber and dye-water. The nitrogen containing fixatives mainly decrease the dye-water attraction and have little effect on dye-fiber attraction. Therefore, they could not markedly improve crock fastness. Using fixatives sacrifices some of the light fastness of direct dyes due to the poorer light fastness of the fixatives than of the dyes. The decomposition of the fixatives and the formation of free radicals and other chemicals promote the decomposition and fading of the dyes. The effects of different fixatives on fastness light of all three dyes are illustrated in Figures 7 to 9. As shown, fixatives decreased the lightfastness of the dyes and the extent of such decrease increased with increasing concentrations of fixatives. At 0.5% (owg) fixative level, the concentration which gave the most wash fastness improvement, lightfastness decreased 0.5 to 1.0 class more than the control fabric, dyed but unfinished, after 40-hour exposure in the standard lightfastness chamber. Nevertheless, the decrease of the lightfastness due to the application of nitrogen containing nonformaldehyde fixatives was similar to, or less than, those finished with the conventional formaldehyde fixative. The influence of shade depth on the effectiveness of the fixatives were also studied by testing all the above properties of fabrics dyed with 2% and 4% (owg) of the direct dyes. Examples of wash fastness of fabrics dyed with 1, 2, and 4% of Direct Red 83 and Direct orange 26 and then finished with cationic polyamide and polyamine con- densate are illustrated in Figures 10 and 11. The ordinates in both figures were color changes before and after laundering. As shown, no matter what depth of shade a fabric had, polyamine condensate was better than cationic polyamide fixative for the Red 83 dyed fabric, while cationic polyamide was better for the fabric dyed with Orange 26. The crock fastness of fabrics dyed with higher shade depths (2% and 4%) were also similar to 1% shade depth. Crock fastness of fabric did not improve remarkably after fixation. As shown in Figure 12, the maximum improvemen of the wet crock fastness of Direct Red 83 dyed fabric was only 0.5 class no matter what fixative and what shade depth were tested. Figure 13 illustrates the effect c shade depth on light fastness of Direct Red 83 dyed fabrics finished with differ ent fixatives. It is very interesting that the degree of reduction of light fastness. due to the use of the fixatives actually deceased with increasing shade depth. With heavier shade, the decrease c light fastness due to the use of fixative were not large. The similar results from the study on the fabric dyed with Direct Orange 26 as presented in Figure 14 further confirmed such a statement. Because of the possible interactions between cellulosic fiber and the fixatives or other chemicals in the fixation bath, the strength of the fabric after fixation was tested to examine whether there was any fiber damages due to the fixation. As illustrated in Figures 15 and 16, there were no notable decrease in either tensile or tear strengths after fixation. The nitrogen containing nonformaldehyde fixation is the fiber safe process. Conclusions Formaldehyde containing fixing agents for direct dyeing could be substituted by nitrogen containing nonformaldehyde fixatives without sacrificing the performance properties of the finished goods. Choosing the suitable nonformaldehyde fixatives could actually produce better products than using the formaldehyde fixative. Using the nonformaldehyde fixatives at 0.5% (owg) level, wash fastness could be improved as much as 2.5 classes based on AATCC Grey Scale. Crock fastness had no marked improvement after using fixing agents. The best improvement 44 was about 0.5 class for the wet crock fastness. The nonformaldehyde fixatives studied decreased the fastness light of direct dyes. At 0.5% (owg) fixative level, the decrease was 0.5 to 1.0 class more than untreated control for 40 hours test for the fabric dyed with 1 % (owg) of dyes. However, the lightfastness decrease due to the application of nonformaldehyde fixatives were similar or less than that caused by the formaldehyde fixative. For the fabrics dyed with 2% and 4% (owg) of dyes, the maximum decrease of lightfastness caused by the addition of the nonformaldehyde fixatives was only 0.5 classes. The tensile and tear strengths of the fabric were not affected by fixation. It is possible that the polyamine condensate tested is better for the dyes with higher water solubility and cationic polyamide studied is better for those dyes with lower water solubility. Acknowledgments The authors would like to thank Neil Stewart, and Dennis Balmforth of the institute of Textile Technology, Nelson Houser and Tim Little of Ciba, and John Cooney of ICI Rayca for their he/p during this research. The donation of the fabric by Milliken & Company, the use of light fastness tester of Ciba are gratefully acknowledged. References (1) Bhattacharyya, N., Doshi. B.A. Sahasrabudhe, AS., & Mistry, P.R. (1990). Improved fastness of direct dyed cotton. American Dyestuff Reporter, 79, 3, 24-37. (2) SDC Reports (1987). Sulphur dyes are important. Society of Dyers and Colourists 103, 297-298. (3) Houser, N. E., & White, M. (1976) Direct dyes for high temperature application to polyester/cotton. AATCC Book of Papers. 105. 112. (4) Etters, J.N., (1989). How to evaluate direct-dye fixatives. American Dyestuff Reporter, 78, 9, 19-22, 91. (5) Varghese, J., Bhattacharyya, N., & Sahasrabudhe, A. S. (1989). Aftertreatments on cellulosic textiles dyed with direct dyes -- a review. Colourage. 6, 15-21. (6) Bhattacharyya, N., & Chouhan. S (1991). Interaction of direct dyes with cation fixing agents. Indian Journal of Fibre & Textile Research, 16, 2, 140-145. (7) Aspland. J.R. (1991). Chapter 2: Direct dyes and their application. Textile Chemists and Colorists, 23, 11, 41-45. (8) Billmeyer and Smith. (1967). Optimized equation for MacAdam color differences. Color Engineering. Nov/Dec, 28-31. (9) American Association of TextlIe Chemists and Colorists. (1985). AATCC Technical Manual. Research Triangle Park, NC American Association of Textile Chemists and Colorists. (10) American Society for Testing and Materials. (1989). Annual book of ASTM standards. D 13 on textile. section 7. Philadelphia, PA: American Society for Testing and Materials. American Dyestuff Reporter October 1996