EC2259 ...

advertisement

EC2259

EC 2259

Electrical Engineering And Control System Lab Manual

ELECTRICAL ENGINEERING AND CONTROL SYSTEM LAB

0 0 3 2

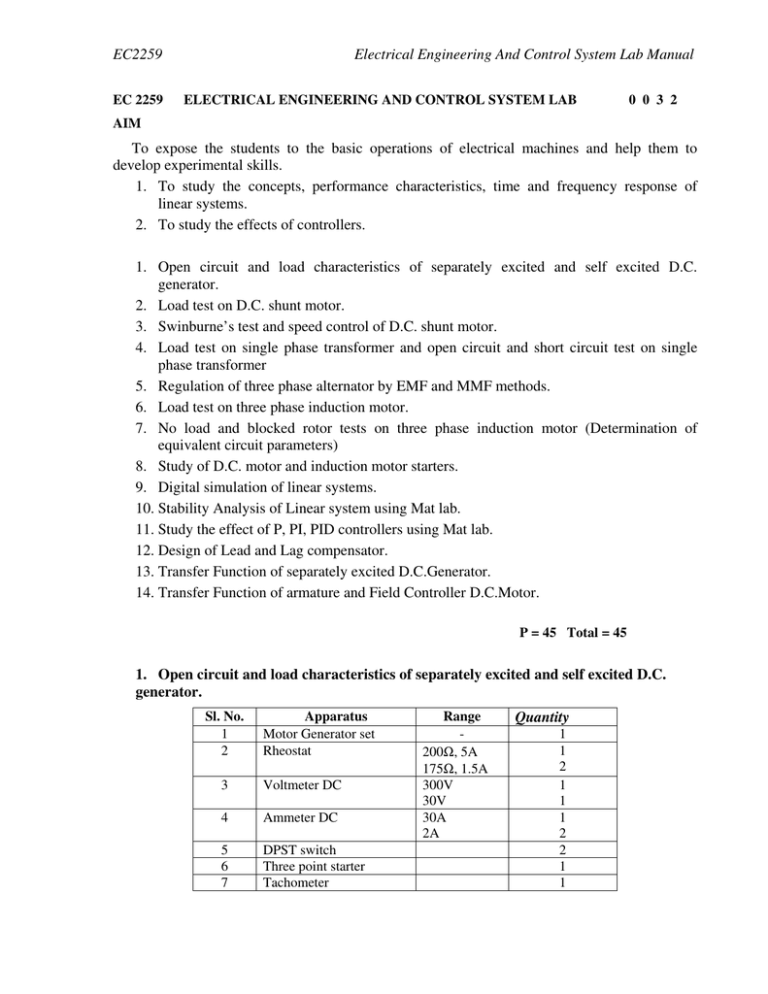

AIM

To expose the students to the basic operations of electrical machines and help them to

develop experimental skills.

1. To study the concepts, performance characteristics, time and frequency response of

linear systems.

2. To study the effects of controllers.

1. Open circuit and load characteristics of separately excited and self excited D.C.

generator.

2. Load test on D.C. shunt motor.

3. Swinburne’s test and speed control of D.C. shunt motor.

4. Load test on single phase transformer and open circuit and short circuit test on single

phase transformer

5. Regulation of three phase alternator by EMF and MMF methods.

6. Load test on three phase induction motor.

7. No load and blocked rotor tests on three phase induction motor (Determination of

equivalent circuit parameters)

8. Study of D.C. motor and induction motor starters.

9. Digital simulation of linear systems.

10. Stability Analysis of Linear system using Mat lab.

11. Study the effect of P, PI, PID controllers using Mat lab.

12. Design of Lead and Lag compensator.

13. Transfer Function of separately excited D.C.Generator.

14. Transfer Function of armature and Field Controller D.C.Motor.

P = 45 Total = 45

1. Open circuit and load characteristics of separately excited and self excited D.C.

generator.

Sl. No.

1

2

Apparatus

Motor Generator set

Rheostat

3

Voltmeter DC

4

Ammeter DC

5

6

7

DPST switch

Three point starter

Tachometer

Range

200Ω, 5A

175Ω, 1.5A

300V

30V

30A

2A

Quantity

1

1

2

1

1

1

2

2

1

1

EC2259

2.

Electrical Engineering And Control System Lab Manual

Load test on D.C. shunt motor.

Sl. No.

1

2

3

4

5

6

7

3.

Apparatus

Range

175Ω, 1.5A

300V

30A

DC Motor

Rheostat

Voltmeter DC

Ammeter DC

DPST switch

Three point starter

Tachometer

Quantity

1

1

1

1

1

1

1

Swinburne’s test and speed control of D.C. shunt motor

Sl. No.

1

2

Apparatus

DC Motor

Rheostat

Range

100Ω, 5A & 175Ω, 1.5A

3

4

Voltmeter DC

Ammeter DC

300V

5A

2A

5

6

DPST switch

Tachometer

Quantity

1

1

1

1

1

1

1

1

4. Load test on single-phase transformer and open circuit and short circuit test on

single-phase transformer.

Sl. No.

1

2

5.

Apparatus

Single phase Transformer

Wattmeter

Range

300V, 5A,UPF & 300V,

5A,LPF

300V

5A

30A

3

4

Voltmeter AC

Ammeter AC

5

6

Single phase auto-transformer

Resistive load

Regulation of three-phase alternator by EMF and MMF method.

Sl. No.

Apparatus

Range

1

Motor Alternator set

2

Rheostat

200Ω, 5A &175Ω, 1.5A

3

4

5

6

Voltmeter DC

Voltmeter AC

Ammeter DC

Ammeter AC

DPST switch

TPST switch

Tachometer

300V

600V

2A

30A

Quantity

1

1

1

2

1

1

1

1

Quantity

1

1

1

1

1

1

1

1

1

1

EC2259

6.

Electrical Engineering And Control System Lab Manual

Load test on three phase Induction motor.

Sl. No.

1

2

3

4

5

6

7

7.

Apparatus

Three Phase Induction Motor

Wattmeter

Voltmeter AC

Ammeter AC

Brake drum arrangement

Star delta starter

Tachometer

Range

600V, 10A,UPF

600V

10A

Quantity

1

2

1

1

1

1

No load and blocked rotor test on three-phase induction motor (Determination of

equivalent circuit parameters)

Sl. No.

1

2

Apparatus

Three Phase Induction Motor

Wattmeter

3

Voltmeter AC

4

Ammeter AC

5

6

Brake drum arrangement

Three phase auto-transformer

Range

600V, 10A,UPF

600V, 5A,LPF

600V

150V

10A

5A

Quantity

1

2

2

1

1

1

1

1

8. Study of D.C. motor and Induction motor starters.

Sl. No.

1

2

3

4

5

Apparatus

Three point starter

Four point starter

Star-delta starter

DOL starter

Three phase auto-transformer

Quantity

9. Digital simulation of linear systems.

Simulink software for minimum 3 users license

10. Stability analysis of linear system using Mat lab.

Matlab software for minimum 3 users license

11. Study of effect of P, PI, PID controllers using Mat lab.

Matlab software for minimum 3 users license

1

1

1

1

1

EC2259

Electrical Engineering And Control System Lab Manual

12. Design of lead and lag compensator.

Sl. No.

1

2

3

4

Apparatus

Resistor

Capacitor

Function generator

Bread Board

13. Transfer function of separately excited D.C. generator.

Sl. No.

1

2

Apparatus

Motor Generator set

Rheostat

3

Voltmeter DC

4

Ammeter DC

5

6

7

DPST switch

Three point starter

Tachometer

Range

200Ω, 5A

175Ω, 1.5A

300V

30V

30A

2A

Quantity

1

1

2

1

1

1

2

2

1

1

14. Transfer function of armature and field controller D.C. motor.

Sl. No.

1

2

3

4

5

6

7

Apparatus

DC Motor

Rheostat

Voltmeter DC

Ammeter DC

DPST switch

Three point starter

Tachometer

Range

175Ω, 1.5A

300V

30A

Quantity

1

1

1

1

1

1

1

EC2259

Electrical Engineering And Control System Lab Manual

!

"

#

"

#

%

$

&

'

*

'

(

(

)

)

+

,

, /

' -

.

0

,

)

(

)

2

%

%2

'

!

$

&

'

)

1 '

34

%

3)

%

)

%

%

'

(5 (-5 (-

'

'

3

)

)

)

% "

#

3

)

3

EC2259

Electrical Engineering And Control System Lab Manual

LOAD TEST ON DC SHUNT MOTOR

AIM

To conduct the load test on a given dc shunt motor and draw its performance curves.

NAME PLATE DETAILS

FUSE RATING

125% of rated current (full load current)

APPRATUS REQUIRED

NAME OF THE

APPARATUS

S. NO

TYPE

RANGE

QUANTITY

1

Ammeter

MC

(0-20A)

1

2

Voltmeter

MC

(0-300V)

1

3

Rheostat

Wire wound

250 , 2A

1

4

Tachometer

Digital

FORMULAE

1. Torque T = (S1~S2) × (R+t/2) × 9.81 in N-m.

Where R- Radius of the Break drum in m.

t- Thickness of the Belt in m.

S1,S2- Spring balance reading in Kg.

2. Input power = VL × IL in Watts.

Where VL – Load Voltage in Volts.

IL- Load current in Amps.

3. Output power = 2 NT/60 in Watts.

Where N- Speed of the armature in rpm.

T- Torque in N-m.

4. Percentage of Efficiency = (Output power/Input power) × 100

1

EC2259

Electrical Engineering And Control System Lab Manual

CIRCUIT DIAGRAM FOR LOAD TEST ON DC SHUNT MOTOR

(0-20A)

MC

3 POINT STARTER

L

F A

A

Fuse

250 , 2A

220V

DC SUPPLY

A

F

D

P

S

T

S

V

(0-300V)

MC

S1

S2

M

AA

FF

BRAKE DRUM

Fuse

Model Graph

(A) Electrical characteristics

N

(B) Mechanical characteristics

T

%

T in N-m

N in rpm

Speed in rpm

Torque Vs Speed

Torque in N-m

IL in Amps

(C) Torque, Speed Vs Load Current

Output power in watts

Torque in N-m

%

Speed in rpm

IL

Speed

Torque

Load Current in Amps

EC2259

Electrical Engineering And Control System Lab Manual

PRECAUTION

•

•

•

The motor field rheostat should be kept at minimum resistance position.

At the time of starting, the motor should be in no load condition.

The motor should be run in anticlockwise direction.

PROCEDURE

•

•

•

•

•

•

Connections are given as per the circuit diagram.

Using the three-point starter the motor is started to run at the rated speed by adjusting the

field rheostat if necessary.

The meter readings are noted at no load condition.

By using the Break drum with spring balance arrangement the motor is loaded and the

corresponding readings are noted up to the rated current.

After the observation of all the readings the load is released gradually.

The motor is switched off by using the DPIC switch.

GRAPH

The graphs are drawn as

• Output power Vs Efficiency

• Output power Vs Armature current

• Output power Vs Torque

• Output power Vs Speed

• Torque Vs Speed

• Torque Vs Armature current

• Speed Vs Armature current

EC2259

Electrical Engineering And Control System Lab Manual

Tabulation for load test on DC shunt motor

Radius of the brake dram =

S.No

Load

Current

(IL)

Load

Voltage

(VL)

Speed of

the motor

(N)

Thickness of the belt =

Spring balance reading

S1

Amps

Volts

Rpm

Kg

S2

Kg

Torque (T)

(S1~S2)(R+t/2)(9.81)

Output

power

2 NT/60

Input

power

(VLIL)

Efficiency (η

η)

O/p / I/p

x100

N-m

Watts

Watts

%

S1~S2

Kg

EC2259

Electrical Engineering And Control System Lab Manual

MODEL CALCULATION

RESULT

Thus the load test on DC shunt motor and its performance curves are drawn.

EC2259

Electrical Engineering And Control System Lab Manual

SPEED CONTROL OF DC SHUNT MOTOR

AIM

To conduct an experiment to control the speed of the given dc shunt motor by field and

armature control method also to draw its characteristic curves.

NAME PLATE DETAILS

FUSE RATING

10% of rated current (full load current)

APPRATUS REQUIRED

S.NO

NAME OF THE

APPARATUS

TYPE

RANGE

QUANTITY

1

Ammeter

MC

(0-2A)

1

2

Ammeter

MC

(0-10A)

1

3

Voltmeter

MC

(0-300V)

1

4

Rheostat

Wire wound

250 , 2A

1

5

Rheostat

Wire wound

50 , 5A

1

6

Tachometer

Digital

PRECAUTION

•

•

•

•

The motor field rheostat should be kept at minimum resistance position.

The motor armature rheostat should be kept at maximum resistance position.

The motor should be in no load condition throughout the experiment.

The motor should be run in anticlockwise direction.

1

EC2259

Electrical Engineering And Control System Lab Manual

CIRCUIT DIAGRAM FOR SPEED CONTROL OF DC SHUNT MOTOR

(0-10A)

MC

3 POINT STARTER

L

A

F A

50 , 5A

Fuse

A

D

P

S

T

S

220V

DC SUPPLY

250 , 2A

(0-2A)

MC

A

F

M

FF

V

(0-300V)

MC

AA

Fuse

Tabulation for Speed control of DC Shunt motor

Armature Control Method

Field Current:

S.No.

Prepared by

Field Control Method

Armature Current:

Armature

Voltage (Va)

Speed

(N)

Field Current

(If)

Speed

(N)

Volts

RPM

Amps

RPM

G.Panneerselvam, Vel Tech Multi Tech

EC2259

Electrical Engineering And Control System Lab Manual

Model Graph

(A) Armature Control Method:

(B) Field Control Method:

Field Current Vs Speed

Speed in rpm

Speed in rpm

Armature Voltage Vs Speed

Field Current in Amps

Armature Voltage in Volts

PROCEDURE

Field Control Method (Flux Control Method)

•

•

•

•

•

Connections are given as per the circuit diagram.

Using the three point starter the motor is started to run.

The armature rheostat is adjusted to run the motor at rated speed by means of

applying the rated voltage.

The field rheostat is varied gradually and the corresponding field current and speed

are noted up to 120% of the rated speed by keeping the Armature current as

constant.

The motor is switched off using the DPIC switch after bringing all the rheostats to

their initial position.

Armature Control Method (Voltage Control Method)

•

•

•

•

•

Connections are given as per the circuit diagram.

Using the three point starter the motor is started to run.

The armature rheostat is adjusted to run the motor at rated speed by means of

applying the rated voltage.

The armature rheostat is varied gradually and the corresponding armature voltage

armature current and speed are noted up to the rated voltage.

The motor is switched off using the DPIC switch after bringing all the rheostats to

their initial position

GRAPH

The graph are drawn as

•

•

Field current Vs Speed

Armature current Vs Speed

RESULT

Thus the speed control of the given DC shunt motor using field control and armature

control method and its characteristic curves are drawn.

Prepared by

G.Panneerselvam, Vel Tech Multi Tech

EC2259

Electrical Engineering And Control System Lab Manual

SWINBURNE’S TEST

AIM

To predetermine the efficiency of a given dc shunt machine when working as a motor as well

as generator by Swinburne’s test and also draw the characteristic curves.

NAME PLATE DETAILS

FUSE RATING

10% of rated current (full load current)

APPRATUS REQUIRED

S.NO

NAME OF THE

APPARATUS

TYPE

RANGE

QUANTITY

1

Ammeter

MC

(0-2A)

1

2

Ammeter

MC

(0-10A)

1

3

Voltmeter

MC

0-300V

1

4

Rheostat

Wire wound

250 ,2A

1

5

Tachometer

Digital

1

EC2259

Electrical Engineering And Control System Lab Manual

CIRCUIT DIAGRAM FOR SWINEBURN’S TEST

(0-10A)

MC

3 POINT STARTER

L

A

F A

Fuse

A

250 , 2A

220V

DC SUPPLY

D

P

S

T

S

V

(0-2A)

MC

A

F

(0-300V)

MC

M

AA

FF

Fuse

Tabulation to find out the Constant loss (Wco)

Terminal

Voltage (V)

No load

Current (I0)

Field Current

(If)

Volts

Amps

Amps

S.No.

No load

Armature

Current (Ia0)

Amps

Constant Loss

2

WCO = VI0-Ia0 Ra

Watts

Resultant tabulation to find out the Efficiency (Running as motor)

Armature Resistance (Ra)=

Constant loss

(WC)=

Load

Fraction Current IL=

S.No.

of

X×Ir

Load

(X)

Amps

1

1/4

2

1/2

3

3/4

4

1

Armature

Current

Ia= IL- If

Armature

Cu Loss

WCu=Ia2Ra

Total

Loss

WTotal

Amps

Watts

Watts

Rated Current (Ir)=

Field Current (If) =

Input

Output Power

Power

Wo =Wi- WTotal

Wi=VLIL

Watts

Watts

Efficiency

= Wo/ Wi

%

EC2259

Electrical Engineering And Control System Lab Manual

FORMULAE

1. Armature resistance (Ra)

= 1.6 × RDC in Ohms.

Where,

RDC – Resistance of the Armature coil, when it is energized by DC supply.

2. Constant loss (WCO )

= (V Io-Iao2Ra) in Watts..

Where V = Terminal Voltage in Volts

Io = No Load Current in Amps

Iao = No Load Armature Current. in Amps

3. Armature Current (Ia)

= (IL ± If ) in Amps.

Where, + is used for Generator,

- is used for Motor.

4. Copper loss (WCU )

= Ia2Ra in Watts.

5. Total loss

= Constant loss + Copper loss in Watts

6. Input power for motor / Output power for generator = V IL in Watts

Where, IL is Load current in Amps

7. Output power for motor

= Input power + losses

Input power for Generator = Output power - losses

8. Percentage of Efficiency = (Output power/Input power) × 100

PRECAUTION

•

•

•

The motor field rheostat should be kept at minimum resistance position.

The motor should be at no load condition through out the experiment.

The motor should be run in anticlockwise direction.

PROCEDURE

•

•

•

•

•

•

Connections are given as per the circuit diagram.

By using the three point starter the motor is started to run at the rated speed.

The meter readings are noted at no load condition.

The motor is switched off using the DPIC switch.

After that the Armature resistive test is conducted as per the circuit diagram and the voltage

and current are noted for various resistive loads.

After the observation of readings the load is released gradually.

EC2259

Electrical Engineering And Control System Lab Manual

Running as generator

Armature Resistance (Ra)=

Constant loss

(WC)=

Fraction

S.No.

of

Load

(X)

1

1/4

2

1/2

3

3/4

4

1

Rated Current (Ir)=

Field Current (If)=

Load

Current

IL= X×Ir

Armature

Current

Ia= IL+ If

Armature

Cu Loss

WCu=Ia2Ra

Total

Loss

WTotal

Output

Power

Wo=VLIL

Amps

Amps

Watts

Watts

Watts

Input Power

Wi

=Wo+WTotal

Efficiency

= Wo/

Wi

Watts

%

EC2259

Electrical Engineering And Control System Lab Manual

Model Graph

Generator

Efficiency

Motor

Output Power (Wo) in Watts

GRAPH

The graph drawn between Load current Vs Efficiency

RESULT

Thus the efficiency of the given DC shunt machine by Swinburne’s test when working as a

motor as well as generator and also draw the characteristic curves are drawn.

EC2259

Electrical Engineering And Control System Lab Manual

OPEN CIRCUIT TEST AND LOAD TEST ON SELF EXCITED DC

SHUNT GENERATOR

AIM

To conduct the open circuit test and the load test on a given self excited dc shunt generator and

draw the characteristic curves.

NAME PLATE DETAILS

FUSE RATING

125% of rated current (full load current)

APPRATUS REQUIRED

S.NO

NAME OF THE

APPARATUS

TYPE

RANGE

QUANTITY

1

Ammeter

MC

(0-2A)

1

2

Ammeter

MC

(0-20A)

2

3

Voltmeter

MC

(0-300V)

1

4

Rheostat

Wire wound

250 , 2A

1

5

Rheostat

Wire wound

350 , 1.5A

1

6

Tachometer

Digital

-

1

7

Resistive Load

Variable

-

1

PRECAUTION

•

•

•

The motor field rheostat should be kept at minimum resistance position.

The generator field rheostat should be kept at maximum resistance position.

At the time of starting, the generator should be in no load condition.

EC2259

Electrical Engineering And Control System Lab Manual

CIRCUIT DIAGRAM FOR OPEN CIRCUIT AND LOAD TEST ON SELF EXCITED

DC SHUNT GENERATOR

3 POINT STARTER

F A

A

Fuse

220V

DC SUPPLY

250 , 2A

D

P

S

T

S

F

17

Fuse

A

(0-20A)

MC

F

M

FF

Prepared by

A

(0-2A)

MC

AA

G

AA

A

A

1050 , 1.5A

L

(0-300V)

MC

Fuse

V

(0-20A)

MC

D

P

S

T

S

L

O

A

D

FF

Fuse

G.Panneerselvam, Vel Tech Multi Tech

EC2259

Electrical Engineering And Control System Lab Manual

PROCEDURE

Open circuit test

•

•

•

•

Connections are given as per the circuit diagram.

The Prime Mover is started with the help of the three point starter and it is made to

run at rated speed when the Generator is disconnected from the load by DPST

switch.

By varying the Generator field rheostat gradually, the Open Circuit Voltage (Eo)

and corresponding Field Current (If) are tabulated upto 150 % of Rated Voltage of

Generator.

The motor is switched off by using the DPIC switch after bringing all the rheostats

to their initial position.

Load test

•

•

•

•

•

•

•

Connections are given as per the circuit diagram.

The Prime Mover is started with the help of the three point starter and it is made to

run at rated speed when the Generator is disconnected from the load by DPST

switch.

By varying the Generator field rheostat gradually, the Rated Voltage (Eg) is

obtained.

The Ammeter and Voltmeter readings are observed at no load condition.

The Ammeter and Voltmeter readings are observed for different loads up to the

rated current by closing the DPST switch.

After tabulating all the readings the load is brought to its initial position gradually.

The Prime Mover is switched off using the DPIC switch after bringing all the

rheostats to their initial position.

GRAPH

The graph are drawn as

• Open Circuit Voltage Vs Field Current

• Load Voltage Vs Load Current

Prepared by

G.Panneerselvam, Vel Tech Multi Tech

EC2259

Electrical Engineering And Control System Lab Manual

Tabulation for OC and Load test on self excited DC Shunt Generator

Generator Armature Resistance (Ra):

S.No.

OC Test

Field

Open circuit

Voltage

Current

(E0)

(If)

Volts

Amps

Load

Voltage

(VL)

Load

Current

(IL)

Volts

Amps

Load Test

Armature Armature

Current

Drop

(Ia)

Ia Ra

Amps

Volts

Generated emf

Eg=VL+ Ia Ra

Volts

Model Graph

Field Current (If) in

Amps

(EgVs Ia)

Armature Current (Ia)

in Amps

Load Voltage (VL) in Volts

(E0) Vs (If)

(B) Internal (EgVs Ia) and External (VLVs IL) Characteristics

Generated EMF (Eg) in Volts

Open Circuit Voltage (E0)

in Volts

(A) Open Circuit Characteristics

(VLVs IL)

Load Current (IL) in Amps

RESULT

Thus the open circuit test and load test on a given self excited DC generator and the

characteristic curves are drawn.

Prepared by

G.Panneerselvam, Vel Tech Multi Tech

EC2259

Electrical Engineering And Control System Lab Manual

OPEN CIRCUIT TEST AND LOAD TEST ON SEPARATELY EXCITED

DC GENERATOR

AIM

To conduct the open circuit test and the load test on a given separately excited dc generator and

draw the characteristic curves.

NAME PLATE DETAILS

FUSE RATING

125% of rated current (full load current)

APPRATUS REQUIRED

S.NO

NAME OF THE

APPARATUS

TYPE

RANGE

QUANTITY

1

Ammeter

MC

(0-2A)

1

2

Ammeter

MC

(0-20A)

2

3

Voltmeter

MC

(0-300V)

1

4

Rheostat

Wire wound

250 , 2A

1

5

Rheostat

Wire wound

350 , 1.5A

1

6

Tachometer

Digital

-

1

7

Resistive Load

Variable

-

1

PRECAUTION

•

•

•

The motor field rheostat should be kept at minimum resistance position.

The generator field rheostat should be kept at maximum resistance position.

At the time of starting, the generator should be in no load condition.

Prepared by

G.Panneerselvam, Vel Tech Multi Tech

EC2259

Electrical Engineering And Control System Lab Manual

CIRCUIT DIAGRAM FOR OPEN CIRCUIT AND LOAD TEST ON SEPERATELY EXCITED

DC GENERATOR

(0-20A)

MC

3 POINT STARTER

L

F A

220V

DC SUPPLY

250 , 2A

D

P

S

T

S

A

A

Fuse

F

A

A

FF

M

AA

(0-300V)

MC

G

V

F

FF

Fuse

AA

(0-20A)

MC

D

P

S

T

S

L

O

A

D

(0-2A)

A

MC

23

Fuse

220V

DC SUPPLY

D

P

S

T

S

Fuse

Fuse

350 , 1.5A

Fuse

Prepared by

G.Panneerselvam, Vel Tech Multi Tech

EC2259

Electrical Engineering And Control System Lab Manual

PROCEDURE

Open circuit test

•

•

•

•

Connections are given as per the circuit diagram.

The Prime Mover is started with the help of the three point starter and it is made to run at rated

speed when the Generator is disconnected from the load by DPST switch.

By varying the Generator field rheostat gradually, the Open Circuit Voltage (Eo) and

corresponding Field Current (If) are tabulated upto 150 % of Rated Voltage of Generator.

The motor is switched off by using the DPIC switch after bringing all the rheostats to initial

position.

Load test

•

•

•

•

•

•

•

Connections are given as per the circuit diagram.

The Prime Mover is started with the help of the three point starter and it is made to run at rated

speed when the Generator is disconnected from the load by DPST switch..

By varying the Generator field rheostat gradually, the Rated Voltage (Eg) is obtained.

The Ammeter and Voltmeter readings are observed at no load condition.

The Ammeter and Voltmeter readings are observed for different loads up to the rated current by

closing the DPST switch..

After tabulating all the readings the load is brought to initial position.

The motor is switched off using the DPIC switch after bringing all the rheostats to initial position.

GRAPH

The graph drawn as

• Open Circuit Voltage Vs Field Current

• Load Voltage Vs Load Current

Prepared by

G.Panneerselvam, Vel Tech Multi Tech

EC2259

Electrical Engineering And Control System Lab Manual

Tabulation for OC and Load test on separately excited DC Generator

Generator Armature Resistance (Ra):

S.No.

OC Test

Open circuit

Field

Voltage

Current

(E0)

(If)

Volts

Amps

Load

Voltage

(VL)

Load

Current

(IL)

Volts

Amps

Load Test

Armature Armature

Current

Drop

(Ia)

Ia Ra

Amps

Volts

Generated emf

Eg=VL+ Ia Ra

Volts

Model Graph

Field Current (If) in

Amps

(EgVs Ia)

Armature Current (Ia)

in Amps

Load Voltage (VL) in Volts

(E0) Vs (If)

(B) Internal (EgVs Ia) and External (VLVs IL) Characteristics

Generated EMF (Eg) in Volts

Open Circuit Voltage (E0)

in Volts

(A) Open Circuit Characteristics

(VLVs IL)

Load Current (IL) in Amps

RESULT

Thus the open circuit test and load test on a given separately excited DC generator and the

characteristic curves are drawn.

Prepared by

G.Panneerselvam, Vel Tech Multi Tech

EC2259

Electrical Engineering And Control System Lab Manual

LOAD TEST ON SINGLE PHASE TRANSFORMER

AIM

To conduct the load test on a given single phase transformer and draw its performance curves.

NAME PLATE DETAILS

FUSE RATING

Primary Current = KVA Rating of the Transformer / Primary Voltage.

Secondary Current = KVA Rating of the Transformer / Secondary Voltage.

125% of Primary current (fuse rating for primary side)

125% of Secondary current (fuse rating for secondary side)

APPRATUS REQUIRED

S.NO

NAME OF THE

APPARATUS

TYPE

RANGE

QUANTITY

1

Ammeter

MI

(0-5A)

1

2

Ammeter

MI

(0-20A)

1

3

Voltmeter

MI

(0-150V)

1

4

Voltmeter

MI

(0-300V)

1

5

6

Watt meter

UPF

300V, 5A

1

Auto Transformer

1φ

230/(0-270V

1

Prepared by

G.Panneerselvam, Vel Tech Multi Tech

EC2259

Electrical Engineering And Control System Lab Manual

CIRCUIT DIAGRAM FOR LOAD TEST ON SINGLE PHASE TRANSFORMER

(0-5A)

MI

A

P

A

SPSTS

(0-10A)

MI

300V, 5A UPF

M

L

A

Fuse

Fuse

C

B

1Ø, 230V, 50Hz

AC SUPPLY

V

150V

P1

S1

(0-150V)

MI

(0-300V)

MI

V

33

P2

D

P

S

T

S

L

O

A

D

S2

C

NL

N

230/(0-270V)

1Ø AUTO

TRANSFORMER

Fuse

1Ø 230/110V, 1KVA

STEP DOWN

TRANSFORMER

EC2259

Electrical Engineering And Control System Lab Manual

FORMULAE

1. Input Power =Wattmeter reading × Multiplication factor in Watts

Where,

(Rating of pressure coil × Rating of current coil × pf )

Multiplication factor =

Full Scale Reading

2.Output power = VSY × ISY × cosφ in Watts.

Where VSY - Secondary Voltage in Volts.

ISY- Secondary current in Amps.

3.Percentage of Efficiency =

× 100 %

Output Power

Input Power

4.Percentage of Regulation =

× 100 %

VO – VL

VO

Where, VO – No Load Voltage in Volts

VL – Load Voltage in Volts

PRECAUTION

•

•

No Load Condition should be observed at the time of starting

Meters are checked for proper Type and rating.

PROCEDURE

•

•

•

•

•

•

•

•

•

Connections are given as per the circuit diagram.

The SPST Switch on the Primary side is closed and the DPST Switch on the Secondary side is

opened.

The Autotransformer is adjusted to Energize the transformer with rated Primary Voltage

The Volt meters and Ammeters Readings are noted and tabulated at No load condition

The DPST switch on the secondary side is closed.

The transformer is loaded upto 130% of the Rated Load, corresponding Ammeters, Voltmeters

and Wattmeters readings are noted and tabulated.

After the observation of all the readings the load is released gradually to its initial position.

The Autotransformer is brought to its initial position

The Supply is switched off.

GRAPH

The graph drawn as

• Output power Vs Efficiency

• Output power Vs Regulation

Prepared by

G.Panneerselvam, Vel Tech Multi Tech

EC2259

Electrical Engineering And Control System Lab Manual

Tabulation for Load test on single phase transformer

Multiplication Factor =

S.No

Primary

Voltage

(VPy)

Volts

Prepared by

Primary

Current

(IPy)

Amps

Secondary

Voltage

(VSy)

Volts

Secondary

Current

(ISy)

Amps

Wattmeter

readings

(W)

Obs. Act.

Watts

Input

power

(W)

Output power

VSy ISy cosφ

φ

Efficiency

(η

η)

O/p / I/p

×100

Watts

Watts

%

% Of

Regulation

VNL-VLOAD

VLOAD

G.Panneerselvam, Vel Tech Multi Tech

EC2259

Electrical Engineering And Control System Lab Manual

Model Graph

% Of Effeciency

% Of Regulation

Regulation

Effeciency

Output power in watts

RESULT

Thus the load test on a given single phase transformer is done and the characteristic curves are

drawn.

Prepared by

G.Panneerselvam, Vel Tech Multi Tech

EC2259

Electrical Engineering And Control System Lab Manual

OPEN CIRCUIT TEST AND SHORT CIRCUIT TEST

ON SINGLE PHASE TRANSFORMER

AIM

To Predetermine the Efficiency and Regulation on a given single phase transformer by

conducting the Open Circuit test and Short Circuit test and also draw its Equivalent circuit.

NAME PLATE DETAILS

FUSE RATING

Primary Current = KVA Rating of the Transformer / Primary Voltage.

Secondary Current = KVA Rating of the Transformer / Secondary Voltage.

10% of Primary current (fuse rating for Open Circuit test)

125% of Secondary current (fuse rating for Short circuit test)

APPARATUS REQUIRED

S.No

Name of the apparatus

Type

Range

Quantity

1

Ammeter

MI

(0-1A)

1

2

Ammeter

MI

(0-10A)

1

3

Voltmeter

MI

(0-150V)

1

4

Voltmeter

MI

(0-300V)

1

5

6

Watt meter

UPF

300V, 1A

1

Watt meter

UPF

75V, 5A

1

7

Auto Transformer

1φ

230/(0-270V)

1

Prepared by

G.Panneerselvam, Vel Tech Multi Tech

EC2259

Electrical Engineering And Control System Lab Manual

CIRCUIT DIAGRAM FOR OPEN CIRCUIT TEST ON SINGLE PHASE TRANSFORMER

(0-5A)

MI

A

P

A

SPSTS

150V, 5A LPF

M

L

Fuse

C

B

150V

P1

1Ø, 230V, 50Hz

AC SUPPLY

V

S1

(0-150V)

MI

V

(0-300V)

MI

P2

39

C

S2

NL

N

230/(0-270V)

1Ø AUTO

TRANSFORMER

Prepared by

1Ø 110/230V, 1KVA

STEP UP

TRANSFORMER

G.Panneerselvam, Vel Tech Multi Tech

EC2259

Electrical Engineering And Control System Lab Manual

CIRCUIT DIAGRAM FOR SHORT CIRCUIT TEST ON SINGLE PHASE TRANSFORMER

(0-5A)

300V, 10A UPF

MI

L

A M

A

P

SPSTS

A

Fuse

C

B

(0-10A)

MI

75V

P1

S1

1Ø, 230V, 50Hz

AC SUPPLY

V

(0-75V)

MI

SC

41

P2

S2

C

NL

N

230/(0-270V)

1Ø AUTO

TRANSFORMER

Prepared by

1Ø 230/110V, 1KVA

STEP DOWN

TRANSFORMER

G.Panneerselvam, Vel Tech Multi Tech

EC2259

Electrical Engineering And Control System Lab Manual

Tabulation for OC and SC test on Single phase transformer

Open Circuit test

S.No.

Multiplication Factor =

Open Circuit

Primary

Current (IOC)

Amps

Open circuit

Primary

Voltage (VOC)

Volts

Open Circuit power (WOC)

Obs.

Act.

Watts

Watts

Open Circuit

secondary

Voltage (V2O)

Volts

Sh

ort

Circuit test

Multiplication Factor =

S.No.

Short Circuit

Primary

Current (ISC)

Amps

Short circuit

Primary

Voltage (VSC)

Volts

Short Circuit power (WSC)

Obs.

Act.

Watts

Watts

Short Circuit

secondary

Current (I2S)

Volts

Resultant Tabulation to find out the Efficiency

Core (Or) Iron Loss

=

Rated Short Circuit Current (ISC) =

Fraction of

Load (X)

Short

circuit

Current

(ISC×X)

Amps

A Rating of Transformer =

Short Circuit Power (WSC) =

Output power

0.2

0.4

0.6

Watts

0.8

1

Copper

Loss

(X2 WSC)

Total Loss

WT =

Wi+WSC

Efficiency

O/p

η= O/p+TL

Watts

Watts

%

1/4

1/2

3/4

1

Prepared by

G.Panneerselvam, Vel Tech Multi Tech

EC2259

Electrical Engineering And Control System Lab Manual

FORMULAE

EQUIVALENT CIRCUIT

Open Circuit Test

Woc

1. No Load Power Factor (Cosφ

φo) = Voc × Ioc

Where, Woc – Open Circuit Power in Watts

Voc – Open Circuit Voltage in Volts

Ioc – Open Circuit Current in Amps

Voc

Ioc × Cosφo

2.No Load Working Component Resistance (Ro) =

in Ohms

Where Voc – Open Circuit Voltage in Volts.

Ioc – Open Circuit current in Amps.

Voc

3. No Load Magnetizing Component Reactance( Xo) = Ioc × Sinφ

in Ohms

o

Where Voc – Open Circuit Voltage in Volts.

Ioc – Open Circuit current in Amps.

Short Circuit Test

Vsc

Isc

4. Equivalent impedance referred to HV side ( Z02 ) =

in Ohms

Where, Vsc – Short circuit Voltage in Volts

Isc – Short circuit current in Amps

5. Equivalent resistance referred to HV side (R02 ) = Wsc2

in Ohms

Isc

Where, Wsc – Short circuit Power in Watts

6. Equivalent reactance referred to HV side (X02) =

Z022 - R022 in Ohms

V

7. Transformation ratio (K) = V2

1

Where, V1 – Primary voltage in Volts

V2 – Secondary Voltage in Volts

R02

K2

8. Equivalent resistance referred to LV side (R01) =

9. Equivalent reactance referred to LV side (X01) =

in Ohms

X02

K2

in Ohms

Efficiency and Regulation

10. Output Power = X ×KVA × cosφ in Watts.

Where, X-Fraction of load

KVA - power rating of Transformer and Cosφ - Power factor

Prepared by

G.Panneerselvam, Vel Tech Multi Tech

EC2259

Electrical Engineering And Control System Lab Manual

11. Copper loss = X2 × Wsc in Watts

Where, Wsc- Copper Loss in Short Circuit condition

12. Total Loss = (Cu Loss + Iron Loss) in Watts

13. Efficiency =

Output power

(Output power +Total Losses)

14. Regulation =

x 100

X × Isc [R02 x cosφ ± X02 x sinφ]

V2o

in %

× 100 in %

Where, V2o – Open Circuit Voltage on HV side.

PRECAUTION

•

•

No Load Condition should be observed at the time of starting

Meters are checked for proper Type and rating.

PROCEDURE

OPEN CIRCUIT TEST

•

•

•

•

•

•

Connections are given as per the circuit diagram.

The SPST Switch on the Primary side is closed.

The Autotransformer is adjusted to Energize the transformer with rated Primary Voltage

on the LV side

The Volt meter, Watt meter and Ammeter Readings are noted at No load condition

The Autotransformer is brought to its initial position

The Supply is switched off.

SHORT CIRCUIT TEST

•

•

•

•

•

•

Connections are given as per the circuit diagram.

The SPST Switch on the Primary side is closed

The Autotransformer is adjusted to energize the transformer with rated Primary Current on

the HV side.

The Voltmeter, Wattmeter and Ammeter Readings are noted down at short circuit

condition.

The Autotransformer is brought to its initial position

The Supply is switched off.

GRAPH

The graph are drawn as

• Output power Vs Efficiency

• Output power Vs Regulation

Prepared by

G.Panneerselvam, Vel Tech Multi Tech

EC2259

Electrical Engineering And Control System Lab Manual

Resultant Tabulation to find out the Regulation

ISC =

Fraction

of Load

(X)

1

Prepared by

Value of Cosø

0.8

0.6

0.4

RO2 =

0.2

1

Value of Sinø

0.8

0.6

0.4

XO2 =

0.2

1

V2(OC) =

% Of Regulation

0.8

0.6

0.4

0.2

Lag. Lead. Lag. Lead. Lag. Lead. Lag. Lead.

G.Panneerselvam, Vel Tech Multi Tech

EC2259

Electrical Engineering And Control System Lab Manual

Equivalent circuit for Single phase Transformer

P

R01

I1

X01

I0

Iw

V1

I

R0

ZL

X0

N

Model Graph

1.0 pf

Regulation

X=1

0.8 pf

X =3/4

X =1/2

Effeciency

0.6 pf

X =1/4

0.4 pf

0.2 pf

Leading pf

Unity pf

Lagging pf

Short Circuit Current (ISC) in Amps

RESULT

Thus the efficiency and regulation of a given single phase transformer by conducing the open

circuit test and short circuit test is determined and the equivalent circuit is drawn.

Prepared by

G.Panneerselvam, Vel Tech Multi Tech

EC2259

Electrical Engineering And Control System Lab Manual

LOAD TEST ON THREE PHASE SQUIRREL CAGE

INDUCTION MOTOR

AIM

To conduct a load test on a three phase squirrel cage induction motor and to draw the

performance characteristic curves.

NAME PLATE DETAILS

!

"

"# $% "&'"

FUSE RATING

125% of rated current (Full load current)

APPARATUS REQUIRED

S.NO

NAME OF THE

APPARATUS

1.

2.

3.

4.

Ammeter

Voltmeter

Wattmeter

Tachometer

TYPE

RANGE

QUANTITY

MI

MI

UPF

(0-10 A)

(0-600 V)

(500V, 10A)

1

1

1

-

-

1

FORMULAE USED

1.Torque = (S1-S2) (R+t/2) x 9.81 N-m

Where, S1, S2 – spring balance readings in Kg.

R - Radius of brake drum in m.

t - Thickness of belt in m.

2. Output Power = 2 πNT/60 watts.

N- Rotor speed in rpm.

T- Torque in N-m.

3. Input Power = (W1+W2) Watts.

W1, W2 – Wattmeter readings in Watts.

Prepared by

G.Panneerselvam, Vel Tech Multi Tech

EC2259

Electrical Engineering And Control System Lab Manual

CIRCUIT DIAGRAM FOR LOAD TEST ON THREE PHASE SQUIRRAL CAGE INDUCTION MOTOR

STAR-DELTA

STARTER

600V, 10A UPF

M

R

L

L1

Fuse

V

415V, 50Hz, 3Ø

AC SUPPLY

Y

T

P

S

T

S

A1

600V

C

C2

S1

(0-600) V

MI

R

A2

A2

A

Fuse

S2

A1

L2

B1

(0-10) A

MI

C1

BRAKE DRUM

B1

B2

STATOR

51

B2

C

600V

C1

B

Fuse

M

L

600V, 10A UPF

L3

C2

NL

N

Prepared by

N

G.Panneerselvam, Vel Tech Multi Tech

EC2259

Electrical Engineering And Control System Lab Manual

4. Percentage of Efficiency = (Output Power/ Input Power) x 100%.

5. Percentage of Slip = (NS-Nr)/Ns x 100%

Ns-Synchronous speed in rpm.

Nr-Rotor speed in rpm.

6.Power factor = (W1+W2)/√3 VLIL.

PRECAUTION

The motor should be started without any load

PROCEDURE:

•

•

•

•

Connections are given as per the circuit diagram.

The TPSTS is closed and the motor is started using On Line starter to run at rated speed.

At no load the speed, current, voltage and power are noted down.

By applying the load for various values of current the above-mentioned readings are noted.

• The load is later released and the motor is switched off and the graph is drawn. .

GRAPH

The graph are drawn as

•

•

•

•

•

•

Output Power Vs Speed

Output Power Vs Line current

Output Power Vs Torque

Output Power Vs Power factor

Output Power Vs % Efficiency

Output Power Vs % Slip.

Prepared by

G.Panneerselvam, Vel Tech Multi Tech

EC2259

Electrical Engineering And Control System Lab Manual

Tabulation for load test on three phase squirrel cage induction motor

Multiplication Factor:

S.No

Load

Curren

t

(IL)

Amps

Prepared by

Load

Voltage

(VL)

W1

Obs.

Volts

Input

power

Wattmeter readings

W2

Act.

Obs.

Watts

Act.

Speed

of the

motor

(N)

W1+W2

Watts

rpm

Spring balance

reading

S1

S2

S1~S2

Kg

Kg

Kg

(S1~S2) (R+t/2)

(9.81)

Torque (T)

Output

power

2 NT/60

Efficiency

(η

η)

O/p / I/p

X100

N-m

Watts

%

G.Panneerselvam, Vel Tech Multi Tech

Power

Factor

(cosφ

φ)

I/p /

√3 VLIL

EC2259

Electrical Engineering And Control System Lab Manual

Load test on Three phase squirrel cage induction motor

Model Graphs:

(A) Mechanical characteristics

Torque Vs Speed

Speed in RPM

Torque in N-m

(B) Electrical characteristics:

Cos φ

N

IL

T

%

%

T in N-m

N in rpm

Cos φ

IL in Amps

O/P power in watts

RESULT

Thus the load test on a given three phase squirrel cage induction motor is done and the

characteristic curves are drawn.

Prepared by

G.Panneerselvam, Vel Tech Multi Tech

EC2259

Electrical Engineering And Control System Lab Manual

EQUIVALENT CIRCUIT OF THREE PHASE SQUIRREL CAGE

INDUCTION MOTOR

AIM

To conduct a No Load test and Blocked Rotor test on three phase squirrel cage induction motor

and to draw the equivalent circuit.

NAME PLATE DETAILS

!

"

"# $% "&'"

FUSE RATING

No Load: 10 % of rated current (Full load current)

Load: 125 % of rated current (Full load current)

APPARATUS REQUIRED

S.NO.

NAME OF THE

APPARATUS

Ammeter

Ammeter

Voltmeter

Voltmeter

Voltmeter

Wattmeter

Wattmeter

Tachometer

1.

2.

3.

4.

5.

6.

7.

TYPE

RANGE

QUANTITY

MC

MI

MI

MI

MC

LPF

UPF

-

(0-10 A)

(0-10 A)

(0-150 V)

(0-600 V)

(0-50 V)

(600V, 10A) (150V,

10A)

-

1

2

1

1

1

2

2

1

FORMULAE USED

OC Test

1. No load power factor (Cos φ0) = P0/V0I0

V0 - No load voltage per phase in volts.

I0 - No load current per phase in amps.

P0 - No load power per phase in watts.

2. Working component current (Iw) = I0 (ph) X Cos φ0

3. Magnetizing current (Im) = I0 (ph) X Sin φ0

4. No load resistance (R0) =V0/I0 (ph) Cos φ0 in Ω.

Prepared by

G.Panneerselvam, Vel Tech Multi Tech

EC2259

Electrical Engineering And Control System Lab Manual

CIRCUIT DIAGRAM FOR NO LOAD TEST ON THREE PHASE SQUIRREL CAGE

INDUCTION MOTOR

(Equivalent circuit)

415 / (0-470) V

3Ø AUTO TRANSFORMER

600V, 10A LPF

A1

B1

R

M

L

A1

Fuse

600V

C

C1

415V, 50Hz, 3Ø

AC SUPPLY

Y

57

T

P

S

T

S

V

C2

(0-600) V

MI

R

A2

A2

B2

A

Fuse

C1

B1

(0-10) A

MI

B2

STATOR

C2

A3

C

600V

B3

B

M

L

600V, 10A LPF

Fuse

C3

N

Prepared by

NL

G.Panneerselvam, Vel Tech Multi Tech

EC2259

Electrical Engineering And Control System Lab Manual

CIRCUIT DIAGRAM FOR BLOCKED ROTOR TEST ON THREE PHASE SQUIRREL CAGE

INDUCTION MOTOR

(Equivalent circuit)

415 / (0-470) V

3Ø AUTO TRANSFORMER

150V, 10A UPF

A1

B1

R

M

L

A1

Fuse

415V, 50Hz, 3Ø

AC SUPPLY

Y

59

T

P

S

T

S

V

S1

150V

C

C1

C2

(0-150) V

MI

R

A2

A2

B2

A

Fuse

S2

C1

B1

BRAKE DRUM

B2

(0-10) A

MI

C2

STATOR

A3

C

150V

B3

B

M

L

150V, 10A UPF

Fuse

C3

N

Prepared by

NL

G.Panneerselvam, Vel Tech Multi Tech

EC2259

Electrical Engineering And Control System Lab Manual

Tabulation for No Load test on three phase Squirrel cage Induction motor

Speed of the Induction motor:

Type of the Stator connection:

Multiplication Factor:

S.No

No Load

Current

(I0)

No Load

Voltage

(V0)

Amps

Volts

No Load Power

Total No Load Power

No Load Power/Phase

P0=(W1+W2)

P0 (Ph)=(P0/3)

Watts

Watts

W1

No Load

Current/Phase

I0 (Ph)

No Load

Voltage/Phase

V0 (Ph)

Amps

Volts

W2

Observed

Watts

Actual

Watts

Observed

Watts

Actual

Watts

Tabulation for Blocked rotor test on three phase Squirrel cage Induction motor

Type of the Stator connection:

Multiplication Factor:

S.No

Short

Circuit

Current

(ISC)

Amps

Prepared by

Short

Circuit

Voltage

(VSC)

Volts

Short Circuit Power

W1

Observed

Watts

W2

Actual

Watts

Observed

Watts

Actual

Watts

Total Short

Circuit Power

PSC=(W1+W

2)

Short Circuit

Power/Phase

PSC

(Ph)=(P0/3)

Short Circuit

Current/Phase

ISC (Ph)

Short Circuit

Voltage/Phase

VSC (Ph)

Watts

Watts

Amps

Volts

G.Panneerselvam, Vel Tech Multi Tech

EC2259

Electrical Engineering And Control System Lab Manual

5. No load reactance (X0) = V0/I0 (ph) Sin φ0 in Ω.

SC Test

6. Motor equivalent Impedance referred to stator (Zsc(ph)) = Vsc(ph) / Isc(ph) in Ω.

7. Motor equivalent Resistance referred to stator (Rsc(ph)) = Psc(ph) / I2sc(ph) in Ω.

8. Motor equivalent Reactance referred to stator (Xsc(ph)) = √(Z sc(ph)2- R sc(ph)2) in Ω.

9. Rotor Resistance referred to stator (R2’(ph)) = Rsc(ph) – R1 in Ω.

10. Rotor Reactance referred to stator (X2’(ph)) = Xsc(ph) / 2 = X1 in Ω.

Where R1 - stator resistance per phase

X1 – stator reactance per chapter

R1 = R(ac) =1.6 x R(dc)

11. Equivalent load resistance (RL’) = R2’ (1/s – 1) in Ω.

Where Slip (S) = (Ns-Nr) / Ns

Ns – Synchronous speed in rpm.

Nr – Rotor speed in rpm.

PRECAUTION

•

The autotransformer should be kept at minimum voltage position

PROCEDURE

•

Connections are given as per the circuit diagram.

•

For No-Load or open circuit test by adjusting autotransformer, apply rated voltage and

•

Note down the ammeter and wattmeter readings. In this test rotor is free to rotate.

•

For short circuit or blocked rotor test by adjusting autotransformer, apply rated current

and note down the voltmeter and wattmeter readings. In this test rotor is blocked.

•

After that make the connection to measure the stator resistance as per the circuit diagram.

•

By adding the load through the loading rheostat note down the ammeter, voltmeter

reading for various values of load.

Prepared by

G.Panneerselvam, Vel Tech Multi Tech

EC2259

Electrical Engineering And Control System Lab Manual

Equivalent circuit for three phase squirrel cage induction motor

P

R1

R2'

X1

X2'

I0

Iw

1Ø, 230V, 50Hz AC

Supply

R0

I

X0

RL' =R2' (1/s-1)

N

RESULT

Thus the no load and blocked rotor test on a given three phase squirrel cage induction motor and

the equivalent circuit is drawn.

Prepared by

G.Panneerselvam, Vel Tech Multi Tech

EC2259

Electrical Engineering And Control System Lab Manual

REGULATION OF THREE PHASE ALTERNATOR BY EMF AND MMF

METHODS.

AIM

To predetermine the regulation of a given three phase Alternator by EMF and MMF method and also draw the

vector diagrams.

NAME PLATE DETAILS

( '" #

"

)

"

FUSE RATING

125% of rated current (Full load current)

For DC shunt motor:

For Alternator:

APPARATUS REQUIRED

S.NO.

1.

2.

3.

4.

5.

6.

7.

8.

Prepared by

NAME OF THE

APPARATUS

Ammeter

Ammeter

Ammeter

Voltmeter

Voltmeter

Rheostat

Rheostat

Tachometer

TYPE

RANGE

QUANTITY

MC

MC

MI

MI

MC

Wire Wound

Wire Wound

-

(0-2 A)

(0-10 A)

(0-10 A)

(0-600V)

(0-50V)

(500Ω, 1.2A)

(300Ω, 1.7A)

-

1

1

1

1

1

2

1

1

G.Panneerselvam, Vel Tech Multi Tech

EC2259

Electrical Engineering And Control System Lab Manual

CIRCUIT DIAGRAM FOR REGULATION OF THREE PHASE ALTERNATOR

BY EMF & MMF METHOD

(Open circuit and Short circuit tests)

3 POINT STARTER

L

F A

A

Fuse

250 , 2A

220V DC

SUPPLY

D

P

S

T

S

F

A

M

R

V (0-600) V

MI

N

B

X

FF

Fuse

Y

XX

AA

T

P

S

T

S

(0-10) A

MI

Fuse

(0-2) A

A

79

Fuse

220V

DC SUPPLY

D

P

S

T

S

MC

Fuse

Fuse

350 , 1.5A

Fuse

Prepared by

G.Panneerselvam, Vel Tech Multi Tech

EC2259

Electrical Engineering And Control System Lab Manual

FORMULAE USED

EMF Method

1. Armature Resistance Ra = 1.6 Rdc in ohms.

Here, Rdc is the resistance in DC supply.

2. Synchronous impedance Zs =

Open circuit voltage (E1 (ph))

Short circuit current (Isc)

(from the graph)

3. Synchronous impedance Xs = (Zs² - Ra²) in ohms.

4. Open circuit voltage

Eo= (V cosø + Isc Ra) ² + (V sinø - Isc Xs) ² in Volts.

(For lagging power factor)

5. Open circuit voltage

Eo= (V cosø + Isc Ra) ² + (V sinø - Isc Xs) ² in Volts

(For leading power factor)

7. Open circuit voltage

Eo= (V + Isc Ra) ² + (Isc Xs) ² in Volts

(For Unity power factor)

6. Percentage regulation

=

Eo –Vrated

Vrated

X 100

(both for EMF & MMF method)

PRECAUTION

•

•

•

The motor field rheostat should be kept in the minimum resistance position.

The Alternator field Potential divider should be in the maximum voltage position.

Initially all Switches are in open position.

PROCEDURE FOR BOTH EMF AND MMF METHOD

•

•

•

•

•

•

Connections are made as per the circuit diagram.

Give the supply by closing the DPST Switch.

Using the Three Point starter, start the motor to run at the synchronous speed by varying the

motor field rheostat.

Conduct an Open Circuit Test by varying the Potential Divider for various values of Field

Current and tabulate the corresponding Open Circuit Voltage readings.

Conduct a Short Circuit Test by closing the TPST switch and adjust the potential divider to

set the rated Armature Current, tabulate the corresponding Field Current.

Conduct a Stator Resistance Test by giving connection as per the circuit diagram and

tabulate the Voltage and Current readings for various resistive loads.

Prepared by

G.Panneerselvam, Vel Tech Multi Tech

EC2259

Electrical Engineering And Control System Lab Manual

PROCEDURE TO DRAW THE GRAPH FOR EMF METHOD

•

•

•

Draw the Open Circuit Characteristics curve (Generated Voltage per phase Vs Field Current).

Draw the Short Circuit Characteristics curve (Short Circuit Current Vs Field Current).

From the graph find the open circuit voltage per phase (E1 (Ph)) for the rated Short Circuit Current

(Isc).

• By using respective formulae find the Zs, Xs, Eo and percentage Regulation.

PROCEDURE TO DRAW THE GRAPH FOR MMF METHOD

•

•

•

•

•

•

Draw the Open Circuit Characteristics curve (Generated Voltage per phase Vs Field Current).

Draw the Short Circuit Characteristics curve (Short Circuit Current Vs Field Current).

Draw the line OL to represent If' which gives the rated generated voltage (V).

Draw the line LA at an angle (90 ± ) to represent If'' which gives the rated full load current (Isc)

on short circuit ((90 + ) for lagging power factor and (90- ) for leading power factor).

Join the points O and A and find the field current (If) by measuring the distance OA that gives the

Open Circuit Voltage (Eo) from the Open Circuit Characteristics.

Find the percentage Regulation by using suitable formula.

Tabulation for Regulation of three phase Alternator by EMF and MMF methods

Open circuit test

S.No.

Prepared by

Field Current

(If)

Open Circuit Line

Voltage (V0L)

Open Circuit Phase

Voltage (V0 (Ph))

Amps

Volts

Volts

G.Panneerselvam, Vel Tech Multi Tech

EC2259

Electrical Engineering And Control System Lab Manual

Short circuit test

S.No.

Field Current

(If)

Amps

Short Circuit Current

(120 to 150 % of rated current)

(ISC)

Amps

Regulation of three phase Alternator by EMF and MMF methods

Model Graph for EMF Method

OCC

Open Circuit Voltage (V0 (Ph)) in Volts

Short Circuit Current (ISC) in Amps

E1 (ph)

SCC

Field Current (If ) in Amps

Prepared by

G.Panneerselvam, Vel Tech Multi Tech

EC2259

Electrical Engineering And Control System Lab Manual

Regulation of three phase Alternator by EMF and MMF methods

Model Graph for MMF Method

E0 (ph)

Lag.

E0 (ph)

Unity

OCC

SCC

E0 (ph)

Open Circuit Voltage (V0 (Ph)) in Volts

Short Circuit Current (ISC) in Amps

Lead.

Unity

A

A

Lead.

90-

O

Prepared by

Lag.

A

90+

L

Field Current (If ) in Amps

G.Panneerselvam, Vel Tech Multi Tech

EC2259

Electrical Engineering And Control System Lab Manual

Resultant Tabulation for Regulation of three phase Alternator by EMF and MMF

methods

Percentage of Regulation

S.No.

Power

Factor

Lagging

EMF Method

Leading

Unity

Lagging

MMF Method

Leading

Unity

1.

0.2

-

-

2.

0.4

-

-

3.

0.6

-

-

4.

0.8

-

-

5.

1.0

+ % Regulation

Regulation curve of Alternator (EMF, MMF and Vector diagram)

From EMF method

From MMF method

Lagging pf

Leading pf

- % Regulation

Unity pf

RESULT

Thus the regulation of three phase alternator by EMF and MMF methods and the regulation curves are

drawn.

Prepared by

G.Panneerselvam, Vel Tech Multi Tech

EC2259

Electrical Engineering And Control System Lab Manual

STABILITY ANALYSIS OF LINEAR SYSTEM

AIM

To analysis the stability of the given linear system using Bode Plot, Nyquist Plot and Root Locus.

APPRATUS REQUIRED

S.No

Name of the apparatus

Type

Range

Quantity

1

Computer

-

-

1

2

MATLAB Software

-

-

1

THEORY

POLAR PLOT

The polar plot of a sinusoidal transfer function G ( jω ) on polar coordinates as ω is varied from zero to

infinity. Thus the polar plot is the locus of vectors G ( jw) and G ( jw) as ω is varied from zero to infinity. The

polar plot is also called Nyquist plot.

NYQUIST STABILITY CRITERION

If G ( s ) H ( s ) contour in the G ( s ) H ( s ) plane corresponding to Nyquist contour in s-plane encircles the

point −1 + j 0 in the anti – clockwise direction as many times as the number of right half s-plane of G ( s ) H ( s ) .

Then the closed loop system is stable.

ROOT LOCUS

The root locus technique is a powerful tool for adjusting the location of closed loop poles to achieve

the desired system performance by varying one or more system parameters.

The path taken by the roots of the characteristics equation when open loop gain K is varied from 0 to

∞ are

called root loci (or the path taken by a root of characteristic equation when open loop gain K is varied

from 0 to ∞ is called root locus.)

FREQUENCY DOMAIN SPECIFICATIONS

The performance and characteristics of a system in frequency domain are measured in term of frequency

domain specifications. The requirements of a system to be designed are usually specified in terms of these

specifications.

Prepared by

G.Panneerselvam, Vel Tech Multi Tech

EC2259

Electrical Engineering And Control System Lab Manual

The frequency domain specifications are

1. Resonant peak M r .

2. Resonant Frequency ωr .

3. Bandwidth.

4. Cut – off rate

5. Gain margin

6. Phase margin

RESONANT PEAK M r

The maximum value of the magnitude of closed loop transfer function is called the resonant peak M r . A large

resonant peak corresponds to a large over shoot in transient response.

RESONANT FREQUENCY ωr

The bandwidth is the range of frequency for which the system gain is more than −3 dB . The frequency at

which the gain is −3 dB , called cut off frequency. Bandwidth is usually defined for closed loop system and it

transmits the signals whose frequencies are less than cut-off frequency. The bandwidth is a measured of the

ability of a feedback system to produce the input signal, noise rejection characteristics and rise time. A large

bandwidth corresponds to a small rise time or fast response.

CUT-OFF RATE

The slope of the log-magnitude curve near the cut off frequency is called cut-off rate. The cut-off rate

indicates the ability of the system to distinguish the signal from noise.

GAIN MARGIN K g

The gain margin K g is defined as the reciprocal of the magnitude of open loop transfer function at phase cross

over frequency. The frequency at witch the phase of open loop transfer function is 180 is called the phase

cross over frequency ω pc .

PHASE MARGIN γ

The phase margin γ is that amount of additional phase lag at the gain cross over frequency required to bring

the system to the verge of instability, the gain cross over frequency ω gc is the frequency at which the

magnitude of open loop transfer function is unity (or it is the frequency at which the db magnitude is zero).

Prepared by

G.Panneerselvam, Vel Tech Multi Tech

EC2259

Electrical Engineering And Control System Lab Manual

PROCEDURE

• Enter the command window of the MATLAB.

•

Create a new M – file by selecting File – New – M – File.

•

Type and save the program.

•

Execute the program by either pressing F5 or Debug – Run.

•

View the results.

•

Analysis the stability of the system for various values of gain.

PROBLEM

Obtain the Bode Plot, Nyquist Plot and Root Locus of the given open loop T.F is H ( s ) =

2

2

s + 3s + 2

Using Bode Plot

num = [0 0 2]

den = [1 3 2]

bode (num,den)

grid

title (‘BODE DIAGRAM’)

% To Find out Gain Margin

sys = tf (num, den)

bode (sys)

Margin (sys)

[ gm, ph, wpc, wgc ] = margin (sys).

Using Nyquist Plot

num = [0 0 2]

den = [1 3 2]

nyquist (num,den)

grid

title (‘Nyquist Plot’)

Using Nyquist Plot

num = [0 0 2]

den = [1 3 2]

rlocus (num,den)

grid

title (‘Root Locus Plot’)

RESULT

Thus the stability of the given linear system using Bode Plot, Nyquist Plot and Root Locus was

analyzed.

Prepared by

G.Panneerselvam, Vel Tech Multi Tech

EC2259

Electrical Engineering And Control System Lab Manual

DIGITAL SIMULATION OF LINEAR SYSTEM

AIM

To simulate the time response characteristics of second order linear system using

MATLAB.

APPRATUS REQUIRED

S.No

Name of the apparatus

Type

Range

Quantity

1

Personal Computer

-

-

1

2

MATLAB Software

-

-

1

THEORY

The desired performance characteristics of control system are specified in terms of time

domain specification. Systems with energy storage elements cannot respond instantaneously and

will exhibit transient responses, whenever they are subjected to inputs or disturbances.

The desired performance characteristics of a system pf any order may be specified in

terms of the transient response to a unit step input signal.

The transient response of a system to unit step input depends on the initial conditions.

Therefore to compare the time response of various systems it is necessary to start with standard

initial conditions. The most practical standard is to start with the system at rest and output and

all time derivatives there of zero. The transient response of a practical control system often

exhibits damped oscillations before reaching steady state.

The transient response characteristics of a control system to a unit step input are

specified in terms of the following time domain specifications.

1. Delay time td

2. Rise time tr

3. Peak time t p

4. Maximum overshoot M p

5. Settling time t s

1. Delay Time

It is the taken for response to reach 50% of the final value, for the very first time.

Prepared by

G.Panneerselvam, Vel Tech Multi Tech

EC2259

Electrical Engineering And Control System Lab Manual

2. Rise Time

It is the time taken for response to raise from 0 to 100% for the very first time. For under

damped system, the rise time is calculated from 0 to 100%. But for over damped system it is the

time taken by the response to raise from 10% to 90%. For critically damped system, it is the

time taken for response to raise from 5% to 95%.

Rise time tr

=

π −θ

ωd

Where, θ

= tan

1−ξ 2

−1

ξ

and

Damped frequency of oscillation ωd = ωn

1−ξ 2

3. Peak Time

It is the time taken for the response to reach the peak value for the very first time. (or) It is the

taken for the response to reach the peak overshoot t p .

Rise time t p

=

π

ωd

4. Peak Overshoot (Mp)

It is defined as the ration of the maximum peak value measured from final value to the final

value.

Let final value = c (e)

Maximum vale = c (t p )

Peak Overshoot, M p =

c (t p ) − c ( e )

c (e)

−πξ

%M p = e

1−ξ 2

× 100

5. Settling Time

It is defined as the time taken by the response to reach and stay within a specified error. It is

usually expressed as % of final value. The usual tolerable error is 2% or 5% of the final value.

Prepared by

Settling Time t s

=

Settling Time t s

=

4

ξωn

3

ξωn

(For 2% error).

(For 5% error).

G.Panneerselvam, Vel Tech Multi Tech

EC2259

Electrical Engineering And Control System Lab Manual

PROCEDURE

•

Enter the command window of the MATLAB.

•

Create a new M – file by selecting File – New – M – File.

•

Type and save the program.

•

Execute the program by either pressing F5 or Debug – Run.

•

View the results.

•

Analysis the time domain specifications of the system.

PROBLEM

Obtain the time domain specifications of the given open loop T.F is H ( s ) =

100

2

s + 2 s + 100

MATLAB PROGRAM FOR UNIT IMPULSE PRSPONSE

num = [ 0 0 100 ]

den = [ 1 2 100 ]

impulse (num, den)

grid

title (‘ unit impulse response plot’)

MATLAB PROGRAM FOR UNIT STEP PRSPONSE

num = [ 0 0 100 ]

den = [ 1 2 100 ]

step (num, den)

grid on

title (‘unit step response plot’)

RESULT

Thus the time response characteristic of second order linear system was verified using

MATLAB.

Prepared by

G.Panneerselvam, Vel Tech Multi Tech

EC2259

Electrical Engineering And Control System Lab Manual

DESIGN OF P, PI, PID CONTROLLER

AIM

To design P, PI, and PID controllers for first order systems using MATLAB.

APPARATUS REQUIRED

1. Controller and system kit.

2. Patch chords.

3. Computer and Interference chord.

THEORY

Proportional Controller

1. The Proportional Controller is a device that produces the control signal, u (t) which is

Proportional to the input error signal e (t).

In P – controller, u (t) e (t).

Therefore u (t) = Kp c (t).

Where Kp – Proportional gain or constant.

2. The Proportional plus Integral Controller (PI – Controller) produces an output signal

consisting of two terms one on proportional to error signal and the other proportional to

the integral of error signal

In PI – Controller, u (t)

[e (t) + | e (t) dt]

Therefore, u (t) = e (t) + Kp / Ti | e (t) dt

Where Kp – Proportional gain or constant,

Ti – Integral Time.

3. The PID Controller produces an output signal consisting of three terms one on

proportional to error signal and the another one proportional to the integral of error

signal and the third one is proportional to derivative of error signal.

In PID Controller, u (t) [e (t) + | e (t) + d /dt ((e (t))]

Therefore, u (t) = e (t) + Kp / Ti | e (t) dt + Kp Td d /dt ((e(t))]

Where Kp – Proportional gain or constant,

Ti – Integral Time.

Td – Derivative Time.

Prepared by

G.Panneerselvam, Vel Tech Multi Tech

EC2259

Electrical Engineering And Control System Lab Manual

Type 0 First Order System with P – Controller

Step Input

(FG)

P Controller

Level Shifter

Computer CH 0

Level Shifter

Computer CH 1

EC2259

Electrical Engineering And Control System Lab Manual

Type 0 First Order System with PI - Controller

Step Input

(FG)

PI Controller

Level Shifter

Computer CH 0

Level Shifter

Computer CH 1

EC2259

Electrical Engineering And Control System Lab Manual

Type 0 First Order System with PID - Controller

Step Input

(FG)

PID Controller

Level Shifter

Computer CH 0

Level Shifter

Computer CH 1

EC2259

Electrical Engineering And Control System Lab Manual

Procedure

Type – 0 First Order System with P – Controller

1. Connections are given as per the circuit diagram.

2. Set Proportional Band = 80, Integral Time = 64000 and Derivative Time = 0.

3. Measure the performance specifications.

Type – 0 First Order System with PI – Controller

1. Connections are given as per the circuit diagram.

2. Set Proportional Band = 80, Integral Time = 30 and Derivative Time = 0.

3. Measure the performance specifications.

Type – 0 First Order System with PI – Controller

1. Connections are given as per the circuit diagram.

2. Set Proportional Band = 80, Integral Time = 30 and Derivative Time = 0.1.

3. Measure the performance specifications.

Transfer Function for P, PI, and PID Controller:

P – Controller:

Transfer Function = Kp

PI – Controller:

Transfer Function = Kp [1 + 1 / Ti S]

PID Controller:

Transfer Function = Kp [1 + 1 / Ti S + Td S]

TABULAR COLUMN

S. No

Time Domain Specification

Prepared by

P controller

PI controller

PID controller

G.Panneerselvam, Vel Tech Multi Tech

EC2259

Electrical Engineering And Control System Lab Manual

Model Graph

RESULT

Thus the design of P, PI and PID controller was done.

Prepared by

G.Panneerselvam, Vel Tech Multi Tech

EC2259

Electrical Engineering And Control System Lab Manual

DESIGN OF LAG AND LEAD COMPENSATOR

AIM

To design and implement the suitable lag and lead compensator for a given linear system

to improve the performance.

APPARATUS REQUIRED

1.

Transfer function and compensator

2.

Computer interface chord

3.

Patch chords

THEORY

LAG COMPENSATOR

A compensator having the characteristics of a Lag network is called a lag

compensator. If a sinusoidal signal is applied to a lag network, then in steady state the output

will have a phase lag with respect to input.

Lag compensation results in a large improvement in steady state performance but

results in slower response due to reduced bandwidth. The attenuation due to the lag compensator

will shift the gain cross over frequency to a lower frequency point where the phase margin is

acceptable.

The general form of lag compensator transfer function is given by:

G(S) = (S+T) / (S+P) = (S + 1/T) / S + 1/BT

Where, T > 0 and B >1

LEAD COMPENSATOR

A compensator having the characteristics of a Lead network is called a Lead

compensator. If a sinusoidal signal is applied to the lead network, then in steady state the output

will have a phase lead with respect to input.

Lead compensation increases the bandwidth, which improves the speed of

response and also reduces, whereas there is a small change in steady state accuracy. Generally,

Lead compensation is provided to make an unstable system as a stable system.

A Lead compensator is basically a high pass filter so it attenuates high frequency

noise effects. If the pole introduced by the compensator is not cancelled by a zero in the system,

then lead compensation increases the order of the system by one.

The general form of Lead compensator transfer function is given by:

G(S) = (S+T) / (S+P) = (S + 1/T) / S + 1/aT

Where, T > 0 and a<1