SILICONE ELASTOMERS TECHNOLOGY AND FABRICATION Wed.-Fri., Nov. 30-Dec. 2, 2011

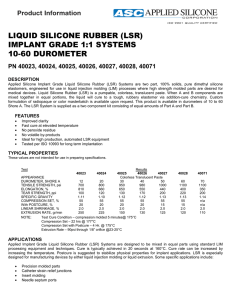

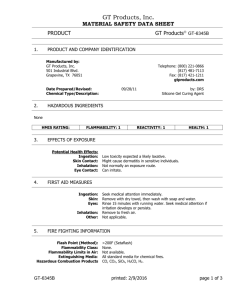

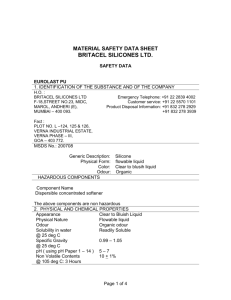

advertisement

SILICONE ELASTOMERS TECHNOLOGY AND FABRICATION Get a comprehensive overview of silicone elastomers, including basic silicone chemistry, types of silicone elastomers, manufacturing processes, fabrication techniques, problem solving, and application areas. Emphasis is on liquid injection molding (LIM/LSR) with detailed information in the areas of material selection, dispensing methods, injection molding process, tool design, and bonding alternatives. This course is presented by a panel of experts in the silicones field, and time is allotted for discussion of specific projects of interest. Who should Attend Both entry-level and experienced rubber technologists, rubber chemists, process engineers, laboratory managers, supervisors, technicians, shop foreman, quality assurance managers and engineers, technical sales personnel, and rubber producers and users. Wed.-Fri., Nov. 30-Dec. 2, 2011 8am-4:30pm Instructors: Mel Toub, Momentive Performance Materials; John Timmerman, Starlim North America Corporation; Bob Pelletier, Fluid Automation, Inc.; Rick Finnie, M.R. Mold & Engineering Corp.; Juergen Giesow, Arburg GmbH Early Bird: $990 (register before Oct. 15) Fee: $1190 CEUs: 2.0 Program No. 4830-8312 Registration COURSE OUTLINE To register call 414-227-3200 or visit sce-rubber.uwm.edu Silicone Elastomer Technology Tooling Design and Construction - Silicone Product Categories - Materials - Why Silicone? - Machining Methods - Silicone Markets and Applications - Hot Runner vs Cold Runner - Silicone Manufacturing Process - Valve Gate vs Open Gate - Nomenclature - Venting and Gating - HCE / HCR Technology - Cavitation - LIM / LSR Technology - Balanced Design - Testing and Specifications - Do’s and Don'ts - Elastomer Properties Adhesion and Bonding of Silicone Rubber - Definition of Adhesion Liquid Silicone Rubber (LSR / LIM) - Why Liquid Silicones? - Types of Adhesion - Comparison with HCE And TPE - Measurement of Adhesion - Process Overview - Overmolding - Dispensing Systems - Two Component Molding - Injection Equipment - Surface Modification - Molding Parameters - Troubleshooting - Automation Project Planning - Demolding - Material and Equipment Requirements - Troubleshooting - Prototyping - Enhanced Functionality - Cost Analysis - Debugging - Customer Communication CHAIR INSTRUCTOR Mel Toub has worked in the silicone elastomers division of Momentive Performance Materials (formerly GE Silicones) for more than 30 years. He has presented numerous technical papers to ACS, SAE, the International Silicones Symposium, and industry journals and holds several patents in the area of silicone rubber technology. His academic background includes BE and ME degrees in Materials Engineering from Rensselaer Polytechnic Institute as a well as an MBA also RPI. Keycode: SILPDF Message Code: AU-27-11-M