Document 10279807

advertisement

Szafran, Z.; Pike, R.; Singh, M., Microscale Inorganic Chemistry, John Wiley & Sons: New York, 1991, p. 176ff.

Experiment 8

Silicone Polymers: Preparation of Bouncing

Putty

INTRODUCTION

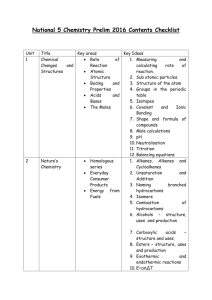

Figure 7.7. Structure of a typical

methyl silicone.

r

CH3

3

3

CH

CH

{

CH3-fi-O-fi-O fi-O

CH 3

CH 3

CH 3

H3

r

i-

CH 3

x

CH3

Silicones, or more specifically.organ.opolysiloxanes, are polymeric materials that

contain silicon, oxygen, and organic groups. The methyl silicones (also called

dimethylpolysiloxanes) are perhaps the most important members of this class

of materials. A typical structure of a methyl silicone is the silcone oil shown in

Figure 7.7.

The formation of these polymers is controlled by the type of Si-e-O linkage.

There are three types available, shown in Figure 7.8. The nonorganic groups

are known as functionalities. The R unit may be various organo groups,

such as methyl, ethyl, phenyl, or vinyl. The ratio of the difunctional to mono­

functional groups control the length of the polymer chain (i.e., x in Fig. 7.7).

These materialls are named as derivatives of disiloxane, H3SiOSiH3 . Thus

(CH3 hSi-O-Sj(CH3 h is named hexamethyldisiloxane. The polymers are

often referred to as diorganopolysiloxanes. Trifunctional units are employed in

the formation of cross-linked structures known as silicone resins.

ExperIment 8

Szafran, Z.; Pike, R.; Singh, M., Microscale Inorganic Chemistry, John Wiley & Sons: New York, 1991, p. 176ff.

I

I ..

R-Si-OI ..

:0:

:0:

I

Trifunctional

177

R

.. I

..

-O-Si-O-

.. .I

..

R-Si-O­

3

••

R

Difunctional

Monofunctional

Figure 7.8. Functionality of Si-O linkage.

The term "silicone" was first used by Friedrich Wohler (better known for

disproving the theory of organic vitalism) in 1857. The term was used to describe

chemicals that had an empirical formula of RzSiO, in an analogy to the organic

"cornpounds called ketones, RzCO, where R is an organic group. Silicones bear

little resemblance to ketones, however, and the differences between these two

types of compounds also illustrate a basic difference between silicon and carbon

chemistry. Carbon shows a-strong tendency to form 1T bonds, and ketones have

the structure RR'C=O, with a double bond between the carbon and oxygen.

They are generally simple 'molecular compounds. Silicon, on the other hand,

does not show this tendency, and P1T-P1T double bonds between silicon and

itself or other elements are relatively unstable, not being discovered until the

mid-1970s.

A second type of 1T bonding is possible, however. Silicon, unlike carbon,

possesses empty, low energy d orbitals, which can effectivelyoverlap with filled

p1T orbitals on other elements, such as nitrogen, oxygen, or fluorine. Evidence

for this p1T-d1T type of bonding is given by the unusually short bond lengths,

even after accounting for differences in electronegativity, and by unusual bond

angles in many compounds. While other explanations have been offered for

these phenomena, the simple fact is that silicon forms extremely stable "single"

bonds to oxygen (466 kJ 'mol- 1), and forms them under a wide variety of

situations.

The most common starting material for the formation of the methyl silicone

polymers is dichlorodimethylsilane, (CH3lzSiCIz. This compound is, in tum,

made in huge industrial quantities by the action of CH 3Cl on silicon powder in

the presence of a copper catalyst at 250-300°C. The resulting mixture of com­

pounds includes (CH3lzSiCIz, (CH3bSiCl, CH3SiCh, SiCk, and other less

abundant products. The mixture is separated by very careful fractional distil­

lation. Dichlorodimethylsilane is a useful starting material for two reasons:

1. The Si-Cl bonds are easily hydrolyzed, making the compound very re­

active.

2. The compound is bifunctional, since there are two chlorines. The chain can

therefore propagate in two directions, resulting in high molecular weight

polymers.

The organopolysiloxanes are prepared by the hydrolysis of the selected chlo­

rosilane. Thus, hydrolysis of (CH3lzSiClz gives rise to the corresponding silanol,

(CH3lzSi(OHlz, and hydrogen chloride. The outstanding characteristic of the

silanols is the ease in which they condense to yield siloxane polymers, as shown

in the following reaction sequence.

n(CH3lzSiClz + nHzO -+ n(CH 3lzSi(OHlz + 2nHCl

n(CH3lzSi(OHjz -+ [(CH3lzSiO]n + nHQ-Si(CH3 ):r- [Q-Si(CH3)x-]Si(CH3):r-OH

178

Chapter 7 I Chemistry of the Main Group Elements

Szafran, Z.; Pike, R.; Singh, M., Microscale Inorganic Chemistry, John Wiley & Sons: New York, 1991, p. 176ff.

The polysiloxanes formed are a.mixture of cyclic compounds (where n = 3,

4, 5, etc.) and open chained compounds having hydroxyl end groups. In the

industrial preparation of silicones, the cyclic species are obtained in good yield

by carrying the hydrolysis out in dilute ether solution. They are isolated and

purified by fractional distillation. The cyclic compound (the tetramer is most

often used) is then polymerized to the linear polymer by a process called

equilibration. Equilibration of cyclic siloxanes is the process by which the

Si-Q--linkages are continuously broken and reformed until the system reaches

an equilibrium condition at the most thermodynamically stable state. Heat alone,

or more commonly acid or base catalysis, is used in the process.

The chain length of the polymer can be controlled by adding (CH3bSiCl, a

monofunctional compound called an endblocker, to the reaction mixture. This

compound terminates the chains with an -oSi(CH3b group (see Fig. 7.7). The

absence of an endblocker can produce chains of high molecular weight, often

referred to as silicone gums.

Silicones can be prepared having a wide range of visc,osities, lubricating prop­

erties, and reactivities. They see extensive use in industrial chemistry in auto­

mobile polishes, cosmetics, water repellants, high-temperature electrical insu­

lation, gaskets, release agents, antifoam agents, high-temperature paints, glass:

cloth laminates, elastomers (rubbers), greases, and other general polymers. The"

framework of all the polymers is the very stable -Si-0--Si- sequence. This

gives silicones good thermal stability at high temperatures (above 500 OF) as

well as flexibility at low temperatures (below -110 OF). The organic groups are

hydrophobic, and thus, so is the polymer. Medicalgrade siliconesare used Widely

in areas such as silicone rubber finger joints for those suffering from various

forms of arthritis, mammary implants following radical mastectomy, hypodermic

needles lubricated with silicone fluidsto make insertion reasonably painless, and

silicone rubber coatings encasing implants such as pacemakers and infusion

pumps to name a few.

In this experiment, the chemistry of silicones will be investigated by preparing

bouncing putty, a silicone polymer, via the hydrolysis of dichlorodimethylsilane.

The silicone, containing residual hydroxyl groups will be cross-linked using boric

acid. This trifunctionalacid, B(OHb, which also contains hydroxyl groups, forms

-Si-Q--a- linkages resulting in a peculiar type of gum. The commercial

bouncing putty found in novelty stores is compounded with softening agents,

fillers, and coloring agents.

Prior Reading and Techniques

Section 5.0.6: Removal of Suspended Particles from Solution

Section 5.F: Concentration of Solutlons

Related experiments

Industrial Chemistry: Experiments 4, 12, and 34

EXPERIMENTAL SECTION

Safety Recommendations

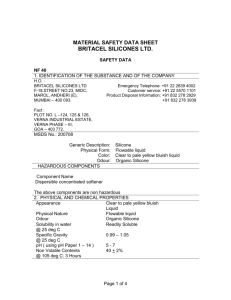

DichlorodilDethylsiiane (CAS No. 75-78-5): This compound is harmful

if swallowed, inhaled, or absorbed through the skin. It is extremely destructive

to the mucous membranes. The compound reacts violently with water. IHL­

RAT LC50: 930 ppm/4H.

Boric acid (CAS No. 10043-35-3): While not generally considered dan­

gerous, this compound is toxic if ingested. ORL-RAT LD50: 5.14 glkg. Death

has occurred from ingestion of 5-20 g in adults.

Experiment 8

Szafran, Z.; Pike, R.; Singh, M., Microscale Inorganic Chemistry, John Wiley & Sons: New York, 1991, p. 176ff.

CHEMICAL DATA

Compound

FW

179

Amount

(mL)

mmol mp (OC) bp (OC) Density

Dichlorodimethylsilane 129.06 1

8.24

-16

70

1.064

Required Equipment

Magnetic stirring hot plate, lO-mL round-bottom flask, magnetic stirring bar,

automatic delivery pipet, water condenser, Pasteur pipet, Pasteur filter pipet,

litmus paper, 5-mL conical vial, sand bath.

Time Necessary for Experiment: 2.5 h.

EXPERIMENTAL PROCEDURE

NOTE: This reaction is carried out in the HOOD.

Place 2 mL of diethyl ether in a lO-mL round-bottom flask containing a

magnetic stirring bar. Using an automatic delivery pipet, add 1 mL of dichlo­

rodimethylsilane to the ether solvent and attach a water condenser to the flask.

NOTE: Dichlorodimethylsilane reacts rapidly with mois·

ture to produce hydrogen chloride gas. Make the transfer

swiftly·

Arrange the assembly on a magnetic stirring hot plate, and with rapid stirring,

carefully add 2 mL of water dropwise. from a Pasteur pipet, through the

top of the condenser.

NOTE: Hydrogen chloride gas is evolved in this hydrolysis

step. The addition must be made slowly at the beginning

of the reaction or too vigorous an evolution of the Hel will

occur. You will note that the ether is warmed to reflux

temperature. This is the reason a cooled water condenser

is used.

Allow the resulting mixture to stir for an additional 10 min at room temper­

ature after addition of the water is complete. Remove the reaction flask from

the condenser. Using a Pasteur iIMr pipet, carefully remove the major portion

of the lower aqueous layer. This is discarded. Reattach the flask to the reflux

condenser and carefullyadd 1 mL of 10% sodium bicarbonate solution dropwise

through the top of the condenser, with stirring.

NOTE: This step is to neutralize any residual acid remain·

ing in the wet ether solution. Vigorous evolution of carbon

dioxide gas is observed at this stage as the neutralization

proceeds.

After bubbling of the solution has stopped, remove the flask and using the

Pasteur filter pipet from the previous step, separate the lower aqueous phase.

180

Chapter 7 I Chemistry of the Main Group Elements

Szafran, Z.; Pike, R.; Singh, M., Microscale Inorganic Chemistry, John Wiley & Sons: New York, 1991, p. 176ff.

Test this phase with litmus paper. Repeat the neutralization step until the dis­

carded aqueous layer is no longer acidic to litmus. Finally, wash the ether solution

with 2 mL of water. Separate and discard the aqueous layer.

Transfer the wet ether layer in two portions to a Pasteur filter pipet column

containing silicagel (bottom layer) and anhydrous sodium sulfate (-1 in. of each

in the column). Collect the dried eluate in a tared 5-mL eeftiMl vial containing

a boiling stone. Wash the column with an additional 3 mL of ether. When

2 mL of eluate has collected in the flask, concentrate the contents on a warm

sand bath in the HOOD under a slow stream of nitrogen. Repeat this procedure

for the other one half of the wet ether layer.

NOTE: The concentration step is done in stages.lJtheflow

oj eluate is too slow the procedure may be speeded up by

placing a pipet bulb on the top oj the column and applying

gentle pressure. This is a simple introfluction to flash

chromatography.

Isolation of Product

Determine the weight of the clear residual silicone fluid. Add boric acid to the

silicone fluid in an amount of 5% of the weight of the fluid, stirring constantly

with a microspatula. Continue stirringfor five minutes. Heat the resulting mixture

to -170-180 °C in a sand bath or on an aluminum block until a stiff silicone

gum is obtained. This usually occurs within a 20-min time span. Allow the prod­

uct to cool to room temperature.

Remove the product from the vial and roll the material into a ball. If the gum

is somewhat brittle, continued kneading will produce the desired gumlike char­

acteristics.

Perform the following tests on your product:

1. It should give a lively bounce on a hard surface.

2. Pulling sharply causes cleavage of the gum.

3. Pulling slowly results in stretching reminiscent of chewing gum.

4. Placed on a hard surface it will flow into a flat plate.

5. If test (4) is done on newspaper, careful removal of the flat gum will reveal

the mirror image of the print.

QUESTIONS

GENERAL REFERENCES

1. By what process is pure silicon prepared in industry?

2. Make a comparison of the chemical and physical properties of Si02 and

CO 2 • Can you account for these differences?

3. What is the composition of carborundum, how is it made, and what major

industrial use does it have?

4. Which would you expect to be the better Lewis base, C 4 - or Si4 - ? Explain.

5. Describe the molecular structure and hybridization of the Si atom in the

following species. (a) (CH3bSiF2 , (b) SiF~-, and (c) SiF4 .

6. There is a wide variety of silicone polymers, both synthetic and naturally

occurring. Carry out a literature search and locate representative examples

of silicones that are used for each of the applications mentioned in the ex­

perimental introduction.

Eabom, C., Organosilicon Compounds, Butterworths: London, 1960.

Meals, R. N.; Lewis, F. M., Silicones, Reinhold: New York, 1959.

Experiment 9

Szafran, Z.; Pike, R.; Singh, M., Microscale Inorganic Chemistry, John Wiley & Sons: New York, 1991, p. 176ff.

181

Kirk-Othmer, Encyclopedia of Chemical Technology, 3rd ed., Wiley-Intersci­

ence: New York, Vol. 20, 1979, p. 922.

Rochow, E. G., Chemistry of the Silicones, 2nd ed., Wiley: New York, 1951.

Stark, F. 0.; Falender, J. R:; Wright, A. P., "Silicones" in Comprehensive Or­

ganometallic Chemistry, G. Wilkinson, Ed., Pergamon Press: Oxford, 1982,

Vol. 2, Chapter 9.3, p. 305.

I