The aims of this assignment are...

advertisement

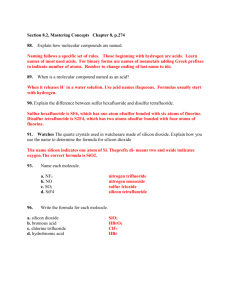

Assignment 2. Fall 2011. The Structure and Properties of Silicon-Based Materials. The aims of this assignment are to introduce you to several silicon-based materials and to illustrate the differences between a semiconducting element (silicon) and several of its compounds (ceramics). This assignment will also reacquaint you with on-line searches; we will be using the world-wide web as a virtual museum. Some basic definitions and terms are also introduced; these are important. The answers to all of the following questions can be obtained on-line. Good places to start, for information on elemental materials, metals, minerals and ceramics are: Wikipedia: The Free Encyclopedia at: http://en.wikipedia.org/wiki/Main_page WebElements.com at: http://www.webelements.com/ Amethyst Galleries at: http://www.galleries.com Mindat.org at: http://www.mindat.org The Hardness Scale at: http://homepages.rpi.edu/~schubert/Educational-resources/Materials-Hardness.pdf Hardness Tables at: http://www.tedpella.com/company_html/hardness.htm Silicon is a semiconductor or a metalloid! However, the compounds silicon carbide (SiC), silicon nitride (Si3N4) and talc (a silicate based on the composition: Mg3Si4O10(OH)2) are ceramics; they have very different properties as compared with the parent element. In the following, we shall compare the structure and properties of these and other ceramics with those of the semiconducting element . We will use, specific gravity (SG), Mohs' hardness (H) and melting point (MP) as property indicators. Note that specific gravity may be defined as the ratio of the density of a given substance to that of water. (The density of water at 4˚C is 1g/cm3 or 1000kg/m3). Mohs' hardness is a measure of the ability of one substance to scratch, or be scratched by another substance; it is a relative measure of the "strength" or resistance to deformation of a material. In about 1850, Freidrich Mohs proposed a scale of hardness, from 110, with diamond the hardest material, assigned a value of 10, and talc the softest material, a value of 1. Note that Mohs used minerals (naturally occurring, crystalline materials) to develop his seemingly primitive, but oft used (and indeed remarkably useful) scale of hardness. Mohs' hardness scale is reproduced in Table 1 Table 1 Mohs' Hardness Scale. 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. Talc Gypsum Calcite Fluroite Apatite Orthoclase Quartz Topaz Corundum Diamond Questions 1-10. Fill in the blanks, indicated by the question numbers in parentheses in Table 2, which lists SG and H property data for silicon and several of its associated ceramics. Note that I have already added the data for elemental silicon. Table 2 Properties of Silicon and Selected Silicon-Based Ceramics. Material Silicon(Fe) Silicon Carbide (SiC) Silicon Nitride (Si3N4) Quartz (SiO2) Fayalite (Fe2SiO4) Talc (Mg3Si4O10(OH)2) Specific Gravity (SG) 2.329 (1) (3) (5) (7) (9) Mohs' Hardness 7.0 (2) (4) (6) (8) (10) When you have filled in the table, go to the Lesson 02 Assignment folder on ANGEL, and use the data in Table 2 to answer the quiz questions. When you have completed questions 1-10, you will find that the properties of silicon and its associated ceramics are very different. This is particularly evident if you compare e.g., the hardness of silicon carbide with talc. Questions 11-14. Even more striking property differences are found when we compare melting points of various silicon-based compounds. Fill in the blanks in Table 3, which lists the melting points for the element silicon and four of its associated ceramics. Again, I have included the data for silicon. Table 3. Melting Points of Silicon and Selected Silicon -Based Ceramics. Material Silicon (Si) Silicon Carbide (SiC) Silicon Nitride (Si3N4) Quartz (SiO2) Silicon Tetrafluoride (SiF4) Melting Point (˚C) 1414 (11) (12) (13) (14) Most materials are crystalline, and this is the case for the materials listed in Tables 2 and 3. A crystalline material may be defined as one in which the atoms/molecules/ions are arranged in a regular, periodically repeating pattern in all three dimensions. In describing a crystalline material, we may employ the analogy of wallpaper. Just as wallpaper may be characterized by a pattern that is repeated in two dimensions, crystals may also be characterized by a pattern, or lattice, which is repeated in three dimensions. We may describe an entire strip of wallpaper by specifying the shape, size and content of the smallest repeat unit. We may do the same for crystals and the smallest repeat unit is called a "unit cell". There are only seven basic shapes for unit cells and these define the seven crystal systems; these are: Cubic (also called isometric), tetragonal. hexagonal, orthorhombic, trigonal (also called rhombohedral), monoclinic and triclinic. (Do not worry about remembering these names!) Figure 1. The unit cell of silicon. Downloaded from: http://worldscheaper.com/wp-content/uploads/2011/02/diamond-crystal-structure.gif Table 4. The Crystal Structure of Several Silicon -Based Materials. Material Silicon (Si) α-Silicon Carbide (α-SiC) β-Silicon Carbide (β-SiC) Quartz (SiO2) Fayalite (Fe2SiO4) Talc (Mg3Si4O10(OH)2) α-Silicon Nitride (Si3N4) Crystal Structure Cubic, Isometric (15) (16) (17) (18) (19) (20) Figure 1 is a schematic drawing of the unit cell of silicon. Silicon is cubic, which means that all of the three sides of the unit cell are of the same length (a0), and all the internal angles are 90˚. Figure 1 is a "ball and stick" representation of the structure of silicon; the atoms (the balls) are not shown at their correct sizes. Note that in Figure 1, the covalent bonds that are associated with each silicon atom are shown by the “spokes” that radiate from each atom; there are four such bonds for each silicon atom. The unit cell is outlined by the thinner lines. Sometimes, it is important to know how many atoms are contained or located in each unit cell and we will now determine this number. Reference to Figure 1 shows that there are eight corners of the unit cell, and each one is associated with a silicon atom. Hence, there are eight corner atoms. However, each corner atom is shared between eight unit cells (eight cubes touch at each corner or vertex), so the number of corner atoms/unit cell is 8 ÷ 8 = 1. There are six face atoms in Figure 1, yet each cube face is shared by two adjacent unit cells, so the number of face atoms/unit cell is 6 ÷ 2 = 3. In addition to the atoms at the corners and centering the faces of the unit cell, there are also four atoms which are wholly contained within the unit cell. Hence, the total number of atoms/unit cell is 3 + 1 + 4 = 8. Questions 15-20 Fill in the blanks in Table 4, which lists the crystal structure of several silicon-based materials. Note that both SiC and Si3N4 are polymorphic, i.e., the exist in more than one crystalline form. Questions 21-23 Figure 2 is a schematic drawing of the unit cell of the β-form of silicon carbide (β-SiC) structure: the blue atoms are silicon and the grey atoms are carbon. The nearest neighbors of each atom are indicated by the thick spokes that radiate from each atom and the unit cell is outlined by the thinner lines. Because we are only showing a unit cell of the structure, not all of the carbon atoms shown will appear to have a full compliment of nearest neighbor atoms; however, the environment of all carbon atoms is the same. Note that in Figure 2, all of the silicon atoms are wholly contained within the one unit cell. Figure 2. The unit cell of β−SiC. Downloaded from: http://en.wikipedia.org/wiki/Silicon_carbide Question 21. How many carbon atoms are there in one unit cell of Figure 2 (Hint: see Figure 1)? Question 22. How many silicon atoms are there in one unit cell of Figure 2 Question 23. Are the numbers of atoms/unit cell, calculated with respect to questions 21 and 22, consistent with the formula, or stoichiometry SiC?