Analysis of Current State And Progress Trends of PCS for VVER NPP

advertisement

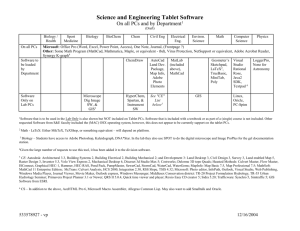

ALL-RUSSIAN RESEARCH INSTITUTE FOR NUCLEAR POWER PLANTS OPERATION Analysis of Current State And Progress Trends of PCS for VVER NPP Arkadov G.V. – Director General, JSC “VNIIAES” Dunaev V.G. – Deputy Director General, JSC “VNIIAES”, Chief Designer of NPP PCS Bozhenkov O.L. – Deputy Chief Designer of NPP PCS Seventh International Scientific And Technical Conference «Safety, Efficiency And Economics of Nuclear Power Industry» Moscow, VNIIAES, 26-27 May 2010 1 Evolutionary Progress of VVER NPP Automated Process Control Systems The strategy of PCS development accepted by the State Corporation “Rosatom” is based on stepwise (evolutionary) improvement of the design solutions and implementation of the requirements to NPP PCS under absolute fulfillment of the Units’ start-up directive dates. 2 Strategy of AES-2006 PCS Development (1/2) Technical solutions of PCS for Russian and foreign NPP Units (Russian design) serve as the bases for technical solutions of AES-2006 PCS: Kalinin NPP, Unit 3, Tianwan NPP (China), Busher NPP (Iran), Kudankulam NPP (India), as well as world tendencies and requirements related to NPP PCS. Development and implementation of the specific perspective and unified technical solutions on the Units being upgraded and in the process of completion will ensure reference of the design solutions for AES-2006 PCS (NV NPP-2 and LNPP-2). 3 Strategy of AES-2006 PCS Development (2/2) Already today the strategy of AES-2006 PCS development is being implemented by the corporation of the Russian enterprises via stepwise introduction of the state-of-the-art design solutions and software and hardware complexes for PCS not only in the designs of the Units in the process of completion and construction (Rostov NPP, Unit 2, Kalinin NPP, Unit 4, Beloyarskaya NPP, Unit 4), but during the PCS upgrading on the operating NPPs (Kola NPP,Units 3 и 4, Novovoronezh NPP, Unit 5) as well. 4 НВАЭС-2 Калинин-4 Ростов-2 Evolutionary Progress of PCS (Improvement of Design Solutions) • System upper level structure id optimized • Communication interface for connecting subsystems is unified • Diagnostics of lower automatic control equipment is expanded • PCS training facilities are implemented • Unified local control panels • New architecture solutions to exclude common cause failure of Unit upper level systems’ functions • In TPTS hardware a high-speed bus TPTS-EN is used • Digital safety control system (technological) • Reduction of cable connections between UCR and back-up shutdown center and the rooms with lower automatics, improving of UCR and BSC fire safety due to digital communications channel • Unification of the subsystems upper level • Diagnostics of electric-driven valves • Digital Reactor Control and Protection System-Safety Control System • 3rd level of NPP automation (Production CS) • Transfer to up-to-date design standards • Man-machine interface optimization 5 Current Tasks of AES-2006 Design Resolution of PCS design unification issues for NV NPP-2 and LNPP-2 Verification of design solutions on Chief Designer test facility in VNIIAES Finalization of soft- and hardware certification for RCPSSafety Control System, TPTS Development of e-designing for NPP PCS based on the principles of system engineering Finalization of automated design system development for control systems Joint development with Rostechnadzor of the guidelines regarding PCS, satisfying the up-to-date world tendencies 6 NPP PCS Progress Trends in VVER-TOI Design (1/4) Experience accumulated when creating PCS designs for Kalinin NPP Units 3 and 4, Rostov NPP Units 2 and 3, NV NPP-2, LNPP-2 and Beloyarskaya NPP Unit 4, Tianwan NPP (China), Busher NPP (Iran), Kudankulam (India), as well as NPP PCS world trending allow to move on to the new stage in PCS designing, which will be implemented when developing VVER-TOI. 7 NPP PCS Progress Trends in VVER-TOI Design (2/4) Functions ranking according to structural levels of PCS architecture : Level 1: data receipt and primary processing, automatic control/regulation Level 2: operational information display, solution of operational rating tasks, remote control Level 3: analysis and accumulation of information about object, solution of analytical tasks, data transfer to outer systems Integration of station monitoring and control systems in one system of station upper level Use of display local control panels for local monitoring and control systems unifying them by common bus Unification of primary systems, arranging of their information exchange by common bus Implementation of digital safety control systems using the principles of diversity of different types 8 NPP PCS Progress Trends in VVER-TOI Design (3/4) Display method of monitoring and control using the touchscreens for systems of normal operation Using display facilities for safety systems monitoring Implementation of SS components control under normal operation using priority control module Using group display and digital control aids on UCR panels Minimizing the use of conventional control and monitoring aids in UCR Reduction of cable connections scope between Unit Control Room (back-up shutdown center) and the rooms with lower automatics, improving of UCR and back-up shutdown center fire safety due to digital (optical) communications channel Improving the automation and optimization level of process control 9 NPP PCS Progress Trends in VVER-TOI Design (4/4) Transfer from Unit process subsystems control to processes control (functional design) Availability of tools for automated design and for testing the normal operation and safety control systems Using the microprocessor-based aids on lower level Implementing the common system of integrated diagnostics for process equipment, PCS facilities and processes, supported by the corresponding methodology and instructions Man-machine interface optimization Using the unified soft- and hardware based on seriesproduced means Using the technology of PCS e-design based on the principles of system engineering 10 Responsibility Distribution Over Stages of PCS Life-Cycle Area of AEP Responsibility Area of PCS Chief Designer Responsibility Technical Assignment for Automation (AEP) Development of electronic PCS technical design Transfer of PCS as a finished product to commissioning Integrated onsite testing of entire PCS SW and HW Complex Testing of edesign on ChD test facility PCS systems HW delivery and installation on Unit Development of order to plant manufacturer in eform PCS systems factory testing Testing of PManufacturer order on ChD test facility System HW manufacturing by the plantsmanufacturers Area of ATE Responsibility Participation in PCS acceptance into trial operation as part of Unit PCS commissioning activities combined with Unit commissioning activities 11 Design Solutions Verification PCS Chief Designer developed and commissioned a special test site for testing PCS SW and HW tools and complexes. Test programmes and methodologies are developed for testing on Chief Designer’s test site and plantmanufacturers’ facilities. On test site the design process algorithms and manmachine interfaces being developed are checked in different modes. By now, the following has been fulfilled on this test site: testing of process algorithms for PCS of Rostov NPP Unit 2, verification of assignments to plant-manufacturer for PCS of Kalinin NPP Unit 4, testing of upper Unit level system prior to shipping to Kalinin NPP. 12 Chief Designer Test Site for PCS in VNIIAES, Including AllMode Unit Model 13 Testing of Unit Upper Level System for Kalinin NPP Unit 4 on Chief Designer Test Site in VNIIAES 14 Development of NPP PCS E-Design (Based On System Engineering Principles ) Development and implementation of NPP RCS e-design technology based on the system engineering principles will ensure: Significant reduction of development period, Increase design quality, Competitive ability of PCS, in the export designs including, PCS support at all life-cycle stages. 15 Technology of PCS Development Considering the Requirements of System Engineering Standards Advantages: Paperless technology and reducing PCS design errors due to application of state-of-the-art design tools. Elimination of errors by ASAP principle, and, consequently, cost reduction. Obtaining adequate documentation at all stages of PCS life-cycle. Significant reduction of costs for commissioning activities due to elimination of PCS design errors at earlier stages of development. 16 Works Arrangement on PCS Development and Delivery Generation of technical policy relating the PCS development is carried out by the Council of Chief Designers of the Consortium and the section on issues of PCS development and implementation in the Directorate on Development and Realization of AES-2006 Design Development of a competitive Russian PCS in frames of AES-2006 design is carried out using maximum scientific and industrial potential of nuclear weapon and energy complexes (NWC + NEC) 17 Parties of Projects on PCS Development System Supplier 1 Normal operation and safety control system (technological) FSUE «VNIIA» 2 Control and protection system – safety control system JSC «VNIIAES» - AREVA JSC «VNIIAES» - Rolls-Royce 3 In-core monitoring and diagnostic system JSC «VNIIAES» / RSC KI 4 Automated system of radiation monitoring JSC«SNIIP» / JSC «VNIIAES» 5 System of upper unit and station levels JSC «VNIIAES» 6 Fire protection monitoring and control system JSC«Tensor» 7 Auxiliary systems (local panels) FSUE «VNIIA» / JSC «VNIIAES» 18 International Cooperation Work Arrangement With Foreign Partners Order for PCS Complete delivery of PCS and NPP CS VNIIAES System integration AEP SIEMENS • Design technology Design OKB GP Site testing • Componentry • Training АЭС VNIIA ... 19 Ways of Involving New Project Partners The procedure for involving new project partners is defined by the uniform Standard for Purchases, authorized by the order of the State Corporation “Rosatom” Director General. NPP PCS Chief Designer also participates in the tenders, e.g., in the tender for LAES-2 PCS, which took place in 2010. According to the Standard of Purchase, all organizations, interested and having the corresponding conditions, of any form of property, may submit their bids for participation in the procedure of purchase of PCS and/or subsystems and complexes, specifically, for automation of Rostov NPP Unit 3 turbine hall. 20 Arrangement of NPP PCS Normative Base (1/4) Analysis of the Russian practice in development PCS is based on sufficiently developed base of standards, norms and regulations and demonstrates the following: Referring to standards, norms and regulations defining the requirements to HW, there exist a high degree of Russian and international standards’ requirements correspondence. At the same time one should consider that over 300 Russian standards relating to HW and about 15 relating to SW are fully identical to IEC and ISO standards; Referring to standards, norms and regulations defining the requirements to SW, the Russian normative base is insufficiently developed and does not satisfy the presentday requirements. 21 Arrangement of NPP PCS Normative Base (2/4) JSC “VNIIAES” elaborated proposals on application of international IAEA and IEC standards to SW in PCS designs of NPP Units under construction and design. Proposals for introducing a package of standard documents, international ones including, were discussed with Rostechnadzor. These proposals are timely and urgent in the context of changes in Federal Law № 184FZ, dated of 27 December 2002, “On Technical Regulation” accepted at the initiative of the Russian Federation President, determining a possibility of acknowledging and using the international and foreign standards and codes in the Russian Federation. 22 Arrangement of NPP PCS Normative Base (3/4) JSC “VNIIAES” in cooperation with Institut fur Sicherheitstechnologie GmbH, Germany and Institutt for Energiteknikk, Norway elaborated the first drafts of the following normative documents: ”Nuclear Plants. Control Systems. Assessment of Software Tools Quality and Reliability”; ”Nuclear Plants. Control Systems. Classification and Qualification”; ”Nuclear Plants. Control Systems. General Requirements”. The above normative documents on development of computer-based PCS may become the basis for elaboration of federal safety norms and rules in the area of nuclear energy use. The elaboration is carried out by joint efforts of the State Corporation “Rosatom” organizations and Rostechnadzor. 23 Arrangement of NPP PCS Normative Base(4/4) JSC “VNIIAES” elaborated a package of guidelines, defining requirements to new generation of PCS on the basis of SW and programmable facilities, requirements to testing, verification, validation, qualification and certification, five of which are submitted for approval to JSC “Atomenergoproject”, JSC “SPbAEP”, RSC “Kurchatov Institute”, JSC OKB “Gidropress” In February 2010 the first draft of the guideline “Nuclear Plants. Control Systems. Stages and Phases of Development. General Provisions” was elaborated and distributed for review, where the requirements are set out to all stages and phases of PCS development and introduction, to the composition and contents of the documents at all stages and phases. 24 Conclusions (1/2) The Russian enterprises have sufficiently great scientific and industrial potential for creation of competitive Russian PCS, which allows us today together with foreign companies to ensure the world scientific and technical level of NPP PCS, and in the near future to compete with the West on equal terms in the area if information technologies. JSC “VNIIAES” in cooperation with the industry enterprises elaborated, introduced and currently are improving and introducing state-of-the-art control systems of in-house design, well comparable with foreign analogues; the PCS test site is functioning. In the industry a complex of activities is being implemented on improving the works on development and introduction of a competitive Russian PCS, specifically, in frames of standard design of optimized and informatized VVER Unit (VVER-TOI). 25 Conclusions (2/2) Technical and commercial proposals were prepared to participate in tenders on supply and putting into operation of PCS for NPP of Russian design (NPP in Turkey, India, Czechia, Hungary). Currently a new enterprise JSC “VNIIASU” is in the process of creation in the interests of the industry to perform the development and complete supply of “turnkey” PCS for the NPPs being finished and the NPPs of new generation. An up-to-date normative base is under arrangement for NPP PCS development and introduction based on computing machinery and harmonized with the international standards 26