Objective - Springer Static Content Server

advertisement

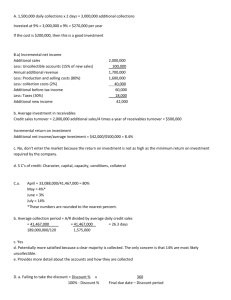

“Education in Pursuit of Supply Chain Leadership” dp&c Chapter8 Chapter 8 Statistical Inventory Management 8-1 dp&c Chapter8 Learning Objectives • Understand the demand driver • Define the concepts of stock replenishment • Describe the replenishment review interval • Review the basic terms of statistical inventory replenishment • Review the basic inventory replenishment techniques • Detail the basic of the reorder point • Work with reorder point lead time and safety stock • Explore min/max and periodic review methods 8-2 dp&c Chapter8 Learning Objectives (cont.) • Define order quantity techniques • Calculate the economic order quantity (EOQ) • Detail the assumption of the EOQ technique • Calculate order quantity discounts • Perform order quantity joint replenishment • Determine the transportation EOQ • Discuss replenishment by item class • Discuss the application of lean to statistical order management 8-3 dp&c Chapter8 Chapter 8 Statistical Inventory Management Inventory Statistical Inventory Management Basics Replenishment Concepts 8-4 dp&c Chapter8 Understanding the Demand Driver Independent Demand The demand for an item that is unrelated to the demand for other items. Demand for finished goods, parts required for destructive testing, and service parts requirements are examples of independent demand Dependent Demand Demand that is directly related to or derived from the bill of material structure for other items or end products. Such demands are therefore calculated and need not and should not be forecast APICS Dictionary, 13th edition 8-5 dp&c Chapter8 Characteristics of Dependent Demand • • • • • • Demand for these items is independent of company inventory decisions. Demand for these items is subject to a level of random variation. These items are usually planned and managed without reference to other items. Planning for these items usually involves the use of forecasting techniques designed to foretell future demand based on past historical usage. These items are best planned with some form of safety or reserve stock to counterbalance variation in forecasting. The critical question for inventory availability is one of quantity rather than timing. 8-6 dp&c Chapter8 Characteristics of Dependent Demand • • • • • • Dependent demand items are always planned and managed in relation to other items as detailed in the bills of material (BOMs) in which they are specified Replenishment quantities for production inventories can be precisely determined by establishing the demand on “parent” level assemblies and then using the BOM structure to calculate exactly the “children” item requirements and due dates Future demand for production inventories should not be forecasted Management inventory planning decisions directly impact the demand for these items Dependent demand items rarely use safety or reserve stocks The critical question for inventory availability is one of timing rather than quantity 8-7 dp&c Chapter8 BOM Structure Example Independent Demand Independent Demand (Service Part) A Dependent B Demand C Dependent Demand D E Dependent Demand Dependent Demand 8-8 dp&c Chapter8 Concept of Inventory Replenishment The theory behind inventory replenishment management is that for each item, an optimal stocking and ordering quantity can be determined either statistically or through some form of experience, or even intuition. The object is to ensure that the optimum stocking level for each item in the inventory is maintained at the targeted service level without creating excess stock. 8-9 dp&c Chapter8 “Saw-Tooth Chart” Quantity Replenishment Order A Trigger Point B Inventory C Lead Time Safety Stock Time 8-10 dp&c Chapter8 Replenishment Review Interval Continuous Review System The inventory level on-hand and on-order for this system is checked whenever a change in inventory level occurs and when the reorder point is reached a restocking order is released Periodic Review System In this model an order is placed every “n” time periods. The order quantity is variable and essentially replaces the items consumed during the current time period 8-11 dp&c Chapter8 Continuous and Periodic Review Systems Issue Continuous Periodic Lower maintenance expense X Ordering by item family X Lower inventory investment X Replenishment predictability X Overall control X Fast-moving items X Low cost bulk items X Higher customer service levels X Use of computer required X Lower purchase order costs X 8-12 dp&c Chapter8 Basic Replenishment Technique Terms Demand Determines the rate at which an item’s inventory is consumed Cycle Stock Determines the average amount of inventory on hand for a product sufficient to satisfy demand during the lead time Safety Stock Determines the extra inventory a company decides to hold in addition to cycle stock Replenishment Trigger On-Hand Balance Determines the available inventory onhand balance at which a replenishment order is triggered Determines the current available quantity of an item 8-13 dp&c Chapter8 Basic Replenishment Technique Terms (cont.) Review Interval Determines the point in time inventory balance records should be reviewed for possible replenishment Lead Time Determines the span of time from the moment the need for resupply is identified until it has been received Reorder Quantity Determines the replenishment quantity to restore inventory above the trigger point Lot Size Determines the standard quantity in which items are either manufactured or purchased 8-14 dp&c Chapter8 Chapter 8 Statistical Inventory Management Inventory Inventory Replenishment Management Basics Techniques 8-15 dp&c Chapter8 Replenishment Ordering Techniques Visual Review Two-Bin Replenishment determined by physically reviewing the inventory on-hand balance Fix order system using two containers: one for picking and one for reserve A fixed review cycle is established and Periodic Review replenishment occurs at the time of review Order Point A targeted quantity is statistically determined that is used as the trigger for replenishment TPOP A computerized method that time phases demand and replenishment activities Lean Replenishment is triggered using noncomputer tools, such as a kanban card 8-16 dp&c Chapter8 Chapter 8 Statistical Inventory Management Inventory Reorder Point Management Basics Systems 8-17 dp&c Chapter8 Order Point Technique The order point calculation consists in determining if there is enough inventory on hand to satisfy Demand during the Lead Time plus Safety Stock OP = Demand x Lead Time + Safety Stock 8-18 dp&c Chapter8 Order Point – Basic Model Demand Quantity Inventory Stockout point Time 8-19 dp&c Chapter8 Reorder Point - Exercise Objective: Calculate a reorder point Data: Average demand per week is 100 units, the replenishment lead time is 2 weeks, and the safety stock is 50 units Formula: ROP = D x LT + SS where: ROP = Reorder point D = Demand LT = Lead time SS = Safety stock Solution: 100 x 2 + 50 = 250 units 8-20 dp&c Chapter8 Reorder Point Using Trend Objective: Calculate a reorder point using trend Data: • • • • • Past week’s demand = 205 units The a factor = 0.1 Prior period’s smoothed average = 174.46 Prior period’s trend = 0.58 Lead time = 2 weeks Solution: 1. New smoothed average demand = a(Dt) + (1 – a) (Dt-1) = 0.1 x 205 + .9 x 174.46 = 177.51 2. The difference is Dt1 – Dt = 177.51 – 174.46 = 3.05 3. The trend is Trendt-1(1 – a) + a x Differencet = 0.82 8-21 dp&c Chapter8 Reorder Point Using Trend – Exercise (cont.) Solution: 4. New expected period demand is ((Trendt(1 – a) / a) + Smoothed averaget = 0.82 x 0.9/0.10 + 177.5 = 184.93 5. New forecast of reorder point demand is expected period demand x LT = 184.93 x 2 = 370 units Smoothing constant (a) Date Week 1 Week 2 Week 3 Week 4 Week 5 Week 6 Demand 170 176 181 189 196 205 Simple Average 168.00 338.00 345.00 353.50 365.75 378.88 394.44 0.1 (1-a) Smoothed Average Difference 168.00 168.20 168.98 170.18 172.06 174.46 177.51 0.9 Lead Time Trend 0.20 0.78 1.20 1.88 2.39 3.05 0.00 0.02 0.10 0.21 0.37 0.58 0.82 8-22 Expected Demand 168.38 169.84 172.04 175.43 179.64 184.93 2 Forecast 337 340 344 351 359 370 Actual Demand 315 348 394 329 352 432 Average Variance 22 -8 -50 22 7 -62 -69 dp&c Chapter8 Cyclical Order Point Using Trend Objective: Calculate a cyclical reorder point using trend Data: • • • • • 13 months of past data The a factor = 0.1 The (1-a) / a factor = 9.0 Current month’s demand = 145 units Current base series = 119.7 (calculated by using the surrounding quarter demand from the previous year.) Solution: 1. New demand ratio = current demand / current base series = 145 / 119.7 = 1.211. 2. New average ratio = (1-a) x Previous average ratio + (a x Current demand ratio) = (.9 x 1.098) + (.1 x 112.11) = 1.109. 8-23 dp&c Chapter8 Cyclical Order Point Using Trend (cont.) Solution: 3. The difference is Current demand ratio – Current average ratio = 1.211 – 1.1090.1= .011. Smoothing constant (a) (1-a) (1-a) / a 0.9 9 4. New trend Base is (1-a) x Previous difference) Demand Average trend + (a x Current Expected Expected Month Demand Difference Trend Series Ratio Ratio Ratio Demand = (.9 x .0034) + (.1 x .011) = .0042. Jan-12 115 1.050 0 1.050 Feb-13 126 120.70ratio1.044 1.049 period -0.001 average -0.0001 ratio 1.049 126.60 5. New expected is Current + (1-a) / Mar-13 141 126.30 1.116 1.056 0.007 0.0006 1.062 134.08 a + Current trend = 1.109 + 9 + .0042 = 1.148. Apr-13 135 127.30 1.060 1.057 0.000 0.0006 1.062 135.18 May-13 125 128.30 0.974 1.048 -0.008 -0.0003 1.046 134.17 6. New expected demand is Current expected ratio x current Jun-13 149 134.70 1.106 1.054 0.006 0.0003 1.057 142.38 base series = 1.1481.183 x 119.7 = 137.36 Jul-13 170 143.70 1.067 0.013 0.0016 1.081 155.37 Aug-13 Sep-13 Oct-13 Nov-13 Dec-13 Jan-14 170 158 133 114 140 145 144 134.3 119.7 113.7 112.3 119.7 1.181 1.176 1.111 1.003 1.247 1.211 1.078 1.088 1.090 1.082 1.098 1.109 8-24 0.011 0.010 0.002 -0.009 0.016 0.011 0.0026 0.0033 0.0032 0.0020 0.0034 0.0042 1.101 1.118 1.119 1.100 1.129 1.148 158.60 150.11 133.96 125.02 126.80 137.36 dp&c Chapter8 Defining Lead Time Oder Review Order Prep The time it takes for review and selection of items for replenishment order action Time to generate the order and review for quantity discounts Order Transmission Time to print, verify, and transmit order to the supply source Supplier Processing Time for supplier order processing, pick and pack, and shipment to the ordering source Receiving Time spent receiving, checking, quality control, and staging the order Item Restocking Time spent in item movement, put-away, and any final information recording 8-25 dp&c Chapter8 Defining Safety Inventory Inventory Expected demand Q A quantity of stock planned to be in inventory to protect against Q/2 fluctuations in demand or supply Cycle S Inventory Safety Stock APICS Dictionary, 13th edition T Time Q = 250 units Q /2 = 250 units / 2 = 125 units S = 125 units / 2 = 63 units Q/2 + S = 313 units 8-26 dp&c Chapter8 Normal Distribution - Diagram 1,000 1,285 715 1σ = 285 units 1,350 600 1,570 430 1,855 145 +/-1σ 68.27% +/ - 2σ 95.45% +/ - 3σ 99.73% 8-27 dp&c Chapter8 Calculating the Safety Stock – Part 1 Week 1 2 3 4 5 6 7 8 9 10 Sales Forecast 1,000 1,000 1,000 1,000 1,000 1,000 1,000 1,000 1,000 1,000 Actual Sales Absolute Deviation 550 450 1,350 350 1,175 175 1,125 125 750 250 1,425 425 675 325 876 124 1,300 300 875 125 Deviation² 202,500 122,500 30,625 15,625 62,500 180,625 105,625 15,376 90,000 15,625 Sum Absolute Deviation Sum Squared Deviation 2,649 841,001 8-28 dp&c Chapter8 Calculating the Standard Deviation – Part 2 Two methods possible: 1. Squared Deviation: Formula: SD = (Actual Demand – Forecast) 2 number of periods-1 a.) Squared deviation = 841,001 / 9 = 93444.6 b.) Standard Deviation (1s) = 93,444.44 = 305.69 units 2. MAD Method a.) Mean Absolute Deviation (MAD) = 2649 / 10 = 264.9 b.) Standard Deviation (1s) = 264.9 x 1.25 = 331.13 units 8-29 dp&c Chapter8 Reorder Point with Safety Stock Calculation Objective: Calculate a reorder point with safety stock Data: • • • • • Demand per week = 1,000 units Lead time = 2 weeks Customer service level (CSL) = 98% Standard deviation (s) = 305.69 Unit cost = US$235.00 Solution: 1. Demand during lead time = 1,000 x 2 weeks = 2,000 units 2. Safety stock (SS) = CSL x (s) = NORMSINV (.98) x 305.69 = 627.81 units 3. ROP = 2,000 units + 627.81 units = 2,627.81 units 4. SS cost = US$235 x 627.81 = US$147,535 (rounded) 8-30 dp&c Chapter8 Safety Stock Using Probability Objective: Calculate safety stock using probability Data: • • • • • • • Demand per week = 1,000 units Lead time = 2 weeks Carrying cost/unit = US$30 Cost of stock out/unit = US$100 Optimum number of replenishment orders per year = 26 Current reorder point = 2,000 units Demand above 2,000 units during reorder point period: Number of units 2,000 2,100 2,200 2,300 2,400 Probability 24% 15% 8% 2% 1% 8-31 dp&c Chapter8 Safety Stock Using Probability (cont.) Safety Stock Solution: Carrying Cost + Stock out Cost = Total Cost 1. Calculate safety (100 stock * .15 * carrying US$100 * 26) +cost by multiplying the (200 *the .08 * US$100 * 26)stock + carrying cost times safety 2,000 0 US$106,600 (300 * .02 * US$100 * 26) + 2. Calculate stock out cost: the sum of the units stocked out x (400 * .01 * US$100 * 26) = US$106,600 the probability x the unit cost x the number of orders per year 2,100 2,200 2,300 2,400 100 * US$30 = US$3,000 (100 * .08 * US$100 * 26) + (200 * .02 * US$100 * 26) + (300 * .01 * US$100 * 26) = US$39,000 200 * US$30 = (100 * .02 * US$100 * 26) + US$6,000 (200 * .01 * US$100 * 26) = US$10,400 300 * US$30 = US$9,000 400 * US$30 = US$12,000 US$42,000 US$16,400 (100 * .01 * US$100 * 26) = US$2,600 US$11,600 0 US$12,000 8-32 dp&c Chapter8 Supply Uncertainty and Safety Stock Objective: Calculate safety stock with supply uncertainty Data: • • • • • Average daily demand (D) = 250 units Lead time (LT) = 9 days Standard deviation of demand (sD) = 85 units Customer service level (CSL) = 95% Standard deviation of lead time (sLT) = 5 days Formula: 8-33 dp&c Chapter8 Supply Uncertainty and Safety Stock (cont.) Solution: 1. Solve for standard deviation of demand during the lead time: sL = = 1,275.74 2. Solve for safety stock (SS): SS = sL x CSL = 1275.74 x 1.65 = 2,105 (rounded) 3. New order point calculation: 250 (D) x 9 (LT) + 2,105 (SS) = 4,355 units 8-34 dp&c Chapter8 Min/Max Order System Definition: Called the min/max system because the inventory position should always be a quantity located between the minimum and maximum stocking values Minimum quantity calculation: Use the standard reorder point equation Maximum quantity calculation: Function of the average daily demand, lad time, and the standard deviation Formula: (Demand x lead time) + (customer service level x standard deviation x square root of the lead time) 8-35 dp&c Chapter8 Min/Max Order System – Example Objective: Calculate min/max order quantity Data: • • • • • Average daily demand (D) = 50 units Lead time (LT) = 4 days Standard deviation of demand (sD) = 20 units Customer service level (CSL) = 98% Min quantity = 125 units Solution: Max = (D x LT) + (CSL x s x 𝐿𝑇) = (50 x 4) + (2.05 x 20 x 4) = 200 + 82 = 282 8-36 dp&c Chapter8 Periodic Review – Overview Definition: Items are reviewed periodically and replenishment orders are launched at each review. The order quantity contains sufficient stock to bring the inventory position up to a target inventory level Uses: 1. Used when it is difficult to record withdrawals and additions of stock on a continuous basis 2. Used when items are ordered in families 3. Used for items with a limited shelf life 4. Significant economies can be gained by ordering in bulk 8-37 dp&c Chapter8 Periodic Review System Technique Review Cycle 1 Target Inventory A 2 3 Order Quantity Demand Review Point Quantity Replenishment Receipt Lead Time Safety Stock 8-38 dp&c Chapter8 Periodic Review Calculation Equations: a. Order review cycle = dividing an item’s units sold annually by the standard lot quantity b. Target inventory level (TI) = TI = (D(L + T)) + (SSsD L T ) where D = the demand rate L = item lead time T = the review period SS = item safety stock 8-39 dp&c Chapter8 Periodic Review Calculation – Example Objective: Calculate a periodic review replenishment Data: • • • • • • Average weekly demand (D) = 1,000 units Lead time (L) = 2 weeks Standard deviation of demand (sD) = 100 units Customer service level (CSL) = 98% Review cycle (T) = 4 weeks On-hand balance = 2,250 units Solution: 1. Demand during lead time and review cycle: 1,000 x (2 + 4) = 6,000 units 2. Target inventory: 6,000 + (503 x 100 x 2 4) = 6,503 units 3. Reorder quantity: 6,503 – 22,50 = 2,403 units 8-40 dp&c Chapter8 Chapter 8 Statistical Inventory Management Inventory Order Quantity Management Basics Techniques 8-41 dp&c Chapter8 Trial and Error Method a. Order cost: (Annual inventory usage / order quantity) x ordering cost (24,000 units / 2,000 units) x US$20 = US$240 b. cost: b. Carrying Carrying cost: Order quantity / 2 x carrying cost % x unit cost (2,000 / 2) units x 24% x US$0.25 = US$60 Order Quantity Order Per Year Carrying Cost Order Cost Total Cost 2,000 12 $60 $240 $300 4,000 6 $120 $120 $240 8,000 3 $240 $60 $300 12,000 2 $360 $40 $400 24,000 1 $720 $20 $740 8-42 dp&c Chapter8 EOQ Graph Costs 800 700 Total Cost 600 500 Optimal Cost Carrying Cost 400 300 200 Ordering Cost 100 50 Quantities 2000 4000 8000 8-43 12000 24000 dp&c Chapter8 EOQ Calcualtion 2 x Demand x Cost of ordering Inventory carrying cost % x Unit cost Annual demand Cost of ordering Unit cost Carrying cost = = = = 20,000 units US$125 US$34 21% 2 x 20,000 x US$125 = 837 units 21% x $34 8-44 dp&c Chapter8 EOQ Assumptions • The cost of the product does not depend on the replenishment • • • • • • • quantity There are no minimum or maximum restrictions on the replenishment quantity Items are considered totally independent of each other Lead time is zero No shortages are permitted and the entire order quantity is delivered at the same time The minimum purchase quantity from the supplier is not three or four times the calculated QOQ Purchase order preparation and carrying costs are known and constant Very high or very low item usage needs to be reviewed in relation to unit costs before applying the EOQ technique 8-45 dp&c Chapter8 Quantity Discounts – Example Objective: Choose from two suppliers based on quantity discounts Data: • • • • Annual demand (D) = 30,000 units Ordering cost (OC) = US$200 Item unit cost (UC) = US$15 Carrying cost (k) = 22% Steps (base calculation): 1. Calculate EOQ = 1,907 (1,906.93) 2. Calculate number of orders per year = 30,000 / 1906.93 = 15.7 3. Calculate material cost = EOQ x orders per year x item unit cost = 1,906.93 x 15.7 x US$15 = US$450,000 4. Calculate ordering cost = order cost x orders per year = US$200 x 15.7 = US$3,146.43 8-46 dp&c Chapter8 Quantity Discounts – Example (cont.) Steps: 5. Carrying cost = (EOQ / 2) x unit cost x carrying cost = (1906.93 / 2) x US$15 x 22% = US$3,146.53 6. Total cost = material cost + ordering cost + carrying cost = US$456,292.85 Steps (supplier 1): Data: • Discount price for minimum quantity of 5,000 units = US$14.55 • Order per year = 6 Summaries: 1. 2. 3. 4. Material cost = US$436,500 Ordering cost = US$1,200 Carrying cost = US$8,002.50 Total cost = US$445,702.50 8-47 dp&c Chapter8 Quantity Discounts – Example (cont.) Steps (supplier 2): Data: • Discount price for minimum quantity of 12,000 units = US$14.25 • Order per year = 2.5 Summaries: 1. 2. 3. 4. Material cost = US$427,500 Ordering cost = US$500 Carrying cost = US$18,810 Total cost = US$446,810 Decision: Suppler 1 has the lowest costs 8-48 dp&c Chapter8 Joint Replenishment – Example Objective: Calculate joint replenishment for three items Data: • • • • • • • Annual demand for item #3925 = 6,000 units Annual demand for item #3819 = 3,575 units Annual demand for item #3442 = 1,250 units Ordering cost (OC) = US$200 Transportation cost (TC) = US$350 Item unit cost (UC) = US$45 Carrying cost (k) = 20% Steps (base calculation): 1. Order cost = (Demand / EOQ) x (Order cost + Transportation cost) 2. Carrying cost = (EOQ / 2) x unit cost x carrying cost 3. Total cost = ordering cost + carrying cost 8-49 dp&c Chapter8 Joint Replenishment – Example (cont.) I. The three items ordered independently Summary: Ordered Independently Product #3925 #3819 #3442 EOQ 856 661 391 # Orders / year 7.0 5.4 3.2 Carrying Cost $ 3,853.57 $ 2,974.58 $ 1,758.91 Ordering Cost $ 3,853.57 $ 2,974.58 $ 1,758.91 Total Cost $ $ $ $ Total Cost 7,707.14 5,949.16 3,517.81 17,174.11 $ $ $ $ Total Cost 7,708.97 3,678.77 2,217.68 13,605.42 II. The three items ordered jointly Summary: Ordered Jointly Product #3925 #3819 #3442 # Orders / year 7.16 7.16 7.16 Order Lot Size 837.9 499.2 174.6 Carrying Cost $ 3,770.56 $ 2,246.62 $ 785.53 8-50 Ordering Cost $ 3,938.41 $ 1,432.15 $ 1,432.15 Total Cost dp&c Chapter8 Joint Replenishment – Example (cont.) III. The three items ordered jointly: selected family items Steps: 1. Identify the most frequently order item (i) 2. Equation: Order frequency for item #3925 3. Calculate the frequency for items #3819 and #3442 4. Determine the order frequency for each item as a multiple of the order frequency of the most ordered item (mi). 5. For item #3819, 7.01 / 7.01 = 1. 6. For item #3442, 7.01 / 5.30 = 1.32 7. Recalcuate the order frequency of items 8. For item #3819, 20% x US$45 x 1 x 6,000 = US$54,000. 8-51 dp&c Chapter8 Joint Replenishment – Example (cont.) III. The three items ordered jointly: selected family items Steps: 9. Sum the values for step 8 10. US$54,000 + US$32,175 + $22,500 = US$108,675 11. Divide the standard order cost by the order frequency 12. For item #3925, 200/1 = US$200 13. Sum the values for step 11 14. US$200 + US$200 + US$100 + US$350 (TC) = US$500 15. New order frequency for item #3925 = 16. New order frequency for item #3819 = 8 / 1 (original rounded order frequency fi) = 8 orders. 8-52 dp&c Chapter8 Joint Replenishment – Example (cont.) III. The three items ordered jointly: selected family items Steps: 17. New order frequency for item #3442 = 8 / 2 (original rounded order frequency fi) = 4 orders 18. Calculate order costs by using steps for ordering jointly Ordered Selectively Product #3925 #3819 #3442 Product #3925 #3819 #3442 Order Frequency 7.01 8.97 5.30 #Orders / year 8.00 8.00 4.00 Freq to most ordered (f ) Round Order Frequency (fi ) $ 54,000.00 $ 32,175.00 $ 22,500.00 SUM $ 108,675.00 SUM TC+ S R/f i Order Lot Size Carrying Cost Ordering Cost 750.4 $ 3,376.94 $ 4,397.47 447.1 $ 2,012.09 $ 1,599.08 312.7 $ 1,407.06 $ 799.54 SUM $ 6,796.09 Total Cost 1.00 0.78 1.32 1.00 1.00 2.00 Cost (kUCf i D i ) 8-53 Order Cost / f i $ $ $ $ $ $ $ $ $ 200 200 100 500 850 Total Cost 7,774.41 3,611.17 2,206.60 13,592.19 dp&c Chapter8 Transportation EOQ Objective: Calculate the EOQ with transportation cost Data: • • • • • • Annual demand (D) = 25,000 units Ordering cost (OC) = US$100 Item unit cost (UC) = US$10 Carrying cost (k) = 22% Rate for small shipments = US$1.25 per unit Rate for large shipments = .75 per unit Step 1: Base EOQ calculation: Item EOQ #3925 1,507.56 Orders/ Year Carrying cost Ordering cost Total cost 17 $1,658.31 $1,658.31 $3,316.62 8-54 dp&c Chapter8 Transportation EOQ (cont.) Step 2: Current EOQ freight cost: 1. Rate for EOQ of 1,507.56 = (Rate x order quantity) x number of orders per year = US$1.25 x 1,507.56 x 17 = $31,250 2. Freight added EOQ = Ord qty Orders/ Year Carrying cost Ordering cost Shipment cost Total cost 1,507.56 17 $1,658.31 $1,658.31 $31,250 $34,566.62 Step 3: Large shipment rate requires OQ = 5,000 units Ord qty 5,000 Orders/ Carrying Year cost 5 $5,500 Ordering cost Shipment cost Total cost $500 $18,750 $24,750 8-55 dp&c Chapter8 Replenishment by Item Class – Steps 1. Divide the inventory into classes based on volume usage, dollar value, or other parameters. 2. Link items to classes. 3. Assign an inventory turnover target for each class. 4. Determine the level below which only dead and obsolete products reside. Eliminate this class from the procedure. 5. Establish the replenishment quantity for each class by dividing the annual usage of each item by the turnover value. 6. Recalculate the inventory classification scheme for all items at least once a month, depending on the expected inventory turnover. 8-56 dp&c Chapter8 Replenishment by Item Class – Calculation Objective: Replenishment using order class Data: ABC Class A B C D E # of Total Items 1,200 10,500 25,250 8,000 6,500 Expected Turns 24 12 6 3 1 Order Interval 15 days 1 month 2 months 4 months 12 months Calculation: Calculate a class A item order quantity with yearly demand of 24,000 units 24,000 units / 24 turns = 1,000 units 8-57 dp&c Chapter8 Investment Order Limit – Calculation Objective: Determine investment limit for multiple items Data: • • • • • • • • • Annual demand for item #3925 = 14,000 units Annual demand for item #3819 = 9,500 units Annual demand for item #3442 = 7,000 units Unit cost #3925 (UC) = US$20.00 Unit cost #3819 (UC) = US$10.00 Unit cost #3442 (UC) = US$15.00 Ordering cost (OC) = US$100 Carrying cost (k) = 20% Investment limit (IL) = US$16,000 8-58 dp&c Chapter8 Investment Order Limit – Calculation (cont.) Step1: Calculate base EOQ for each item EOQ Product #3925 #3819 #3442 # Orders / year 16.73 9.75 10.25 EOQ 836.66 974.68 683.13 Carrying Cost $ 1,673.32 $ 974.68 $ 1,024.70 Ordering Cost $ 1,673.32 $ 974.68 $ 1,024.70 Total Cost $ 3,346.64 $ 1,949.36 $ 2,049.39 Step2: Determine total inventory investment Inventory investment = UC1(Q1/2) + UC2(Q2/2) + UC3(Q3/2) = US$20(836.66/2) + US$10(974.68/2) + US$15(683.13/2) = $18,363.47 Step3: Adjust original EOQ quantities Since inventory investment of $18,363.47 exceeds the US$16,000 level, the original EOQs will need to be reduced by inflating (k) and determining an adjustment factor (a) 8-59 dp&c Chapter8 Investment Order Limit – Calculation (cont.) Step3: Adjust original EOQ quantities Since inventory investment of $18,363.47 exceeds the US$16,000 level, the original EOQs will need to be reduced. The formula is: Step 4: Adjust original EOQ quantities with a factor 8-60 dp&c Chapter8 Investment Order Limit – Calculation (cont.) Step 5: Combine new EOQ values and validate that they match the investment limit Min Investment EOQ Product #3925 #3819 #3442 # Orders / year 19.20 11.19 11.76 New EOQ 728.98 849.23 595.21 Carrying Cost $ 1,457.96 $ 849.23 $ 892.81 Ordering Cost $ 1,920.50 $ 1,118.66 $ 1,176.06 Totals 8-61 Total Cost $ 3,378.45 $ 1,967.89 $ 2,068.87 $ 7,415.21 Investment Cost $ 7,289.78 $ 4,246.17 $ 4,464.06 $ 16,000.00 dp&c Chapter8 Chapter 8 Statistical Inventory Management Inventory Lean Inventory Management Basics Management 8-62 dp&c Chapter8 Defining Lean A management and operations philosophy based on the planned minimization of all resources, the continuous improvement of productivity, and a relentless search to convert product and process waste into customer winning value both within the enterprise and outside in the supply chain. APICS Dictionary, 13th edition 8-63 dp&c Chapter8 Lean Philosophy Operations Excellence Dedication to continuous product and process improvement focused on total customer service Value-Added Processes Eliminate all business functions and activities that do not add value to the company or the customer Continuous Improvement All aspects of business processes must be dedicated to incremental improvement in ways great and small Lean/TQM Combination of lean techniques focused on productivity, total quality management (TQM), and people empowerment 8-64 dp&c Chapter8 Lean Tactics to Reduce Inventory • Focus on continuous inventory reduction • Implement an inventory pull system • Establish lean ordering and delivery with suppliers • Deliver inventory directly to the point of use • Map and streamline inventory flows • Reduce batch sizes and production queues • Reduce setup times 8-65 dp&c Chapter8 Inventory Flow Analogy Clogged Inventory Channel Poor Controls Inventory Inventory Inventory Lack of Training Unclear Responsibilities Lack of Disciplines Open Inventory Channel Inventory 8-66 dp&c Chapter8 Key Points of a Lean-Pull System Produce products only to customer order Create a level schedule so that production may proceed according to a desired flow rate Schedule a mix of products in varying lot sizes so that the factory or the supplier produces and delivers inventory close to the same mix of products that will be sold that day Link scheduling management to pull production through the use of visual demand signals Maximize process flow-through by maximizing the flexibility of people and machinery 8-67 dp&c Chapter8 The Pull System – Basic Concepts C B Operator #1 receives requirement and makes more inventory Demand pull signal triggered and requirement sent to feeding workstation Buffer Inventory Process 1 Operator #1 Operator #2 removes material from buffer inventory to start work Process 2 Operator #2 Workstation #1 D A Workstation #2 Replenishment quantity moved to Workstation #2 buffer inventory 8-68 dp&c Chapter8 Three Types of Kanban Production Specifies the quantity of product that must be produced by upstream production work centers Move Specifies the quantity of product that will be moved from a reserve or remote buffer location to the requested buffer area Supplier Is used in place of a purchase order to replenish products from an outside supplier 8-69 dp&c Chapter8 Calculating Supplier Kanbans Objective: Calculate the number of kanbans in a system Data: • • • • • • Daily demand (D) = 300 units Transit delay pick up (Td) = 2 days Transit delay delivery (Tp) = 2 days Safety stock (SS) = 50% Kanban container size (Q) = 50 units Deliveries per day (R) = 1 delivery per day Equation: 𝐷 𝑇𝑑 + 𝑇𝑝 (1 + 𝑆𝑆) # 𝑘𝑎𝑛𝑏𝑎𝑛 = 𝑄𝑅 Solution: ((300 x (2 + 2)) x (1 + .50) / (1 x 50) = 36 kanbans 8-70 dp&c Chapter8 “Education in Pursuit of Supply Chain Leadership” dp&c Chapter8 Chapter 8 End of Session 8-71 dp&c Chapter8