Land Application of Food Process/Rinse Water

advertisement

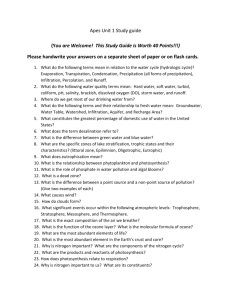

Land Application of Food Process/Rinse Water California League of Food Processors Brown and Caldwell Kennedy/Jenks Consultants Manual of Good Practice for Land Application of Food Processing/Rinse Water Rob Neenan Director of Regulatory Affairs California League of Food Processors Background • CLFP, in conjunction with Brown and Caldwell and Kennedy-Jenks developed the first Manual in 2002 for fruit and vegetable processors. • The objective was to provide a comprehensive science-based guide to processors and consultants. • RWQCB staff expressed some concerns about several elements of the 2002 Manual, including text regarding salinity, source control, and BOD loading rates. • CLFP recognized the need to address concerns and obtain a common agreement as to what should be expected/required of application sites. • In 2006 CLFP collected financial contributions from members to revise the document. 2006 – 2007 Manual Revision Project Objectives • Provide detailed technical guidance to industry based on the best available science. • Encourage implementation of best practices. • Promote clear and consistent risk-based regulatory requirements. • Improve the level of communication and cooperation between processors and Board staff. • Coordinate CLFP efforts with other industry wastewater research initiatives. • Identify areas where further research would be useful. Project Participants CLFP Consultants and Working Group Consultants: • Brown & Caldwell: Rob Beggs, Ron Crites • Kennedy-Jenks: Sharon Melmon, Gary Carlton, Bob Chrobak Steering Committee: • RWQCB Staff: Pamela Creedon, Wendy Wyels, Bert Van Voris, Jo Anne Kipps • State Water Board: Wayne Verrill • Food Processors: Tim Ruby, Tim Durham, Ray Medeiros, Dennis Tristao, Ben Hall, Doug Langum • Others: Paula Hansen, Dan Burgard, Troy Elliott, Matt Wheeler, Burt Fleischer Project Timeline • Formation of Manual working group—March 2006 • First meeting of working group—May, 2006 • Subcommittee meetings– June to October, 2006 • Oct. 2006—first draft completed • Oct – Jan 07 review of the draft document • February 27, 2007 workshop • Spring 2007--Manual presented to RWQCB for adoption as a guidance/reference document (but not a regulatory document). Next Steps • Present the document to the Regional Board • Distribute the document to industry • Possible annual training classes • Continue to pursue funding for additional research Manual Contents • Introduction • Salinity Control • Beneficial Reuse • Distribution • Regulatory • Monitoring • Process Water • Research Needs • Site Characteristics • Examples • Crops and Climate • Appendices • Loading Rates Appendix Material • Glossary • Anti-Degradation Policy • Form 200 and Information Needs • Monitoring Wells • Soil Evaluation • Groundwater Transport • Measuring Salinity and Organics Chapter 1 Introduction Subcommittees • Development of a Waiver • BOD Loading Rate • Point of Compliance • Soil Monitoring Waiver Subcommittee • Rob Beggs • Dan Burgard • Bob Chrobak • Wendy Wyels BOD Subcommittee • Bob Chrobak • Ron Crites • Troy Elliott • Jo Anne Kipps • Tim Ruby • Wayne Verrill Point of Compliance • Rob Beggs • Dan Burgard • Gary Carlton • Tim Durham • Burt Fleischer • Bill Jennings • Bert Van Voris • Matt Wheeler Soil Monitoring • Rob Beggs • Dan Burgard • Wayne Verrill Chapter 2 Beneficial Reuse Chapter 3 Regulatory Constraints for Land Application California Framework • Porter Cologne Act – Cannot impact beneficial uses of GW • Basin plans – Define beneficial uses for each region • Anti-degradation policy – GW protection beyond beneficial uses – Best Practicable Treatment and Control Best Practicable Treatment and Control • Show progress by: – Comparing process water treatment and control options – Segregating high-strength wastes – Demonstrating source reduction Waste Discharge Requirements • Submit Report of Waste Discharge in advance • ROWD defines planned operations and wastewater management strategy • ROWD includes – Site and facility description – Water balance – Cropping plan – Monitoring plan Waiver Programs • Existing waivers – Small processors and wineries – Ag commodity waste – Non-toxic industrial waste (soil amendment) • Potential low-threat waiver – Low constituent loading – Appropriate management – Lowest “relative risk” category in Manual Chapter 4 Process Water Characteristics Potentially Limiting Constituents • Nitrogen • Organics • Salinity Nitrogen • Process water typically contains organic N and ammonium • Converted to nitrate in moist, well-aerated soil • Plants take up nitrate and ammonium • Nitrate may be leached from soil or lost to denitrification Measurement of Nitrogen • Analyze process water for: – Total Kjeldahl Nitrogen (TKN) • Organic N + Ammonium (NH4+) – Nitrate (NO3-) – Ammonia (NH3) • Refer to Chapter 7 for guidance on evaluating nitrogen balance Organics • Decaying plant/animal residue • Enhances soil humus and fertility, boosting crop production • Rapid aerobic decomposition can lead to anaerobic soil conditions • Must balance loading to crop demand Measurement of Total Organics • Use 5-day Biochemical Oxygen Demand (BOD5) – Chemical Oxygen Demand (COD) test may overstate BOD – Total organic carbon (TOC) captures nonbiodegradable fraction Salinity • Sources may include supply water, processing, sanitation chemicals • Risk of leaching to groundwater if land application system is not well managed • Likely to be the limiting constituent for land application and cropping Measurement of Process Water Salinity • Want to quantify only the minerals – Analyze for individual ions – Correlate sum of ions with fixed dissolved solids (FDS) – Use FDS x correction factor • Total dissolved solids (TDS) analysis is a sum of minerals and non-minerals Irrigation Water Quality • Most crops tolerate irrigation water with EC of 0 to 1 dS/M • Yield losses occur at EC of >3 dS/M • Refer to Table 4-1 for Irrigation Quality Guidelines Chapter 5 Site Characteristics Climatic Factors • Rainfall • Evapotranspiration (ET) • Temperature Topographic Factors for Crop Irrigation Percent Slope Limitations • <2 Slight • 2-6 Moderate • 6-12 Severe • >12 Very Severe Soil Characteristics • Soil texture • Soil depth • Infiltration rate • Soil chemistry Soil Treatment Factors • Filtration – removal of suspended solids • Adsorption – removal of P, NH4,metals • Organic content – sustainable infiltration, adsorption, energy, fertility Soil Infiltration • Infiltration rate • Available water holding capacity • Deep percolation • Depth of soil, > 2 ft • Depth to groundwater, > 2 ft during application season Soil Chemistry • pH • Electrical conductivity (EC) • Cation exchange capacity (CEC) • Exchangeable sodium percentage (ESP) • Soil nutrients, N,P,K Groundwater Quality • Preapplication backgound quality • Determine preapplication flow direction • Hydropunch versus permanent wells Chapter 6 Crop Selection Crop Water Use • Reference ET, Crop Coefficients • ETc = ETo·Kc • Pan ET can also be used to estimate ETo Crop Coefficients Table 6-6. Crop Coefficients for Perennial Forage Crops (Doorenbos and Pruitt, 1977) Condition Crop Alfalfa Minimum Mean Peak Grass for hay Minimum Mean Peak Clover, grass legumes Minimum Mean Peak Pasture Minimum Mean Peak Humid (light to moderate wind) Dry (light to moderate wind) 0.50 0.85 1.05 0.40 0.95 1.15 0.60 0.80 1.05 0.55 0.90 1.10 0.55 1.00 1.05 0.55 1.05 1.15 0.55 0.95 1.05 0.50 1.00 1.10 Kc (minimum) represents conditions just after cutting. Kc (mean) represents value between cuttings Kc (peak) represents conditions before harvesting under dry soil conditions. Under wet conditions increase values by 30 percent. Nutrient Uptake Table 6-7. Nutrient Uptake Rates for Selected Crops (USEPA, 1981) Crop Lb/acre·year Nitrogen, N Phosphorus, P Potassium, K 200-600 115-200 20-30 35-50 155-200 220 Coastal bermudagrass 350-600 30-40 200 Kentucky bluegrass 175-240 40 175 Quackgrass Reed canarygrass 210-250 300-400 25-40 35-40 245 280 Ryegrass 160-250 50-75 240-290 Sorghum-Sudan Sweet clover Tall fescue Orchardgrass 180-260 155 130-290 220-310 18-26 18 27 18-45 90-140 90 270 200-280 Barley 110 13 18 Corn 155-220 18-27 100 Cotton 65-100 13 36 120 13 60 Forge crops Alfalfa Bromegrass Field crops Grain Sorghum Rooting Depth and N Loading • Rooting depth - Deeper roots provide more opportunity for nutrient uptake. • Matching N uptake with available N – difficult because of mineralization lag • Match annual N uptake rates, monitor soil nitrate, modify application timing if necessary. Salt Uptake Table 6-9. Yield and Salt Removal of Various Crops Average Yield dry tons/acre Salts Removed lb/acre Ash % Alfalfaa 6.6 2093 16% Barleya 3.9 759 10% Cornb 11.7 1750 7.5% Winter wheatb 5.2 1321 13% Tall Fescuea 8.4 2083 12% Source: Tim Ruby, Del Monte Foods Company Process water spray irrigation site located outside Boise, ID, three year average b Process water surface irrigation site. Kingsburg, CA, one year a Apply nutrient and salt uptake for calculations in Chapters 7 and 12. Chapter 7 Loading Rates and System Design Approach Avoiding Unintended Consequences Development/ Application of Risk Categories Development/ Application of Risk Categories Risk Category Description 1 (lowest) Loading rates substantially below agronomic rates. Waiver may be appropriate for low flows. 2 Loading rates up to agronomic criteria, minimal risk of unreasonable groundwater degradation. 3 Loading rates above agronomic criteria, but within calculated capacities. 4 (highest) Loading rates above calculated capacities; pilot testing recommended to prove efficacy. Objective: Encourage greater reuse with lower loading rates. Loading-Rate Based Planning and Design • Nitrogen • Organic (BOD) • Salts • Others (hydraulic, TSS, specific ions, etc.) Nitrogen Nitrogen Loading Rate Categories Risk Category 1 2 3 Criteria (% of Crop N Requirements) <= 50% 50% to 150% > 150% Organic Organic Loading Rate Categories Table 7-5. Organic Loading Rate Risk Categories Risk Categorya Averageb BOD5 Loading Rate, lb/acre•d 1 <= 50d 2 <= 100d > 5 ft 3 > 100d >2 ft Depth to Groundwaterc, ft > 5 ft Notes De-minimus loading rate is indistinguishable from common agronomic conditions. Good distribution is important. Good distribution more important. Use Eqs. 7-2 and 7-4 in design. Good distribution very important. See Chapter 10 for monitoring recommendations. Note: Both BOD loading and depth to groundwater apply. Hydraulic Loading • Try to match typical irrigation rates. • Higher rates in “shoulder months” are OK if designed properly. • Supplemental low salinity water is desirable during periods of low process/rinse water flows. Salinity Risk Categories (concentration based guidelines, based on Tulare Lake Basin Plan) Risk Category Process/Rinse Water FDSa (mg/L) 1 < local irr.b 2 < local irr.+ 320 AND < 640 mg/L 3 >local irr.+320 OR >640 mg/L, but not excessive for crops grown a. FDS is used as a reasonable basis for comparison. b. “Local irr.” refers to the upper end of the range of TDS concentrations of local irrigation wells near the process/rinse water reuse area. Salinity Compliance Approaches • Category Guidelines • Site Specific Factors and Permit Requirements • BPTC (source control, switch to K) • Average Annual Deep Percolate Salinity (Cd) Other Constituents • Solids: TSS, SM (odors, vectors – good distribution uniformity important) • Specific ions – sodium, chloride, boron, etc. (soil and crop effects) • Acidity (high rainfall areas) • THMs (from using bleach, chlorine gas) Using Loading Rates in Design • Identify likely limiting design parameters. • Perform initial loading rate and land area needs calculations. • Consider desired risk category. • Iterative process; consider options for site, crops, pretreatment, distribution. Chapter 8 Source Control Sources of Waste Constituents • Filtration backwash from supply water treatment • Water softener regenerant • Boiler blowdown • Flume or other transport water • Storage and processing solutions • Cleanup and sanitation water Waste Minimization • Source reduction and recycling • Critical for salt control • Strategies (most to least favorable): - Eliminate - Reduce - Recycle - Treat at the source - Treat at end of the pipe Waste Minimization Approach • Planning • Assessment • Feasibility Analysis • Implementation Assessment • Compile and evaluate facility data – Source water chemistry and volume – Chemical usage data – Individual waste stream characteristics – Total effluent characteristics – Energy use – Permit requirements Assessment • May need to collect additional data to characterize discrete waste streams • Data provides basis for identifying waste minimization options • Consider facility operations holistically when looking for options Typical Options • Product substitution • Housekeeping changes • Process modifications • Operational changes • Recycling/reuse Feasibility Analysis • Technical and economic evaluation • Consider: – Impact of change on product – Ease of implementation and maintenance – Regulatory requirements – Capital and ongoing O&M costs – Risks Develop Action Plan • Describe: – Production activities and associated waste streams – Options that were considered – Feasibility analysis results – Rationale for selected option(s) – Schedule for implementation Implementation • Install equipment, initiate procedural changes • Monitor and record results • Reevaluate program annually – Did the changes “stick”? – Are goals being met? – Are additional changes needed? – Communicate successes to staff Pretreatment for Land Application • Solids removal • Constituent removal – Screening – Salinity – Centrifuging – BOD – Gravity settling – Nitrogen – Dissolved air floatation – Filtration Salinity Reduction Options • Last resort – try source reduction first • Membrane systems – Reverse osmosis or nanofiltration – Expensive – Residual brine to manage • Evaporation – Residual brine to manage BOD Pretreatment • Could be needed if BOD load exceeds agronomic capacity • Non-soluble BOD screened out • Soluble BOD treatment – Membranes – Aerobic systems – Anaerobic systems Nitrogen Pretreatment • Could be needed if nitrogen load exceeds agronomic capacity • Biologic treatment – Expensive – Inconsistent loading can cause upsets – Used for municipal wastewater treatment Chapter 9 Distribution Systems Distribution Systems Components • Collection • Pretreatment • Storage • Transmission • Field Distribution • Tailwater/return Flow System Storage Considerations • Odors/aeration • Lining • Equalization • Blending • Pumping Transmission Considerations • Cleaning and flushing pipelines and ditches • Accommodate supplemental water • Prevent and monitor for leaks Results of an undetected leak Field Distribution Systems • Surface • Sprinkler – periodic move – mechanical move – solid set • Drip See Tables 9-2 and 9-3 for considerations. Chapter 10 Monitoring Risk Based Monitoring Approach What we want to avoid! Monitoring Approach – Process/Rinse Water Table 10-5. Typical Process/Rinse Water Quality Monitoring Parameters and Frequency Parameter pH EC Temperature BOD/COD TSS FDS Objective: Compliance (C), Operational (O) or Both (B) B B B C C C Risk Cat. Typical Frequency 1 Monthly 2 Weekly 3 Daily or continuous 1 Monthly 2 Weekly 3 Daily/cont. all Process specific 1 2 / year 2 2 / month 3 Weekly 1 2 / year 2 Monthly 3 2 / month 1 2 / year 2 Monthly Comment Low pH may be used as an indirect indicator of anaerobic conditions. The EC is primarily a result of the dissolved inorganic ions in the sample – measurement can be correlated with FDS and with TDS when BOD is negligible. Often not of critical importance BOD loading rates assigned in WDRs should reflect site assimilation capacity and need to prevent nuisance odors. COD is a good proxy for BOD for high frequency characterization. Higher TSS levels can result in fouling of pipelines and nozzles. High TSS may not be distributed well with border strip irrigation. Measurement of the inorganic portion of TDS, without the organic fraction, is important; FDS, measured by heating a sample to Monitoring Approach - Soil Table 10-7. Soil Chemical and Physical Monitoring Parameters Parameter Organic matter, CEC, TKN pH, ECe, NO3-N, NH4-N Available K, Available P Extractable Na, Ca, Mg, Cl, SO4, SAR, ESP Risk Category Frequency Depths (feet) 1 Initial 0-2 2,3 5 years 0-1, 2-3, 4-6 1 Annual 0-2 2 Annual 0-1, 2-3, 4-6 3 2 / year 0-1, 2-3, 4-6 1 5 years 0-2 2,3 Annual 0-1, 2-3, 4-6 1 5 years 0-2 2,3 Annual 0-1, 2-3, 4-6 Considerations Slowly changing basic soil parameters. Mobile constituents and good indicator parameters to assess soil fertility and process water loading capacity. Low mobility nutrients Soil salinity and sodicity status parameters, some mobile Definitions: Electrical conductivity of saturated paste extract (ECe),Total Kjeldahl Nitrogen (TKN), Nitrate-Nitrogen (NO3-N), Ammonium-Nitrogen (NH4-N), Calcium (Ca), Magnesium (Mg), Potassium (K), Sodium (Na), Sulfate (SO4), Chloride (Cl), Phosphorus (P), Sodium Absorption Ratio (SAR), ESP (Exchangeable Sodium Percentage) Other Monitoring Issues • Use lysimeters for test plots. • Consider geophysical surveys for long term salinity monitoring. • Crop management and monitoring (vigor, ash, nutrients) • Operational adjustments (Table 10-14) Groundwater Monitoring Requirements • Minimum number of wells: – one upgradient / two downgradient • Downgradient point of compliance: – As close to edge of application area as practicable (within 150 feet) – Within application area is not appropriate Groundwater Monitoring Requirements • First encountered groundwater • If groundwater is deep (>100 ft), use soil monitoring as an early indicator Compliance vs Operational • Compliance monitoring is specified by WDRs for the facility • Operational monitoring can include – Compliance monitoring – Routine inspections – Soil sampling and other techniques to obtain early warning of potential impacts Chapter 11 Research Needs Organic/N Topics • Determine soil aeration under various BOD loading rates. • Evaluate use of soil-gas testing to confirm soil aeration under various BOD loading rates. • Assess the correlation of BOD loading with TDS, alkalinity, dissolved iron and manganese, and arsenic in receiving groundwater. • Determine the minimum organic loading necessary to maintain and enhance soil health and fertility. • Determine the nitrogen mineralization rates of organic nitrogen for common process/rinse waters. Salinity Management • Compare the salinity uptake by various cover crops, considering climate and applied water quality. • Identify best practicable treatment and control methods to minimize salinity impacts on groundwater. • Determine if crops can be developed to remove specific ions, such as sodium and chloride. • Determine the management approach to long-term immobilization of salts by chemical precipitation in the soil mantle. Salinity Control • Identify alternative methods for peeling fruit to minimize use of caustic. • Identify alternative cleaning products to minimize introduction of sodium. • Identify alternatives to water softener and boiler blowdown chemicals. Groundwater Protection • Evaluate the actual nature and extent of groundwater quality impacts at land application sites based on existing groundwater quality monitoring data. • Determine the protection from degradation of TDS afforded by using potassium in place of sodium in caustic and water softener regeneration. Vadose Zone Monitoring • • • Assess the correlation between the thickness of vadose zone and treatment processes. Define appropriate operational monitoring programs for land application sites to ensure that the systems are functioning as intended. Establish whether vadose zone monitoring by lysimeters can provide representative samples. Compare intensive soil sampling versus lysimeters for operational monitoring. Soil/Site Selection • Investigate whether long-term wastewater application has an effect on soil buffering capacity. • Confirm that soil (and soil solution) is not adversely affected by wastewater with a pH in the range of 3 to 10. Crop Irrigation • Determine whether the guidelines for land application of food process rinse water are applicable to the reuse of process wastewater for crop irrigation. Chapter 12 Design Examples Are we having fun yet? Steps • Initial process/rinse water characterization • Identify/investigate sites • Select initial risk category target • Calculate loading rates of major constituents, compare with guidelines • Iterate as necessary; considering site(s), crops, pretreatment, distribution Example 1 – N and BOD Loading Rate = Flow * Concentration * Conversion Factor * Duration Area Loading Rate (lbs/ac) = Total Loading Rate / Area Daily Area Loading Rate (lbs/ac*d) = Area Loading Rate / Days Note: lbs/ac*d means same thing as lbs/ac/d • Calculate for N • Calculate for BOD • Increase site area as needed and available for the limiting loading rate Example 1 - Hydraulic • Get ET factors (CIMIS), other hydraulic data (Table 124). • Calculate agronomic irrigation rates (monthly, or at least max and min) using Eq. 7-5. • Determine needs for supplemental water, additional land, storage, or EPA Type 1 operation (application in excess of irrigation need). Example 1 – Salts and Other Considerations • Check FDS concentration against guidelines. • Select/finalize appropriate distribution system. • Plan other associated facilities. Example 2 • Same broad steps as for Example 1: – – – – – Initial process/rinse water characterization Identify/investigate sites Select initial risk category target Calculate loading rates; compare with guidelines Iterate as necessary; considering site(s), crops, pretreatment, distribution • More calculation details: – N loss – Aeration capacity – Monthly water balance – Average annual percolate salinity Example 2 – N Loading Rate = Flow * Concentration * Conversion Factor * Duration Allowable N Loading Rate = U / (1-f) C:N ratio >8 1.2-8 0.9-1.2 • • • • Table 7-2. Nitrogen Loss Factor for Varying C:N Ratios Nitrogen Loss Factor, f Example Flooda Sprinklerb Food processing wastewater 0.5 - 0.8 0.2 – 0.4 Primary municipal effluent 0.25 - 0.5 0.15 – 0.3 Secondary municipal effluent 0.15 - 0.25 0.1 – 0.25 Calculate allowable N loading. Compare with planned loading for area identified. Conversely, can calculate area required. Increase site area as needed and available for the limiting loading rate. • Consider other options (crops, application methods). Example 2 – BOD Loading Rate = Flow * Concentration * Conversion Factor * Duration BODu ~ 1.4 * BOD5; alternatively can use COD as a max • Apply Eqs. 7-2 and 7-4 to calculate oxygen availability. • Compare with BODu loading. • Increase site area as needed and available . • Consider other options (application methods, cycle duration). Example 2 - Hydraulic • Get ET factors (CIMIS), other hydraulic data (Table 124). • Calculate irrigation needed using Eq. 7-5 and monthly water balance. • Determine needs for supplemental water, additional land, storage, or EPA Type 1 operation (application in excess of irrigation need). • Note annual totals for possible use in other loading calculations. Example 2 - Salts Cd = (Salt Applied – Salt Uptake) / Deep Percolate • Using FDS, calculate average mineral salinity and compare with risk category guidelines. • Using totals from monthly water balance, calculate average annual Cd. • Compare with “background” groundwater upper limit. • Other salinity compliance methods could be more applicable, depending upon permit and BPTC considerations. Example 2 – Other Considerations • High TSS design system to accommodate – furrows or corrugations instead of border strips – shorts runs, high flows • Select/finalize appropriate distribution system • Check other crop nutrient needs • Plan other associated facilities Questions and Answers