(Textbook) Behavior in Organizations, 8ed (AB Shani)

advertisement

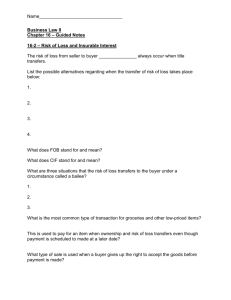

Chapter 12 Logistics: Positioning Goods in the Supply Chain McGraw-Hill/Irwin ©The McGraw-Hill Companies, Inc. 2008 Learning Objectives • Understand and describe the logistics function and its importance to business. • Describe the concept of logistics networks. • Explain why businesses outsource logistics functions and issues to consider when selecting a logistics service provider. • Explain what reverse logistics is and why its importance is increasing. • Describe and compare the modes of transportation used in supply chains. • Describe the configuration of different warehousing and distribution strategies, as well as the strengths and weaknesses of each. • Explain the concept of postponement and how it can be used in supply chains. • Compute the center-of-gravity solution for determining distribution center location. • Compute the landed cost to determine product costs that include logistics. • Describe the Customer-Trade Partnership Against Terrorism (C-TPAT) • Explain how radio frequency identification (RFID) and global positioning system (GPS) technologies can enhance logistics effectiveness. 12-2 Introduction to Logistics “the process of planning, implementing, and controlling the efficient, effective flow and storage of goods, services, and related information from point of origin to point of consumption for the purpose of conforming to customer requirements.” Exhibit 12.1 Logistics and the Supply Chain 12-3 Logistics Network Configuration • Costs are incurred and time is required to move goods from raw materials to consumers. • An important task for supply chain management is to determine distances and how travel will take place. • Logistics networks include warehouses, production facilities, retailers, and the inventory that flows between them. 12-4 Outsourcing Logistics Services • Third party providers are known as 3PLs • 3PLs can be narrow in focus or quite broad 12-5 3PL Selection • Steps to selecting a 3PL Exhibit 12.2 Ten Steps to Selecting a 3PL 12-6 Reverse Logistics • The flow of goods back to their producer • Increasing in importance • Often outsources Exhibit 12.3 Reverse Logistics Paths for Product Returns 12-7 Transportation Modes • U.S. Commercial Freight Activity by Transportation Mode Truck is the largest mode. Air is fastest growing 12-8 Road Transport – Truck is most commonly used cargo mode – Most goods transportation ends with a truck delivery – FTL is the cheapest. LTL costs more. 12-9 Rail Transport • Less flexible than truck. But less costly over long distances. • Trend is toward specialty wagons. • Double stacking is becoming more common. 12-10 Marine Transport • Breakbulk ships carry loose freight • Containerships carry containers. – Faster loading and unloading – Easy transfer to rail or truck 12-11 Pipeline • Least flexible • Often used to transport between isolated areas • High initial investment, but low operating costs 12-12 Intermodal Transport • At least two different modes are used • Marine/rail, rail/road, marine/road, marine/rail/road, etc. • Integrated transport carriers use whatever is best – Customer doesn’t have to deal with modes and is given total cost up front • Utilizes containerized shipping. 12-13 Incoterms: International Carriage Not Paid By the Seller • FCA stands for Free Carrier. The seller delivers the goods, cleared for export, to the carrier the buyer specifies, at a named location, not loaded. The seller’s responsibility is fulfilled when he delivers the goods to the carrier. • FAS means Free Alongside Ship. The seller delivers when the goods are placed alongside the vessel at the named port of shipment. This is specifically used for ocean shipments that aren’t containerized. • FOB stands for Free on Board. FOB means that the seller delivers when the goods pass the ship’s rail at the named port of shipment. The buyer is responsible for costs and risks as soon as the goods pass the ship’s rail. 12-14 Incoterms: International Carriage Paid By the Seller • CFR designates Cost and Freight. The seller is responsible for the cost and fright required to bring the goods to the named destination, but risks become the buyers when the goods pass the ship’s rail in the port of shipment. • CIF means Cost, Insurance, and Freight. This is the same a CFR, except that the seller is responsible for insurance against loss or damage. • CPT stands for Carriage Paid To. The seller is responsible for the cost of freight to the named destination. The risks associated with loss, damage, or cost increases becomes the buyer’s when the goods have been delivered to the custody of the first carrier. • CIP stands for Carriage and Insurance Paid To. This is the same as CPT, except the seller is responsible for transport insurance against loss or damage. 12-15 Incoterms: Arrival at Stated Destination • DAF stands for Delivered at Frontier. DAF means that the seller’s responsibility stops when the goods have arrived at the frontier, but before the customs border of the country specified in the contract. • DES stands for Delivered Ex Ship. DES means that the seller’s responsibility ends upon placement of the goods at the disposal of the buyer on board the ship at the named port of destination. • DEQ stands for Delivered Ex Quay. DEQ means that the sellers obligation is fulfilled when the goods are made available on the quay (wharf) to the buyer at the named port of discharge. • DDU stands for Delivered Duty Unpaid. DDU means that the seller’s responsibility goes up to the point when the goods have been made available to the buyer at the named place in the country of importation. The buyer has to pay all duties, taxes, and customs charges required for importation. • DDP stands for Delivered Duty Paid. DDP is like DDU in that the seller’s obligation ends when the goods have been made available to the buyer at the named place in the country of importation. However, the seller is responsible for all duties, taxes, and customs charges. 12-16 Transportation Management Systems • Integrate transportation decisions with inventory and warehousing, order management, forecasting, and production planning. 12-17 Warehousing • Distribution Strategies: 12-18 Direct Shipment • Shipping directly from manufacturer to retailer • Eliminates warehouse costs • Probably won’t take advantage of FTL transportation savings. • High inventory level needed 12-19 Consolidation Warehousing • Storage in warehouse, then shipped. • More likely to use FTLs • Risk pooling benefits of reduced inventory in system • Used in combination with postponement 12-20 Cross-Docking • Most sophisticated system • High cost, but very efficient • Used by high-volume retailers like Wal-Mart and dollar General • FTL bulk shipments to crossdock center, then FTL mixed loads to retailers 12-21 Warehouse Location Decisions • Center-of-gravity method: used for locating a distribution center among warehouses or retail stores. • Finds the “most central location” for the DC by calculating the X and Y coordinates that minimize transportation costs. • Considers distance between the DC and warehouses or stores as well as the number of shipments necessary between them 12-22 Location Decision-Making Techniques:Centerof-Gravity Method ΣdixVi Cx = Σ Vi ΣdiyVi Cy = Σ Vi where Cx = X coordinate of the center of gravity Cy = Y coordinate of the center of gravity dix = X coordinate of the ith location diy = Y coordinate of the ith location Vi = Volume of goods moved to or from the ith location 12-23 Location Decision-Making Techniques: Center-of-Gravity Example • Example 12.1 – Regional bottler finding good location for a new facility – Uses data on the locations of its four suppliers and the number of truckloads shipped from each Exhibit 12.6 Graphical Representation of Supplier Locations 12-24 Location Decision-Making Techniques: Center-of-Gravity Example • Example 12.1 – For the cardboard and paper supplier, dix = 60, diy = 290, and Vi = 13 ΣdixVi Cx = Σ Vi ΣdiyVi Cy = Σ Vi Exhibit 12.7 X and Y Coordinates for Suppliers 12-25 Location Decision-Making Techniques: Center-of-Gravity Example • Frequency of deliveries Exhibit 12.8 Truckloads per Month 12-26 Location Decision-Making Techniques: Center-of-Gravity Example • Solution: – Cx = (60 x 13) + (340 x 15) + (120 x 19) + (440 x 60) 13 + 15 + 19 + 60 = 322.99 – Cy = (290 x 13) + (280 x 15) + ( 200 x 19) + (110 x 60) 13 + 15 + 19 + 60 = 171.68 Locate DC at coordinates (322.99, 171.68) 12-27 Location Decision-Making Techniques: Center-of-Gravity Example • Example 12.1 – The coordinates for the center-of-gravity location are approximately (323, 172) Exhibit 12.9 Center-of-Gravity Location 12-28 Supply Chain Security • Customs-trade partnership Against Terrorism (C-TPAT) – Voluntary certification – Must comply with guidelines and submit security profile questionnaire – Benefits include expedited processing at borders and reduced delivery times. Exhibit 12.10 C-TPAT Certification 12-29 Information Technology • Radio Frequency Identification (RFID) – RFID tags emit a signal that can be read at a distance. – The signal contains a unique identifier that can be read by a reader – Information about the item can be stored on a host computer – RFID can be used to aid in inventory counts, security, product tracking, etc. 12-30 Information Technology • Radio Frequency Identification (RFID) – Each tag has a unique identifier that uses the electronic product code (EPC) format. Exhibit 12.12 EPC Format 12-31 Information Technology • Potential RFID Applications: 12-32 Information Technology • Global Positioning systems – – – – – Determine precise locations using satellites. Used to monitor vehicle locations Estimate arrival times Update customers on delays Increase security 12-33 Logistics Costs • Example 12.2: Landed Cost computations – Convert all logistics-related costs to a per unit basis for comparison Exhibit 12.14 Landed Cost Computations 12-34