Innovative examples of energy efficiency in the German sugar

advertisement

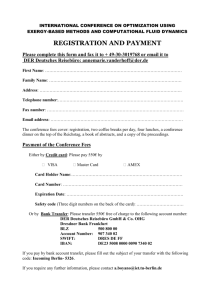

Energy Efficiency in IPPC installations, 21.-22. October 2004 in Vienna Austria Trend Parkhotel Schönbrunn VEREIN DER ZUCKERINDUSTRIE Innovative examples of energy efficiency in the German sugar industry - dewatering and drying process for sugar beet pulp Dipl.-Ing. Christian Voß Südzucker AG for the German Association of Sugar Industry Dr.- Ing. Joachim Wieting U MWELT B UNDES A MT, Berlin Werk Warburg, D-34414 Warburg Tel. 05641/ 9413 Postfach 33 00 22, D-14191 Berlin Tel. 030/ 8903-2829 Christian.Voss@Suedzucker.de joachim.wieting@uba.de Structure VEREIN DER ZUCKERINDUSTRIE 1. Introduction (targets and development of the specific energy requirement) 2. Mechanical dewatering process for sugar beet pulps in the sugar industry as regards energy 3. Drying processes (drum drying, low temperature drying and evaporation drying) 4. Energy aspects of pulp drying 5. Comparison of energy consumption and the economics of different types of installations with examples 6. Characterisation of the technology – economic and ecological aspects Background and Motivation VEREIN DER ZUCKERINDUSTRIE With the finalisation of the Council Directive 96/61/EC concerning „Integrated pollution prevention and control“, the so-called „IPPC Directive“, the concept of an integrated approach to reduce environmental pollution is being pursued at European Community level for the first time, with all installations covered by the directive now requiring permits. The EU Commission is supporting the implementation of the directive as part of its exchange of information by having leaflets compiled on the „best available techniques (BAT)“ by the European Integrated Pollution Prevention and Control (IPPC) Bureau in Sevilla, Spain. Background and Motivation VEREIN DER ZUCKERINDUSTRIE • The „food, drink and milk“ BREF gives information at community level on the best available techniques in the sugar industry to help promote the use of these techniques and to support the member countries effectively in their efforts to protect the environment. • The efficient use of energy in the industry helps avoid and/or control emissions in the air, in water and in the ground as far as possible. •The formulation of the directive into a new VDI guideline in Germany will set out primary and secondary control measures and new reduced emission figures for production technology. VEREIN DER ZUCKERINDUSTRIE Introduction precautions in the interest of the climate Agreement between German sugar industry and the government board signed on 19.12.2000: Reduction of the specific CO2 emissions of 41 – 45 % by 2005/06 Base year 1990: CO2 emissions/beet Target year 2005/06: 148 kg/t 81 – 87 kg/t achieved 2000/01: 84 kg/t with 288.5 kWh/ton of beet Target achievement: almost 100 % Introduction Specific energy consumption in the German sugar industry VEREIN DER ZUCKERINDUSTRIE 125 kWh / 100 kg beets 100 75 50 25 current 1996: 30,6 ABL DDR / NBL basis 1990: 35,6 D, ges target 2005 : 29 0 1950 1960 1970 1980 year ABL = old Federal states NBL = new Federal states D = Germany as a whole 1990 2000 2010 Introduction Specific energy consumption in the German sugar industry VEREIN DER ZUCKERINDUSTRIE Since 1990 > 300 Million € have been invested in projects for combined heat and power generation (CHP). Degree of efficiency of heat and power combinations > 90 % re-use of the heat several times normalf = 7 – 8 Future: physical limits increasing technical expenditure (costs) marginal energy savings ______________________________________________________ Personal remarks on sugar market regulation Introduction Energy conversion in a beet sugar factory and VDI extra edition 2594 VEREIN DER ZUCKERINDUSTRIE Main flows of energy and technical processes are more closely interlinked than in any other sector of industry. Amount of energy used Sugar production : Dried pulp production 2 : 1 VDI-Guideline 2594 „Emission reduction in pulp drying plants in the sugar industry“, First printed August 2004 VEREIN DER ZUCKERINDUSTRIE Energy aspects of the dewatering process for beet cossettes Production of dried pulp with 90 % dry substance and 10 % water from extracted cossettes with 10 (- 14) % dry substance and 90 % water in 2 dewatering stages: mechanical thermal Amount of energy used kWh/t water approx. 30 approx. 3.000 1 Target: : 100 To remove as much water as possible mechanically. Energy aspects VEREIN DER ZUCKERINDUSTRIE of the dewatering process for beet cossettes State of the art: Spindle presses horizontal/vertical pulp inlet screen ring, axially relocatable for pressing pressure variation press water collector pulp outlet VEREIN DER ZUCKERINDUSTRIE Energy aspects of dewatering process for beet cossettes 34 3,4 32 3,2 30 3 28 2,8 26 2,6 24 2,4 22 2,2 20 2 Water carrying in kg Water/ kg Dry-substance content Dry-substance content in Press-pulps in % Quantity of material pressed out depends on capacity of presses Hardening with calcium ions (gypsum), Development by Südzucker (SZ): Campaign Dry-substance content in % Watercarying in kg Water/kg Dry-substance content SZ-Pressing target before drying: 32.5 % dry substance in the pressed pulp Energy aspects VEREIN DER ZUCKERINDUSTRIE of dewatering process for beet cossettes Other mechanical dewatering processes % dry substance in the pressed pulp • Diffusive dewatering: 65 in combination with evaporation plant to concentrate the press water Disadvantage: no suitable separation of solids/liquids • High-pressure, multi-layer pressing: 50 Filter band press: 300 bar; 15 min. pressing time Disadvantage: no suitable filter cloth quality no reliable control of the 300 hydraulic control loops • Extraction under alkaline conditions Pilot installations in France, Germany and England 45 – 50 Energy aspects VEREIN DER ZUCKERINDUSTRIE of dewatering process for beet cossettes Combination of electroporation and alkaline extraction • Alkaline extraction results in increased deposits of calcium ions and thus to a definite increase in the pressability of the extracted cossettes - Dry substance (DS) content of extracted cossettes : 40 - 45 % (an increase of approx. 10 % DS) • Opening the cells by electroporation to prepare for deposit of calcium ions - opening the cell membranes by high voltage impulses • high voltage impulses: a voltage of several hundred kV for the duration of approx. 1 µsec • low energy demand: approx. 1 kWh/t beet Energy aspects VEREIN DER ZUCKERINDUSTRIE of dewatering process for beet cossettes Changes in the mechanical properties of beet due to electroporation • Electroporation increases the flexibility of the cossettes considerably and enables them to stand up to heavier mechanical stress. Energy aspects VEREIN DER ZUCKERINDUSTRIE of dewatering process for beet cossettes Possible configuration of electroporation and extraction* electroporation electroporated beets electroporated and alkalined cossettes slicing machine lime mash *patent applied for juice towards juice purification VEREIN DER ZUCKERINDUSTRIE Drying process Start-up line 1,5 bar 85 bar DU 2 VD 2-7 Heating oil Generator Generator Steam turbine 85 25 25 3 3 bar 3 bar 4,5 MW Gas turbine Boiler 14,7 MW 25 bar VD 1 3,3 bar VT 1 VT 2 DU 1 DU 3 Steam system of a sugar factory with steam drying Drying process VEREIN DER ZUCKERINDUSTRIE Legend: 1 Cossette feed screw in cell 1 2 Stationary guide vanes 3 Cylinder with cyclone effect 4 Cyclone over cell 16 for separating entrained cossettes 5 Steam inlet into cyclone 6 Stationary guide vanes for steam return 7 Superheater for secondary steam 8 Blower fan for creating fluidised bed 9 Generated steam exit 10 Feed screw for cossette output from cell 16 Steam system of a sugar factory with steam drying Energy aspects of cossettes drying VEREIN DER ZUCKERINDUSTRIE In order to consider the energy aspects of the installations described, the general data of the factories with both direct and indirect dewatering systems have been standardised as follows: Beet processing 10.000 tons/day . Length of „campaign“ (season) 90 days p.a. Mass flow of pressed pulp: 160 kg/t beet processed = 66,7 tons/h Dry substance content of the pressed pulp 31 % Dry substance content of the dried pulp 90 % Steam consumption of a sugar factory for 200 kg/t processed beet = 83.4 t/h Live steam pressure 85 bar Live steam temperature 525 °C Thermal value of the fuel 40.195 kJ/kg Energy aspects of cossettes drying Electrical energy demand of the sugar factory without drying 10.4 MW = 24.96 kWh/t beet processed Complete crystallisation of the thick juice in the beet campaign VEREIN DER ZUCKERINDUSTRIE These norms pre-suppose that the factories have the . following technical installations: A steam generator with 85 bar and 525 °C. A corresponding back pressure turbine 3 bar back pressure to supply the evaporation station or 3 bar back pressure and 25 bar extraction pressure to supply the steam dryer. A gas turbine to reduce the use of electric energy when using a steam dryer. effluent treatment plant which can process the condensed vapours from the evaporation dryer. Summary of the examples of installations VEREIN DER ZUCKERINDUSTRIE Steam High Low/high Factory dryer temperature temperature without dryer dryer a dryer Total electric energy demand MW 11.55 11.20 12.10 10.40 Total fuel energy MW 73.72 111.83 104.80 67.13 Total electric energy obtained MW 11.48 11.66 11.66 11.66 Total energy costs €/h 1,182 1,780 1,695 1,048 Total energy costs 103 per campaign €/a 2,532 3,845 3,661 2,264 Summary of the examples of installations VEREIN DER ZUCKERINDUSTRIE Additional energy costs in comparison to a factory without dryers for the individual variations: • High temperature dryers • Low/high temperature dryers • Steam dryers 1.581 103 € 1.397 103 € 268 103 € Operation related costs (higher investment costs of installations in comparison to lower fuel costs in operation) • High temperature dryers • Low/high temperature dryers • Steam dryers 388 103 € p.a. 460 103 € p.a. 554 103 € p.a. Summary of the examples of installations VEREIN DER ZUCKERINDUSTRIE Investment costs plus net running costs of the dryer for the individual variations: • High temperature dryers • Low/high temperature dryers 38.4 Mio. € 40.7 Mio. € • Steam dryer 40.9 Mio. € Characterisation of the technology: At the present time steam drying is the best available technique for new sugar factory construction or for complete reconstruction of energy production and heat control systems. However, it cannot be integrated easily into a normal existing factory. Advantages achieved by steam drying VEREIN DER ZUCKERINDUSTRIE Main achievement - Improvements for the environment with regard to emissions and energy consumption: • Emissions are avoided by direct primary use of energy for drying. • No application of steam-volatile and odorous vapours. • Energy consumption 30% less than in a factory with direct drying. Inter-media effects • Transfer of the exhaust fumes into the effluent (approx. 1.200 m3 effluent with a chemical oxygen requirement of 1.500 mg/l and a NH4content of 25 mg/l). VEREIN DER ZUCKERINDUSTRIE THANK YOU In conclusion we should like to thank all those who participated the members of the VDI working group 2594, the participating companies in the Sugar Association and all of you for your attention. THANK YOU