Fasteners and Sealants

advertisement

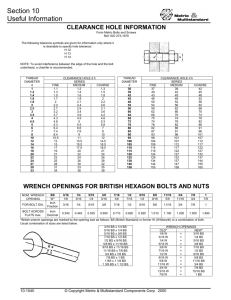

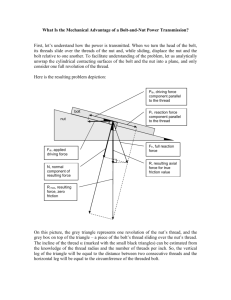

Question: What is the most important yet typically taken for granted component of an internal combustion engine? Answer: Fasteners If one little rod bolt fails you can general kiss the bottom end goodbye. If a cylinder head does not get the proper clamping force from a fastener, the head gasket is sure to blow. • Fasteners are devices that hold the parts of a car together. There are thousands of fasteners that hold a vehicle together. • Bolts: A bolt is a metal rod with external threads on one end and a head on the other. When a bolt is threaded into a part other than a nut it can also be called a cap screw. • Every bolt behaves like a spring. If we apply a tensile (a metal's resistance to being pulled apart) pre-load to the bolt it will elongate (stretch). Also present within the bolt is a force waiting to return the bolt to its original length. • It is this property of the bolt trying to return to its original length that gives the fastener its holding ability. • As long as the bolt's pre-load is within the elastic range of the stress/strain, permanent deformation of the bolt will not result. • • • • • • Bolt and Nut terminology: Bolts and nuts come in various sizes, grades, strengths, and thread types. It is important to be familiar with these different bolt dimensions. Bolt size – the measurement of the outside diameter of the bolt threads. Bolt head size- the distance across the flats or the outer sides of the bolt head (same as wrench size) Bolt length – measured from the bottom of the bolt head to the thread end of the bolt. Thread pitch- Is the number of threads per inch. With metric fastener it’s the distance between each thread in millimeters. • • • • Thread types: Course threads UNC- unified national course Fine threads UNF- unified national fine Metric threads SI (international standard) Thread pitch gauge TPI stands for Threads Per Inch. This is simply a count of the number of threads per inch measured along the length of a fastener. TPI is used only with American fasteners. • • Metric fasteners are specified with a thread pitch instead of a thread count. The thread pitch is the distance between threads expressed in millimeters (measured along the length of the fastener). For example a thread pitch of 1.5 means that the distance between one thread and the next is 1.5mm. • Tensile strength or grade, refers to the amount of pull a fastener can withstand before breaking. • Bolts are made of different metals, some stronger than others. Tensile strength can vary from bolt to bolt. • US customary bolts are marked with slash marks on the head of the bolt . • Metric bolts are given a number for example 8.8 or 10.9 the larger the number the stronger the bolt. ¾ - 10 UNC- 2A X 1 3/4 • • • • • ¾ - Thread diameter or bolt size 10 – Threads per inch UNC – Unified coarse 2A – Fit symbol 1 ¾ - Bolt Length M – 20 X 2.00 X 50 – 8.8 • • • • M-20 – Metric thread/ diameter of threads in mm (bolt size) 2.00 - Distance between threads (pitch) 50- Length in mm 8.8 – Strength (grade) • There are many types of nuts used in a vehicle. These are some of the most common ones used in the automotive manufacturing sector. A cotter pin slides through a castle nut and a hole in the bolt. This makes sure the nut cannot turn and come off. Nylon nut uses a plastic ring placed at the end of the nut to act like a stop. These two styles of nuts are often used in the automotive industry. • Washers are used under bolt heads and nuts. The two basic types are flat washers and lock washers. • Washer must be correctly sized to fit the shank of the bolt to prevent damage to the bolt's shank and be concave (dish) resistant. If the washer is too soft, the washer will concave and fail to provide a uniformed load transfer • Washers that are too hard could fracture and fall out of position, releasing the bolt's pre-load. • Increases the clamping surface under the fastener and it prevents the bolt or nut from digging into a part. • • Prevents the bolt or nut from becoming loose under stress and vibration. Lock washers are not to be used were high heat is present or they loose their locking memory. These are split lock washer and a toothed lock washer • • Are similar to bolts, but they normally have screw type heads. They are threaded along their full length and are relatively small. Machine screws are used to secure parts when clamping loads are light. They come in various head shapes. • • A snap ring fits into a groove in a part and commonly holds shafts, bearings, gears, pins, and other similar components in place. Snap ring pliers are needed to remove and install snap rings. The snap rings shown are internal type, external type, and external “E”-type • A metal key fits into a key seat, or slot, cut into a shaft and a key way cut into the mating part, such as a gear, pulley, or collar. The key prevents the part from turning on its shaft. • • Are normally used to lock a part onto a shaft. They can be used with or without keyways. A set screw is a headless fastener normally designed to accept a hex (Allen) wrench or screwdriver • • • It is very important that bolts and nuts are tightened properly. This is called torquing. If over tightened, a bolt will stretch and possible break. The threads could also fail. If under tightened the bolt may loosen and fall out. Part movement could also shear the fastener or break a gasket, causing leakage. • Tightening values are given by the auto manufacturer so technicians can tighten the fasteners to their stretching limits without compromising the integrity of the fastener. Torque specifications are given for all precision assemblies, such as engines, transmissions, and differentials. • Service manuals sometimes recommend new bolts because of torque to yield process (Head bolts). • • • Bolt tightening methods requires a specific bolt torque, followed by turning the bolt a specific number of degrees. After using a torque wrench, a degree wheel adapter is placed between the wrench and the socket. The fastener is then turned until the degree wheel reads as specified by the manufacturer. This stretches the bolt to its correct yield point and preloads the fastener for better clamping under varying conditions. • • • Determined by measuring bolt length change while torquing the bolt. Example; measuring connecting rod bolts before and after tightening using a gauge. Too much stretch indicates bolt weakness. Not enough stretch may indicate thread problems affecting torque. • • • • • • • • Keep a steady pull on the wrench Clean the fasteners threads Avoid using universal joints Read a torque wrench looking straight down at the tool Only use a general torque scale when the manufactures specifications are not available Pull only on the handle of the wrench Tighten the bolts in a step torque Retorque when required by the manufacture. Example cylinder heads, and exhaust manifolds. • • • A technician must be able to remove broken bolts, screws, studs and fasteners that have rounded-off heads. Locking pliers - used for badly rusted heads and rounded off fasteners. Stud puller-can remove studs and broken bolts that have been broken off at the surface of the part. • • • • If fasteners are too short to grasp with a tool there are a variety of methods to use; Hammer and punch – Angle the punch on the fastener so the blows from the hammer will walk out the bolt. Hacksaw and Flat screwdriver- Cut a channel into the broken fastener then use the screwdriver to turn the fastener out Weld a bolt onto the broken fastener • • “Easy out” screw extractor – Drill a hole into the center of the broken fastener. Then, lightly tap the correct size extractor into the hole. Then, unscrew the broken bolt by simple turning the extractor with a wrench. Note: DON’T BREAK THE EXTRACTOR OFF • • It is a chemical that dissolves rust or corrosion. It is often applied to rusted fasteners to aid in their removal. Allow the penetrate to soak for a few minutes. This will help the fastener to free up without breakage. • • • • Gaskets and seals are used between parts to prevent leakage of engine oil, coolant, transmission oil, and other fluids. Gasket: Is a soft, flexible material. It can be made of fiber materials, rubber, neoprene, cork, treated paper, or thin steel. When the parts are fastened tightly together the gasket is compressed and deformed. This fills in small gaps or imperfections in the surfaces and a leak proof seal is created. 1. 2. 3. 4. 5. 6. 7. Inspect for leaks before disassemble. Be careful not to nick, gouge, or dent mating surfaces while removing parts. Clean off old gaskets carefully. Wash and dry parts thoroughly using solvent. Then wipe the surface clean. Compare the new gasket to the surface of the part to make sure everything will line up (bolt holes, cut outs). Use sealer if needed. Use sealer sparingly! Tighten the fastener in steps. When more then one fastener is used to retain the part don’t over tighten. • • • • They help prevent leakage and hold the gasket in place during assembly. There are numerous sealers with different uses: Hardening sealers - used on permanent assemblies, such as threads and fittings. They are usually heat and chemical resistant. Non-hardening sealers - used on assemblies that are to be removed, such as plates, covers, flanges. • • • Are special sealers used instead of conventional fiber or rubber gaskets. The two types are: R.T.V (room temperature vulcanizing)- comes in a tube and is used to make a rubber like gasket that dries when it comes in contact with air. Anaerobic sealer - cures to a plastic like substance in the absence of air. It is used on thick parts and the surface must be smooth, true and not flexible. Lets make a gasket