Combustion Chambers - Florida Institute of Technology

advertisement

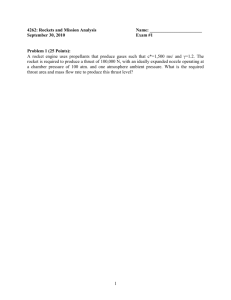

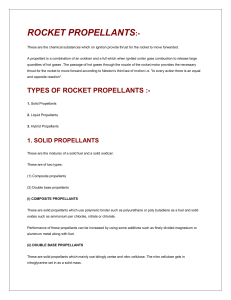

MAE 4262: ROCKETS AND MISSION ANALYSIS Rocket Combustion Chambers Mechanical and Aerospace Engineering Department Florida Institute of Technology D. R. Kirk 1 CONTENTS • Overview • Thermal Rocket Combustion Chambers – Liquid Rocket – Solid Rocket – Hybrid Rocket • Rocket Fuels – Liquid Propellants – Solid Propellants • Thermochemistry Review: How to perform calculations • Nozzle Flow of Reacting Gases – 2 Limiting Cases – Physical Understanding of these 2 Cases – Calculations 2 OVERVIEW • In our development of models for Thermal Rocket Thrust Chambers, we considered two primary components 1. Combustion (or Heating) Chamber 2. Nozzle • Developed a 1-D model that allowed us to predict important parameters – Ue, Isp, Thrust (and associated derived characterization coefficients: CF, C*) – Model simplified with many assumptions • Next step was to examine nozzle – Types of nozzles, performance, impact of altitude, etc. – Connect performance to shape and design of optimum and realistic shapes • Now examine Component 1: Combustion Chamber 3 SUMMARY OF KEY EXIT VELOCITY EQUATIONS 1 p U e 2C pTo 2 1 e p02 1 QR pe Ue 2 1 M p02 1 p 2R To 2 1 e 1M p02 • Key Assumptions – Quantity of heat added at constant pressure – Constant specific heats • For high Ue (for all thermal rockets), desire: – Propellants with low molecular weight, M – Propellant mixtures with large QR/M – High combustion chamber pressure, P02 4 TYPES OF COMBUSTION CHAMBERS • • General comments made on previous slides are true for all types of thermal rockets In this portion of course, we will be dealing with two types of rockets 1. Liquid Rockets • Mono-Propellant (single compound) • Bi-Propellant (fuel and oxidizer) 2. Solid Rockets (see next set of slides) • Nozzles may look similar for these two types, but combustion chamber design quite different • Goals same for each type: 1. Understand factors that govern combustion process 2. Choice of fuels for each of these options 3. Design of combustion chamber • Sizing: Length, Area, Volume, residence time 4. Performance of the solid vs. liquid rocket thrust chambers 5 LIQUID COMBUSTION CHAMBER OVERVIEW Atomization/vaporization 6 SIZING OF CONTRACTION RATIO 7 SIZING OF COMBUSTOR LENGTH 8 SIZING OF COMBUSTOR LENGTH 9 PROPELLANTS: BASIC DEFINITIONS • Propellant: general term to describe combustion materials (both oxidizer and fuel) • Some liquid propellants are gases at atmospheric conditions – Only when temperature is dropped sufficiently and material pressurized does propellant become a liquid • Why do we have to do this? – Called cryogenic - maintained in low temperature condition – Common cryogenic propellants are liquid hydrogen and liquid oxygen • In contrast to many liquid propellants storable at room temperature conditions – Storable liquid propellants easier to use, but don't provide as high Isp – High reliability, Shuttle orbital maneuvering and re-entry • Cryogenics add significant complexity to a rocket system, but extra Isp is worth it – Venting system, special tanks, shrinkage, flexible joints, leakage, etc. 10 PROPELLANT ALSO SERVES AS COOLANT • Propellants are often used to cool portions of the rocket (combustion chamber and nozzle) prior to entering combustion chamber to be burned Combustion chamber and portion of nozzle are cooled with propellants 11 PROPELLANT WILL VARY WITH CYCLE 12 COMMON LIQUID ROCKET FUELS • Most Common Liquid Oxidizers – LOX – Hydrogen Peroxide – Nitric Acid – Nitrogen Tetroxide – Liquid Florine • Most Common Liquid Fuels – Hydrocarbon fuels (RP1, kerosense, methane) – Liquid hydrogen – Hydrazine (also mono) – Unsymmetrical Dimethylhydrazine 13 PROPELLANTS: GENERAL COMMENTS • Combustion temperature directly reflects chemical energy of reaction • Using O2 and RP-1 produces higher temperature than O2 and H2 – This is because RP-1 contains more chemical energy than H2 – However, H2 has much lower molecular weight – Result is that O2 and H2 produces highest exit velocity (except F2-H2) • Additional H2 may be added, which actually raises exit velocity • Maximum exhaust velocity is shifted away from stoichiometric value, in direction of lower molecular weight • Why use a propellant with high molecular weight? – Exhaust velocity is not only criterion – Also interested in high thrust – Heavy propellants giver higher mass flow rate • Velocity might be lower, but overall thrust might be increased – This is an application dependent design trade-off 14 PROPELLANTS: GENERAL COMMENTS • RP-1 is an inexpensive fuel, but provides lower performance (similar to kerosene) • Fluorine and LH2 produces highest temperature of any bi-propellant system – Highly toxic and corrosive • Hydrogen peroxide (H2O2) deteriorates at about 1% a year, so cannot be used for long term missions. • Hydrazine (N2H4), Florine (F2) and UDMH (unsymmetrical dimethylhydrazine) are good propellants but highly toxic and flammable. Very dangerous to handle • Nitrogen tetroxide (N2O4) is a very good oxidizer – Easy to store and transport, but also very toxic, hazardous to skin contact and creates toxic cloud (BFRC) in when exposed to atmosphere 15 SUPPLEMENTAL PROPELLANT DATA 16 PROPELLANTS: ADDITIVES • Sometimes additives are mixed into propellants for: – Lower molecular weight – Improve cooling characteristics • Rocket designs may be limited by temperature on turbine, combustion chamber, or nozzle – Lower freezing point (prevent propellant from freezing in space) – Reduce corrosive effects – Facilitate easier ignition – Stabilize combustion 17 MONO-PROPELLANT SYSTEM • Monopropellant hydrazine thrusters for satellites, space probes and spacecraft • Used for station-keeping (orbital correction) and small thrust level applications • Launch vehicle roll control and upper stage orientation and precision maneuvers (used on Ariane 5 launcher) Examples of 0.1N Hydrazine mono-propellant thrusters, Isp~210 s 18 WHY MONO-PROPELLANTS? • Less complicated – Only need 1 propellant – Only need 1 set of drive turbines and pumps – Less plumbing • Easy to turn on and off, reliable • Less dangerous, no chance of interaction of high pressure fuel and oxidizer • Less costly to build and low maintenance • Drawback is limited performance, Isp and thrust • Mono-propellants – Most common propellant in use today are Hydrazine (N2H4) and Hydrogen Peroxide (H2O2) – Also useful with catalyst to decompose to produce heat and gas – Storable for long periods of time – Useful for short bursts of thrust 19 BI-PROPELLANT LIQUID ROCKET SYSTEM • Most liquid fuel rockets are bipropellant • Most also require a spark or some other method of activation to ignite • Mixtures of liquid oxygen (LO2) with hydrocarbons such as kerosene and RP1 or with liquid hydrogen (LH2) are most typical • These types of rockets produce enormous thrust due to massive amount of propellant used – Example: External tank on the space shuttle contains over 1 million pounds of LO2 and over 200,000 pounds of LH2 • Some work being done on Tri-Propellant Rockets – These work in basically same way as bipropellant rockets – Combine two fuels and one oxidizer to give a mixture of efficiency and thrust 20 ROCKET FUEL SELECTION GUIDE • Desirable Physical Properties – Low freezing point – High specific gravity (dense propellant) – Stability (with time) – Heat transfer properties – Pumping properties (low vapor pressure, low viscosity) – Small variation in physical characteristics with temperature – Ignition, combustion, and flame properties • • • • • Performance of Propellants Economic Factors Physical Hazards (Explosion, Fire, Spills) Health Hazzards Corrosion 21 BI-PROPELLANT LIQUID ROCKET 22 EXAMPLE: STS EXTERNAL TANK • External tank contains liquid hydrogen fuel and liquid oxygen oxidizer • ~ 1 million pounds of LO2 and ~ 200,000 lb LH2, r = O/F~5 23 • So if there is 5 times as much oxidizer as fuel, why is H2 tank so much bigger? LIQUID ROCKET PROPELLANT INJECTORS • Various injector geometries and configurations • Characterized by discharge coefficient and pressure drop across injector plate m C D Ainj 2 P 24 INJECTION • Injector should fulfill 3 primary functions 1. Ensure that fuel and oxidizer enter combustion chamber in a fine spray so that evaporation occurs as quickly as possible • Droplet model 2. Enable rapid mixing of fuel and oxidizer (in liquid or gaseous phase) 3. Deliver propellants into combustion chamber with a high flow rate and minimal pressure losses • • Specific injector design will take into account nature of propellants For cryogenic propellants (LO2, LH2), evaporation into the gaseous phase is necessary before ignition and combustion. Droplet model For hypergolic or self-igniting propellants (nitrogen tetroxide and UDMH) both components (which react as liquids at room temperature) should come into contact early, and impinging jets are usually used. In some case, pre-mixing is necessary, and here swirl injectors are employed • • 25 WHY DO LH2-LOX ROCKETS RUN FUEL RICH? • Desire high heating value, QR, and low molecular weight, M – Running rocket fuel rich (or lean) will reduce QR – However, if fuel is lighter in molecular weight than oxidizer, fuel rich will reduce average molecular weight – The overall ratio QR/M is increased – “In many cases fuel-rich mixtures are burned, as it is found that the resultant reduction in M more than offsets the accompanying reduction in QR” H&P, Section 11.2 – Also note that when dissociation is present, O/F ratio, much less than stoichiometric for maximum specific impulse • Explains why SSME run fuel-rich (H2-O2) – fuel has lower molecular weight • Also explains why rockets use oxidizer-rich case when oxidizer has lower molecular weight (V-2 rocket for example, alcohol-oxygen rocket) 26 SOLID PROPELLANT ROCKETS • • • • Solid fuel rockets rely on controlled explosion of a mixture of substances Nearly a homogeneous material that is burned Similar to gunpowder ~(75% potassium nitrate, 10% carbon, and 15% sulfur) Example: STS Solid Rocket Boosters: – Contain ammonium perchlorate as an oxidizer and aluminum as a fuel – Rest of mixture devoted to bonding two reactants – Once a solid rocket is ignited, can not be turned off 27 SOLID PROPELLANT ROCKETS 28 SOLID ROCKET FUEL DATA 29 SOLID ROCKETS AND NOZZLE FLOW • Special issue with solid propellants that use powdered metals as a fuel additive • Adding aluminum to formation of solid propellant increases gas temperature, but incurs performance penalties related to solid particles that are generated – Aluminum burns with oxygen to form Al2O3 particles • Particles are initially liquid and solidify during expansion process • Also tend to agglomerate to become large particles • Large particles do not accelerate as quickly as the gas surrounding them • These particles may constitute as much as 10-25% of total mass • Need to consider this in nozzle design, which must account for two-phase flow • Simplified models exist for analysis of performance: – Results indicate that large particle sizes are a detriment – However, for small particles, there is an optimum amount of Al to add 30 HYBRID ROCKETS Solid Fuel, Liquid Oxidizer 31 32 33 34