Critical Chain Project Management (CCPM)

advertisement

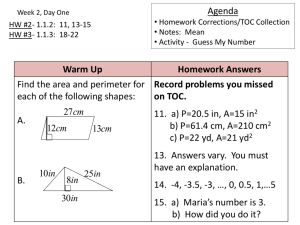

THEORY OF CONSTRAINTS (TOC) AND CRITICAL CHAIN PROJECT MANAGEMENT (CCPM) LEO LAURAMAA IBM - HELSINKI, SEPTEMBER 20 2013 Presentation for PMI Chapter Finland Constraint 2 Constraints are the physical limitations and policies that prevent the system from achieving more of its goal. Bottleneck and constraint are often used interchangeably - pay attention to context Time saved at the bottleneck can rapidly increase throughput. More efficient use of a non-capacity constrained resource does not increase throughput– only gives illusion of efficiency. Traditional improvement provides less leverage since it encourages improving the entire process, including non-constrained resources. TOC provides high-leverage improvements – Almost 100% of the improvement comes from work done at the constraint. Leo Lauramaa - TOC & CCPM 2013 09 20 3 “There really is no choice in the matter. Either YOU manage the constraints or THEY manage you. The constraints will determine the output of the system whether they are acknowledged and managed or not.” Source: Noreen, Smith, and Mackey, The Theory of Constraints and its Implications for Management Accounting (North River Press, 1995) Leo Lauramaa - TOC & CCPM 2013 09 20 Some remarks 4 Most improvements to most links do NOT improve overall performance (the chain) System wide, or "global" improvement are NOT equal to the sum of the local improvements The way to improve the organization is, definitely not through inducing many local improvements Thus a company should focus on best possible flow “allowed by” the "chain strength" – managing the constraint(s)! Leo Lauramaa - TOC & CCPM 2013 09 20 The constraint is 5 The leverage point – where the biggest effect can be achieved from the least effort Leo Lauramaa - TOC & CCPM 2013 09 20 TOC, Theory Of Constraints 6 provides a set of holistic processes and rules, all based on a systems approach, exploiting the inherent simplicity within complex systems through focusing on the (few) “leverage point(s)” as a way to synchronize and align the parts to achieve ongoing improvement in the performance of the system as a whole Leo Lauramaa - TOC & CCPM 2013 09 20 Constraint Management 7 System stability: Often times it makes sense to manage the bottleneck where it is rather than to try and break it 1. Called Constraints Management 2. Improvement becomes iterative process a. Improve the bottleneck b. Ensure non-constraints have sufficient protective capacity (PC) c. If they don’t then refocus improvement to add PC Operating any part of the process above 85% of capacity will eventually create delays and interruptions – wait time increases exponentially as capacity utilization nears 100% Leo Lauramaa - TOC & CCPM 2013 09 20 TOC Knowledge in the Areas of 8 The four pillars of TOC Process of ongoing improvement the five focusing steps the change question sequence buffer management Thinking Processes Manufacturing Distribution & Supply Chain Sales & Marketing Finance & Measurements Throughput accounting Managing People Applying new technology Project management Retail Internal, Engineering, R&D, IT Strategy Education Healthcare Public services Personal issues Leo Lauramaa - TOC & CCPM 2013 09 20 About TOC applications 9 When TOC is used to manage production, manufacturers make the most of their capacity, finding anywhere from 15-50% more capacity than they thought they had – product flows faster, and orders are on time, every time. When used in Distribution and Supply chains, TOC’s pull approach ensures near 100% availability while at the same time increasing inventory turns significantly. The TOC-based selling process increases salespeople’s hit rate by systematically removing the obstacles to closing the sale. TOC-marketing provides the capability to define an offering that satisfies a significant need of a market (unrefusable offer); When used in Projects, TOC’s approach shortens the overall project timelines and projects are at least 95% on time, without compromising budget or scope. And, when TOC is used to develop strategy, it puts all of the above together in an integrated way to lead the entire company to profitable growth and stability. Leo Lauramaa - TOC & CCPM 2013 09 20 The 25 Most Influential Business Management Books - The Goal (1984), by Eliyahu Goldratt 10 Unusual among business management books for at least two reasons. Goldratt wasn't a titan of industry, a b-school professor, or even a consultant, but rather a physicist. The Goal is a novel. Centered on a production manager named Alex Rogo who has three months to turn around a deficient, unprofitable manufacturing plant, The Goal explains the "Theory of Constraints," which among other points incorporates the idiom, "A chain is only as strong as its weakest link;" Sold more than 3 million copies, translated in 21 languages and focuses on bottlenecks, the great hindrances to productivity. Rogo uses the Socratic method to help fix his marriage, then applies it to his plant crew, coming up with steps to solve the plant's problems. The Goal has been in print since 1984, and a revised third edition was released on the book's 20th anniversary. The Time Magazine, August 2011 Leo Lauramaa - TOC & CCPM 2013 09 20 Eli Goldratt 11 “We must have the honesty to see reality as it is, we must have the courage to challenge assumptions, and above all, we must use the gift of thinking. “ Leo Lauramaa - TOC & CCPM 2013 09 20 The four pillars of TOC 12 Leo Lauramaa - TOC & CCPM 2013 09 20 Inherent simplicity: WHICH system is more complex? 13 Leo Lauramaa - TOC & CCPM 2013 09 20 Convergence - simplicity 14 Everything within a system is connected by cause and effect relationships. Identification of the causes leads us to converge onto an apparent core problem/contradiction/conflict. As long as you cannot clearly verbalize your intuition, the only thing you will communicate is your own confusion. Leo Lauramaa - TOC & CCPM 2013 09 20 Theory of Constraints The theory was developed by Dr. Eliyahu Goldratt, physicist (1947 – 2011) OPT 1970’s 1980’s Optimized Production Technique 1990’s Sales Marketing Production 2000’s Ever Flourishing Projects Supply Chains Distribution Strategy & Tactics Eli Goldratt was an educator, author, scientist, philosopher and business leader. But he was, first and foremost, a thinker who provokes others to think. Often characterized as unconventional, stimulating, and "a slayer of sacred cows," Dr. Goldratt exhorted his audience to examine and reassess their business practices with a fresh, new vision. Leo Lauramaa - TOC & CCPM 15 2013 09 20 The Evolution of TOC – 30 years 16 TOC & Business Strategy - Viable Vision TOC & Technology – Necessary but not Sufficient The TOC Holistic Approach Project Management – Critical Chain Distribution, Marketing, Management Skills – It’s Not Luck The Thinking Processes – Jonah Program Production, Throughput Accounting – OPT, The Goal, The Race, The Haystack Syndrome 1975 1985 1990 1995 2000 Leo Lauramaa - TOC & CCPM 2005 2013 09 20 The Five Focusing Steps of TOC 17 1. IDENTIFY the system’s constraint. 2. Decide how to EXPLOIT the system’s constraint. 3. SUBORDINATE everything else to the above decisions. 4. ELEVATE the system’s constraint. 5. Warning!!!!! Do not let INERTIA become the system’s constraint. When a constraint is broken, return to Step 1. A process of ongoing improvement that can be applied to any organization to continuously improve the achievement of more “goal units”. Leo Lauramaa - TOC & CCPM 2013 09 20 The change question sequence 18 Why change What to change To what to change How to cause the change How to measure and sustain the change and achieve a process on ongoing improvement. Leo Lauramaa - TOC & CCPM 2013 09 20 TOC Buffer Management (BM) 19 A control mechanism based on the amount of time (till the due date) or stock remaining used in the execution phase of TOC applications (operations, distribution and projects). Buffer management functions Prioritize tasks/orders based on buffer penetration / consumption. Signal when to expedite (red zone). Provide feedback to the planning process (changing parameters etc.) Identify prime causes of delay to focus ongoing improvement activity. Leo Lauramaa - TOC & CCPM 2013 09 20 Drum-Buffer-Rope (DBR) 20 The TOC method for scheduling and managing operations when there is an internal resource constraint. Drum Release Inventory buffer Internal constraint Rope Leo Lauramaa - TOC & CCPM 2013 09 20 Layers of resistance 21 The six layers of resistance, as expressed by the person(s) resisting change, are: 1. Disagree on the problem. 2. Disagree on the direction of the solution. 3. Disagree that the solution solves the problem. 4. Yes, but there are potential negative consequences. 5. Yes, but there are obstacles to implementing the solution. 6. Unverbalized fears. “Resistance” is a force for managing change. How? By systematically overcoming each layer of resistance and obtaining buy-in. More recently, nine layers of resistance have been identified: 0. “There is no problem.” 1. Disagreement on the problem. 2. “The problem is out of my control.” 3. Disagreement on the direction for the solution. 4. Disagreement on the details of the solution. 5. “Yes, but… the solution has negative ramification(s).” 6. “Yes, but… we can‘t implement the solution.” 7. Disagreement on the details of the implementation. 8. You know the solution holds risk. 9. “I don‘t think so” – Social or psychological barriers. TOC tool: The thinking processes Leo Lauramaa - TOC & CCPM 2013 09 20 “Show me how you measure me, I’ll show you how I’ll behave” "If you measure me in an irrational way, don't complain about irrational behavior." Eli Goldratt 22 Leo Lauramaa - TOC & CCPM 2013 09 20 Cost World vs. Throughput World 23 Cost World Thinking Throughput Thinking ”We want to minimize the cost of capacity”. ”We want to maximize the use of capacity”. Leo Lauramaa - TOC & CCPM 2013 09 20 TOC metrics – Throughput accounting 24 Metrics - Real improvement vs. the goal is measured by the change (Δ) in T, I, &OE: ΔT: Increasing Throughput - cash flow over and above truly variable costs ΔI: Reducing Investment - cash tied up in the business, including working capital items such as inventory and accounts receivable ΔOE Reducing Operating Expenses - costs of running the business, not including raw materials System level metrics Net Profit ROI Cash Flow Productivity Investment Turns Leo Lauramaa - TOC & CCPM = ΣT – ΣOE = Net Profit / I = ΔT- ΔOE / ΔI = T / OE =T/I 2013 09 20 Green & Red curve Performance 25 Time Leo Lauramaa - TOC & CCPM 2013 09 20 Three mechanisms distorting management attention 26 Fear of complexity Fear of Unknown Imposing Simplicity on Complexity create and manage sub systems – local optima, conflicts between sub sections Imposing Certainty on Uncertainty manage by “accurate” indicators – micromanagement, reacting to “noise” Fear of conflicts Imposing Harmony on Conflicts strive for a compromise between extremes – struggling with unacceptable compromises, dealing with symptoms other than core conflict, loose-loose in stead of win-win Leo Lauramaa - TOC & CCPM 2013 09 20 Logical Thinking Process for Strategy Goal Tree Critical Chain Project Current Reality Tree Prerequisite Tree Evaporating Cloud 27 Future Reality Tree By Bill Dettmer Focus (CRT) – One of the TOC ways to analyze reality We are losing sales Our reputation is deteriorating We have We are losing profit margins We are losing sales OurIt reputation is to is impossible deteriorating have a good forecast shortages of some items We are losing profit/profit Our suppliers are marginsnot reliable We cant hold the full product portfolio We have shortages of some items Our suppliers do not react fast enough We have too many write offs We give to many We are discounts overstocked with some items We have space limitations We have cash limits are Our suppliers not reliable We have space limitations We cant hold the full product portfolio We have cash limits We have too many write offs We are 28 The common practice- launch multiple improvement / correction initiatives. Spread overstocked with It is impossible to some items suppliers do not attention too thin and waste a lot of your resources &Our management resources with have a good react fast enough forecast limited results. Leo Lauramaa - TOC & CCPM We give to many discounts 2013 09 20 Some reported TOC results 29 73% 63% On-Time Delivery, 44% Revenue, Availability Throughput Lead Times Cycle Times Combined Financial Inventory Levels 49% 65% 70% The World of Theory of Constraints, Vicky Mabin & Steven Balderstone, Leo Lauramaa - TOC & CCPM 2013 09 20St. Lucie Press, 1999 All material © CMG &/or CMS, 2004 ABB – Multiple TOC based initiatives 30 Leo Lauramaa - TOC & CCPM 2013 09 20 Average payback time 2,14 months! TOC RESULTS – CASE SANMINA TOC-LEAN-SIX SIGMA 31 Leo Lauramaa - TOC & CCPM 2013 09 20 About TOC LEAN and SIX SIGMA 32 The best results to improve the system performance is achieved by: Using TOC / Constraint Management as a focusing mechanism And then Using Lean and Six Sigma on focused way Recommended reading: Velocity: Combining Lean, Six Sigma and the Theory of Constraints to Achieve Breakthrough Performance A Business Novel by Dee Jacob, Suzan Bergland, Jeff Cox, 2010 Leo Lauramaa - TOC & CCPM 2013 09 20 33 Critical Chain Project Management (CCPM) The TOC solution for planning, scheduling, and managing performance in a project environment. Legacy from Eli Goldratt since 1997 Leo Lauramaa - TOC & CCPM 2013 09 20 Typical complaints 34 Our project lead times are too long. Project ROI and cash flow are frequently jeopardized. Due dates, budget, quality and/or scope are frequently compromised. There is a constant battle to reduce safety time. We sometimes miss dependencies in the project plan. Deliverables are not always clear. Critical resources are losing a lot of time moving from one task to another and having to report progress on all tasks. Erroneous belief: In order to finish the project on time, we must finish each task on time. Leo Lauramaa - TOC & CCPM 2013 09 20 Background phenomena 35 Early start Start the project sooner, you’ll finish it sooner? Parkinson’s law Work expands so as to fill the time available for its completion. And … work continues because it must take the full scheduled time to be of high quality. The “Students syndrome” When people will start to fully apply themselves to a task just at the last possible moment before a deadline. This leads to wasting any buffers built into individual task duration estimates. What if and when Murphy will strike? Bad Multitasking Occurs when resources stop work on a task to start another task even though they could still work on the first task. The lead time increases significantly, even without considering additional setup time. Leo Lauramaa - TOC & CCPM 2013 09 20 The vicious cycle 36 Resources receive a poor evaluation for missed deadlines Resources will inflate estimates more The project still does not complete on time, within budget and scope Promised lead times for future projects are even longer (causing lost work?) Leo Lauramaa - TOC & CCPM 2013 09 20 Responsibilities & task estimates 37 Reliability of a person and negotiating position How much safety buffer is needed, if you must be fully in charge of your task estimate? - what if the task itself is on planning stage a bit fuzzy? Resources do not typically report early finishes. Leo Lauramaa - TOC & CCPM 2013 09 20 Critical Path vs. Critical Chain 38 Critical Path Longest sequence of task dependencies in terms of time. This is the traditional term and path that is NOT used in TOC. Critical Chain Longest sequence of task and resource dependencies in terms of time. In other words, it is the longest sequence of dependencies, with explicit consideration of resource availability. Leo Lauramaa - TOC & CCPM 2013 09 20 CCPM in breaf 39 Objective of a project: On time, full content, within budget In a single-project environment the critical chain project management solution includes the following: 1. Removal of existing behaviors that are harmful for the project 2. A plan, or project network, that includes all task and resource dependencies as well as time estimates with safety removed 3. A schedule showing the critical chain and the buffers 4. Implementation of new behaviors critical to streamlining flow such as the relay runner work ethic and frequent reporting of work remaining 5. Expediting and improvement activities based on buffer management Leo Lauramaa - TOC & CCPM 2013 09 20 CCPM principle 40 Securing the project, not individual tasks Leo Lauramaa - TOC & CCPM 2013 09 20 Buffer management for projects 41 Buffer Management is the process used to plan for and take any necessary corrective actions based on the impact of actual and predicted variability. These actions include: Assessing status of the project and, if appropriate, taking steps to recover schedule on the few tasks that are having impact, Assessing status and taking steps to recover schedule on the few materials that are having impact, Prioritization of available task work for a given resource to minimize queuing on the wrong tasks, and Reducing developing peak loads that can lead to serious resource delays. Leo Lauramaa - TOC & CCPM 2013 09 20 Dilemma regarding: Our project lead times are too long Background: Our customers have been complaining that our project lead times are too long. Some customers have defected to our competitors as a result of our long lead times. Assumption Assumption Objective Requirement / Strategy Prerequisite / Tactics B We must Make reliable promises D We Feel Pressure to Add significant safety time to each task time estimate A Satisfy customer and shareholder expectations (time, budget, scope) Assumption Assumption C We must Contribute to creating a competitive lead time advantage and not create opportunities for wasting time D’(But) We also feel pressure to Add the absolute minimum safety to task time estimates Assumption 42 Leo Lauramaa - TOC & CCPM 2013 09 20 Dilemma regarding: Critical resources are losing a lot of time moving from one task to another and having to report progress on all the tasks Background: Our resources have to spend a long time getting up to speed on a task that was set aside for a period of time. This time is non-productive time. A significant amount of set-up and set-down time is affecting resource productivity. Objective Requirement / Strategy Prerequisite / Tactics B We must Ensure that progress is made on all tasks D We Feel Pressure to Frequently multitask C We must Minimize time lost on “set-ups” and progress reporting D’(But) We also feel pressure to Limit the amount of multitasking A Satisfy customer and shareholder expectations (time, budget, scope) 43 Leo Lauramaa - TOC & CCPM 2013 09 20 Dilemma regarding: Project ROI and cash flow are frequently jeopardized Background: We must pay our subcontractors when they start working for us and for materials when we start using them. However, we do not receive payments until progress is made on the project. Therefore, our cash outflows exceed our cash inflows during initial stages of projects. Objective Requirement / Strategy Prerequisite / Tactics B We must Ensure that we have sufficient safety for each task D We Feel Pressure to Start work as early as possible A Satisfy customer and shareholder expectations (time, budget, scope) C We must Postpone spending 44 D’(But) We also feel pressure to Delay start of work as late as possible (especially on subcontractors) Leo Lauramaa - TOC & CCPM 2013 09 20 Systemic Core Conflict/Dilemma Requirement / Strategy Objective B We must Complete the project based on the original promises A Satisfy customer and shareholder expectations (time, budget, scope) C We must Finish projects in minimum time and cost 45 Prerequisite / Tactics D We Feel Pressure to Take actions / use rules that will optimize task and resource performance (increase safety, multitasking; start as early as possible) D’(But) We also feel pressure to Take actions / use rules to improve overall project performance (reduce safety, multitasking; start as late as possible) Leo Lauramaa - TOC & CCPM 2013 09 20 Direction of the Solution 46 Do not turn estimates into commitments. Minimize the wasting of safety. Enable early and late finishes to compensate each other. Minimize bad multitasking. Leo Lauramaa - TOC & CCPM 2013 09 20 Example 47 Remove task safety Resource contention Critical chain Add project safety Leo Lauramaa - TOC & CCPM 2013 09 20 Example: Insert the feeding buffers 48 The feeding buffer, which is half the safety removed from the non-critical chain tasks, is placed where a path feeds into the critical chain or end of the network Leo Lauramaa - TOC & CCPM 2013 09 20 Example: Insert the resource buffers 49 Project lead time = 90 (25% less than 120) PB is 1/3 of lead time Leo Lauramaa - TOC & CCPM 2013 09 20 Critical Chain Project Management 50 Before (Traditional) A-14 B-10 C-16 E-20 D-20 C-16 Resolving Resource Contention (CC) A-14 B-10 C-16 E-20 D-20 LT = 60 days LT = 72 days C-16 Aggressive Schedule & Inserting Buffers A-7 B-5 FB-6 C-8 E-10 D-10 C-8 PB-18 LT = 54 days Note: ALWAYS check “given” information: are times padded or has padding been removed? Five Focusing Steps - CCPM 51 1 Identify the system’s constraint(s) Identify the critical chain (the longest sequence of task and resource dependencies) 2 Decide how to exploit the systems constraint(s) Ensure that the critical chain time is minimized, but protected strategically with safety We use an early warning mechanism (resource buffer) to ensure that resources working on the critical chain are prepared to start on time or start earlier than the scheduled start date if gains were achieved in upstream tasks on the critical chain The project buffer (which is HALF of the safety removed from critical chain tasks) is used to ensure timely or early completion of the project overall. Introduce and use measures that reinforce road runner and relay race behaviors. 3 Subordinate everything to the above decision. Use feeding buffers (HALF of the safety removed) wherever non-critical paths/tasks feed into a critical chain task [to protect the constraint from delays]. Schedule non-critical chain tasks to start as late as possible. Introduce and use measures to reinforce road runner and relay race behaviors [eliminates problematic behaviors]. 4. Elevate the System’s Constraint(s) Shorten project lead time by adding resources to break resource contention. Leo Lauramaa - TOC & CCPM 2013 09 20 Fever chart 52 % Project Buffer Consumed Progress along the Critical Chain is typically accompanied by a reduction in the amount of safety that is required in the Project Buffer – The overall Project Buffer requirement is indeed dynamic, not static, during project execution. 100% 66% 33% 0 100 % Critical Chain completed Leo Lauramaa - TOC & CCPM 2013 09 20 Strategy & Tactics Tree - Projects 53 All generic TOC application S&T Trees are available free of charge – see the link below http://www.goldrattresearchlabs.com/default.aspx?ven=goldrattmarketing Check these links http://www.youtube.com/watch?v=5QVLjQJdIBo Leo Lauramaa - TOC & CCPM 2013 09 20 CCPM results 54 Leo Lauramaa - TOC & CCPM 2013 09 20 CCPM results 55 Leo Lauramaa - TOC & CCPM 2013 09 20 Practical Ideas for Improving Project Execution 56 Start projects as late as possible Cut the number of projects in the portfolio by half (don’t start a new one until you finish one) One person decides work priorities Don’t start a task unless you can finish it completely By Mark Woeppel /Pinnacle Strategies Leo Lauramaa - TOC & CCPM 2013 09 20 CCPM software 57 CCPM+: Advanced Projects Inc. - http://www.advanced-projects.com/ ProChain : ProChain Solutions Inc. - http://www.prochain.com/ cc-Pulse & cc-MPulse : Spherical Angle - http://sourceforge.net/projects/cc-mpulse/ Exepron - http://exepron.com/ Lynx - www.a-dato.net PS8 : SciForma - http://www.sciforma.com/en-uk/ Adept Tracker AgileCC - http://www.adepttracker.com/agilecc/index.html Guided Innovations - http://www.guidedinnovation.com/simplecc/ Aurora - http://www.stottlerhenke.com/products/index.htm Being Management - http://www.toc-ccpm.net/eng/bm2.html FLOW MPM from Glow Management - http://www.glow-management.com/ Concerto: Realization - http://www.realization.com/ Schedlyzer Lite: , http://www.optisol.biz/lean-production.html Sciforma VPM Lite (free IOS app) – very simple… Leo Lauramaa - TOC & CCPM 2013 09 20 Other links 58 Books Other TOC links The Goal - Special Edition Eli Goldratt (1 May 2013) http://www.toc.tv order newsletter http://www.goldratt.com Eli Goldratt, Jeff Cox 2004 Critical Chain, Eli Goldratt 1997 Simplifying Innovation, Mike Dalton 2010 TOC4U – Theory of Constraints Ebook Theory Of Constraints – Do It Yourself Kit For Small and Medium Sized Companies, Rajeev Athavale, 2011 TLS – TOC Lean Six Sigma TOC4FINLAND Critical Chain Visual Project Management Some TOC linkedin groups TOC roof organization TOCICO see www.tocico.org (also free guest membership possibility) Best free TOC source www.dbrmfg.co.nz/ Leo Lauramaa - TOC & CCPM 2013 09 20 CV Summary Leo Lauramaa 59 Age 55, M. Sc. (Econ), Consultant Company: Kukonaskel Oy 2008 leo.lauramaa (at) kukonaskel.com +358 400 727 625 Management Consultant Kaukomarkkinat Oy1981 - 2008 2005 – 2008 Director strategic development, management systems, member of management team 1998 – 2005 Deputy Director, development, international activities & group level 1989 – 1998 Controller/Business Controller, import, international activities Strengths Good business overview, holistic approach Wide experience of strategy and development work in different businesses and levels Strategy driven development projects with different tools including process modeling Helping in change management, e.g. in integration or organizational change situations Positive purposeful approach, analytical, creative problem solving Using constantly TOC thinking, tools and applications on consulting engagements Languages finnish (native), english (good), swedish (moderate) Leo Lauramaa - TOC & CCPM 2013 09 20 60 Thank You for Your attention! Leo Lauramaa - TOC & CCPM 2013 09 20