Link to full report

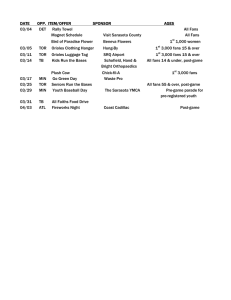

advertisement