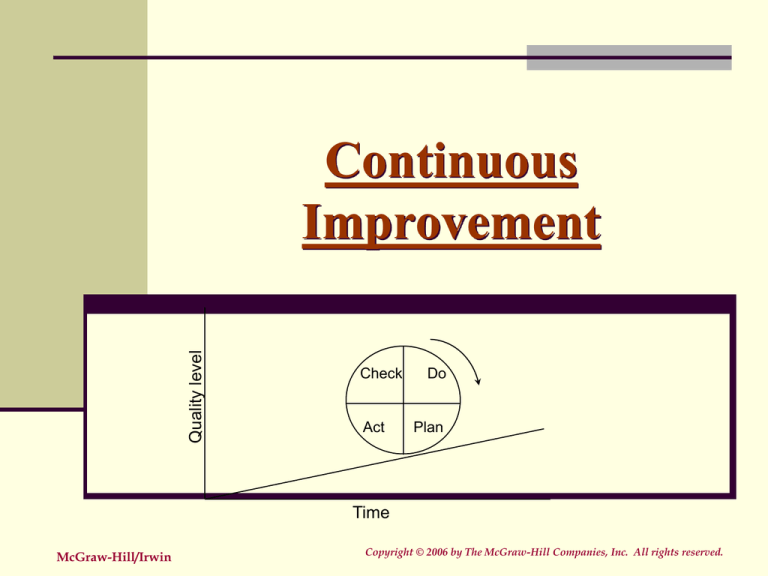

Quality level

Continuous

Improvement

Check

Act

Do

Plan

Time

McGraw-Hill/Irwin

Copyright © 2006 by The McGraw-Hill Companies, Inc. All rights reserved.

Learning Objectives

Lead a Plan-Do-Check-Act (PDCA) process

improvement initiative.

Use quality tools for analysis and problem

solving.

Compare and contrast the corporate

programs for quality improvement.

Quality and Productivity Improvement

Process

Foundations of Continuous Improvement

- Customer Satisfaction

- Management by Facts

- Respect for People

Plan-Do-Check-Act (PDCA) Cycle

Problem Solving (10 steps)

Quality Tools

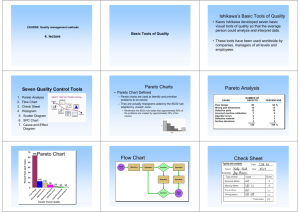

Check Sheet

Run Chart

Histogram

Pareto Chart

Flowchart

Cause-and-Effect Diagram

Scatter Diagram

Control Chart

Check Sheet

Month

Lost

Departure Mechanical Overbooked

Luggage

Delay

January

1

2

3

3

February

3

3

0

1

March

2

5

3

2

April

5

4

4

0

May

4

7

2

3

June

3

8

1

1

July

6

6

3

0

August

7

9

0

3

September

4

7

3

0

October

3

11

2

3

November

2

10

1

0

December

4

12

2

0

Total

44

84

24

16

Other

1

0

3

2

0

1

2

0

2

0

0

1

12

Quality Tools

Check Sheet

Run Chart

Histogram

Pareto Chart

Flowchart

Cause-and-Effect Diagram

Scatter Diagram

Control Chart

Run Chart

14

12

Departure Delays

10

8

6

4

2

0

1

2

3

4

5

6

7

Months

8

9

10

11

12

Quality Tools

Check Sheet

Run Chart

Histogram

Pareto Chart

Flowchart

Cause-and-Effect Diagram

Scatter Diagram

Control Chart

Histogram of Lost Luggage

3.5

3

Frequency

2.5

2

1.5

1

0.5

0

1

2

3

4

5

Occurrences per Month

6

7

Quality Tools

Check Sheet

Run Chart

Histogram

Pareto Chart

Flowchart

Cause-and-Effect Diagram

Scatter Diagram

Control Chart

Pareto Chart of Problems

Number of Problems

90

80

70

60

50

40

30

20

10

0

Departure

Lost

Delay

Luggage

Mech.

Overbooked

Other

8-11

Pareto Analysis of Flight

Departure Delay Causes

Cause

Percentage of

Incidents

Cumulative

Percentage

Late passengers

53.3

53.3

Waiting for pushback

15.0

68.3

Waiting for fuel

11.3

79.6

Late weight and

balance sheet

8.7

88.3

Quality Tools

Check Sheet

Run Chart

Histogram

Pareto Chart

Flowchart

Cause-and-Effect Diagram

Scatter Diagram

Control Chart

Flowchart at Departure Gate

Passenger

Arrives at Gate

Wait for row

call

No

Directed to

Appropriate

Gate

Yes

Check

Luggage

Yes

No

Passenger

Boards

Aircraft

8-14

Quality Tools

Check Sheet

Run Chart

Histogram

Pareto Chart

Flowchart

Cause-and-Effect Diagram

Scatter Diagram

Control Chart

Cause-and-Effect Chart for Flight

Departure Delay (Fishbone Chart)

8-16

Quality Tools

Check Sheet

Run Chart

Histogram

Pareto Chart

Flowchart

Cause-and-Effect Diagram

Scatter Diagram

Control Chart

Scatter Diagram

12

Departure Delays

10

8

6

4

2

0

0

1

2

3

4

Late Passengers

5

6

7

Quality Tools

Check Sheet

Run Chart

Histogram

Pareto Chart

Flowchart

Cause-and-Effect Diagram

Scatter Diagram

Control Chart

Percentage of flights on

time

Control Chart of Departure Delays

100

expected

90

Lower Control Limit

80

70

60

1998

p(1 p

UCL p 3

n

1999

p(1 p

LCL p 3

n

Corporate Programs for Quality

Improvement

Marriott Personnel Programs

Zero Defects (Crosby)

Deming’s 14 Point Program

Malcolm Baldrige Quality Award

ISO 9000

Six-Sigma

Six Sigma DMAIC Process Steps

Step

Define

Definition

Measure

Define project objectives, internal and

external customers

Measure current level of performance

Analyze

Determine causes of current problems

Improve

Identify how the process can be improved

to eliminate the problems

Control

Develop mechanisms for controlling the

improved process

8-22

The Seven-Step Method (SSM)

Step 1: Define the project

Step 2: Study the current situation

Step 3: Analyze the potential causes

Step 4: Implement a solution

Step 5: Check the results

Step 6: Standardize the improvement

Step 7: Establish future plans