N08

advertisement

n08_fea

1 of 10

Finite Element Analysis – One Dimensional Example

straight cantilever beam with constant thickness in pure tension

w = 1 in

L = 10 in

t = 0.5 in

aluminum

E = 10.4e6 psi

P = 1000 lbf

1000 lbf 10 in

PL

PL

in 2

= 0.001923 in = 1.923 mil

6

0.5 in 1 in 10.4x10 lbf

AE twE

Pk

k

twE

L

1000 lbf = 2.0 ksi

P

P

A t w 0.5 in 1 in

n08_fea

2 of 10

tapered cantilever beam with constant thickness in pure tension

L = 10 in

b = 2 in

x

t = 0.5 in

a = 1 in

aluminum

E = 10.4e6 psi

P = 1000 lbf

w b

b a x b m x

L

P

P

E

A tw

L

L

0

0

dx

m

b a

L

0xL

P

Etw

P

P

dx

Et

E t w

L

L

0

1

PL

P 1

b

dx

ln

ln b m x

Et m

0 E t b a a

bm x

2 in

1000 lbf 10 in

in 2

ln

6

0.5 in 2 in 1 in 10.4x10 lbf 1 in

= 1.333 mil

(NOT 1.923 / 1.5 = 1.282 mil)

n08_fea

3 of 10

five elements – six nodes

width 2.0

node

length

element

width

1

1.8

1.6

1.4

1.2

1.0

2

3

4

5

6

2.0

2.0

2.0

2.0

2.0

1

2

3

4

5

1.9

1.7

1.5

1.3

1.1

n08_fea

4 of 10

five elements – six nodes

u1

u2

u3

u4

u5

u6

F1

F2

F3

F4

F5

F6

element1

element2

element3

element4

element5

ui = displacement of node i

Fi = external force applied at node i

li = length of element i

Ai = cross sectional area of element i

ti = thickness of element i

wi = width of element i

Ei = modulus for element i

ki = stiffness of element i

fi = internal force on element i

ui

ui+1

NO LOAD

u

WITH LOAD

u

f i li

fi li

Ai Ei t i w i Ei

f i k i u i1 u i

fi

fi

fi

t i wi Ei

u k u k i u i 1 u i

li

ki

t i wi Ei

li

n08_fea

5 of 10

nodei

Fi

fi-1

fi

elementi-1

F on node 1

F on node 2

F on node 3

F on node 4

F on node 5

F on node 6

k 1

k

1

0

0

0

0

F1 f1 FWALL 0

F2 f 2 f1

F3 f 3 f 2

F4 f 4 f 3

F5 f 5 f 4

F6 f 5 0

elementi

F1 k 1u 1 k 1u 2 FWALL

F2 k 1u 1 k 1 k 2 u 2 k 2 u 3

0

0

0

0

F3 k 2 u 2 k 2 k 3 u 3 k 3 u 4

F4 k 3 u 3 k 3 k 4 u 4 k 4 u 5

F5 k 4 u 4 k 4 k 5 u 5 k 5 u 6

F6 k 5 u 5 k 5 u 6

k1

0

0

0

k1 k 2

k2

0

0

k2

k2 k3

k3

0

0

k3

k3 k4

k4

0

0

k4

k4 k5

0

0

0

k5

0 u 1 F1 FWALL

0 u 2

F2

0 u 3

F3

0 u 4

F4

k5 u5

F5

k 5 u 6

F6

impose restraints u1 = 0 and F1 = 0 in first row of equations

1

k

1

0

0

0

0

0

0

0

0

k1 k 2

k2

0

0

k2

k2 k3

k3

0

0

k3

k3 k4

k4

0

0

k4

k4 k5

0

0

0

k5

0 u1 0

0 u 2 F2

0 u 3 F3

0 u 4 F4

k 5 u 5 F5

k 5 u 6 F6

[K] = system stiffness matrix

{u} = vector of nodal displacements

{F} = vector of external forces on nodes

displacement analysis - solve for u K F

1

Ku F

n08_fea

6 of 10

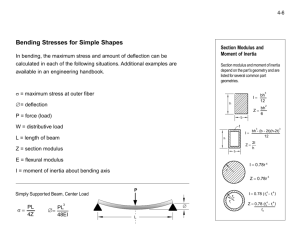

stress analysis

i = strain in element i

i = stress in element i

i

u i 1 u i

i Ei i

li

1 E 1 / l 1

0

2

3 0

0

4

5 0

0

E2 / l2

0

0

0

0

0

E3 / l3

0

0

0

0

0

E4 / l4

0

Ei

li

u i 1

ui

0 u 2 u 1

0 u 3 u 2

0 u 4 u 3

0 u 5 u 4

E 5 / l 5 u 6 u 5

{} = vector of stresses on each element

[C] = elasticity matrix

{u} = vector of differences in nodal displacements

Cu

n08_fea

7 of 10

SUMMARY FOR THREE-DIMENSIONAL ANALYSIS

1) Know material properties – E, G, (Poisson’s ratio)

2) Generate mesh – create elements and nodes

reduce mesh size by factor of 2, increases number of nodes by factor of 8

3) Compute stiffness matrix – order n = number of degrees of freedom (DOF)

n = 3 * number of nodes

4) Define restraints – modify stiffness matrix to force specific nodal displacements to zero

5) Define loading – form right-hand-side (RHS) vector

6) Invert stiffness matrix and pre-multiply loading RHS vector to solve for nodal displacements

computation time proportional to n2

7) Compute nodal deformations RHS vector (differences of nodal displacements)

8) Compute elasticity matrix

9) Pre-multiply elasticity matrix times deformation RHS vector to solve for stresses at nodes

find von Mises stress, maximum shear stress, normal stress, Dowling stress

10) Know strength of material – SY, SUT, SUC

11) Compute factor of safety at each node

n08_fea

8 of 10

% fea_1d.m - one dimensional finite elemnent analysis

% HJSIII, 12.09.05

%

P

L

t

E

axial load,

= 1000;

= 10.0;

= 0.5;

= 10.4e6;

geometry, material

% axial load [lbf]

% length [inch]

% thickness [inch]

% Young's modulus for aluminum [psi]

% analytical solution - constant width

w = 1.0;

% width [inch]

delta_const_w_mil = P *L /w /t /E *1000;

% [mils]

% analytical solution - tapered

a = 1.0;

% width at tip [inch]

b = 2.0;

% width at root [inch]

delta_taper_mil = P *L /t /E /(b-a) *log(b/a) *1000;

% element stiffness - tapered

n = 5;

li = L/n * ones(n,1);

ti = t * ones(n,1);

Ei = E * ones(n,1);

wi = [ 1.9 1.7 1.5 1.3 1.1 ]';

%

%

%

%

%

% [mils]

number of finite elements

length [inch]

thickness [inch]

Young's modulus for aluminum [psi]

width [inch]

k = wi .*ti .*Ei ./li;

% global stiffness

K = [ +1

0

-k(1) +k(1)+k(2)

0

-k(2)

0

0

0

0

0

0

% external forces

F = [ 0 0 0 0 0

0

-k(2)

+k(2)+k(3)

-k(3)

0

0

0

0

-k(3)

+k(3)+k(4)

-k(4)

0

P ]';

% displacements

u = inv(K) * F;

delta_fea_mil = u(6) *1000;

delta_const_w_mil

delta_taper_mil

delta_fea_mil

% stress

C = diag( Ei ./li );

strain = diff( u );

stress = C * strain;

stress_ksi = stress /1000

% [mils]

0

0

0

-k(4)

+k(4)+k(5)

-k(5)

0

0

0

0

-k(5)

+k(5)

;

;

;

;

;

];

n08_fea

>> fea_1d

delta_const_w_mil =

1.9231

delta_taper_mil =

1.3330

delta_fea_mil =

1.3306

stress_ksi =

1.0526

1.1765

1.3333

1.5385

1.8182

9 of 10

n08_fea

FEA sensitivity study for

10 of 10

tee_01.sldprt

mesh control

size parameter

[inch]

max von Mises

stress

[ksi]

DOF

relative

computations

0.086

0.06

0.04

0.02

0.01

45.59

50.80

51.55

50.38

50.42

35496

61335

87162

205329

762018

1

2.99

6.03

33.46

460.86