Power Factor Correction (Word)

advertisement

Electrical Systems: Power Factor Correction

Resistive devices, like electric resistance heaters and incandescent lights transform all the

power supplied to the device into heat or useful energy. Inductive devices, like motors,

use some of the power supplied to the device to energize the inductive windings and

create a magnetic field. This power, called reactive power, is alternately stored and given

up by the windings, but is not used to do actual work. When this happens, the line

supplying power to the device now carries the actual power used by the device and the

reactive power created by the device.

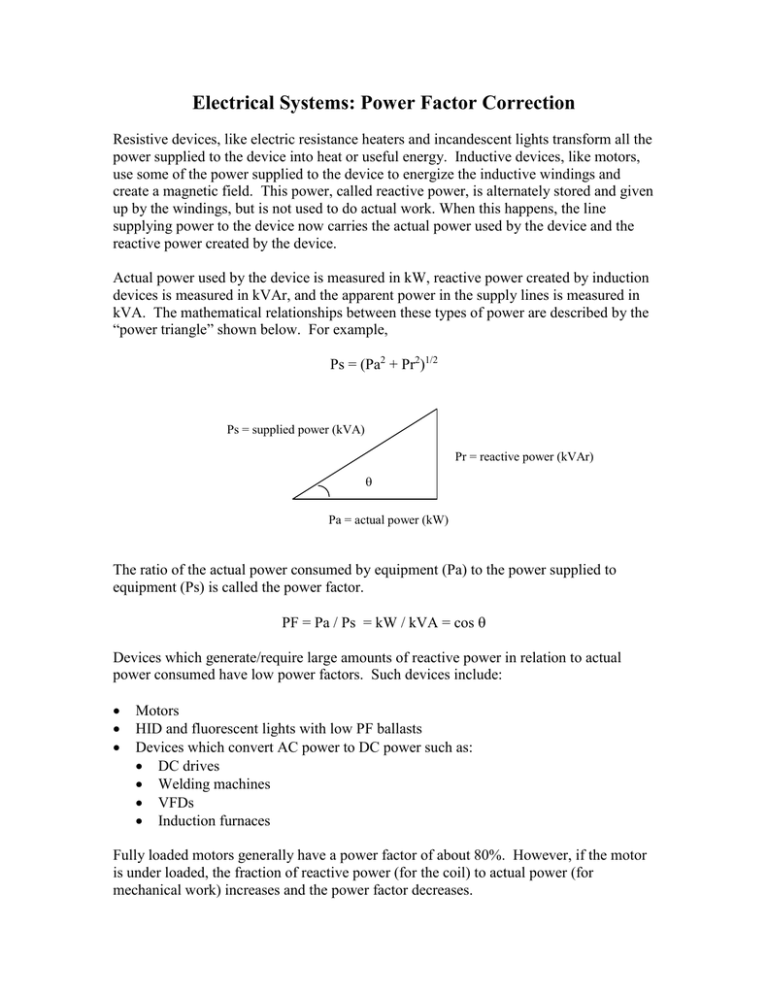

Actual power used by the device is measured in kW, reactive power created by induction

devices is measured in kVAr, and the apparent power in the supply lines is measured in

kVA. The mathematical relationships between these types of power are described by the

“power triangle” shown below. For example,

Ps = (Pa2 + Pr2)1/2

Ps = supplied power (kVA)

Pr = reactive power (kVAr)

Pa = actual power (kW)

The ratio of the actual power consumed by equipment (Pa) to the power supplied to

equipment (Ps) is called the power factor.

PF = Pa / Ps = kW / kVA = cos

Devices which generate/require large amounts of reactive power in relation to actual

power consumed have low power factors. Such devices include:

Motors

HID and fluorescent lights with low PF ballasts

Devices which convert AC power to DC power such as:

DC drives

Welding machines

VFDs

Induction furnaces

Fully loaded motors generally have a power factor of about 80%. However, if the motor

is under loaded, the fraction of reactive power (for the coil) to actual power (for

mechanical work) increases and the power factor decreases.

Two potential problems are associated with low power factor. First many utilities have

explicit or implicit charges for low power factor. Second, low power factor increases the

current, and hence losses, in transformers and the electrical distribution system. These

losses cost money and generate excess heat in the electrical distribution system, which

may shorten equipment lifetime or cause production shut downs. These potential

problems are discussed in the sections that follow.

Power Factor Charges

Many utilities charge for low power. To measure power factor, the most common type of

utility meter measures the total kVAr-hours and kVA-hours over the billing period and

calculates the average power factor as:

PF = Cos [ ArcSin (kVArh / kVAh) ]

The most common methods of charging for low power factor are:

1. Adding a demand penalty when the power factor dips below a set amount (usually

90%)

For example: the Cinergy DS rate specifies a demand penalty of:

0.9 - PF

kWactual

when PF < 0.9

PF

If actual power was 100 kW, the power factor was 80%, and the avoided

cost of demand were $15.67 /kW, the monthly power factor charge would

be:

0.9 - 0.8

100 kW

12.5 kW

0.8

12.5 kW x $15.67 /kW = $196

2. Basing the demand charge on the supplied power Ps (kVA), rather than the actual

power used Pa (kW).

For example, assume billing demand is based on kVA rather than kW and

the demand charge is $15.00 /kVA-month. If actual demand was 100 kW,

the power factor was 80%, the implicit monthly power factor charge

would be:

kVAPF = 80% = kW / PF = 100 kW / 0.8 kW/kVA = 125 kVA

kVAPF = 100% = kW / PF = 100 kW / 1.0 kW/kVA = 100 kVA

Penalty = $15 /kVA-month x (KVAPF = 80% - KVAPF = 100%)

Penalty = $15 /kVA-month x (125 kVA – 100 kVa) = $375 /month

3. Basing part of the overall charge on the reactive power kVAr, which increases as

power factor decreases.

For example, the Dayton Power and Light General Service Primary Rate

specifies a charge of $0.30 per kVAr. The relationship between reactive

and actual power is:

Pr (kVAr) = Pa (kW) x Tan[Cos-1(PF)]

If the actual power was 100 kW and the power factor was 80%, then the

power factor charge would be:

Pr (kVAr) = 100 (kW) x Tan[Cos-1(0.8)] = 75 kVAr

75 kVAr x $0.30 /kVAr = $23

Power Losses and Excess Heat Generation

In addition to possible power factor charges, low power factor also results in excess

current in the electrical distribution system upstream from the device. The excess line

current results in increased resistive losses, and hence heat gain, in the wiring and

electrical distribution equipment. The quantity of line losses associated with low power

factor correction can be calculated as follows:

LL1 = Line loss before power factor correction

LL2 = Line loss after power factor correction

% Line Loss Savings = (LL1 – LL2) / LL1

LL1 = I21R1 = (kVA1/V1)2 R1 =[(kW1/PF1) / V1]2 R1 = [kW2 R / V2]1 / PF12

Thus:

LL2 = [kW2 R / V2]2 / PF22

Assuming everything remains constant except for the power factor:

[kW2 R / V2]1 = [kW2 R / V2]2 = [kW2 R / V2]

And,

% Line Loss Savings = (LL1 – LL2) / LL1

% Line Loss Savings = [(kW2 R / V2) / PF12 – (kW2 R / V2) / PF22] / (kW2 R / V2)1 / PF12

% Line Loss Savings = [1 / PF12 – 1 / PF22] / 1 / PF12

% Line Loss Savings = 1 – (PF1/ PF2)2

For example, if the power factor were improved from 80% to 90%, the percent line loss

savings would be:

% Line Loss Savings = 1 – (PF1/ PF2)2 = 1 – (80%/ 90%)2 = 21%

In addition, the heat generation in upstream electrical distribution equipment would be

reduced by 21%. This may or may not be significant. If the electrical circuits are fully

loaded and tripping due to excess current, then power factor correction could mitigate this

problem.

Although percent line loss savings are relatively high, total energy savings are typically

small since line losses are small. For example, if line losses are 2% of the total power

draw, the total power savings from correcting the power factor would be:

2% x 21% = 0.42%

Some manufactures of power factor correction equipment claim that actual losses are

much greater than those calculated here, but there is little documented evidence of this in

the open literature.

Because of these effects, it is generally in the client's interest to maintain a relatively high

power factor. To maintain a high power factor:

purchase equipment with high power factor ratings, such as high power factor

lighting ballasts

avoid or replace dramatically oversized motors, since under-loaded motors have

low power factors.

If power factor is still a problem, consider adding electrical capacitors.

Sizing Capacitors and Estimating Savings

Capacitors work by canceling reactive power and current on the primary or upstream side

of the capacitor. For example, if a motor operates at 70% power factor, installing a

capacitor in the power supply line to the motor would reduce reactive power and line

current on the primary side of the capacitor, but would not change the line current on the

secondary (motor) side of the capacitor. Thus, installing capacitors directly upstream

from low-power-factor loads reduces line current throughout the plant’s electrical

distribution system; whereas installing capacitors directly down stream of the utility

meter at the electrical service entrance to the plant, results in power factor correction for

utility billing purposes, but will not reduce line losses and overheating throughout the

plant.

Primary side of

capacitor

Secondary side

of capacitor

Capacitor

Motor

kVAprimary < kVAsecondary

PFprimary > PFsecondary

The two primary types of capacitors are oil-filled and gas-filled. Oil-filled capacitors

typically last about 60,000 hours and may introduce voltage transients to the downstream

equipment. In addition, the oil is potentially flammable and may contain toxins requiring

special disposal. Nitrogen and helium gas-filled capacitors last about 120,000 hours,

filter voltage transients, are non-flammable and non-toxic. However, the substantially

lower cost of oil-filled capacitors make them much more popular than gas-filled

capacitors.

Capacitors are sized by the amount of reactive power (kVAr) they can cancel. Simple

capacitors are sized to compensate for a fixed amount of power. “Stepped” capacitors

have internal controls that adjust the amount of reactive power compensation.

Adding too much capacitance can push the system from “lagging” to “leading”; for

example, adding too much capacitance may change the power factor from 95% to 105%.

Although leading power factor does not harm equipment, purchasing excess capacitors is

expensive and serves no useful purpose. In addition some meters may read a leading

105% power factor as 95%. If so, you would not get credit for the power factor

correction from 95% to 100%. (Other utility meters would read a power factor of 105%

as 100%). Because of these reasons, we recommend a conservative approach to power

factor correction in which we never overcorrect the power factor past 100%.

A simple method to size the amount of capacitor kVAr required is described in the steps

that follow:

1. Find kVAr for each month: Pr (kVAr) = Pa (kW) x Tan[Cos-1(PF)]

2. To increase PF as close to 1.0 as possible, recommend additional capacitance equal to

minimum monthly kVAr during the past 12 months. This approach minimizes the

possibility of adding too much capacitance.

3. Subtract the recommended capacitance (kVAr) from recorded (kVAr) for each

month. This difference represents the reactive power (kVAr) if the recommended

capacitance were added.

4. Recalculate PF, kVA or kVAr and electricity costs for each month, using the reactive

power calculated in the previous step. These costs represent the costs if the

recommended capacitance had been added.

5. Calculate savings as the difference between the actual costs and the costs calculated

in the previous step.

6. To estimate the implentation cost, we note that the installed cost of capacitors is about

about $20 /kVAr - $50 /kVAr, depending on control complexity and size.

Examples follow:

AR x: Consider Installing Capacitors to Improve Power Factor

Annual Savings

Project Cost

CO2

Resource

Dollars Capital Other

Total

(tonne)

Electrical Fees

None $12,305 $46,000 $46,000 $92,000

ARC: 2.3212.3

Simple

Payback

90 months

Analysis

Electrical equipment that generates inductive loads, such as motors, creates current that is

not in phase with the current supplied by the electric utility. Inductive loads cause the

current waveform to lag behind the voltage waveform. This causes a portion of the

energy to return to the source, hence leaving less usable power for the equipment. The

power associated with this unusable current is called reactive power (kVAr). Because

some energy is returned to the source, a higher supply power (kVA) must be generated by

the utility in order to meet equipment needs. The ratio of power consumed by equipment

(kW) to total power in the electrical lines (kVA) is called the power factor. Most utilities

charge for low power factor. Low power factor can be corrected by adding capacitors,

which are rated in terms of kVAr.

Power Factor of 1. All Power is usable.

Power factor of 0.71. Unusable power is created.

(Source: www.wikipedia.com)

The diagram below shows the relationship between the various types of power: supplied

power (kVA), reactive power (kVAr), and actual used power (kW). The quantity of each

type of power can be calculated using trigonometric relations defined by the power

triangle.

kVA (power

supplied

by utility)

kW

PF =

kVA

kVAr (measure of

unused power)

kW (actual power used by machines)

Power factor is ratio of the actual power, kW, and supplied power, kVA. The power

factor can be calculated using the following relationships:

PF = kW / kVA = cos (tan-1 (kVAr/kW))

(1)

Reactive power is a measure of the unused power in the lines. The reactive power can be

calculated using the following relationship:

Reactive Power (kVAr) = kW x tan (cos-1 (PF))

(2)

The supplied power (kVA) can be calculated from the reactive power (kVAr) and power

factor from the following relationship:

kVA = kVAr/sin (cos-1(PF))

(3)

According to your rate structure “Large General Service Rate”, the power factor charge is

about $0.48 per kVAr per month. Your utility company charges for all kVAr in excess of

10% of the billed demand. According to the utility bills, the current power factor

averages about 0.85. Savings would be achieved if the power factor were increased from

0.85 to 1.0.

Recommendation

We recommend considering adding an additional 2,300 kVAr of capacitance to improve

the average power factor.

Estimated Savings

The data listed below is extracted from the utility bills for the years 2006 and 2007. The

utility bills summary shows actual demand (kW) and your current lagging reactive

demand (kVAr). According to your rate structure, the power factor charge is about $0.48

/kVAr in excess of 10% of billed demand. As indicated in the table below, installing

2,300 kVAr of capacitance would increase your average annual power factor from 0.85

(kW/kVA) to 1.0 (kW/kVA). Savings are calculated as the product of power factor

charge ($/kVA) and the current billed reactive demand (kVA).

Meter

Reading

Date

8/27/07

9/26/07

10/26/07

11/27/07

12/27/07

1/25/08

2/26/08

3/27/08

4/25/08

5/27/08

6/25/08

7/25/08

Tot/Avg

Billed

Unit Power

Metered

Actual

Actual Lagging

Power

Proposed

Reactive

Factor

Consumption Demand

Reactive

Factor

Capacitance

Demand

Charge

(kWh/period) (kW)

Demand (kVAr) (kW/kVA)

(kVAr)

(kVAr)

($/kVA)

2,780,825

4,219

2,065

2,538

0.86

$0.48

2,300

2,623,534

4,238

2,057

2,532

0.86

$0.48

2,300

2,669,789

4,185

2,247

2,719

0.84

$0.48

2,300

2,959,728

4,240

2,114

2,590

0.85

$0.48

2,300

2,616,545

4,235

2,138

2,612

0.85

$0.48

2,300

2,634,931

4,235

2,138

2,612

0.85

$0.48

2,300

2,936,662

4,443

2,138

2,624

0.86

$0.48

2,300

2,653,735

4,235

2,138

2,612

0.85

$0.48

2,300

2,566,901

4,235

2,138

2,612

0.85

$0.48

2,300

2,584,217

4,081

2,081

2,540

0.85

$0.48

2,300

2,311,135

4,251

2,136

2,614

0.85

$0.48

2,300

0.84

2,145,290

4,217

2,262

2,739

$0.48

2,300

31,483,292

4,234

2,300

2,138

2,612

0.85

$0.48

New

Reactive

Demand

(kVAr)

238

232

419

290

312

312

324

312

312

240

314

439

312

New Billed

New Power

Reactive

Factor

Demand

(kW/kVA)

(kVAr)

0

1.00

0

1.00

1

1.00

0

1.00

0

1.00

0

1.00

0

1.00

0

1.00

0

1.00

0

1.00

0

1.00

17

0.99

2

1.00

Savings

($/Period)

$991

$987

$1,078

$1,015

$1,026

$1,026

$1,026

$1,026

$1,026

$999

$1,025

$1,078

$12,305

The table shows that 1,300 kVAr of additional capacitance would be sufficient to avoid

almost all power factor penalties, and the savings from installing additional capacitance

would be about $12,305 per year. Hence, we propose adding an additional 2,300 kVAr of

capacitance.

Estimated Implementation Cost

Based on previous experience, simple capacitors can be installed for about $40 per kVAr.

Therefore, the estimated implementation cost would be about:

(2,300 kVAr x $40 /kVAr) = $92,000

We estimate that about 50% of this is for materials and 50% for labor.

Estimated Simple Payback

($92,000 / $12,305 /year) x 12 months = 90 months

AR x: Install Capacitors to Improve Power Factor

Annual Savings

Project Cost

CO2

Resource

Dollars Capital Other

Total

(tonne)

Electrical Fees

None $26,537 $10,625 $10,625 $21,250

ARC: 2.3212.3

Simple

Payback

10 months

Analysis

Electrical equipment that generates inductive loads, such as motors, generates current that

is not in phase with the current supplied by the electric utility. The power associated with

this unusable current is called reactive power (kVAr). The total power in the line (kVA)

includes both the useable (kW) and the reactive power (kVAr). The ratio of power

consumed by equipment (kW) to total power in the electrical lines (kVA) is called the

power factor. Most utilities charge for low power factor. Low power factor can be

corrected by adding capacitors, which are rated in terms of kVAr.

The diagram below shows the relationship between the various types of power: total

power (kVA), reactive power (kVAr), and actual used power (kW). The quantity of each

type of power can be calculated using trigonometric relations defined by the power

triangle.

kVA (total

power)

kW

PF =

kVA

kVAr (reactive

unusable power)

kW (actual power used by machines)

Power factor is ratio of the actual power, kW, and total power, kVA. The power factor

can be calculated using the following relationships:

PF = kW / kVA = cos (tan-1 (kVAr/kW))

(1)

The reactive power can be calculated using the following relationship:

Reactive Power (kVAr) = kW x tan (cos-1 (PF))

(2)

The total power (kVA) can be calculated from the reactive power (kVAr) and power

factor from the following relationship:

kVA = kVAr/sin (cos-1(PF))

(3)

In the “Utility Analysis” section of this report, both on-peak and off-peak power factors

less than 0.9 increase the billed demand. The cost for power factor below 0.9 during onpeak is:

= (measured on-peak kW) / (on-peak PF) x 0.9 x (on-peak demand cost)

The cost for power factor below 0.9 during off-peak is:

= {[(max kW) / off-peak PF x 0.9] - [(measured on-peak kW) / (on-peak PF) x 0.9]} x

(off-peak demand cost)

Recommendation

We recommend considering adding an additional 425 kVAr to improve the average

power factor.

Estimated Savings

The table below shows on-peak and off-peak actual demand (kW), power factor

(kW/kVA), supplied power (kVA), reactive power (kVAr), and billing demand (kW).

The on-peak and off-peak power factor remains lower than 0.9 for the entire year. Using

the rate structure form the “Utility Analysis” section of this report, the cost for this low

power factor is about $26,537 per year.

Meter

Reading

Date

Days

On-peak

Demand

(kW)

Off-Peak

Demand

(kW)

9/11/06

10/10/06

11/8/06

12/11/06

1/12/07

2/12/07

3/12/07

4/12/07

5/11/07

6/12/07

7/12/07

8/10/07

Tot/Avg

32

31

29

33

32

31

28

31

29

32

30

29

367

864

862

842

838

810

842

804

814

823

827

806

845

825

860

864

840

838

812

827

806

827

817

827

793

845

830

On-peak

Power

Factor

(kW/kVA)

0.73

0.73

0.73

0.73

0.74

0.76

0.74

0.76

0.74

0.75

0.73

0.75

0.74

Off-Peak

Power

Factor

(kW/kVA)

0.74

0.73

0.73

0.74

0.75

0.74

0.75

0.75

0.73

0.74

0.73

0.74

0.74

On-peak

Supplied

Power

(kVA)

1,187

1,174

1,157

1,145

1,093

1,114

1,093

1,076

1,106

1,107

1,099

1,123

1,123

Off-peak

Supplied

Power

(kVA)

1,157

1,192

1,151

1,130

1,077

1,115

1,076

1,103

1,117

1,112

1,084

1,146

1,122

On-Peak

Reactive

Power

(kVAr)

814

797

793

780

734

729

741

703

739

736

748

740

755

Off-Peak

Reactive

Power

(kVAr)

774

821

787

757

708

747

713

730

762

743

740

775

755

On-Peak

Billing

Demand

(kW)

1,068

1,057

1,041

1,030

984

1,003

984

968

996

997

989

1,011

1,011

Off-Peak

Billing

Demand

(kW)

0

16

0

0

0

1

0

25

10

4

0

21

6

Calculated

Power Factor

Cost ($/period)

$2,603

$2,371

$2,402

$2,322

$2,098

$1,937

$2,177

$1,885

$2,094

$2,165

$2,340

$2,143

$26,537

The on-peak and off-peak reactive power (kVAr) measured at the meter will be reduced

by 425 kVAr per month by installing 425 kVAr of capacitance. This is depicted in the

table below. 425 kVAr of capacitance will raise the on-peak and off-peak power factor

above 0.9. Therefore, the annual power factor cost would be about $0 per year.

Meter

Reading

Date

Days

On-peak

Demand

(kW)

Off-Peak

Demand

(kW)

9/11/06

10/10/06

11/8/06

12/11/06

1/12/07

2/12/07

3/12/07

4/12/07

5/11/07

6/12/07

7/12/07

8/10/07

Tot/Avg

32

31

29

33

32

31

28

31

29

32

30

29

367

864

862

842

838

810

842

804

814

823

827

806

845

825

860

864

840

838

812

827

806

827

817

827

793

845

830

On-peak

Power

Factor

(kW/kVA)

0.91

0.92

0.92

0.92

0.93

0.94

0.93

0.95

0.93

0.94

0.93

0.94

0.93

Off-Peak

Power

Factor

(kW/kVA)

0.93

0.91

0.92

0.93

0.94

0.93

0.94

0.94

0.92

0.93

0.93

0.92

0.93

On-peak

Supplied

Power

(kVA)

947

939

919

910

867

896

864

860

881

884

868

902

895

Off-peak

Supplied

Power

(kVA)

928

950

915

902

860

888

856

882

883

886

853

914

893

On-Peak

Reactive

Power

(kVAr)

389

372

368

355

309

304

316

278

314

311

323

315

330

Off-Peak

Reactive

Power

(kVAr)

349

396

362

332

283

322

288

305

337

318

315

350

330

On-Peak

Billing

Demand

(kW)

864

862

842

838

810

842

804

814

823

827

806

845

831

Off-Peak

Billing

Demand

(kW)

0

0

0

0

0

0

0

0

0

0

0

0

0

Calculated

Power Factor

Cost ($/period)

$0

$0

$0

$0

$0

$0

$0

$0

$0

$0

$0

$0

$0

The annual savings for installing 425 kVAr of capacitance would be about:

$26,537 /yr - $0 /yr = $26,537 /yr

Estimated Implementation Cost

Based on previous experience, simple capacitors can be installed for about $50 per kVAr.

Therefore, the estimated implementation cost for installing 425 kVAr of capacitance

would be about:

425 kVAr x $50 /kVAr = $21,250

We estimate that about 50% of this is for materials and 50% for labor.

Estimated Simple Payback

($21,250 / $26,537 /yr) x 12 months = 10 months

AR x: Install Capacitors to Improve Power Factor

Annual Savings

Project Cost

CO2

Resource

Dollars Capital Other

Total

(tonne)

Electrical Fees

None $44,362 $6,750 $6,750 $13,500

ARC: 2.3212.3

Simple

Payback

4 months

Analysis

Inductive loads, such as motors, generate a reactive current that is not in phase with the

current supplied by the utility, hence, it is unusable. The power associated with this

reactive current is called reactive power, and is measured in kVAr. The useful power

drawn by machines and supplied by the utility is measured in kW. The total power in the

lines is the sum of the useful and reactive power and is measured in kVA. The ratio of

power consumed by equipment (kW) to power in the lines (kVA) is called the power

factor. Most utilities charge for low power factor. Low power factor can be corrected by

adding capacitors, which are rated in terms of kVAr.

The diagram below shows the relationship between the various types of power. The

quantity of each type of power can be calculated using trigonometric relations defined by

the power triangle.

kVA (line

power)

kW

PF =

kVA

kVAr (reactive

power)

kW (actual power used by machines)

The power factor can be calculated using the following relationships:

PF = kW / kVA = cos (tan-1 (kVAr/kW))

(1)

Reactive power is a measure of the unused power in the lines. The reactive power can be

calculated using the following relationship:

Reactive Power (kVAr) = kW x tan (cos-1 (PF))

(2)

The line power (kVA) can be calculated from the reactive power (kVAr) and power

factor from the following relationship:

kVA = kVAr/sin (cos-1(PF))

(3)

In the utility analysis section of this report, the power factor charge is kVA x 0.9. The

utility rate for meter 1 and 3, “General Rate DS01 Service at Secondary Distribution

Voltage”, the monthly power factor charge for each meter with a power factor less than

0.9 and a billed demand less than 1,000 kW is:

Billed kW/mo x 300 kWh/kW x ($0.033076 - $0.020094) kWh + Billed kW x $15.1454

/kW

The monthly power factor charge for each meter with a power factor less than 0.9 and a

billed demand greater than 1,000 kW is:

Billed kW/mo x 300 kWh/kW x ($0.033076 - $0.020094) kWh + Billed kW x $15.1454

/kW

According to the utility bills, the current power factors for meter 1 & 3 are less than 0.9

for every month. Savings would be achieved if the power factor were increased to 0.90.

Recommendation

We recommend considering adding an additional 250 kVAr to Meter 1 and an additional

200 kVAr of capacitance to Meter 3 to improve the average power factor for each meter.

Estimated Savings

The table below shows meter 1 actual demand (kW) current reactive demand (kVAr),

current power factor and the total calculated electrical costs based upon the current rate

structure for the previous seven billing periods. The calculated electrical cost for meter 1

is about $290,089 for the last seven billing periods.

Meter 1

Meter

Reading

Date

Days

Metered

Consumption

(kWh/period)

Avg. Daily

Consumption

(kWh/day)

Actual

Demand (kW)

Supplied

Power

(kVA)

10/5/2007

11/5/2007

12/6/2007

1/9/2008

2/7/2008

3/7/2008

4/8/2008

29

31

31

34

29

29

32

240,064

508,236

596,096

678,600

724,944

418,725

482,823

8,278

16,395

19,229

19,959

24,998

14,439

15,088

803

976

1,062

1,256

1,317

853

979

1,005

1,192

1,336

1,549

1,586

1,100

1,243

Current

Reactive

Demand

(kVAr)

604

685

810

907

883

694

765

Tot/Avg

215

3,649,488

16,974

1,035

1,287

764

0.80

0.82

0.80

0.81

0.83

0.78

0.79

Power

Factor

Penality

(kW)

102

97

140

138

110

137

139

0.80

863.08

Power

Factor

(kW/KVA)

Billed

Demand

(kW)

Calculated Total

Cost ($/period)

905

1,073

1,202

1,394

1,427

990

1,118

$26,402

$39,694

$45,123

$51,166

$53,369

$34,840

$39,495

1,158

$290,089

The table below shows meter 1 actual demand (kW) new reactive demand (kVAr), new

power factor and the total calculated electrical costs based upon the current rate structure

for the previous seven billing periods. The calculated electrical cost for meter 1 by adding

250 kVAr of reactive power would be about $276,063 for the last seven billing periods.

Meter 1

Meter

Reading

Date

Days

Metered

Consumption

(kWh/period)

Avg. Daily

Consumption

(kWh/day)

Actual

Demand (kW)

10/5/2007

11/5/2007

12/6/2007

1/9/2008

2/7/2008

3/7/2008

4/8/2008

29

31

31

34

29

29

32

240,064

508,236

596,096

678,600

724,944

418,725

482,823

8,278

16,395

19,229

19,959

24,998

14,439

15,088

803

976

1062

1256

1317

853

979

New

Supplied

Power

(kVA)

878

1084

1180

1395

1463

947

1087

Tot/Avg

215

3,649,488

16,974

1,035

1,148

354

435

560

657

633

444

515

0.91

0.90

0.90

0.90

0.90

0.90

0.90

Power

Factor

Penality

(kW)

0.00

0.00

0.00

0.00

0.00

0.00

0.00

514

0.90

0.00

New Reactive

Power

Demand

Factor

(kVAr)

(kW/KVA)

Billed

Demand

(kW)

Calculated Total

Cost ($/period)

803

976

1,062

1,256

1,317

853

979

$24,469

$37,990

$42,863

$49,312

$52,116

$32,231

$37,082

1,035

$276,063

The table below shows meter 3 actual demand (kW) current reactive demand (kVAr),

current power factor and the total calculated electrical costs based upon the current rate

structure for the previous seven billing periods. The calculated electrical cost for meter 3

is about $94,078 for the last seven billing periods.

Meter 3

Meter

Reading

Date

Days

Metered

Consumption

(kWh/period)

Avg. Daily

Consumption

(kWh/day)

Actual

Demand (kW)

Supplied

Power

(kVA)

10/5/2007

11/5/2007

12/6/2007

1/9/2008

2/7/2008

3/7/2008

4/8/2008

29

31

31

34

29

29

32

73,871

128,492

159,205

183,097

177,265

124,927

147,326

2,547

4,145

5,136

5,385

6,113

4,308

4,604

232

282

362

368

387

309

368

296.3

417.8

494.7

547

548

437

527

Current

Reactive

Demand

(kVAr)

184

309

338

405

387

309

378

Tot/Avg

215

994,183

4,624

330

467

330

0.78

0.67

0.73

0.67

0.71

0.71

0.70

Power

Factor

Penality

(kW)

34.67

94.42

83.60

124.39

105.64

84.23

106.57

0.71

633.52

Power

Factor

(kW/KVA)

Billed

Demand

(kW)

Calculated Total

Cost ($/period)

267

376

445

492

493

393

475

7,919

12,084

14,573

16,382

16,169

12,272

14,679

420

$94,078

The table below shows meter 3 actual demand (kW) new reactive demand (kVAr), new

power factor and the total calculated electrical costs based upon the current rate structure

for the previous seven billing periods. The calculated electrical cost for meter 3 by adding

200 kVAr of reactive power would be about $82,226 for the last seven billing periods.

Meter

Reading

Date

Days

Metered

Consumption

(kWh/period)

Avg. Daily

Consumption

(kWh/day)

Actual

Demand (kW)

Supplied

Power

(kVA)

10/5/2007

11/5/2007

12/6/2007

1/9/2008

2/7/2008

3/7/2008

4/8/2008

29

31

31

34

29

29

32

73,871

128,492

159,205

183,097

177,265

124,927

147,326

2,547

4,145

5,136

5,385

6,113

4,308

4,604

232

282

362

368

387

309

368

232.0

301.8

386.9

421.2

430.1

327.4

408.6

0

109

138

205

187

109

178

1.00

0.93

0.93

0.87

0.90

0.94

0.90

Power

Factor

Penality

(kW)

0.00

0.00

0.00

11.05

0.00

0.00

0.00

Tot/Avg

215

994,183

4,624

330

358

132

0.93

11.05

New Reactive

Power

Demand

Factor

(kVAr)

(kW/KVA)

Billed

Demand

(kW)

Calculated Total

Cost ($/period)

232

282

362

379

387

309

368

$7,259

$10,286

$12,981

$14,224

$14,157

$10,668

$12,650

331

$82,226

The annual savings for installing 250 kVAr of capacitance to meter 1 and 200 kVAr of

capacitance to meter 3 would be about:

($290,089 - $276,063) / 7 mo + ($94,078 - $82,226) / 7 mo = $25,878 / 7 mo

$25,878 / 7 mo x 12 mo/yr = $44,362 /yr

Estimated Implementation Cost

Based on previous experience, simple capacitors can be installed for about $30 per kVAr.

Therefore, the estimated implementation cost for installing 400 kVAr of capacitance

would be about:

(450 kVAr x $30 /kVAr) = $13,500

We estimate that about 50% of this is for materials and 50% for labor.

Estimated Simple Payback

($13,500/ $41,595/year) x 12 months = 4 months

AR I632: TAKE CORRECTIVE ACTIONS TO IMPROVE POWER FACTOR

Annual Savings

Project

Simple

Cost

Payback

Resource

CO2 (lb)

Dollars

Electrical Demand

437 kVA

$94,812

$8,000

1 month

Analysis and Recommendation

Motors and other inductance devices require more power in the lines than they actually

consume. Power factor is ratio of power used (kW) to the power that must be supplied in

the lines (kVA). The relationship between actual, supplied and reactive power is shown

in the figure below.

kVA

(power supplied

by utility)

PF =

kW

kVA

kVAr

(measure of

unused power)

kW (power used by machines)

According to the your electricity bills, the average plant power factor is about 68%.

Based on your electric rate structure, you can lower your demand charges by improving

power factor. However, you do not want to over correct the power factor to more than

100%. In March 2000, power factor peaked at 74%. Thus, we recommend adding only

enough capacitance to raise your power factor to 97% for that month. According to the

analysis below, this would be about 400 kVAr of capacitance.

Estimated Savings

Determining How Much Capacitance to Add

The highest power factor registered during the period for which we were supplied with

electricity data was for March 2000, when the plant power factor was 74% and the peak

power was 594 kW. If the power factor during this month were corrected to 97%, the

power factor during the rest of the year would never exceed 97%. Using standard

trigonometric relations, the angle theta in the power triangle shown above was about:

Cos = kW / kVA

= Cos-1 (PF)

= Cos-1 (74%) = 42.27 o

The reactive power was about:

Tan = kVAr / kW

kVAr = kW x tan

kVAr = 594 kW x tan (42.27) = 540 kVAr

If the power factor were increased to 97%, the reactive power would be about:

Cos = kW / kVA

= Cos-1 (PF)

= Cos-1 (97%) = 14.07 o

kVAr = kW x tan

kVAr = 594 kW x tan (14.07) = 149 kVAr

Thus, the amount of capacitance required to boost your power factor from 74% to 97%

during March 2000 would be about:

540 kVAr – 149 kVAr = 391 kVAr

We recommend adding about 400 kVAr.

Calculating Savings

According to your electricity bills, the annual average power factor is 68% and the annual

average demand is 579 kW. Using standard trigonometric relations, the angle theta in the

power triangle shown above is about:

Cos = kW / kVA

= Cos-1 (PF)

= Cos-1 (68%) = 47.156 o

The reactive power is about:

Tan = kVAr / kW

kVAr = kW x tan

kVAr = 579 kW x tan (47.156) = 624 kVAr

If 400 kVAr of capacitance were added, the average kVAr would be about:

624 kVAr – 400 kVAr = 224 kVAr

The angle theta would be about:

= Tan-1 (kVAr/kW) = Tan-1 (224/579) = 21.150 o

The annual average power factor would be about:

PF = Cos = Cos (21.150) = 93%

The annual average kVA would be about:

kVA = kW / Cos = 579 / Cos(21.150 o) = 621 kVA

The billing kVA would be about:

621 kVA x [1 + (0.9 - 93%)] = 602 kVA

According to your electricity bills, the annual average power factor is 68% and the annual

average kVA is 852 kVA. Thus, without power factor correction the annual average

billing kVA would be about:

Actual kVA x [1 + (0.9 – PF)] = 852 kW x [1 + (0.9 – 68%)] = 1,039 kVA

Thus, the savings from correcting the average power factor to 93% would be about:

1,039 kVA – 602 kVA = 437 kVA

437 kVA x $18.08 /kVA-month x 12 months/yr = $94,812 /yr

Estimated Implementation Cost

According to quotes from other utilities, the total installed cost for simple capacitors is no

more than $20 per kVAr. If so, the total implementation cost for installing 400 kVAr of

capacitors would be about:

400 kVAr x $20 /kVAr = $8,000

Estimated Simple Payback

$8,000 / $94,812 /yr x 12 months/yr = 1 month

AR E061501: TAKE CORRECTIVE ACTIONS TO IMPROVE POWER FACTOR

Annual Savings

Project

Simple

Cost

Payback

Resource

CO2 (lb)

Dollars

Electric Demand

42 kVA

$3,669

$2,800

9 months

Analysis and Recommendation

Motors and other inductance devices require more power in the lines than they actually

consume. Power factor is ratio of power used (kW) to the power that must be supplied in

the lines (kVA). The relationship between actual, supplied and reactive power is shown

in the figure below.

kVA

(power supplied

by utility)

kW

PF =

kVA

kVAr

(measure of

unused power)

kW (power used by machines)

According to the your electricity bills, the average plant power factor is about 92.4%.

Based on your electric rate structure, you can lower your demand charges by improving

power factor. However, you do not want to over correct the power factor to more than

100%. In February 2000, power factor peaked at 95%. Thus, we recommend adding

only enough capacitance to raise your power factor to 99% for that month. According to

the analysis below, this would be about 140 kVAr of capacitance.

Estimated Savings

During February 2000, the plant power factor was 95% and the peak power was 765 kW.

Using standard trigonometric relations, the angle theta in the power triangle shown above

was about:

Cos = kW / kVA

= Cos-1 (PF)

= Cos-1 (95%) = 18.195 o

The reactive power was about:

Tan = kVAr / kW

kVAr = kW x tan

kVAr = 765 kW x tan (18.195) = 251 kVAr

If the power factor were increased to 99%, the reactive power would be about:

Cos = kW / kVA

= Cos-1 (PF)

= Cos-1 (99%) = 8.11 o

kVAr = kW x tan

kVAr = 765 x tan (8.11) = 109 kVAr

Thus, the amount of capacitance required to boost your power factor from 95% to 99%

during February 2000 would be about:

251 kVAr – 109 kVAr = 142 kVAr

We recommend adding about 140 kVAr. According to the your electricity bills, the

average plant power factor is about 92.4%. The average power supplied is about 811

kVA and the average power consumed is about 750 kW. Using these numbers, the

average reactive power during the year is about:

Cos = kW / kVA

= Cos-1 (PF)

= Cos-1 (92.4%) = 22.482 o

Tan = KVAr / kW

kVAr = kW x tan

kVAr = 750 x tan (22.482) = 310 kVAr

If 140 kVAr of capacitance were added, the average reactive power would be about:

kVAr2 = 310 kVAr – 140 kVAr = 170 kVAr

The average power supplied would be about:

2 = Tan-1(kVAr / kW) = Tan-1(170 / 750) = 12.771 o

kVA = kW / Cos2 = 750 kW / Cos(12.771) = 769 kVA

The average reduction in kVA would be about:

811 kVA – 769 kVA = 42 kVA

Thus, the power factor savings would be about:

42 kVA x $7.28 /kVA–mo x 12 mo/yr = $3,669 /yr

Estimated Implementation Cost

According to quotes from other utilities, the total installed cost for capacitors about $20

/kVAr. If so, the total implementation cost for installing 140 kVAr of capacitors would

be about:

140 kVAr x $20 /kVAr = $2,800

Estimated Simple Payback

$2,800 / $3,669 /yr x 12 months/yr = 9 months

AR E062901: INSTALL 500 KVAR OF CAPACITANCE TO IMPROVE POWER

FACTOR

Annual Savings

Project

Simple

Cost

Payback

Resource CO2 (lb)

Dollars

Power factor charge

500 kVAr

$6,000

$7,500

15 months

Analysis

Power factor is the ratio of actual power consumed (kW) to the line power supplied

(kVA). The utility recorded an annual average power factor of 83% for the electricity

service to the plant. Most plants strive to achieve a power factor of 95% or more to

reduce demand costs, reduce line losses and allow electrical equipment to run cooler.

kVA (power

supplied

by utility)

kW

PF =

kVA

kVAr (measure of

unused power)

kW (power used by machines)

Recommendation

We recommend installing at least 500 kVAr of capacitance to raise the plant power factor

and save on electricity charges.

Estimated Savings

Monthly demand, reactive power and power factor from the last year of billing data is

shown in the table below.

KW

1,322

1,258

1,243

1,188

1,298

1,181

1,084

1,175

1,231

1,154

1,064

1,163

Tot/Avg/Max

KVAr

522

662

932

984

1,058

886

743

774

763

805

701

767

9,598

PF

93%

89%

80%

77%

78%

80%

83%

84%

85%

82%

84%

84%

82%

The monthly average reactive power varies from a low of 522 kVAr to a high of 1,058

kVAr. Thus, it would be highly unlikely that you would ever over-correct your power

factor by installing 500 kVAr of capacitance. If you did, the annual savings would be

about:

500 kVAr x $1 /kVAR-mo x 12 mo/yr = $6,000

Estimated Implementation Cost

The contract price for installation of simple capacitors varies from $10 to $20 per kVAr.

Assuming $15 /kVAr, the implementation cost would be about:

500 kVAr x $15 /kVAr = $7,500

Estimated Simple Payback

$7,500 / $6,000 /yr x 12 months/yr = 15 months

AR X: INSTALL CAPACITORS TO IMPROVE POWER FACTOR

PF charge

Implementation Cost

Simple Payback

Present

27,048 kVAr/yr

Recommended

3,048 kVAr/yr

Annual Savings

24,000 kVAr; $7,200

$60,000

8.3 years

Analysis

Many types of electrical equipment require that more power be supplied to the equipment

than is actually consumed by the equipment. The ratio of power consumed by equipment

to power supplied to equipment is called the power factor. Your utility charges you for

both how much power your plant actually uses (measured in kW) and for the excess

power that the utility was required to supply (a measure of which is kVAr). Thus, low

power factor results in higher utility costs. In addition, low power results in overheating

in wires, circuit boards and motors. This overheating may cause circuit breakers to shut

off the load and interrupt production, and always reduces the lifetime and increases

maintenance costs for electrical equipment. It is therefore in your interest to maintain a

power factor as close to 100% as is economically feasible.

kVA (power

supplied

by utility)

kW

PF = kVA

kVAr (measure of

unused power)

kW (power used by machines)

The utility recorded an annual average power factor of 79% for the electricity service to

the main plant. Most industrial facilities have a power factor of 90% or above. A 79%

power factor corresponds to an average of 2,254 kVAr per month, for which the utility

charges 30 cents per kVAr. Thus, your average power factor charge is about $676 per

month or about $8,114 per year. Installing 2,000 kVAr of capacitors would raise the

average monthly power factor to about 99% without ever switching from lagging to

leading. The annual utility savings would be about $7,200.

Additional savings from longer equipment lifetimes, lower maintenance costs, and

avoided production stoppages are difficult to quantify, but are potentially even greater

than the utility savings. We think that this is especially critical in your plant where the

general difficulty of obtaining spare parts can put machines out of production for

extended periods. In addition, your past problem with circuit overheating was worsened

by your plant’s low power factor.

Recommendation

We recommend that you contact your utility about a power quality survey to identify the

circuits with the lowest power factors. You could then install corrective capacitance on

those circuits or on the main utility feed. In this way, you could raise the power factor

into the acceptable range of 90% or greater. This will increase the lifetime and efficiency

of your equipment and help minimize production shutdowns. It will also provide modest

savings on your utility bill.

Our recommendation of 2,000 kVAr represents the maximum capacitance you currently

need. Lesser amounts of capacitance would reduce your utility savings accordingly. We

estimate the cost of 2,000 kVAr to be approximately $60,000 with simple controls. It

could be as high as $100,000 with more complicated controls and features. Based on

utility savings alone, the simple payback would be 8.3 years; however, the payback

would be shorter if production and equipment maintenance savings were included.

Estimated Savings

2,000 kVAr/month x 12 months/year x $0.30 /KVAR = $7,200

Estimated Implementation Cost

2,000 KVAr x $30 /KVAr = $60,000

Estimated Simple Payback

$60,000

Simple Payback =

= 8.3 years

$7,200 / yr

AR X: INSTALL TWO 100-KVAR CAPACITOR BANKS

Present

Electric Demand (kW)

Estimated Implementation Cost:

Simple Payback:

Recommended

Annual Savings

476 kVA; $3,570

$1,000 for installation

4 months

Analysis

Your electric demand charge is assessed in terms of kVA, not in kW. This means that the

electrical demand charge directly depends on the overall power factor in your plant. A

high power factor results in several benefits: lower demand costs, lower voltage drop in

the circuit, lower overheating in wiring, and less maintenance. The power factor in the

last 12 months varied between 88.8% and 97.9%. Some capacitor banks were already

installed on bus bars high above the floor. You also have five 100-kVAR capacitor banks

in stock.

Recommendations

We tried to strike a balance between raising power factor and not to cross to “lead” power

factor. Our analysis indicated that you could install two 100-kVAR capacitor banks to

your circuits, preferrably at locations where some low power factor equipment items such

as welders, rectifiers, and HID lamps with low power factor ballasts, are located. In

addition, we have learned from the experience in other plants that an audio failure

warning system allows for instant detection of capacitor malfunction and thus helps avoid

excessive cost penalties if a capacitor bank fails. Without audio failure systems, it could

be many months before you discover a capacitor bank failure.

Estimated Cost Savings

Present

The billing demand varied between 829 kVA and 1,382 kVA, totalling 13,654 kVA for

the year (August 94 to July 95).

After adding two 100-kVAR capacitor banks

The annual total billing demand will be lowered from 13,654 kVA to 13,088 kVA for a

reduction of 476 kVA

Savings

476 kVA x $7.50/kVA = $3,570/year in annual demand cost savings

Estimated Implementation Cost

$1,000 for installing two 100-kVAR capacitor banks

Estimated Simple Payback

4 months

AR X: INSTALL CAPACITORS TO RAISE POWER FACTOR

Electric Demand (kW)

Estimated Implementation Cost:

Simple Payback:

Present

2,003 kW

After AR

0 kW

Annual Savings

2,003 kW; $25,819

$30,000

14 months

Analysis and Recommendation

Your monthly power factor during the past 12 months was consistently below the 90%

level required by your utility company. As a result, a total of 2,003 kW in accumulated

power factor related demand penalties were assessed resulting in $25,819 in cost

penalties. The power factor varied between 83.3% and 85.7%. This low power factor

problem could be corrected by adding capacitor banks at the source of the problem, the

electric main, or both.

When large electric motors are operated below 50% of their rated capacity, their power

factor decreases signficantly. The thermo-mechanical refiner was equipped with a huge

700 hp motor. Other large motors include a 500 hp motor at the hydropulper, 400 hp and

a 150 hp motors at wood refiner, and a 100 hp motor at primary screen. These are good

candidates to check for under loading. If so, capacitors should be installed at the motor.

500 kVArs of capacitors will be needed to raise the power factor to 90% level. You

should consult local heavy equipment vendors to check out motor loading problems and

to determine how to position the capacitors between the motors and the electric main.

Some capacitors have already been installed, but it is suspected that they were either

knocked out by lightning or power surges. If existing capacitors and fuses can be

repaired and put back into operation, the net need of new capacitors will be reduced

accordingly.

Estimated Savings

Based on last year's utility bills, we estimate that adding 500 kVAr would save you about

$25,819 per year in utility penalties. It would also reduce heat generation and voltage

drop, and allow you to decrease the size of wiring. The improvement of power factor

from 83% to 91% would result in an 8.8% reduction in electric current, an 8.8%

reduction in voltage drop across the circuit, and an 18% reduction in excess heat

generation.

Estimated Implementation Cost

$30,000 for 500 - 600 kVAR capacitors and controls

Capacitors installed at the electric main might require a sophisticated controls costing an

additional $10,000.

Simple Payback

14 months

AR X: INSTALL AUDIBLE CAPACITOR FAILURE ALARM

Electric Demand

Implementation

Cost:

Simple Payback:

Present

123 kW

Recommended

0

$150

Annual Savings

123 kW; $1731

$150

1 month

Analysis

Recently 200 kVAr of capacitance failed. The visual alarm which should signal when the

capacitor bank is not operational also failed. This dual failure caused the power factor of

the plant to drop below 90% and cost the company $1,731 in demand penalties.

Recommendation

Although a properly functioning visual alarm may alleviate such problems in the future,

we recommend installing an audible alarm. This type of alarm is almost impossible to

ignore and assures that you will be alerted to a capacitor bank failure.

Estimated Savings and Implementation Cost

Looking backward, we can say that a malfunctioning alarm caused the company to be

charged for 123 kW in demand penalties costing $1,731. A functioning audible alarm

would have avoided this cost. Audible alarms can be purchased and installed for about

$150.

Simple Payback

SP = $150 initial cost / $1,731 /yr savings x 12 months/yr = 1 month