FDA Device Classification and How it Can Rock Your World

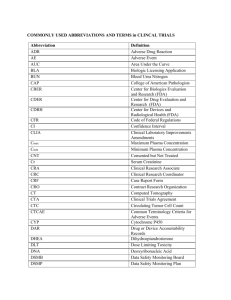

advertisement

Weaving regulations into sound value analysis processes Barbara Strain, MA, SM(ASCP) Director Value Management University of Virginia Health System Learn key healthcare agency resources Understand the importance of the relevant guidance documents Apply resource information to value analysis processes Know the role of the VAP in patient safety New Devices Documentation New Devices &Drugs Safety Quality US FDA – Food and Drug Administration ◦ http://www.fda.gov/ Master guidance resource for devices, drugs, radiation emitting sources, other Expert assistance Incident follow up CDC Centers for Disease Control & Prevention ◦ http://www.cdc.gov ◦ NIOSH National Institute of Occupational Safety & Health http://www.cdc.gov/niosh/ http://www.cdc.gov/niosh/topics/bbp/ http://www.cdc.gov/niosh/topics/bbp/sharps.html http://www.cdc.gov/niosh/npptl/topics/respirators/di sp_part/n95list1.html http://www.cdc.gov/niosh/topics/latex/ OSHA Occupational Safety & Health Administration – US Dept of Labor; code of regulations (CFR) http://www.osha.gov/ Federal Register e.g. 29CFR Part 1910 Blood Borne Pathogens Introduction of new devices ◦ ◦ ◦ ◦ ◦ evaluations, use, research, manufacturer discussions, physician discussions Assuring Quality Creating/Maintaining a culture of Safety A Medical Device is: "an instrument, apparatus, implement, machine, contrivance, implant, in vitro reagent, or other similar or related article, including a component part, or accessory” They range from simple tongue depressors and bedpans to complex programmable pacemakers with micro-chip technology and laser surgical devices as well as in vitro diagnostic products, such as general purpose lab equipment, reagents, and test kits, which may include monoclonal antibody technology. certain electronic radiation emitting products with medical application and claims meet the definition of medical device. E.g. diagnostic ultrasound products, x-ray machines and medical lasers. Device Classes and Regulatory Controls Class I General Controls ◦ With Exemptions ◦ Without Exemptions Class II General Controls and Special Controls ◦ With Exemptions ◦ Without Exemptions Class III General Controls and Premarket Approval Classification is risk based, that is, the risk the device poses to the patient and/or the user is a major factor in the class it is assigned. Class I includes devices with the lowest risk and Class III includes those with the greatest risk. The class to which a device is assigned determines the type of premarketing submission/application required for FDA clearance to market. If your device is classified as Class I or II, and if it is not exempt, a 510k will be required for marketing. All devices classified as exempt are subject to the limitations on exemptions. For Class III devices, a premarket approval application (PMA) will be required unless the device is has been on the market prior to 1976 which in that case, a 510k will be the route to market. Device classification depends on the intended use of the device and also upon indications for use. For example, a scalpel's intended use is to cut tissue. A subset of intended use arises when a more specialized indication is added in the device's labeling such as, "for making incisions in the cornea". Indications for use can be found in the device's labeling*. * on label use FDA has exempted almost all class I devices premarket notification requirement, It is important to confirm the exempt status and any limitations that apply with 21 CFR Parts 862-8927. If a manufacturer's device falls into a generic category of exempted class I/II devices as defined in 21 CFR Parts 862-8928, a premarket notification application and FDA clearance is not required before marketing the device in the U.S. However, these manufacturers are required to register their establishment and list the generic category or classification name. A new 510(k) submission is required for changes or modifications to an existing device, where the modifications could significantly affect the safety or effectiveness of the device or the device is to be marketed for a new or different indication for use. Class III devices are those that support or sustain human life, are of substantial importance in preventing impairment of human health, or which present a potential, unreasonable risk of illness or injury. Due to the level of risk associated with Class III devices, FDA has determined that general and special controls alone are insufficient to assure the safety and effectiveness of class III devices. Premarket approval (PMA) is the FDA process of scientific and regulatory review to evaluate the safety and effectiveness of Class III medical devices. Class I exempt Class I non-exempt Class II exempt Class II non-exempt Class III Cotton tip applicator Heel warmer; transport media Wheeled stretcher IV pump accessories; antigen reagents Defibrillator, biologics, hemodialysis catheters An investigational device exemption (IDE) allows the investigational device to be used in a clinical study in order to collect safety and effectiveness data. Clinical studies are most often conducted to support a PMA. Investigational use also includes clinical evaluation of certain modifications or new intended uses of legally marketed devices. All clinical evaluations of investigational devices, unless exempt, must have an approved IDE before the study is initiated. Clinical evaluation of devices that have not been cleared for marketing requires: ◦ an IDE approved by an institutional review board (IRB). If the study involves a significant risk device, the IDE must also be approved by FDA; ◦ informed consent from all patients; ◦ labeling for investigational use only ◦ monitoring of the study and; ◦ required records and reports. Evaluation, Research/IRB or Use User facility must know what is in use ◦ Safety ◦ FDA approvals ◦ Device/Tissue tracking http://www.fda.gov/MedicalDevices/DeviceRegulation andGuidance/GuidanceDocuments/ucm071756.htm Joint Commission: TS03.01.01 - .03 ◦ Issue reporting ◦ Recalls Assure in-service education Keep a log Problem reporting ◦ Internal- equipment, supplies, accessories Before use: foreign body in sterile packaging During use: bovie does not fire After use: observe brown liquid in basin leaching out of a blue OR towel How to report: manually/electronically Saving the effected item Assess seriousness, trends, lot#, serial# Communicate Educate ◦ External Contact quality department at manufacturer Follow instructions Document Communicate ◦ FDA reporting: Manufacturer and User Facility Device Experience (MAUDE) “You are encouraged to report all serious adverse events and product quality problems to FDA MedWatch at www.fda.gov/medwatch/report.htm” MedSun http://www.fda.gov/MedicalDevices/Safety/MedSunMedicalPro ductSafetyNetwork/default.htm Recalls, Market Withdrawals and Safety Alerts Where to find the most up to date info? ◦ http://www.fda.gov/Safety/MedWatch/SafetyInform ation/SafetyAlertsforHumanMedicalProducts/default .htm ◦ Subscription services: examples RASMAS, ECRI Who, what, when, where, why & how Institutional policy Key process owners Well defined Automated or manual Centralized Accountable Log Reporting up through institutional committee structure New Devices Documentation New Devices &Drugs Safety Quality