File - Vagabond Geology

advertisement

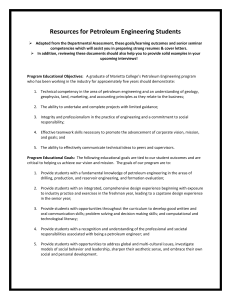

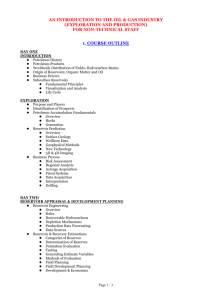

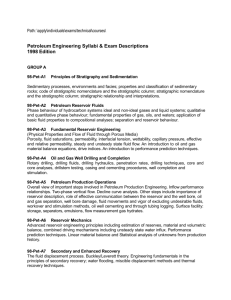

Geology in the News From the New York Times, Feb. 3, 2012 Mount Isa , Queensland, Australia World’s Largest Cu, Pb, Sn Mining Operation Mount Isa Mount Isa Mount Isa , Queensland, Australia World’s Largest Cu, Pb, Sn Mining Operation Mining Operation Toxic waste area Open Pit Mine Copper. Lead, silver miners in Pre-Cambrian shale and volcanic rock, 2 billion years old Northwest Offshore Australia Gas Barrow Island Anticline Oil Field Vagabond Venture Oil Group SEARCH FOR FOSSIL FUELS Winter 2012 The Course Outline The Basics: Week 1: Geology of Coal, Oil and Gas Week 2: Processes of Exploration Week 3: Engineering Processes: Reservoir/ Drilling/Production The Adventure: Week 4: ‘Vagabond Group’ chooses 2 prospects Week 5: ‘Vagabond Group’ drills! Your chance to invest Week 6: the Payout?! A black-gold millionaire or dry hole hobo? By now, you should start to see that deciding -WHAT to drill -WHERE to drill & - HOW to drill is a TEAM EFFORT Composed of GEOLOGIST, GEOPHYSICIST, LANDMEN, & ENGINEERS Today . . . . 12 Petroleum Engineer Primary Jobs: Reservoir Characterization Well Design Production & & Drilling Enhancements Economic Analysis 13 Petroleum Engineer: Reservoir Characterization Job #1 Reservoir Characterization 14 Petroleum Engineer: Reservoir Characterization “Reservoir characterization methodology: determining reservoir architecture, establishing fluid-flow trends, constructing reservoir model, and identifying reserve growth potential Further investigations within reservoir type: integrating data: petrophysical, seismic, and geologic attributes 3-D geo-celluar model building; delineating flow units and fluid flow compartments, documenting reserve growth concepts under varying reservoir conditions” Texas Bureau of Economic Geology 15 Petroleum Engineer: Reservoir Characterization From Seismic Data 16 Petroleum Engineer: Reservoir Characterization Generalized Stratigraphic Map 17 Petroleum Engineer: Reservoir Characterization PETROPHYSICAL & PALEO DATA Laboratory Analysis Well core Paleo Analysis Lithology 18 Petroleum Engineer: Reservoir Characterization PETROPHYSICAL DATA Laboratory Analysis Gulf of Mexico Pliocene Sandstone 1 millimeter Porosity – a measure of the open spaces within a rock that can contain oil or water. Unit of measurement is PERCENT Permeability – a measure of the ability for fluid to flow thru a rock. Unit of measurement is DARCY Point of Reference: Concrete Block Porosity +/- 20% Permeability 2–5D Brick +/- 5 % .025 D (25 mD) 19 Petroleum Engineer: Reservoir Characterization PETROPHYSICAL DATA – Rules of Thumb Porosity (%) RESERVOIR QUALITY 0 – 5% Insignificant 5 – 10% Poor 10 – 15% Fair 15 – 20% Good 20 – 25% Excellent PERMEABILITY mD (milliDarcy) RESERVOIR QUALITY 1 – 10 mD Poor 10 – 100 mD Good 100 – 1000 mD Excellent 20 Petroleum Engineer: Reservoir Characterization Correlation of Well Logs (more on logging later…) 21 Petroleum Engineer: Reservoir Characterization Resulting in Reservoir Model • Reservoir characteristics are input to a program that generates a 3D map of the subsurface reservoir • The 3D map can then be used to assess where hydrocarbon has migrated to which then indicates where future wells should be drilled 22 Petroleum Engineer: Reservoir Characterization TYPICAL QUESTIONS TO ASK REGARDING RESERVOIR CHARACTERIZATION • • • • • • • • • • • What is the source rock? What type of reservoir rock is expected? What reservoir porosity is expected? What reservoir permeability is expected? What is the expected trapping mechanism? What type of drive mechanism is expected? Is the well type a straight hole or deviated? What is the planned TD (total depth) of the well? How many feet of pay is expected? How do characteristics vary between in-field wells? How many PROVEN reserves are expected to be found? 23 Petroleum Engineer: Reservoir Characterization Classification of Reserves is key! What are Reserves? The amount of oil & gas in a reservoir currently available for production Why are they important?: Reserves when produced generate a cash flow and by estimating the total cash flow from a well, the “expected value” of that well can be calculated. This sets the limit on much you can spend in developing the well for any expected Return on Investment (ROI)! 24 Petroleum Engineer: Reservoir Characterization Classification of Reserves is key! BUT… There are several different reserves names used: • Reserves in Place (physically contained in the reservoir; remember that only 25 to 30% of that can actually be recovered with conventional technologies; OOIP) • Recoverable Reserves (estimate of what can be produced from the reservoir) • Proven Reserves, Developed or Undeveloped (reserves that can be calculated with reasonable certainty because the field has been defined by appraisal well(s) that have been tested) • Proved Behind-Pipe Reserves (undeveloped, proven reserves calculated behind the casing) • Proved (P90), Probable (P50) and Possible (P10) Reserves 25 Petroleum Engineer: Reservoir Characterization Classification of Reserves is key! • Proved (P90) Reserves – 90 % chance or greater that the reserves are there; must have “very high certainty” that reserves can be “economically” recovered with current technology. Security and Exchange Commission (SEC) allows only reporting of P90 as official data. • Probable (P50) Reserves- 50 % chance that the reserves are there • Possible (P10) Reserves - 10 % chance that the reserves are there • Remember estimates are based on data from a location as much as 2 miles below the surface, and on characteristics of a hole 6” in diameter extrapolated over several hundred acres of reservoir… Reserves estimating is more of an art than a science! 28 Petroleum Engineer: Reservoir Characterization Note that the world understands that “proved” reserves is what’s important… USA Today 29 Petroleum Engineer: Reservoir Characterization Note that the world understands that “proved” reserves is what’s important… 10th ! Domestic International 30 Petroleum Engineer: Reservoir Characterization Note that the world understands that “proved” reserves is what’s important… 6th ! 31 Petroleum Engineer: Well Design & Drilling Job #2 Well Design and Drilling 32 Petroleum Engineer: Well Design Well Design during drilling Blowout Preventer Blowout Preventer – Monitor & Controls the pressure within each casing string of the well Casing String – Successive sections of pipe of decreasing diameter set one inside the other and cemented in place Surface Casing Strings `` 33 Petroleum Engineer: Well Design How is Casing Installed? • Drill 36” hole to design depth Surface • Slide 30” casing to depth within 36” hole • Cement 30” casing to 36” hole • Drill 24” hole thru cement in 30” casing to design depth 30” Casing 36”hole • Slide 20” casing to depth within the 24” hole 24”hole • Cement 20” casing to 24” hole 20” Casing • And so on …. 34 Petroleum Engineer: Well Design Typical Well Casing Program • 30” Casing = Conductor Pipe (hung at surface; it is drilled or driven) Casing Size Depth • 20” Casing = Surface Casing (hung at surface; may not be necessary, depends on geology) 30 in (36”hole) 500 ft • 13 3/8” Casing = Intermediate Casing (hung at the surface) 20 in (26”hole) 3,000 ft 13 3/8 in (17 ½” hole) 7,000 ft 9 5/8 in (12 ½” hole) 10,000 ft 7 in Liner (8½” hole) 15,000 ft • 9 5/8” Casing = Intermediate casing (depending on design, could be hung off of 13 3/8”) • 7” Liner = Not a casing per se because it is hung off the end of the 9 5/8” casing; it doesn’t run to the surface 35 Petroleum Engineer: Well Design Well Casing Program Why is casing needed? • Protect freshwater aquifers that might be present in the subsoil • Prevents contamination between rock strata layers • Contain any unusual pressure in the layers of rock strata that might be encountered • Prevent borehole collapse while drilling deeper • Provide control of drilling mud being pumped down-hole Freshwater Aquifer Low Pressure Zone or future producing zone High Pressure Zone Wellbore thru the rock strata Black Gold! 36 Petroleum Engineer: Well Design Well Design during completion Xmas Tree Xmas Tree– Monitor & Controls the pressure within the each casing of the well while allowing the well to flow to the surface Surface Perforations – Holes shot thru the casing to allow fluid to flow into the wellbore Down-hole Completion Equipment – Devices & tools installed in the well to control which reservoir is produced and Perforations to give real-time data `` Down-hole Completion Equipment` Captured from a YouTube Video. This is a section of pipe tubing; Shaped charges will be set off to make the perforations. These pictures show the power of the shaped charges… 38 Petroleum Engineer: Well Design Well Design during completion To Production Facilities Xmas Tree Production Tubing – A string of pipe that runs from the producing zone to the wellhead in which oil and/or gas flows to the surface facilities Surface `` Perforations Down-hole Completion Equipment` 39 Petroleum Engineer: Well Design Types of Well Design •“Straight-hole” •Directional or “Deviated Well” •“Horizontal Well” Black Gold! 40 Petroleum Engineer: Well Design Deviated Well Why drill a deviated well? • Known fault can cause an unplanned deviation from the projected drill path • High pressure zones might exist to one side of a fault • Subsurface “debris” like ancient reefs could cause a slower drill rate (ROP) than desired (time is money!) High Pressure zones behind fault Fault Black Gold! 41 Petroleum Engineer: Well Design Deviated, Horizontal Wells Why drill a horizontal well? • Low permeability reservoirs are best produced by horizontal wells, the ultimate in “deviated well” • Three kinds of horizontal wells, long/short/medium radius: • Long = 10 per 100ft • Medium = 20 per 100ft • Short = 40 per 100ft Target Reservoir 42 Petroleum Engineer: Well Design Horizontal Well Procedure • At start of deviation, replace drillbit with a “bent sub”, gyroscope, steerable mud motor & bit • Add logging-while-drilling (LWD) unit & power pack within 20 ft of bit • Slowly rotate drillstring to prevent “sticking” & start “pushing” steerable system forward while flowing mud to mud motor • Drill while being pushed forward & steer system as need be to maintain horizontal direction 43 Petroleum Engineer: Well Design Multilateral, Horizontal Wells • Added advantage of horizontal well design is to include “Multilaterals” (additional boreholes from the same drillsite) Drillsite Significant Production Increase • From one wellsite, several sections of the reservoir can be accessed & produced Plan view 44 Petroleum Engineer: Drilling Plan Horizontal Drilling Advantages • Increase in reserves in place by 2% of the original oil in place (OIIP)** • Cost ratio of horizontal versus vertical wells is approximately 2 to 1** • Production ratio for horizontal wells versus vertical wells is approximately 3.2 to 1** • Inclusion of multilaterals increases production ratio even more!! ** per U.S. Department of Energy 45 Petroleum Engineer: Well Design Final Well Program • Well Schematic – Showing hole (bit) size, casing plan, mud plan, planned TD • Drilling Time Estimate – Breakdown total time into key components to various depths • Well Cost Estimate – Listing of all expected costs for the well • Well Time VS. Depth Plot – a “picture” of how much drilling time is planned for each casing run 46 Petroleum Engineer: Drilling 47 Petroleum Engineer: Drilling Well Location? Onshore Offshore 48 Petroleum Engineer: Drilling Well Type? Exploratory (“Wildcat Well”) On-structure (“In-field”, Appraisal) Normal Success Rate = +/- 1 in 10 to +/- 3 in 10 Normal Success Rate = +/- 5 in 10 to +/- 9 in 10 49 Petroleum Engineer: Drilling Main Components of Drilling Derrick Traveling Block/Swivel Turntable/Kelly/ Kelly Bushing Blowout Preventer Casing (different sizes) Drill String Drill Bit Drill Mud 50 Petroleum Engineer: Drilling What is Drilling Mud A mixture of clay with either water, oil, oil and water, or synthetic organic matter and water. To this, various viscosity and density enhancers and additives to achieve specific objectives (adjust pH, control bacteria, defoam, filtrate reducers, etc.) are added. Mud IN Mud out Drilling Mud Well How does it get in the well? bore Mud is pumped into the drill pipe, flows down the drill pipe, exits out the drill bit, and flows, along with rock cuttings, up the borehole back to the rig. Drill Bit 51 Petroleum Engineer: Drilling What is the Drilling Mud System? A ‘CLOSED SYSTEM’ where the drilling mud is mixed & pumped: 3. Mud Hose 2. Mud Pump 1. Mud Pit or Tanks 4. Circulate Mud down drillstring and back up borehole exit below Blowout Preventer 5. Shale shakers • from the mud pit/tanks, • up into the mud hose • down into the drillstring, • thru the drillbit, • up the wellbore, • over the shellshakers and • back to the mud pit/tanks 52 Petroleum Engineer: Drilling What does Drilling Mud do? • Cools drill-bit • Stabilizes borehole walls • Transports rock cuttings (“cuttings”) to surface (mud engineer examines cuttings w/microscope to check for oil and porosity) • Offsets hydrostatic/reservoir pressure 53 Petroleum Engineer: Drilling Plan How Critical is Drilling Mud? 0 500 • Blue line is Pore Pressure (the pressure from the overburden) • Yellow line is Mud Weight pressure • If Mud weight is too hi, it will damage the reservoir; if too low, a well blowout is possible! 20" 1,500 TVDBDF (m) • Red line is the Pressure that will fracture the Reservoir 1,000 2,000 2,500 13.5/8" 3,000 3,500 Overpressure zones 4,000 10.3/4" x 9.7/8" 4,500 5,000 5,500 0.5 0.6 0.7 0.8 0.9 1.0 1.1 1.2 1.3 1.4 1.5 1.6 1.7 1.8 1.9 2.0 2.1 2.2 2.3 SG Specific Gravity 55 Petroleum Engineer: Drilling Drilling Contract Types • Costs per Day (DAY RATE) • Costs per Foot (FOOTAGE RATE) • Set Costs (TURNKEY BASIS) • Success often depends on quality & experience of Operator 56 Petroleum Engineer: Drilling Drilling Operations • Survey well location • Build roads, clear and level ground • Drill water well (optional) • Layout casing pipe/drill string & equipment • Prepare drilling mud • Assemble Rig • Drill each segment; set casing & cement 57 Petroleum Engineer: Drilling Drilling Operations (cont’d) • Planned drill breaks: layout and position casing on deck, circulate bottom to remove cuttings, coring, drill stem testing, etc. • Unplanned drill breaks: stuck pipe,lost circulation, required fishing trip, etc. • Let’s look at POSSIBLE DRILLING PROBLEMS, CORING and WELL LOGGING 58 Petroleum Engineer: Drilling Possible Drilling Problems • Lost tool (something breaks off or is dropped in well) • Stuck Pipe (drill pipe adheres to well walls due to suction/differential pressure or dogleg in wellbore) • Sloughing shale (swelling of shales, drops to bottom, can’t circulate out) • Lost circulation (high porosity zone/cavernous zone) • Corrosive gases encountered (hydrogen sulfide) • Abnormal high pressure (drill into/through a high press zone) • Blowout (mud weight not sufficient to hold back abnormal high pressure gas; gas flows to surface and ignites unexpectedly) 59 Petroleum Engineer: Drilling What is Coring? • Two types of coring: • Sidewall Cores (1”dia X 4” long) • Rotary Cores (3 ½” to 5 ¼” dia X 30-50 FEET long) 60 Petroleum Engineer: Drilling What is a Well Log? • After reaching the well “TD”, the well-bore is logged using a tool that is “run” downhole on a cable. • In the tool are sensors that measure rock and fluid properties continuously down the borehole. • • Properties measured include: resistivity of the rock, conductivity thru the rock, size of borehole, rock’s reaction to nuclear radiation, etc. • A long, fan-folded, “chart” prints out the data 61 Petroleum Engineer: Drilling Logging Types (not all) • • • • • • • • • Caliper Log SP (spontaneous potential) Log Dip/dipmeter Log Electrical Resistivity Log Sonic/Acoustic Velocity Log Natural Gamma Ray Radiation Log Neutron (Formation) Density Log Neutron Porosity Log Nuclear Magnetic Resonance Log Each type of log has its advantages and disadvantages and hence are used at different times and in different situations. 62 Petroleum Engineer: Drilling Drilling Questions • How many bidders? What are the advantages of selected contractor? • What type of rig contract? • What is fixed price / what is variable price? Any rented equipment included? • Does contractor use own-crew or “rented” crew? • What has been safety record of this rig/crew? • Who is the Tool Pusher and what is his/her experience? • How much coring and logging is planned? 63 Petroleum Engineer: Drilling Click here to see an Onshore Drilling Animation REVIEW – SESSION 3 WHAT HAVE WE TALKED ABOUT? TEAM effort composed of a • Deciding what, where and how to drill is a _______ GEOLOGIST ____________, LANDMAN GEOPHYSICIST ENGINEER __________, __________ and __________ and many others. POROSITY • The measure of open spaces in rock is the __________; the measure of the ability PERMABILITY of fluid to flow thru rock is the ___________. • The amount of oil/gas in a reservoir currently available for production is called RESERVES what? _________. • The most important type reserves and the only one the SEC will accept are the P90 OR PROVED ______________ reserves. ART than a science. • Reserves estimating is more of an ______ • Successive sections of pipe of decreasing diameter set one inside the other and CASING STRING cemented in a wellbore is the _______ ______. CASING • Protection of freshwater aquifers in a well is done by the ________. Next page 64 REVIEW – SESSION 3 WHAT HAVE WE TALKED ABOUT? EXPLORATION OR “WILDCAT” and _______________________. APPRAISAL OR ON-STRUCTURE • Two well types: ______________________ 1 • The worst odds of an exploratory well being successful is ___in 10; 3 the worst odds of an on-structure/appraisal well being successful is ___in 10. MUD • When drilling, the drill bit is kept cool by the ______. RESERVOIR • If mud weight is too high, it will damage the ___________; if too low, a well BLOWOUT is possible. __________ TOTAL DEPTH • The depth below surface to the bottom of a well is the _____ _____ abbr. as “TD”. • A technique of running a special tool downhole to take measurements around the LOGGING payzone is called well _________. • Engineers are highly trained, overworked, and under-appreciated and therefore MILLIONS! they should be paid _________! 65 REVIEW – SESSION 3 Thank You! Remember Geology Rocks! 66 The Course Outline The Basics: Week 1: Geology of Coal, Oil and Gas Week 2: Processes of Exploration Week 3: Engineering Processes: Reservoir/ Drilling/Production The Adventure: Week 4: ‘Vagabond Group’ chooses 2 prospects Week 5: ‘Vagabond Group’ drills! Your chance to invest Week 6: the Payout?! A black-gold millionaire or dry hole hobo? 68 Petroleum Engineer - REFERENCES INTERNET • http://www.oilprimer.com/ • http://oilandgasinvesting.com/ • http://www.beg.utexas.edu/mainweb/presentations/2004 _presentations/pdf/wang_111704.pdf • http://www.petroleum-economist.com/ • http://www.eia.doe.gov/bookshelf/brochures/gasolinepric esprimer/index.html • http://www.eia.doe.gov/pub/oil_gas/natural_gas/data_pu blications/cost_indices_equipment_production/current/cos tstudy.html • http://oilandgasinvesting.com/news/1-latest-news/50investing-in-oil-a-gas-based-on-cash-flow-a-costs-versusrecoverable-reserves.html • http://www.energyinst.org.uk/education/glossary/ • http://fossil.energy.gov/programs/reserves/npr /publications/Drilling_for_Oil_and_Gas.pdf • http://www.glossary.oilfield.slb.com/ • http://en.wikipedia.org/wiki/Well_drilling • http://en.wikipedia.org/wiki/Drilling_mud • http://www.youtube.com/watch?v=LcNZfJbH5pk • http://www.youtube.com/watch?v=oZUUGpecphc&NR=1 • http://www.youtube.com/watch?v=fl8L4qSqSqE • http://www.youtube.com/watch?v=cXd01nq_HK8 • http://www.geolab.unc.edu/Petunia/IgMetAtlas/mainmen u.html • http://www.offshore-mag.com/index.cfm • http://tonto.eia.doe.gov/ftproot/petroleum/tr0565.pdf • http://www.horizontaldrilling.org/ • http://home.versatel.nl/the_sims/rig/lakepeigneur.htm • http://www.youtube.com/watch?v=BdRcALtA8CE&NR=1 • http://www.api.org/ehs/performance/explore/moreexplorprod uction.cfm • http://tonto.eia.doe.gov/dnav/ng/ng_enr_sum_dcu_rusf_a.ht m • http://www.eia.doe.gov/pub/oil_gas/natural_gas/data_publica tions/crude_oil_natural_gas_reserves/current/pdf/appb.pdf • http://www.eia.doe.gov/pub/oil_gas/petrosystem/petrosysog. html • http://www.energy.gov/energysources/fossilfuels.htm • http://tonto.eia.doe.gov/energy_in_brief/foreign_oil_depende nce.cfm • http://www.eia.doe.gov/pub/oil_gas/petroleum/data_publicati ons/company_level_imports/current/import.html • http://www.eia.doe.gov/neic/speeches/Caruso061305.pdf • http://www.npc.org/Study_Topic_Papers/7-STGGlobalAccess.pdf • http://www.eia.doe.gov/neic/infosheets/crudeproduction.html • http://www.eia.doe.gov/pub/oil_gas/petroleum/analysis_publi cations/chronology/petroleumchronology2000.htm#T_2_ • http://images.google.com/imgres?imgurl=http://www.osha.go v/SLTC/etools/oilandgas/images/rig09.jpg&imgrefurl=http://w ww.osha.gov/SLTC/etools/oilandgas/illustrated_glossary.html& h=628&w=353&sz=56&hl=en&start=18&tbnid=TwN7VuGlNKMVM:&tbnh=137&tbnw=77&prev=/images%3Fq%3 Drotary%2Boil%2Bdrilling%2Brig%26gbv%3D2%26hl%3Den%26 safe%3Doff%26sa%3D • http://www.investopedia.com/features/industryhandbook/oil_ services.asp 69 Petroleum Engineer - REFERENCES INTERNET http://www.osha.gov/SLTC/etools/oilandgas/images/bop_stac k.jpg http://www.youtube.com/watch?v=lkqpEXy0frE&feature=relat ed http://www.youtube.com/watch?v=sYTO_0_0ReQ&feature=rel ated http://www.youtube.com/watch?v=4ntsk1g2oY&feature=related http://www.techstreet.com/apigate.html http://en.wikipedia.org/wiki/Jackup_barge http://www.youtube.com/watch?NR=1&v=fNq2uKfSvhw&feature= endscreen http://www.youtube.com/watch?v=Q9gGqNUxQ5Q&feature=ends creen&NR=1 http://en.wikipedia.org/wiki/Completion_(oil_and_gas_wells) http://gekengineering.com/Downloads/Free_Downloads/Perforati ng_Basics.pdf http://en.wikipedia.org/wiki/Semi-submersibles http://www.ehow.co.uk/info_8712642_deep-vs-shallow-waterdrilling.html http://www.ehow.co.uk/about_4597210_offshore-oil-rigs.html JACKUP DRILLING RIGS 70 SEMI-SUBMERSIBLES RIGS 71 INLAND WATER RIGS 72 Deepwater system types (2008) 73