Laboratoire des Matériaux Macromoléculaires URA CNRS n°507

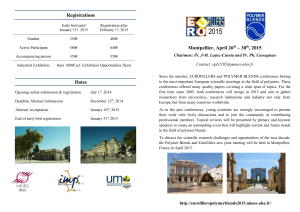

advertisement

UMR CNRS #5627 INGENIERIE DES MATERIAUX POLYMERES Institut National des Sciences Appliquées de Lyon 69621 Villeurbanne (France) http://www.insa-lyon.fr/Laboratories/LMM UMR CNRS #5627 / IMP Ingénierie des Matériaux Polymères Head UMR: Prof. J.F. Gérard Laboratoire des Matériaux Macromoléculaires Institut National des Sciences Appliquées Head: Prof. J.F. Gérard Laboratoire des Matériaux Polymères & Biomatériaux Université Claude Bernard Lyon I - ISTIL Head: Dr. G. Seytre UMR CNRS #5627 Polymer Materials Engineering IMP Head: Prof. Gérard J.F. Laboratory Macromolecular Materials Laboratory Polymer Materials & Biomaterials STAFF (47 permanents) 22 Professors or Assistant professors 12 CNRS senior scientists 14 Engineers/Technicians & Administratives 62 PhD students 5 Post-Docs 25 DEA (Masters) IMP - UMR CNRS #5627 Outcomes 1999-2002 302 93 250 204 24 48 8 Papers (referred) Invited lectures Lectures Posters Patents PhDs (defended) PhDs (shared with other research groups) International symposia organized Workshops or Conferences Polymer Blends May 2002, ‘Nanocomposites à charges lamellaires’ March 2003, Journées Transalpines des Polymères October 2003, Elaboration matériaux polymères nanoporeux January 2004, MODEST September 2004 IMP - UMR CNRS #5627 Research Topics Fundamental research devoted to practical objectives (Materials Engineering) Polymer chemistry (Chemical Engineering) Polymer chemistries Blends, Filled polymers and Composite materials Surface and interface chemistries Processing / Formulation Reactive and non-reactive processes Influence of the Process Parameters Frontiers with polymer physics Properties IMP - UMR CNRS #5627 Research Topics 1. Synthesis of Polymers Having Controlled Architecture & Properties Syntheses and Chemical Modifications 2. Processing Engineering of Polymers, Blends, and Composite Materials 3. Surfaces & Interfaces Organization & Functionality 4. Architecture-Morphology / Mechanical, Electrical, and Transport Relationships of Polymers & Multimaterials 5. Natural & Bioartificial Polymer Materials IMP - UMR CNRS #5627 Applications - Examples Composites / Nanocomposites Materials Toughening, Gas barrier, Durability / Aging Intelligent Processing, Formulations, etc. Surfaces, adhesives, coatings & multilayers Formulations, Processing requirements, powder coatings, UV coatings, adhesives, Designed surfaces Practical adhesion properties, Wettability, gas barrier Polymers with Controlled Properties Mechanical Properties, Life Cycle (Aging, Recyclability,..) Electrical and dielectric properties (low K, etc) Transport / Barrier / Permeation, Diffusion, etc. Research Topic#1 IMP UMR #5627 Synthesis of Polymers Having Controlled Architecture & Properties Syntheses and Chemical Modifications 1.- Reaction mechanisms and kinetics * Conventional polymerization routes (condensation, free radical, hydrol. condens.) * Interfacial route: in-situ crosslinking of particles, microencapsulation * Controlled radical polymerization: end-linking crosslinking, grafting from, … * Structural changes during polymerization – chemiorheology – 2.- Formulations of reactive systems * Chemical modification of oligomers (PUA, silicon alkoxide-term., HBP, TPU) * Chemistries et organization at different scale lengths - dispersion of pre-formed heterogeneities (HPB, grafted nanosilica, mgels) - organized polymer nanolayers (CRP grafting from) * Amphiphilic networks TPU/PDMS 3.- Phase separation thermodynamics and kinetics in reactive systems * High Tg thermoplastic/thermoset formulations (PEI, PES, PPE, PVC, PET, sPS) * Nanostructured thermosets from block copolymers, POSS, HBP * Porous networks from phase separation process Research Topic#1 IMP UMR #5627 Synthesis of Polymers Having Controlled Architecture & Properties Syntheses and Chemical Modifications High Tg thermoplastic-thermoset blends Toughening (KIc) Processing aids POLYETHERIMIDE PEI PURE EPOXY 10% EPOXY MATRIX 20% PHASE INVERSION 30% TP MATRIX 45% 60% PURE THERMO PLASTIC 3 mm (A.Bonnet et al, Macromolecules 1999) POLYPHENYLENE PPE ETHER Research Topic#1 Synthesis of Polymers Having Controlled Architecture & Properties IMP UMR #5627 Syntheses and Chemical Modifications Chemical modifications of thermoplastic polyurethanes TPU done in the molten state - reactive extrusion - 3 TPU « self crosslinkable » from ‘soft’ hydrolysis aminoalkoxysilane 2 Direct crosslinking complete and fast humidity 1 O O O N-C-O C=O NH N-C-O C=O NH N-C-O C=O NH N C O N C O N C O hydroxyalkylacrylate crosslinkable TPU from photopolymerization diol, diamine 4 network with designed properties LMM/IMP INSA Lyon - UMR CNRS #5627 Scientific Topics Chemistries Under Study •EPOXIES epoxy-amine, anhydride, homopolymerisation, cationic , anionic types encapsulation of amines, functionalization of hyperbranched pol. water-borne and solvent-based formulations, linear epoxies photopolymerization of cycloaliphatic epoxies epoxy-thermoplastic blends (toughening, processing-aids) PPE, PES, PEI, PS, sPS, PVC, … •POLYURETHANES, POLYUREAS alcohol-isocyanate, amine-isocyanate, blocked and encapsulated isocyanates, functionalization of hyperbranched pol. segmented and crosslinked PU /PUR dispersed TPU, reactive extrusion of TPU for crosslinking •CYANATE-ESTERS •POLYESTERS (PET) LMM/IMP INSA Lyon - UMR CNRS #5627 Scientific Topics Chemistries Under Study (continued) •FREE RADICAL POLYMERIZATION unsaturated polyesters, acrylates •BENZOXAZINES •ACRYLATE CHEMISTRY FOR COATINGs epoxy- and polyurethane-acrylate based formulations for thermal or UV curings •SOL-GEL CHEMISTRY FROM SILICON - ALKOXIDES hybrid organic – inorganic materials based on PU and (meta) acrylates synthesis and introduction of polyhedralsilsesquioxanes POSS •CHEMISTRIES AT THE INTERFACES reactive extrusion of immiscible polymers and filled polymers generation of tailored interphases from specific interactions establish at the interface (metal – epoxy/amine) grafting on various types of surface (silica and silicates, …) Research Topic#2 IMP UMR #5627 Processing Engineering of Polymers, Blends, & Composite Materials 1.- Chemistry and processing – Reactive processing * Reactive extrusion - Polymerization copolymer synthesis on-line crosslinking of a dispersed phase (TPV, epoxy-amine) - Chemical modifications - Control and stabilization of morphologies in blends and nanocomposites * Reactive molding - Resin Transfer Molding RTM - Reaction Injection Molding RIM 2.- Physics associated to processing * Pressure-Volume-Temperature behaviour * Pressure and shear effects on crystallization processes * Generation of designed morphologies in thermoplastic-based blends Deformation of the dispersed phase Research Topic#2 IMP UMR #5627 Processing Engineering of Polymers, Blends, & Composite Materials Reactive extrusion Dryer Feeders (V, w) Pumps NIR & MIR spectroscopies Polymerization in bulk and in the dispersed phase Spectro UV Homopolymerization of e-caprolactone Reactive epoxy-amine dispersed phase in PS Thermoset/thermoplastic blends Chemical modification in extruder Anhydride-alcohol reaction (copolymers) Alcoholis of PET TPU modification m-wave channel Computer-controlled extruder (P,T, rot., …) Instrumention of twin-screw extruder Reactive solvants – Foams Other investigated routes Exchange reactions ester – alkoxysilane (TPV) Compatibilization blends nanofillers (nanoclays) Non-compatibilized and in-situ compatibilized PP/PE blends Research Topic#2 IMP UMR #5627 Processing Engineering of Polymers, Blends, & Composite Materials Reaction Injection Molding RIM Design of reactive systems In-situ analysis of reaction FT-IR (NIR) Microdielectrometry Resin Transfer Molding RTM Intelligent processing (in-situ analysis: mdielectrometry, US, NIR) Modeling mold filling (chemiorheology, permeability) Combined processes (in-situ dissolution of TP films or fibers) Gl ass fi ber s Thermoplastic film Diffusion of thermoplastic Stacking of prepreg layers RTN Polynetset GROWTH Soltex Curing Matrix Research Topic#2 IMP UMR #5627 Processing Engineering of Polymers, Blends, & Composite Materials Design of morphologies from processing conditions High shape factor dispersed phase PE/PET blend Effect of pressure and shear rate on crystallization processes Device for high shear rate testing in the molten state PVT apparatus Injection molding process SCOOP (Shrinkage Crystallinity Orientation of Polymers) FISH (Fiber-filled polymer Injection & Shrinkage) Solvay / Moldflow / legrand Research Topic#3 Surfaces & Interfaces IMP UMR #5627 Organization and Functionality 1.- Development of new methods for analysis and processing of surfaces * Controlled Radical Polymerization applied to surfaces (grafting from) * AFM developments: chemical mapping, surface forces, etc. * Modeling of interfaces in blends and composites (microcomposites) * Molecular modeling of bulk and surface properties 2.- Study of structure/organization of surfaces and interfaces in macromolecular systems * PRC for grafting ultra-thin PS layers * Effect of interactions at the interface with an inorganic surface (nanofillers) * Interactions/reactions at polymer-polymer interfaces * Interfacial adhesion in polymer-based materials 3.- Design, modification, and functionalization of surfaces and interfaces * Methodology for intercalation/exfoliation of lamellar nanofillers and nanoparticles in TPs and TSs * Synthesis of gradient interphases – Chemistries of interfaces * Design of interactive/reactive surfaces using chemical and/or physical methods Research Topic#3 Surfaces & Interfaces IMP UMR #5627 Organization and Functionality Development of tools and methodologies for studying surfaces and interfaces Theoretical Modeling wettability of polymer surfaces Analysis of interactions between PDMS and silica Experimental ADCB method for fracture energy of polymer-polymer interfaces Microcomposites Research Topic#3 Surfaces & Interfaces IMP UMR #5627 Organization and Functionality Nanocomposites - Management of nanoparticles dispersion state in polymers from tailoring the interactions at the interface PDMS - silica Effect of grafting level of silica Polypropylene PP – montmorillonite MMT Effect of the nature of the quaternary ammonium chains on intercalation/exfoliation Research Topic#4 IMP UMR #5627 Architecture-Morphology / Mechanical, Electrical, and Transport Relationships of Polymers & Multimaterials 1.- Mechanical and viscoelastic properties of polymer and multimaterials * Molecular architecture-morphology / mechanical behavior relationships * Feedback to synthesis, formulation, and processing conditions * Adhesion of polymer layers on substrates 2.- Electrical and optical properties of polymers * Study of diffusion and relaxation mechanisms * Electrical response – physicochemical events relationships * Electroactive polymers * Interfacial adhesion in polymer-based materials 3.- Transport of small molecules in dense macromolecular materials * Transport mechanisms and modeling: solubility vs. diffusion * Architecture-morphology / transport properties relationships * Effects of additional parameters: humid environment, etc. Research Topic#4 Architecture-Morphology / Mechanical, Electrical, and Transport Relationships of Polymers & Multimaterials IMP UMR #5627 Polarized light E AC : PEN spacer (25 µm) Permittivity Dielectric spectroscopy DEA Optical microscopy (f = 1 kHz, T = 161 °C) : PVDF sample (30 µm) : Aluminium lead : ITO glass 13 3,0E-08 12 2,5E-08 11 2,0E-08 10 1,5E-08 9 1,0E-08 8 5,0E-09 7 0 500 PVDF crystallization 200 s. 520 s. Ionic conductivity (ohm.cm)-1 Use of combined methods for studying crystallization of thermoplastics 714 s. 944 s. 1000 1500 2000 time (sec.) 1274 s. 2500 1694 s. Research Topic#5 Native & Bioartificial Materials IMP UMR #5627 1.- Basic analysis of kinetics and thermodynamics of extraction mechanisms of polymers from biomass 2.- Kinetics and thermodynamics of chemical modification reactions of chitine and chitosane for processing biomimetic structures 3.- Study of interactions in solution and in the solid state 4.- Design of complex physical shapes from solutions * Physical hydrogels from chitosane * Nanoparticle formation * Bio-encapsulation 5.- Physico-chemical interactions from physical hydrogels 6.- Metallic ions and dyes sorption on chitosane and cellulose 7.- Interface with life sciences Research Topic#5 Native & Bioartificial Materials IMP UMR #5627 Objectives Use of native structures existing partially which can be induce various non-conventional biological responses, i.e. polysaccharides : glycosaminoglycanes (GAG), chitine, chitosane - N-acetylglucosamine extracellular matrix (GAG, glycoconjuguated) as simple and sulfate forms - b bond, (14) biological media, - Influence of DA management of the biological response IMP - UMR CNRS #5627 European Research Training Networks POLYNETSET Thermoset-Based Polymer Blends LMM-IMP INSA Lyon Institute Polymerforschung Politecnico Milano Université Catholique de Louvain Imperial College Basque County University Siegen University Lyon (France) Coordinator Dresden (Germany) Milano (Italy) Louvain (Belgium) London (Great Britain) San Sebastian (Spain) Siegen (Germany) NBB-HYBRIDS Hybrid Organic-Inorganic Materials LMM-IMP INSA Lyon Institute Polymerforschung UPMC Université Paris VI Trento University Institute Macromolecular Sci. Franhaufer Inst. Silicatforschung Lyon (France) Coordinator Dresden (Germany) Paris (France) Trento (Italy) Prague (Czech Republic) Wursburg (Germany) IMP - UMR CNRS #5627 European Programme 6th PCRD Network of Excellence NANOFUN-POLY Nanostructured and Multifunctional Polymer-Based Materials and Nanocomposites INSTM (Italian Univ.) Perugia (Italy) IMP INSA Lyon Lyon (France) Consortium of 28 partners Coordinator Vice-Coordinator STREP ‘NANOFIRE’ Nanocomposites for Fire Retardancy Materials Politecnico Torino LMM-IMP INSA Lyon Alessandria (Italy) coordinator Lyon (France) Partner IMP - UMR CNRS #5627 Scientific Collaborations PICS Program CRMM /Technical University Lodz Coal Institute Australia Monash University Queensland University Queensland University of Technology Wollongong University Weizmann Institute INTEMA W. & M. College Ecole Polytechnique de Lausanne Politecnico Torino Réseau Transalpin des Polymères Lodz (Poland) Gliwicze (Poland) Melbourne Brisbane Brisbane Wollongong Rehovot (Israël) Mar-del-Plata (Argent.) Williamsburg (USA) Lausanne (Switzerland) Torino (Italy) CH – Vaud /Genève / Valais I - Lombardie / Ligurie / Vallée d’Aoste F – Région Rhône-Alpes IMP - UMR CNRS #5627 Scientific Collaborations Fédération des Polyméristes Lyonnais NMR facilities Center, etc. Programmes (GDR, ACI...) CPR " Reactive Extrusion" ACI Nanomaterials " Clay-Based Nanocomposites" ACI Adhesion " Metal / Polymer Interfaces" PREDIT Transportation " RTM Process" Ministry of Industry " RTM Preforms " RECORD 2000 " Recycling of Polymer Blends " RNMP " PROSPET ", " NENATEX " PACO " POLYSTOCK " Hydrogen storage Rhône-Alpes County Emergence " Nanocomposites Varnishes and Adhesives " Materials ‘Non-permeable/Breathing PU’ Materials " Nanocomposites based on lamellar nanofillers"" Materials " Reactive TS/TD formulations for new cables " French Research groups ISITEM Nantes, ENSAM Paris, ESPCI Paris, Univ. Lille, Clermont-Ferrand Univ., etc. IMP - UMR CNRS #5627 Connections with Industry About 87% of research activities are associated with industrial contracts Chemical Companies Ato-Fina, Solvay, Rhodia, Rhodia Silicones, Dow Chem., Exxon Vantico, Tergal, Wacker Chem. Polymer Users Companies Compounding/ Formulation Automotive/Aeronautics Coatings/Paints Packaging Electricity / Electronics Civil Engineering Others Multibase Dow Corning, Gemoplast, SAMI Acome, Merilithe, Chauzu, Allrim Renault, Inoplast, EADS – Airbus, CTTM Celliose, Becker Ind., Arcelor Pechiney/Cébal, Nestlé, Pernod-Ricard, Vitembal, Tetrapak Nexans, EDF, Porcher, RCE, Trixell-Thalès St. Gobain, Soprema, Lafarge, Gerflor, Spit IFP, CEA, Rossignol, IFTH Kodak , Air Liquide IMP - UMR CNRS #5627 Connections with industrial partners Types of collaboration PhD Doctorates CIFRE, BDI-CNRS, DGA, R-A County, EC 5th PCRDT Post-doctorates R-A County, EC 5th PCRDT ‘End of Study’ / Master Projects which can be connected with a following 5/6 month-long training period in industry ‘Transfer Engineer’ INSA Initial Research and Development Studies for SME companies (duration: few months ) Technology and Literature Survey and Watching Experiments / Data Analysis