Assessing Maintenance Effectiveness and Efficiency

advertisement

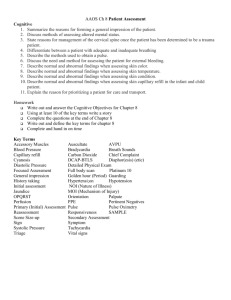

Assessing Maintenance Effectiveness and Efficiency • How is your maintenance dollar used, breakdown, inspection, improvements, demolition, operational support, or capital expense? Do you have a "value added" assessment process? • Are preventive maintenance activities/critical inspections are at their optimum? The right frequency, accurate plans, no sacred cows. • What is the typical environment maintenance personnel work in, reactive or proactive. How do you know? What's the average lead time for planning and scheduling. • How accurate and effective is your maintenance schedule, start and finish time, equipment readiness, material and tool requirements, coordination, lockout tag out requirements identified, permit requirements, plan versus actual • What is the average time required to obtain a safe work permit? do you have the available resources or schedules to optimize. • Time on tools, are you working the most effective schedule, what are your current work practices, how much time do you actually have to perform maintenance work. • Maintenance effectiveness survey (survey to obtain perspective from operations and maintenance personnel as to your current maintenance work process) • When was the last time you've managed by wandering around? you get what you inspect not what you expect. Assessing Maintenance Effectiveness and Efficiency How is your maintenance dollar used, breakdown, inspection, improvements, demolition, operational support, or capital expense? Maintenance: 10 Predictive/Preventive Maintenance (P/PM) Material, labor or equipment used in the prediction or prevention of routine maintenance or failures. This would include all work associated with the 10 PPM Elements such as services for lube oil and vibration analyses, regularly scheduled oil or filter changes, regularly scheduled inspections, root cause analysis investigations, etc. 20 Repair Maintenance Normal work performed on equipment. This includes repairs due to failures, normal wear, process upset that mechanically damages the equipment, and work performed to correct problems that were identified as a result of using predictive tools (such as vibration analysis, non-destructive evaluation (NDE), or routine inspections). It also includes painting or insulation work that is done as part of a repair. 30 Project Maintenance Includes any planned shutdowns or "planned projects" that modify, refurbish or replace facilities which are intended to reduce maintenance cost, or to improve reliability, and yet do not meet the capitalization rules. These expenditures are normally not recurring. Projects which install new and improved** equipment or materials and increase the asset base are not included in maintenance. Assessing Maintenance Effectiveness and Efficiency Non-Maintenance 60 Process Cleaning Chemical cleaning, hydro blasting, grit blasting, etc., of mechanical equipment, exchangers, vessels and piping. 70 Environmental This includes activities such as clean up of process spills, pond closures and other remediation. 80 Engineering Work that will be recharged to an engineering account. 90 Start-Up This includes expenses preparatory to, as well as those resulting from actual start-up of a new or major expanded facility. This work is always done on a special account assigned by the Accounting function. The work must meet their pre-determined guidelines before the account will be assigned. 100 Process Reconfiguring Any work done to reorganize the equipment or piping when two or more products are routinely produced in the same equipment. This would not include any cleaning that is involved, as this should be included with "Process Cleaning". Assessing Maintenance Effectiveness and Efficiency Non-Maintenance 110 Capital Projects that will be charged to a capital authorization. 120 Project/Improvement Activity that may modify assets but do not reduce maintenance cost, or improve reliability. Improvements that do not meet the capitalization requirement. This would include any modifications for safety or quality purposes. These expenditures are normally not recurring. 130 Demolition Removal of equipment or facilities that are no longer needed and will not be re-installed or replaced. 140 Other All other activities that are not defined as maintenance, environmental or capital. This includes work such as contract labor for operations (bagging laborers, etc.), routine clean-up of facilities. Assessing Maintenance Effectiveness and Efficiency Do you have a "value added" assessment process? Assessing Maintenance Effectiveness and Efficiency Are preventive maintenance activities/critical inspections are at their optimum? The right frequency, accurate plans, no sacred cows. To Frequent To Infrequent Assessing Maintenance Effectiveness and Efficiency What is the typical environment maintenance personnel work in, reactive or proactive. How do you know? Lead Time Vs Resource Utilization Utilization What is the average lead time you get for a job ? 60%- 100% 50%-60% 40%-50% 30%-40% Days 14 13 12 Manage Resources 11 10 9 8 7 6 5 Sharing Enabled 4 3 2 1 Reactive E-Job % High Assessing Maintenance Effectiveness and Efficiency What's the average lead time for planning and scheduling. Work Request Define Needs Work Order Plan Net Capacity Communicate Schedule Create Coordinate Schedule Resources Execute The Schedule Non - Work Current Week Next Week 1 2 3 4 5 6 7 M T W T F S S 8 M 9 T Lead Time Five Day Schedule 10 11 12 W T F Assessing Maintenance Effectiveness and Efficiency How accurate and effective is your maintenance schedule, start and finish time, equipment readiness, material and tool requirements, coordination, lockout tag out requirements identified, permit requirements, plan versus actual. Assessing Maintenance Effectiveness and Efficiency Assessing Maintenance Effectiveness and Efficiency Assessing Maintenance Effectiveness and Efficiency What is the average time required to obtain a safe work permit? do you have the available resources or schedules to optimize. What is the average time to acquire an typical safe work permit? Do you require a safe work permit for all maintenance work? How many permits are required per day? How many permit writers are available? Do you stager maintenance start times to accommodate issuing safe permit? Have you completed risk assessments for levels of safe permit requirements? Assessing Maintenance Effectiveness and Efficiency Time on tools, are you working the most effective schedule, what are your current work practices, how much time do you actually have to perform maintenance work. Eight Hour Day 7:30 8:30 9:30 10:30 11:3012:00 1:00 2:00 3:00 4:00 2:30 3:30 4:30 Legend Wrench Time Safety Meeting Wrench Time Job Line Up 28 Hours 45 Minutes per week Break Lunch Ten Hour Day Wash Up Travel 7:00 8:00 9:00 10:00 11:00 12:0012:30 1:30 Wrench Time 31 Hours per week 5:30 Assessing Maintenance Effectiveness and Efficiency Maintenance effectiveness survey (survey to obtain perspective from operations and maintenance personnel as to your current maintenance work process) Assessing Maintenance Effectiveness and Efficiency Assessing Maintenance Effectiveness and Efficiency When was the last time you've managed by wandering around? When did you last attend a morning tail gate and job lineup? Have you observed the control room at the start of the work day? When was the last time you reviewed a routine job plan with your planner? When was the last time you randomly picked a job from the daily schedule and observed with the maintenance supervisor if the activates were occurring as scheduled? Have you made radium observations to asses time on tools? Have you meet with the planner and maintenance supervisor to review plan Vs actual on routine schedules? You get what you inspect not what you expect. HEART OF THE MAINTENANCE WORK PROCESS ‘Fix it when you can’ mentality Operators trained in troubleshooting techniques, certain minor maintenance activities, and defined Operator Assisted Maintenance duties. Operators are identified as the primary equipment owners. Value Added work requests. All personnel are trained to correctly write a work request / notification and evaluate each work request / notification as to whether or not it adds value to the unit/business. Operations/Maintenance Coordinator Concept Person performing the OMC Role must have an in depth knowledge of Unit Operations, Maintenance Procedures and Business plans. The individual must be capable of making difficult decisions and challenging “Sacred Cows”. This person must also have the full support of the Operations Leadership. Value Added Focus Business rules are established Projects and improvements are reviewed to insure value creation. Inspections and Predictive/Preventive task are optimized. All jobs approved meet business needs. A culture must be created where personnel recognize the need to be realistic in setting priorities for work. The system will drive out unnecessary schedule interruptions. Reliance on retrieval of previous planned and critiqued jobs. Archived planned jobs are available. Planners use common planning practices to improve quality and reduce variability in the planning process The ability of the computerized maintenance management system to retrieve developed job plans. Job Packages include cost estimate Planners focus their effort on future work. Interruptions are planned and executed by the execution supervisor. HEART OF THE MAINTENANCE WORK PROCESS Resource Management and Scheduling. Planned work is scheduled on a weekly basis Standard planning process for Daily Planning and Turnaround Planning Scheduler Focused on meeting Operations needs while optimizing Maintenance resources. Schedule provides site integration. Final Approval and Cost Control is the responsibility of Operations Gatekeeper Work will be completed safely without environmental insults and will comply with regulatory requirements. Procedures exist. Employees must be trained to use proper procedures There should be an understanding of the interrelationships of all of the work processes in order for seamless “handoffs” to occur. Completed work is analyzed for improvement opportunities. A culture exists that encourages continuous improvement. Accurate and complete data must be recorded in CMMS such that the Improvement Process can be successful. Each job should be evaluated for areas of improvements i.e. equipment reliability using RCFA, job plans, etc. Key performance indicators are used to manage Work Process Key performance indicators are identified, measured, monitored and communicated. Every one in the organization owns some part of the work process. Each person is responsible and accountable for their role. They measure the outcome of the activities that they control.