MirrorMount_Mar13

advertisement

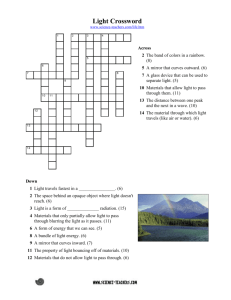

Mirror Mount Concepts Location: •3-point support to locate mirror tiles •lift mirror into place •Accurately adjust mirror tiles in the plane Material: •Minimise photon scattering – hence minimise thicknesses •Same type and lengths of plastic and metal as central pivot Adjustment to focus Cerenkov light: •Use 500 μm pitch screws to position reflected light spot Geometry of a single tile A Central (load-bearing) pivot B, C Location & adjustment supports Angle BAC = 90o AB = AC = 400 mm A B C Screw pitch at B, C = 500 µm Angular adjustment of 10o is equivalent to 15 µm perpendicular to plane, corresponding to 35 µrad mirror tilt which equates to 0.5 mm at 14 metres A little Engineering • Most of the engineering is in the design of the central, load-bearing pivot !!! Nota Bene !!! • Forces at B and C are small, so the aims are: – Minimise material seen by photons – Match the longitudinal material structure to the central pivot so that effects from temperature and humidity changes cancel to first order – Decouple horizontal frictional forces from movement perpendicular to the mirror plane Concept for Mirror Supports Fibre glass composite Glue to mirror Screw thread Bolt to mirror plate Hollow aluminium cylinder Mirror supports at B and C •Standard mirror support with individual inserts for mirror tile •Central region is strictly vertical to decouple frictional forces from screw-head Aluminium insert to ensure: •Contact surface with screw-head does not deform •Contact surface is vertical Plane of mirror (exaggerated) Tolerances dictate design • Why don’t we have a spherical region in the centre of the mirror supports B and C to locate the spherical head of the screw? – Tolerances (gluing, assembly) will give contention at B and C and there will be large frictional forces; – Any relative movement of the structure in the mirror plane will translate into displacement perpendicular to the mirror and hence defocus the Cerenkov ring; • We cannot position the mirror by dead reckoning but must do so (carefully) on assembly Assembly Procedure •Set screws at B, C to give required mirror plane for each tile •Load mirror tile onto central pivot •Locate mirror tile on supports at B, C •Adjust edge vertical using plumb line •Load all tiles and make vertical all edges •Fine adjustment of mirror plane using fine-pitched screws at B and C Tolerance on central pivot: Δx Balancing moments: 300 F = Δx Mg Δx [mm N] Mg = 250 N Suppose Δx = 0.1 mm Then F ≈ 0.1 N F Mg This must be provided by friction at the two lower supports. Probably OK ... If not, then Spacers to supplement friction Spacers are ... •Flexible plastic insert •Trim to size •Glue to edge of one tile •No force perpendicular to mirror NB: Force between tiles ≈ 0.1 N