File

Energy Conservation Awareness Workshop For

Students of Final Year Engineering

(An Exclusive Program for Engineering Colleges in Gujarat)

Organized & Sponsored by

Gujarat Energy Development Agency

A Government of Gujarat Organization -

We are thankful to

Dr. B.G.DESAI

for his guidance and help in preparing this Presentation

Module especially for the EC

Awareness Workshops for

Engineering Colleges

CONTENTS

ENERGY IN INDIA

WHY SAVE ENERGY

INTRODUCTION TO ELECTRICITY

ELECTRICITY CONSUMPTION OF EQUIPMENTS

TARIFFS AND ELECTRICITY BILLS

ENERGY AUDIT

ELECTRIC MOTORS AND PUMPS

LIGHTING

COMPRESSED AIR

REFRIGERATION

P.F. CONTROL

CASE STUDIES

ANNEXURE- 1 Energy Conservation Act

ANNEXURE- 2 BEE Star Labeling,

ANNEXURE- 3 Tips for Industries

1

ENERGY IN INDIA

ENERGY IN INDIA

Commercial Energy Sources

Non Commercial Energy Sources

Renewable Sources of Energy

Non Renewable Sources of Energy

COMMERCIAL ENERGY SOURCES

Coal and Lignite *

Natural Gas *

Oil *

Nuclear Energy *

Hydro Electricity

* Non Renewable Sources of Energy

Non Commercial Energy Sources

Fire Wood

Agricultural Waste

Dung Cake

Renewable Sources of Energy

Solar Energy

Wind Energy

Tidal Energy

Geothermal Energy

Wave Energy

Hydro Electricity

ENERGY RESERVES

TYPE

OIL(MT)

GAS(MTOE)

COAL(MT)

INDIA WORLD

800

1100 139700 0.8

98000 1031610 9.00

HYDRO(MTOE) 30

138300

218

%

0.58

13.76

NUCLEAR 2

MT - MILLION TONS

596 0.34

MTOE – MILLION TONS OIL EQUIVALENT

OIL

COAL

GAS

Expected Life

20 YEARS

200 YEARS

25 YEARS

INDIA HAS LESS THAN 1% OF WORLD OIL & GAS

RESERVES AND 17% OF WORLD POPULATION

CONCLUDING REMARKS

1.

India is importing 80% of oil, 15 to 20% of coal and Gas. This dependence will only increase in foreseeable future.

2.

Such heavy dependence on imported energy, poses serious questions about energy security and balance of payment. Rupee has already declined to rupee 68 /$.

3.

To meet challenge of climate change and environmental pollution, improving energy efficiency is a cost effective solution.

4. Present planning remains supply oriented. It must be oriented to demand management.

5. Major resources, financial and human; must be provided to demand management.

CONTD…….

CONCLUDING REMARKS

6. Non commercial sources firewood, agriculture waste and dung cake still contribute about 33% of our energy needs. Their end use efficiency as well as supply management must form an integrated part of our energy policy. Energy efficient cook stoves, solar cookers , decentralized solar systems must form part of major policy initiative.

7. Education system must emphasize Energy Efficiency and Energy

Conservation and Moderate Life Style.

ENERGY CONSERVATION MEANS

AVOIDING WASTAGE OF ENERGY

USE OF EFFICIENT EQUIPMENT

MODERATION OF ENERGY USE

ENERGY CONSERVATION MEANS

AVOIDING WASTAGE OF ENERGY

SWITCHING OFF IDLE LIGHTS,FANS

SWITCHING OFF IDLE AND REDUNDANT

EQUIPMENT

REDUCING WATER ,STEAM,COMPRESSED AIR

LEAKEAGES

EFFICIENT USE OF ENERGY

EFFICIENT EQUIPMENT AND PROCESSES

HIGH EFFICIENCY PUMPS,FANS,MOTORS,LIGHTS

EFFICIENT OPERATION AND MAINTENANCE

CLEANING OF EQUIPMENTS,WATER TREATMENT

ETC.

MODERATION OF ENERGY USE

MODERATION OF ENERGY USE

USE COMPRESSIORS , FANS, PUMPS WITH MINIMUM

PRESSURE, TEMPERATURE, FLOW

USE OF SMALL SIZE EQUIPMENT LIKE MOTORS, PUMPS,

REFRIGERATOR, T.V.SETS, VEHICLES

400 LIT. HIGH EFFICIENCY FRIDGE WILL CONSUME MORE

ENERGY THAN 165 LIT. MODEL

42 INCH T.V. WILL CONSUME 4 TIMES MORE POWER THAN

21 INCH T.V.

FAN POWER 50 WATTS

AIRCOOLER 200 WATTS

AIRCONDITIONER 1500 WATTS

CYCLING/WALKING IN PLACE OF 2/4 WHEELERS

TELEPHONE ,E-MAIL IN PLACE OF TRAVEL

DIRECT AND INDIRECT USES OF

ENERGY

1. ELECTRICITY, LPG, DIESEL, PETROL, COAL ARE

DIRECT USES OF ENERGY

2. WE USE LOT OF MATERIALS, TAKE FOOD, WEAR

CLOTHES. ALL THESE ACTIVITIES CONSUME

LOT OF ENERGY. CONSTRUCTION OF

BUILDINGS ALSO USE ENERGY

ENERGY CONSERVATION MEANS

REDUCING BOTH DIRECT AND

INDIRECT USES OF ENERGY

WHY SAVE ELECTRICIY - 1

ELECTRICITY IS GENERATED BY BURNING COAL,OIL,GAS

IN THERMAL POWER STATION

1 UNIT (KWH) OF ELECTRICITY REQUIRES 3 UNITS OF

PRIMARY FUELS LIKE COAL, OIL, GAS (EFFICIENCY – 30%)

HUGH TRANSMISSION & DISTRIBUTION NETWORK IS

REQUIRED TO BRING ELECTRICITY FROM POWER

STATIONS TO CONSUMERS

T & D LOSSES ARE ABOUT 25%

1 KWH (UNIT) SAVED BY CONSUMER LEADS TO SAVING OF

4 UNITS OF PRIMARY FUEL

WHY SAVE ELECTRICITY - 2

HYDRO ELECTRICITY, WIND, SOLAR BIOMAS ELECTRICITY

IS RENEWABLE AND NON POLLUTING

SHARE OF HYDRO ELECTRICITY HAS DROPPED FROM 50%

TO ABOUT 15% NOW

WIND POWER IS NOW COMPETITIVE WITH COAL/GAS/OIL

SOLAR PV (PHOTOVOLTAIC) IS VERY EXPENSIVE

7-8 crores/MW Rs. 10-15/KWh

WHY SAVE ELECTRICITY - 3

SETTING UP POWER STATIONS IS VERY EXPENSIVE

1 MW REQUIRES 4 CRORES TO 5 CRORES

1 KW REQUIRES Rs. 40,000 TO 50,000

WITH TRANSMISSION AND DISTRIBUTION TOTAL

INVESTMENT REQUIRED IS Rs. 60,000 TO Rs. 70,000 PER

KW

1 KW DEMAND SAVED LEADS TO SAVINGS OF Rs. 60,000 to 70,000

WHY SAVE ELECTRICITY 4

POWER STATIONS REQUIRE LEAD TIME OF 5 TO 7 YEARS

CONSERVATION PROJECTS CAN BE IMPLEMENTED IN SIX

MONTHS TO 1 YEAR

CAPITAL COSTS FOR CONSERVATION PROJECTS IS Rs.

2000 TO Rs. 10,000 PER KW

GENERATION OF ELECTRICITY LEAD TO ENVIRONMENTAL

POLLUTION

1 KWH LEADS TO 1KG OF CO2 FOR COAL

1 KWH LEADS TO 0.4 KG OF CO2 FOR GAS

1 KWH LEADS TO 0.65 KG OF CO2 FOR OIL

THIS LEADS TO GLOBAL WARMING

1 KWH GENERATION REQUIRES 4 TO 8 LITERS OF WATER

WHY SAVE ELECTRICITY - 5

SAVING OF ELECTRICITY LEADS TO SAVING OF

COAL,OIL,GAS

SAVINGS OF COSTS TO CONSUMERS

REDUCES COSTS OF SETTING UP EXPENSIVE POWER

STATIONS

REDUCES ENVIRONMENTAL POLLUTION REDUCING

GLOBAL WARMING

SAVES TIME FOR SETTING UP POWER STATION

WHY SAVE ELECTRICITY - 6

AN EXAMPLE

10 100WATTS BULB COSTS Rs. 100 LOAD = 1000 WATTS

10 20 WATTS CFL COST Rs. 1500 LOAD = 200 WATTS

AN EXTRA INVESTMENT OF Rs. (1500-100)Rs.1400 LEADS

TO SAVING OF (1000-200) 800 WATTS. THIS IS EQUAL TO

Rs. 1750 PER KW

COMPARE THIS TO Rs. 60,000 TO Rs. 70,000 KW

WHY SAVE ELECTRICITY - 7

AN EXAMPLE

FOR 5 HRS/DAY, TOTAL HRS/YR = 5 X 365 =

1825 HRS.

ELECTRICITY CONSUMED BY ONE 100 WATTS

BULB

IS 1825X100 / 1000 = 182.5 KWH (UNIT)

ELECTRICITY CONSUMED BY 20 W CFL IS

1825X20/1000 = 36.5 KWH (UNIT)

SAVING IN ELECTRICITY 182.5 – 36.5 = 146

KWH

AT 5 Rs./KWH THIS IS 146X5 = Rs.730

EXTRA INVESTMENT Rs. 150 – 10 = Rs. 140

PAY BACK PERIOD = 2.3 MONTHS ( 160/730)

ENERGY EFFICIENT TUBE LIGH T

POWER CONSUMPTION OF T-5 WITH ELECTRONIC

BALLAST

POWER CONSUMPTION OF T-12 WITH NORMAL

BALLAST

POWER SAVING

30 WATTS

55 WATTS

25 WATTS

FOR 2000 HRS/ANNUM RUNNINGS UNIT SAVED= 25 *

2000 / 1000

PRICE DIFFERIENCE

= 50

=Rs.200

Rs.350

PAY BACK PERIOD

FOR 25WATTS DEMAND REDUCTION INVESMENT

21 MONTHS

Rs.350

FOR 1 KW DEMAND REDUCTION INVESTMENT 350 ÷ 25 *1000

=Rs.14,000

COMPARE THIS WITH Rs.50,000 to 70,000 for 1 KW

NEW CAPACITY

ENERGY EFFICIENT CEILING FANS

POWER CONSUMPTION OF NORMAL FANS

POWER CONSUMPTION OF EFFICIENT FANS

SAVING

FOR 5000 HRS RUNNING KWH SAVED IS

PRICE DIFFERENCE

PAY BACK PERIOD

FOR 25 WATT DEMAND REDUCTION ADDITIONAL

INVESTMENT

FOR 1 KW DEMAND REDUCTION INVESTMENT

COMPARE THIS WITH Rs. 50,000-70,000 PER KWFOR

NEW CAPACITY

75 WATTS

50WATTS

25 WATTS

125 KWH

=Rs.500

Rs.200

5 MONTHS

Rs.200

Rs.8000

Energy Consumption of Domestic Appliances

(Normal Appliance)

ITEM

BULB

TUBE

LIGHT

FANS

REFRIGAT

ORS

TOTAL

No. X Rating LOAD Hrs/annum kWh/ annum

3 X 40W 120 W 4 X 365 120*4*365/ 1000

=175.2 units

4 X 55W 220W 6 X 365 220*6*365/ 1000

=481.8 units

3 X 75W

1 X 150W

225W 15X 300

150W 8 X 365

715W

225*15*300/ 1000

=1012.5 units

150X8X365/1000

= 438 units

2119.5 kWh per annum

Avg.Monthly Consumption = 177 units

Energy Consumption of Domestic Appliances

(Energy Efficient Appliances)

Hrs/annum kWh / annum ITEAM

CFL

No. X

Rating

3 X 10(W)

Total

Load

30W

T-5

TUBE

LIGHT

EFFICIENT

FANS

4 X 30(W)

3 X 50(W)

REFRIGAT

OR

TOTAL

1 X 100W

120W

150W

100W

400W

4 X 365

6 X 365

15 X 300 150X15X300/1000

8 X 365

30X4X365/1000

120X6X365/1000

100X8X365/1000

UNITS

43.8

262.8

675

292

1281.6

Avg.Monthly Consumption = 107 units

SUSTAINABLE DEVELOPMENT

For sustainable development, adopt a moderate life style using less natural resources and using them efficiently

Use of public transport in place of private transport

Use of vegetarian diet in place of nonvegetarian diet

Avoid use of energy intensive materials like plastics, metals

REDUCE REUSE RECYCLE

Energy Conservation Awareness Workshop For

Students of Final Year Engineering

(An Exclusive Program for Engineering Colleges in Gujarat)

Organized & Sponsored by

Gujarat Energy Development Agency

A Government of Gujarat Organization -

INTRODUCTION TO ELECTRICITY

CONCEPT OF POWER FACTOR

Electric motors, tube lights, transformers all work on principles of electromagnetic induction by faraday. To establish electromagnetic field in these device a type of current is required which is known as reactive current. For actually doing work, producing torque, heat, an active current is required. Total current flowing in line is vector sum of active and reactive currents.

INTRODUCTION TO ELECTRICITY

CONCEPT OF POWER FACTOR

For better utilization of generators, transmission, distribution lines, it is necessary to restrict flow of reactive currents in these lines. Reduction of reactive current is known as power factor correction.

Power Factor = Active Current/ Total Current

(Total Current) 2 = (Active Current) 2 +(Reactive Current) 2

P.F. = kW / kVA

Power Factor correction is done by connecting capacitors.

They must be connected near loads. Like motors, tube lights etc.

INTRODUCTION TO ELECTRICITY

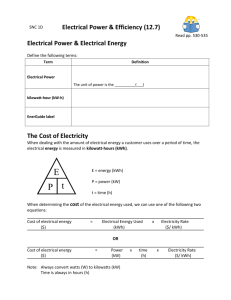

POWER

POWER CONSUMED BY ELECTRICAL EQUIPMENT IS GIVEN

IN WATTS.

FOR SINGLE PHASE EQUIPMENT

POWER IN WATTS = VI COS

ø

WHERE

• V = VOLTAGE VOLTS ,

•

I = CURRENT AMPS

•

COS

ø

= P.F.

FOR THREE PHASE EQUIPMENT

POWER IN WATTS =

√

3 V I COS

ø

INTRODUCTION TO ELECTRICITY

ENERGY

ELECTRICAL ENERGY IS MEASURED IN KWH(UNIT)

1 KWH = 1000 KWH

ONE LIGHT BULB OF 100 WATTS RUNNING FOR 10 HOURS

CONSUME 100 X 10 = 1000 WATT HOURS = 1 UNIT

FOR 230 VOLTS SUPPLY, BULB HAS P.F. = 1

CURRENT TAKEN FOR 100 WATT BULBS

100 = 230 X AMP X P.F.

= 230 X AMP X 1

AMP = 100/230 = 0.434 AMP

INTRODUCTION TO ELECTRICITY

ENERGY

FOR 40W TUBE LIGHT TOTAL POWER TAKEN WITH CHOKE

40 + 15 = 55 WATTS P.F. = 0.5

55 = 230 X AMPS X 0.5

AMPS = 55 / 230 X 0.5 = 0.478 AMP

215 L REFRIGERATION MOTOR CONSUMES ABOUT 150

WATTS POWER FACTOR IS 0.7

150 WATTS = 230 V X AMPS X 0.7

AMPS = 150/230 X 0.7 = 0.93

INTRODUCTION TO ELECTRICITY-9

ENERGY

3 phase motors consume power as follows

POWER = √ 3 V I cosø

For a 5 hp (3.75 kw) 1 hp = 746 watts

At Full Load P.F. = 0.8 amps = 7.5

Power Input = _/3 x 415 x 7.5 x 0.8 = 4307 watts

Power Output = 3730 watt

Efficiency = output/input = 3730/4307 = 86.67%

ELECTRICITY CONSUMPTION BY EQUIPMENT

ELECTRIC BULBS

BULBS COME IN RATINGS OF 25W, 40W, 60W, 100 WATTS

ENERGY CONSUMED IS GIVEN BY NUMBER OF HOURS

USED.

FOR 4 HRS/DAY USE FOR A 30 DAY MONTH

60 WATTS WILL CONSUME ELECTRICITY

4 X 30 X 60 = 7200 WATT HR = 7.2 KWH (UNIT)

FOR 6 HRS / DAY USE FOR A 30 DAY MONTH

100 WATTS BULB WILL CONSUME ELECTRICITY

6 X 30 X 100 = 18000 WATT HR = 18.0 KWH

HIGHER THE WATTS, HIGHER THE HOURS, HIGHER IS

CONSUMPTION

ELECTRIC BULBS

ZERO WATT BULB CONSUMES 15 WATT

FOR 30 DAYS, 9 HRS/DAY USE, ELECTRICITY CONSUMED

30 X 15 X 9 = 4050 WATT HR = 4.05 UNITS

A 3 WATT CFL WILL CONSUME

30 X 3 X 9 = 810 WATT HR = 0.81 UNITS

Compact Fluorescent Lamp

CFLs SAVE 80% ELECTRICITY

NORMAL BULBS LIFE IS 1000 HRS

CFLS’ LIFE IS 5000 HRS

BULB CFL

25 7

40 10

60 15

100 25

FOR 6 HRS / DAY 30 DAY MONTH 25 WATT CFL

CONSUMPTION

6 X 30 X 25 = 4500 WATT HR = 4.5 UNITS

COMPARE THIS WITH 18 UNITS FOR 100 WATT BULB

Fluorescent Tubelights

NORMAL TUBELIGHTS (T-12) CONSUME 40

WATT. CHOKE OR BALLAST CONSUME 12 TO 15

WATTS. TOTAL CONSUMPTION IS 52 TO 55

WATTS

SLIM TUBELIGHTS (T-8) CONSUME 36 WATTS.

CHOKE OR BALLAST CONSUME 12 TO 15 WATTS.

TOTAL CONSUMPTION IS 48 TO 50 WATTS.

NEW T-5 TUBELIGHTS CONSUME 28 WATTS.

ELECTRIC BALLAST CONSUME 2 WATTS. TOTAL

T-5 CONSUMPTION IS 30 WATTS.

Ceiling Fans

1200 MM FAN AS PER BLS 374 (2002)

WILL CONSUME 50 WATTS

MOST OF THE WELL KNOWN BRANDS CONSUME BETWEEN

65 TO 85 WATTS

CONSUMPTION FOR OTHER SIZES IS AS FOLLOWS:

900 MM 42 WATTS

1200 MM 50 WATTS

1500 MM 63 WATTS

FAN AT LOWER SPEED CONSUME LESS ELECTRICITY

Ceiling Fans Regulators

FAN CONSUMPTION AT DIFFERENT SPEEDS

REGULATOR POSITION NORMAL ELECTRONIC

1 40 WATTS 15 WATTS

2 51 WATTS 34 WATTS

3 61 WATTS 40 WATTS

4 68 WATTS -

5 76 WATTS 76 WATTS

Refrigerators

165 – 180 litres refrigerators consume 35 to 40 units per month

Consumption increases with age as air leaks through gaskets

300 litres refrigerators consume 50 to 60 units per month

Frost free refrigerators have heating coils to defrost. They consume 50% more energy

Keep thermostat at highest possible temperature

TV, Computer, etc.

21” Colour TV consumes 100 watts

Larger sizes consume more electricity

Computer with 17” LCD screen consumes 70 - 80 watts

Other equipments

Immersion Heater 1000 watts

Instant heater 3000 watts

Storage heater 1000 watts

Washing machine 150 watts

Air conditioner 1500 watts/ton

Air cooler 150 to 200 watts

EFFECT OF VOLTAGE on Lamp Wattage Consumption

40W Bulb 11W CFL Voltage T-8 Slim

FTL

190 V 26.03

---

210 V

230 V

250 V

29.11

32.20

34.30

35.26

40.50

45.85

9.40

10.21

11.40

EFFECT OF VOLTAGE on Fan (Wattage) Consumption

Voltage Normal

Regulator

(watts)

210 V 1 35.40

2 44.91

3 51.85

230 V 1 41.14

2 51.62

3 59.46

258 V 1 46.86

2 58.31

3 67.00

Electronic

Regulator

(watts)

9.97

27.94

52.50

12.57

33.66

59.32

15.58

39.07

66.69

Electricity Tariff and Bill Analysis

Different Tariffs are Applicable for different categories of consumers. Main categories are:

• Residential

• Commercial

• LT Industries

• HT Industries

For Residential , Commercial and LT

Industries Tariff consist of 2 part

• Fixed Charge depending on Connected Load

• Energy Charge depending on actual energy use

RESIDENTIAL TARIFFS

RATE – RGP of MGVCL

FIXED CHARGES / MONTH:

Range of Connected Load: (Other than BPL Consumers)

(a) Up to & including 2 kW Rs. 15/- per month

(b) Above 2 to 4 kW Rs. 25/- per month

(c) Above 4 to 6 kW Rs. 45/- per month

(d) Above 6 kW Rs. 65/- per month

ENERGY CHARGES

For the total monthly consumption:

(other than BPL consumers)

(a) First 50 units 315 paise per Unit

(b) Next 50 units

(c) Next 150 units

360 paise per Unit

425 paise per Unit

(d) Above 250 units 520 paise per Unit

ENERGY CHARGES

RATE: NON-RGP (COMMERCIAL)

• This tariff is applicable to the services for the premises those are not covered in any other tariff categories and having aggregate load up to and including 40kW.

FIXED CHARGES PER MONTH:

(a) First 10 kW connected load Rs.45/- per kW

(b) Next 30 kW connected load Rs.75/- per kW

ENERGY CHARGES

1.

2.

For installation having Contracted

Load up to and including 10kW; for entire consumption during the month -

425 paise per Unit

For installation having Contracted

Load exceeding 10kW; for entire consumption during the month 455 paise per Unit

For L.T. Industries

Fixed Charge

Upto 40 kW of Demand: Rs. 85 kW/month

Next 20 kW of Demand: Rs. 120 kW/month

Above 60 kW of Demand:Rs. 185 kW/month

Energy Charges

Rs. 460/kWh

Reactive Energy Charge

10 paise per kVRh

For H.T. Industries

Demand charges vary from Rs. 120 per kVA/month to Rs. 350 per kVA/month

Energy Charges vary from 425 paise/kWh to 450 paise/kWh.

In addition Time of Use Charges are applicable for peak hour consumption.

PF has to be maintained at 0.9

For higher PF rebate is available. For lower

PF penalty has to be paid

Fuel Surcharge

All consumers have to pay fuel surcharge depending on

actual cost

of fuel compared to a

standard value

.

At present it varies from 110 paise / kWh to 150 paise/kWh

Electricity Duty

Electricity Duty is applicable on

Demand and Energy Charges at following rate.

- Residential 15%

- Commercial 25%

- LT Industries 10%

- HT Industries 15 %

ANALYSIS OF BILLS

It is essential to analyze Electricity Bills for

1 year for Commercial and Industrial users

The Bill Analysis should work out relation between production and electricity consumption. It is preferable to work out an index like kWh/metre of cloth, kWh/kg of yarn, kWh/Ton of cement, kWh /Ton of steel

ANALYSIS OF BILLS

Each plant consist of production machines and utilities.

When production is reduced number of production machines and utilities must be reduced.

For energy efficiency it is always worthwhile running machines at full load rather than partial load

ANALYSIS OF BILLS

LOAD FACTOR

For large Industries it is worthwhile working out load factor every month to control maximum demand

L.F. = Average Demand for month

Peak Demand

Peak Demand is measured every half an hour.

Highest value in a month is taken as Peak Demand

Average Demand = KWH/Month

Running Hours

For continuous process industries L.F. Of 0.7 and above is achievable.

General Observations from Electricity Bills of last 12 months

Present Contract Demand

Average Billing Demand

Average Actual Max Demand

Total Electrical Consumption

Purchase Elect Billed Amount

Minimum Electricity Consumption in the month

Feb-2012

Maximum Electricity Consumption in the month

Dec-2011

Monthly Average Electricity Consumption

/Month

Monthly Average Power Bill Amount

Average Net Unit Cost

Average Power Factor maintained

4500 KVA

3825 KVA

3855 KVA

2,60,64,255 kWh

16,73,00,735/-

18,13,200 kWh

24,80,475 kWh

21,72.019 kWh

1,39,41,728/month

6.43/kWh

0.994

Table 1

Specific Power Consumption

Details of last two years & month wise production along with respective Power consumption is shown here under

Based on the figure of power & production, the specific

Power consumption is calculated for energy performance evaluation, which are shown in the following tables

Table 2: Annual Specific Power Consumption Last Two Years

(Jan-Dec)

Year

2010

2011

Total

Avg

Total

Production

(Kpcs)

345.798

444.279

790077

395039

Consumptions

(Kwh)

26932.679

31210.589

58143.268

29071.634

Specific Power

Consumption

(Kwh/Kpcs)

77.89

70.25

74.07

Energy Conservation Awareness Workshop For

Students of Final Year Engineering

(An Exclusive Program for Engineering Colleges in Gujarat)

Organized & Sponsored by

Gujarat Energy Development Agency

A Government of Gujarat Organization -

ENERGY AUDIT

ENERGY AUDIT (1)

ENERGY AUDIT IS A SYSTAMETIC STUDY OF ENERGY

INPUTS, ENERGY CONVERSION AND OUTPUTS OF ENERGY

CONSUMING EQUIPMENTS.

GOAL OF ENERGY AUDIT IS TO IMPROVE ENERGY

PRODUCTIVITY I.E. TO REDUCE ENERGY CONSUMPTION

PER UNIT PRODUCT.

IT IS NECESSARY TO REMEMBER THAT BOTH ENERGY

INPUT AND OUTPUT OF ENERGY USING EQUIPMENTS MUST

BE STUDIED.

ENERGY AUDIT (2)

SYSTEMS APPROACH

It is also necessary to study all links in a chain from energy input to output.

For Water Pumping - the following needs to be studied.

• Electric Motor

• Pump

• Pipe line

• Valves

• Leakages in system

• Quantity of water required

• Scope of Variable Speed Drive

• Many plants have reduced water requirement and reduced energy use.

ENERGY AUDIT (3)

SYSTEMS APPROACH IN COMPRESSED AIR SYSTEMS

Similarly for compressed air system, energy audit will study.

Scope of reducing compressed air use

Reducing compressed air pressure

Reduce leakage

Efficient motor, efficient compressor

Variable speed drives

SYSTEMS APPROACH IN

Refrigeration and Air-conditioning

Reduce need for Refrigeration Air

Conditioning

Increase Temperature Setting

Reduce Heat Ingress

Larger Heat Exchangers

Energy Storage

Use of Absorption Chillers (Using Heat For

Refrigeration)

Efficient Motor, Compressor and Drive

Transmission

69

ENERGY AUDIT (4)

SYSTEMS APPROACH IN LIGHTING

FOR LIGHTING AUDIT , LOOK AT FOLLOWING :

EFFICIENT LIGHT SOURCE

USE OF DAY LIGHT

TASK LIGHTING

PROVIDING LIGHT WHERE AND WHEN REQUIRED

LIGHTING CONTROLS LIKE, SWITCHES, DIMMERS,

OCCUPANCY SENSORS

VOLTAGE CONTROL

ENERGY AUDIT (5)

ENERGY AUDIT HAS FOLLOWING STEPS

MONITORING AND CONTROL

REDUCTION OF LOSSES

MAINTENANCE

MORE EFFICIENT EQUIPMENTS

MORE EFFICIENT PROCESSES

MONITORING AND CONTROL

It is necessary to put energy meters on all important equipment. It is also necessary to put instruments for measurement of flow, temperature, pressure etc.

Plant equipments can be divided into two categories

Production equipment like, machine tools, reactors, furnaces

Utility equipment like pumps, fans, compressors

Both these types of equipment need to be monitored.

MONITORING AND CONTROL

Monitoring of energy accounts on a shift daily, weekly, monthly basis immediately gives an indication of plant energy efficiency

Production has dropped but energy use is not dropping means production machines utilities are not used properly. Compressor, pumps, furnaces can be switched off when not required. Use all equipment at full capacities. One equipment at full load is to be preferred to two equipment at half load

Monitoring itself can give 2% to 5% energy saving

REDUCTION OF LOSSES

All electric equipment have high efficiencies, ranging from 99.9% for circuit breakers to 85% to 90% for motors.

Total distribution losses in a plant in cables etc will be in range of 2% to

4% nothing much need to be done about this.

MAJOR LOSSES

Major losses are in compressed air leakage(10% to 50%) water and steam leakage heat loss through radiation, heat ingress in refrigeration and air-conditioned spaces. These have to be minimized

COMPRESSED AIR LEAKAGE 7BAR(100PSIG)

HOLE DIA.

AIR LEAKAGE KW LOSS COST OF LOSS/YR

8000 hrs.&@ Rs.5/kWh

1/32”

1/8”

1/4”

1.62CFM

26CFM

104CFM

0.275

4.42

17.68

11,000

1,76,800

7,07,200

HOLE DIA

3MM

6 MM

STEAM LEAKS

7 KG/CM 2

22.5 KG/HR.

20 KG/CM 2

59 KG/HR

STEAM LEAKAGE PREVENTION IS MOST

IMPORTANT.

76

INSULATION OF PIPELINES

All equipments including pipelines should be properly lagged. All flanges should also be lagged. This is the cheapest energy conservation opportunity. The following table shows effect of insulation.

BARE

25 MM INSULATION

50 MM INSULATION

75 MM

100 MM

150 MM PIPE AT 300 0 C – AMBIENT 30 0 C

HEAT LOSS KCAL/M/HR REMARK

3415

505

307

232

191

With increasing thickness cost goes up but savings increase marginaly economic thickness of insulation can be studied.

77

IMPROVEMENT IN OPERATIONS

Minimize end use like water, compressed air

Minimize idle running

Operate equipment at best efficiency

Avoid partial load running of motors, pumps etc

Operate most efficient equipment

Different compressors, pumps, refrigeration equipment have different efficiencies monitor it and use the best

Improved maintenance

Cleaning of filters, lighting fixtures, condensers is essential

MORE EFFICIENT EQUIPMENTS

High efficiency motors

High efficiency pumps

High efficiency chillers

Technology has improved efficiency by 5% to 15%

T-5 tube lights, electronic ballasts

Select and look for best - on basis of Life

Cycle Cost (LCC)

MORE EFFICIENT PROCESSES

New process technologies are developed to reduce energy use

Dry process in place of wetprocess for cement

Membrane process in place of mercury cell for caustic soda

Low pressure technology for polypropylene, oxygen and other chemicals

Saving 10% to 75%

COAL

INTER FUEL SUBSTITUTION

COST HEAT VALUE COST FOR

1000KCAL

Rs.2000/TON 4000KCAL/KG.

0.50 Rs.

OIL

GAS

Rs.40/KG

Rs.30/M 3

.

10000KCAL/KG 4.00 Rs.

9000KCAL/M 3 3.33 RS.

ELECTRICITY Rs.6/KWH 860KCAL/KWH 6.97Rs.

ELECTRICITY IS MOST EXPENSIVE FOR HEATING

Energy Conservation Awareness Workshop For

Students of Final Year Engineering

(An Exclusive Program for Engineering Colleges in Gujarat)

Organized & Sponsored by

Gujarat Energy Development Agency

A Government of Gujarat Organization -

MOTORS & PUMPS

Saving Electricity In Motors & Pumps

About 50% of electricity in is used for pumping of water in residences, industry and agriculture

Opportunities for saving electricity in pump systems

Proper size of motor and pumps

Operation of motor and pumps

High efficiency motor and pump

Most important point is to minimize use of water

IMPORTANCE OF RUNNING COST

Motor Rating (kW)

Efficiency

Power Input (kW)

Running Hours/Year

7.5

0.86

8.72

6000

7.5

0.88

8.52

6000 kWh/Year 52320 51120

Rs/year (Rs.5/kWh) 261600 255600

Running Cost (10yr.) 2616000 2556000

First Cost 20000 23000

First Cost As % Of

Running Cost

0.8

0.8

Observations

Even a 7.5kw (10hp) motor consumes electricity worth Rs. 26 lakhs in 10 yrs

A small difference in efficiency (88%-

86%) leads to saving of rs.5000/yr

Extra cost (Rs.3000) is recovered in 7 months

Running cost accounts for 99% of total life cycle cost.

Give importance to running cost

ENERGY EFFICIENCY STANDARDS

It is worthwhile to refer to latest BIS standars. In market motor pumps are available with efficiencies higher than standards.

IS 12615-2011 ENERGY EFFICIENT MOTOR

IS 7538-1910 MOTORS FOR AGRICULTURE PUMP

IS 9238-1995 MOTOR FOR SUBMERSIBLE PUMP

IS 6595-2002 CENTRIFUGAL PUMS

IS 8034-2002 SUBMERSIBLE PUMP

IS 9079 MONOBLOCK PUMP

BEE STAR LABEL PRODUCTS MUST BE USED

MOTOR PERFORMANCE

CHARACTERISTICS

PUMP CHARACTERISTICS

Observations

It can be seen from above

Motor efficiency is constant upto 50% load

Pump efficiency goes on dropping with flow. At

50%flow efficiency drop by 20%

Selection of proper size of pump is much more important than proper size of motor

Motor no load current is 20%-40%of full load current. No load power is only 5% of full load power.

Pump power at no load is 25%-35%

Pump can not run on 0 flow, motor can run on no load with out any problem

Oversized Motors

Oversize motors and pumps lead to following problems

High initial investment

High running cost due to low efficiency

High maximum demand due to poor power factor

High installation cost

High rewinding cost

Replace with proper size and high efficiency

Motor and pump efficiencies are being increased with better materials, better manufacturing technologies and reduction of losses

For motor following table gives necessary information

For pumps refer to standard given earlier

STANDARD

IS 7538-1996

(AGRICULTURE

MOTORS)

IS 12615-2004

EE MOTORS

AMERICAN

STARNDARD

NEMA-MG-1-2003

PREMIUM EFFICIENCY

2.2 KW/ 3 HP

4 POLE

3.7 KW /5HP

4 POLE

7.5KW/ 10 HP

4 POLE

79% 83% 85%

86.4%

89.5%

88.3%

89.5%

90.1%

91.7%

PROPER OPERATIONS AND

MAINTENANCE

ALL PLANT EQUIPMENTS ARE DESIGENED FOR MAXIMUM

OUTPUT

WORST AMBIENT CONDITION

IT IS POSSIBLE TO SAVE ENERGY BY FOLLOWING

AT LOW LOADS LOW AMBIENHT TEMPS NO OF PUMPS CAN

BE REDUCED FLOW CAN ALSO BE REDUCED

MOTORS MUST BE CLEANED REGULARLY

PUMP IMPELLERS MUST BE CHECKED FOR WEAR AND TEAR

REGULAR MAINTAINANCE OF COOLING TOWERS,HEAT

EXCHANGERS IMPROVE EFFICIENCIES

PROPER WATER TREATMENT ALSO IMPROVE EFFICIENCY

ENERGY LOSSES DUE TO THROTTLING

VALVES ARE ROUTINELY USED TO REDUCE

PRESSURE AND FLOW AS PUMPS ARE OVER SIZES

THROTTLING LOSSES CAN BE

30%-70%

THROTTLING LOSSES

TO REDUCE THROTTING LOSSES

TRIM IMPELLER

SMALLER IMPELLER

SMALLER PUMP

VARIABLE SPEED DRIVE

VARIABLE SPEED DRIVES

VARIABLE ASPEED DRIVE WITH INVERTOR IS THE BEST OPTION

THROTTLING CONTROL

FLOW LPM

SYSTEM PRESSURE

PUMP PRESSURE

PUMP EFFICIENCY

PUMP INPUT

MOTOR LOAD

MOTOR EFFICIENCY

MOTOR INPUT

12,000

23.5

23.5

86.0

53.58 KW

97.41%

90%

59.53

STARTER EFFICIENCY 99.8

INPUT KW 55.65

6,000

13.35

29.5

69.0

41.92KW

76.20

89%

47.10

99.8

47.2

VARIABLE SPEED CONTROL

FLOW LPF 12,000

SYSTEM / PUMP

PRESSURE

PUMP EFFICIENCY

PUMP INPUT KW

MOTOR RPM

MOTOR LOAD

23.5

86.0

53.58

1450

97.4%

MOTOR EFFICIENCY

MOTOR INPUT KW

93.7

57.18

CONVERTOR EFFICIENCY 97.0

INPUT KW 58.95

SAVING KW

SAVING %

0.7

1.12

6,000

13.35

78

16.78

1000

30.5%

90

18.64

84.0

20.83

26.37

55.8

HIGH EFFICIENCY

MOTOR

VARIABLE

SPEED DRIVE

IS 12615-2011

Standards for

High Efficiency Motor

IS 12615-2011

Energy Efficient Induction Motors

Three Phase Squirrel Cage

IS 12615 is now revised to bring IS

In Line With International Standards

IEC 60034-30-2008

Also Testing Method as Per

IEC 60034-2-1:2007 And

IEEE 112B----IS 15999:2011

IS 12615-2011

IE1 - Only for VFD drive

IE2 –High Efficiency

IE3 –Premium Efficiency

IE4 -Super Premium Efficiency

IE2 Mandatory 30th June 2011

IE3 – 31 st Jan 2014

Rating Up to 375 KW,2,4,6 Pole

Major Change in Test Method

IS - 15999 -2011

IEC 60034-2-1:2007

IS & IEC Standards Used To Take Stray

Losses As 0.5% of Input.

American Standards Prefer Determining

Stray Losses by Tests.

Determination Of Stray Loss is Time

Consuming and Difficult.

IEC & IS Standards are now aligned with American Standards

Stray Loss Allowance

IEC 60034-2-1 IEEE-112

1KW - 2.5% 1.8% -100K

10KW -2% 1.5% -375KW

100KW -1.5% 1.2% -2000KW

1000KW-1%

OTHERS.

0.90% -

10000KW-0.5%

IS – 15999 -2011 Similar to IEC

High Efficiency Motors IE2 is Mandatory

With New Test Method

Test With Higher Stray losses.

Existing Machine Designs Have To Improve

Substantially to Achieve this Standard

IS 12615-2011 IE2 , IE3 Motors Available in Market

Premium Efficiency Mandatory in USA

Starting Currents are Higher for these

Motors

ISO 50001

2011 –06-15

Energy Management System – Requirements with

Guidance for use

The purpose of this International Standard is to enable organizations to establish the systems and processes necessary to improve energy performance, including energy efficiency, use and consumption.

This international standard is applicable to all types and sizes of organizations irrespective of geographical, cultural or social conditions.

LIGHTING

INCANDESCLENT

BULB

FLUORESCENT TUBE

COMPACT

FLUORESCENT

HIGH PRESSURE

MERCURY VAPOUR

HIGH PRESSURE

SODIUM VAPOUR

METAL HALIDE

LED LAMPS

LIGHT SOURCES

Rating Efficien cy

Lumen/

Watt

8 TO17 15W TO

500W

18W TO

65W

40 TO 70

50TO 75 5W TO

25W

80W TO

1000W

70W TO

1000W

70W TO

250W

MILLIWATS

TO WATTS

40 TO 50

60 TO 90

70 TO 80

10 TO 30

CRI

(Colour

Renderin g Index)

100

65 TO 80

70 TO 80

50

40

80

> 80%

Life

Hours

1000

5000

8000

8000 TO

10000

12000

10000

50000 TO

100000

LIGHT LEVELS

GENERAL

LIGHTING

20 TO 50 LUX

INTERIOR

LIGHTING

50 TO 200

OUTDOORSTORES

YARDS,BOILER HOUSE

WAREHOUSES,DINING

HALLS,LOBBY

OFFICE

LIGHTING

150 TO 250 OFFICE WORK

READING ROOM

WORKSHOP

ASSEMBLY

DRAWING

300 TO 500

TASK LIGHTING

INSPECTIONDRAWING

FACILITY

500 AND ABOVE VISUALLY DIFFICULT

TASK

ENERGY SAVING OPPORTUNITIES

USE OF DAYLIGHT

EFFICIENT LIGHT SOURCES

TASK LIGHTING

VOLTAGE CONTROL

SENSORS, DIMMERS ,CONTROL DEVICES

DAYLIGHT

In industries use of glass or polycarbonate sheets has reduced lighting consumption during daytime

In offices lighting use can be minimized near windows. Dimmers with sensors can do this automatically

Large complexes provide central atrium with FRP sheets

MORE EFFICIENT LIGHT SOURCES

Replace incandescent bulb with CFL

Replace standard fluorescent tube light with tri-phosphorous tube lights

Replace electro-magnetic ballast with electronic ballast

Replace T–12, T–8 with T-5

Replace Mercury Vapor with Metal Halide

Lamps High Pressure Sodium Vapor lamps

Replace Halogen Lamps with Induction Lamps

Replace normal streetlights with LED Lamps

TASK LIGHTING

Task lighting means provide illumination for a given task at that point only when required

For factories provide CFLs on machine tools provide intensive lighting at inspection benches only

For offices provide CFL for reading on a table keeping low overall lighting levels

Engineering, textile industries have reduced fixtures heights to reduce number of lamps and provide better lighting

VOLTAGE CONTROL

Lighting feeder voltage rises during night time from 415v to 460/470v.This leads to wasteful energy consumption

For single phase, keep voltage 190-210

For three phase, keep voltage 390-410

Separate lighting transformers with taps to be used

Energy saving 10%-20%

Light output does decrease

Effect of Voltage on Lamps

Voltage GLS

Watts

T 8

Watts

210

230

250

35

40

46

29

32

34

CFL

Watts

Fan Electronic regulator

(Watts)

16 Step 1- ….. 10

Step 5 –…..52

18 Step 1- ….. 12

Step 5 – …..60

20 Step 1- ….. 16

Step 5 – …..67

Fan Normal

Regulator

(Watts)

Step 1- ….. 35

Step 5 –….. 52

Step 1- ….. 41

Step 5 –….. 60

Step 1- ….. 47

Step 5 –….. 67

Lighting SENSORS & CONTROLS

Dimmers available for incandescent as well as fluorescent tubes

Provide multiple switches so that individual ,machine, table lighting can be controlled

Occupancy sensors can

switch off

lights, AC when rooms not occupied.

NEW TECHNOLOGIES

ELECTRONIC BALLAST CONSUMES ONLY 1 TO 2

WATTS COMPARED TO 10 TO 16 WATTS OF

NORMAL BALLAST

NORMAL TUBE + CHOKE - 50 TO 55WATTS

SLIM TUBE WITH ELECTRONIC CHOKE - 32 TO

38 WATTS

ELECTRONIC BALLAST OPERATION 30 TO 50KHZ

T- 12 TUBELIGHT DIA 12/8 INCH 40W

T - 8 TUBELIGHT DIA 8/8 INCH 36W

T - 5 TUBELIGHT DIA 5/8 INCH 28W

SUPER REFLECTIVE ALUMINIUM COATING

ALLOW FEWER TUBES

COMPRESSED AIR

INTRODUCTION

COMPRESSED AIR IS VERY INEFFICIENT

AND EXPENSIVE UTILITY

ONLY 10% TO 15% INPUT ENERGY IS

AVAILABLE TO DO WORK. REST IS

WASTED AS HEAT

AFTER DISTRIBUTION LOSSES LEAKAGES

ACTUAL WORK DONE BY COMPRESSED

AIR IS ONLY 5% OR SO

100 CFM AT 7 BAR(100LBS/INCH 2 )

REQUIRE 16 TO 17 KW

COMPRESSORS

Reciprocating & Screw Compressors have similar efficiencies

Centrifugal Compressors most efficient

Centrifugal compressor expensive and available in large sizes > 1000cfm

Reciprocating Compressors requires maintenance

Screw Compressors preferred are as base load machines

No-load power of reciprocating and screw compressors range between 20 to 40%.

PRESSURE RECIPROCATING SCREW CENTRIFUGAL

7 BAR

3BAR

16.0KW

10.0KW

17.0KW

10.5KW

14.0KW

8.5KW

Above Power is for 100 CFM Capacity

ENERGY SAVING OPPORTUNITIES

Alternative to compressed air

- Minimize compressed air leakage

- Regular compressor maintenance

- Proper type of air drier

- Minimize air pressure

ALTERNATIVES TO COMPRESSED AIR

Vacuum cleaning in place of compressed air

Minimize air pressure if at all used in cleaning. 2 bar in place of 7 bar

Mechanical transport of material in place of pneumatic transport implemented in cement, paper chips, chemicals savings 80%

Electrical tools in place of pneumatic tools. If necessary use 200hz supply (for high speed)

COMPRESSED AIR LEKAGE

AT 3BAR(45PSIG)

HOLE DIA AIR LEKAGE

CFM

POWER

LOST

(KW)

1/64”

1/8”

0.211

13.5

1/4” 54.1

AT 7BAR(100PSIG)

1/64”

1/8”

1/4”

0.406

26

104

0.0207

1.323

5.3

0.069

4.42

17.68

ANNUAL

COST

8000HRS.

5RS./KWH

826

52867

211860

2758

176623

706493

LEAKAGE TEST

OBSERVE LOADING,UNLOADING TIME WHEN NO

ACTUAL USE

LEAKAGE= Q*ON TIME/ON+OFF TIME

Q – CAPACITY CFM

CAN BE DONE WITH DIFFERENT SECTIONS

TO BE DONE EVERY MONTH

LEAKAGE FROM FLANGES ,JOINTS, VALVES, PIPES

TO BE PLUGGED BY NOTTING NOISE

BETTER TO OUTSOURCE

5% TO 10% ACCEPTABLE

20% TO 50% ACTUAL

COMPRESSOR MAINTENANCE

Carry capacity test with receiver by P

Initial Pressure TO P

2

Final Pressure

1

Q = P

2

-P

1

/Pa*Vr / t

Q = CFM CAPACITY

P

2

= Final Pressure in bar

P

1

= Initial Pressure in bar

Pa= Atmospheric Pressure, 1 BAR

Vr = Receiver Volume, mtr 3 /ft 3 t = Time in minutes

DO THIS EVERY SIX MONTHS

Replace worn out parts, provide proper oil grease

DRYERS

Pressure

Dew Point

REFRIGERATION -20 O C

1 st

Cost

Power

Consumption

1000m 3 /Kw

LOW 2.9KW

DESSICANT BY

COMPRESSED

AIR PURGING

HEAT OF

COMPRESSION

-20 O C

-40 O C

LOW 20.7KW

HIGH 0.8KW

NEW TECHNOLOGIES

Air amplifier takes outside air uses small amount of compressed air

VFDs are used for capacity control of reciprocating and screw compressors

20% to 30% saving

REFRIGERATION

REFRIGERATION

CHILLED WATER, BRINE FOR PROCESSES

ICE PLANTS

AIR CONDITIONING

HUMIDIFICATION – MOISTURE REMOVAL

VAPOUR COMPRESSION SYSTEM RUNS ON

ELECTRICITY

VAPOUR ABSOBPTION SYSTEM RUNS ON

HEAT

VAPOUR COMPRESSION SYSTEM

REFRIGERATION COMPRESSORS

RECIPROCATING - UPTO 200TR

SCREW - 100 To 750 TR

CENTRIFUGAL - 200 TR Or MORE

1TON OF Refrigeration is removal of heat at a rate of 3023 kcal/hr or 12000 BTU/hr

VAPOUR ABSOBPTION SYSTEM

LITHIUM BROMIDE AND WATER SYSTEM

FOR TEMP UPTO 6 0 C

WATER(ABSORBENT) AND

AMMONIA(REFRIGERENT) FOR TEMP.

SYSTEM LESS THAN 0 0 C.

SAVES 90% POWER BUT HEAT INPUT IS

QUITE SIGNIFICANT

OVERALL ECONOMICS DEPEND ON

COSTOF HEAT SUPPLIED

VAPOUR COMPRESSION SYSTEM

COP = COEFFICIENT OF PERFORMANCE

= REFRIGERATION EFFECT/WORK DONE

VALUE- 4.0 TO 6.0 VAPOUR COMPRESSION

1.0 FOR VAPOUR ABSORPTION

SPECIFIC POWER CONSUMPTION

KW/TON 0.6 TO 1.0 FOR CHILLED WATER AT 8 0 C

EER= ENERGY EFFICIENCY RATIO

EER = BUT/HR REFRIGERATION EFFECT/WATTS

9 TO 13 FOR AIR CONDITIONER

EVAPORATOR

TEMP.

EFFECT OF TEMPERATURE

CONDENSER

TEMP.

+5 0 C TR

+40 0

143

POWER 102

0 0 C

KW/TR 0.72

TR 118

POWER 96.8

KW/TR 0.82

-5 0 C TR 96

POWER 89.6

KW/TR 0.93

OPERATE AT HIGHEST POSSIBLE EVAPORATOR TEMP.

+50 0

127

117

0.93

104

108.9

1.05

84

99.4

1.19

OPERATE AT LOWEST CONDENSER TEMP.

ENERGY SAVING OPPORTUNITIES

Optimum temperature setting

Each 1 0 c temp increase in air condition space reduces power by 2% to 3%

Set AC temperature at 27 0 to 30 0

Use fans for circulation

For cold storage better and equal air distribution allows higher temp.

Better heat exchangers

REDUCTION IN HEAT LOAD

PROVIDE AIR CONDITIONING IN USED AREA

PROVIDE FALSE CEILING

REDUCE OUTSIDE HEAT BY INSULATION,SUN

CONTROL FILMS ETC.

FOR VEGETABLES 5 0 C REQUIRED

FOR ICECREAMES -30 0 C REQUIRED

SEGREGATE SUCH LOAD

KEEP MOTORS,HEATING DEVICES OUTSIDE

CONDITIONED SPACE

AIR CURTAINS,AUTOMATIC DOOR CLOSURES

LARGER HEAT EXCHANGER

Larger heat exchanger, condenser and evaporators allow higher evaporator temp and lower condenser temp

Regularly clean all heat exchanger

Provide proper water treatment

Performance can drop by 50% in absence of cleaning and water treatment

NEW TECHNOLOGY

THERMAL STORAGE TO TAKE ADVANTAGE

OF CHEAP POWER AT NIGHT

TARIIFF AS WELL AS TEMP. FAVOURABLE

HEAT RECOVERY SYSTEMS

HEAT PIPES,HEAT WHEELS VARIABLE

SPEED DRIVES HEAT PUMPS

POWER FACTOR

P.F.IMPROVEMENT

Electric equipments like motors, furnaces, welding transformers, tube lights

All draw reactive current from power supply. This current affects heating of lines, cables, conductors and hence their utilization.

A 3 phase circuit of 415 V and 10 amps can carry different amounts of power for different PF.

V

415

415

415

I

10

10

10

P.F.

0.5

0.7

1.0

POWER = √ 3 VI COSǾ

3590 WATTS

5025 WATTS

7179 WATTS

FOR POWER SYSTEM OPERATION, HIGHEST PF IS DESIRED

Power Factor Mandate

MANDATORY P.F. FOR H.T. CONSUMERS

WAS 0.8 EARLIER IS 0.9 NOW

INCENTIVE AVAILABLE FOR P.F. HIGHER

THAN 0.95

REBATE OF 1% IN ENERGY AND DEMAND

FOR 1% RISE IN P.F. ABOVE 95%

PENALTY OF 1% FOR P.F. BELOW 90%

REBATE REMOVED FROM JUNE 2006

P.F. IMPROVEMENT

P.F.

Is improved by connection of capacitors near load centers like motors, tube lights.

Please see table for selection

Connect capacitors near motors

Automatic PF Correction required in few cases of fluctuating loads like induction furnaces, welding, etc.

REACTIVE KVAR REQUIRED TO ACHIEVE

VARIOUS P.F. VALUES (kVAr per kW)

OLD P.F.

DESIRED NEW POWER FACTOR

0.90 0.95 0.96 0.97 0.98 0.99 0.999

0.80 0.266 0.421 0.458 0.499 0.547 0.608 0.705

0.85 0.135 0.291 0.328 0.369 0.417 0.477 0.575

0.90 0.000 0.156 0.193 0.234 0.281 0.342 0.440

0.91 -

0.92 -

0.93 -

0.94 -

0.95 -

0.96 -

0.97 -

0.98 -

0.99 -

0.000 0.037 0.078 0.126 0.186 0.284

-

-

-

-

0.126 0.164 0.205 0.253 0.313 0.411

0.097 0.134 0.175 0.223 0.284 0.381

0.067 0.103 0.145 0.192 0.253 0.350

0.034 0.071 0.112 0.160 0.220 0.318

0.000 0.041 0.089 0.149 0.247

-

-

-

0.000 0.048 0.108 0.206

-

-

0.000 0.061 0.158

0.000 0.098

OTHER ADVANTAGES

P.F. IMPROVEMENT REDUCES KVA

DEMAND

KVA = KW/P.F

P.F. IMPROVEMENT REDUCES

DISTRIBUTION LOSSES

PF IMROVEMENT WILL BE REQUIRED

IN FUTURE BY RESIDENTIAL,COMMERCIAL

CONSUMERS

TIME OF DAY TARRIFFS

POWER SYSTEMS GET PEAK LOADS IN MORNING AND

EVENING

PEAK LOADS ALSO COME IN SUMMER DUE TO FANS,

COOLERS, AIR CONDITIONING.

SINCE 1 MW REQUIRE 4 CRORE TO 6 CRORE INVESTMENT,

UTILITIES REQUIRE CONSANT DEMAND

FOR OPTIMUM CAPACITY USE LARGE CONSUMERS GIVEN

INCENTIVE TO SHIFT LOAD TO NIGHT FROM PEAK PERIOD

FOR GUJARAT

75 PAISE/KWH 7.0 TO 11 A.M.

EXTRA 18.0 TO 22 HRS.

75 PAISE/KWH 10 P.M. TO 6 P.M

REBATE FOR MORE THAN 33% CONSUMPTION

Energy Conservation Awareness Workshop For

Students of Final Year Engineering

(An Exclusive Program for Engineering Colleges in Gujarat)

Organized & Sponsored by

Gujarat Energy Development Agency

A Government of Gujarat Organization -

T HERMAL UTILITIES

Boilers -

Preheat combustion air with waste heat (22 0C reduction in flue gas temperature increases boiler efficiency by 1%).

Use variable speed drives on large boiler combustion air fans with variable flows.

Burn wastes if permitted.

Insulate exposed heated oil tanks.

Clean burners, nozzles, strainers, etc.

Inspect oil heaters for proper oil temperature.

Close burner air and/or stack dampers when the burner is off to minimize heat loss up the stack.

Improve oxygen trim control (e.g. -- limit excess air to less than 10% on clean fuels). (5% reduction in excess air increases boiler efficiency by 1% or: 1% reduction of residual oxygen in stack gas increases boiler efficiency by 1%.)

Automate/optimize boiler blowdown. Recover boiler blowdown heat.

Use boiler blowdown to help warm the back-up boiler.

Optimize deaerator venting.

Inspect door gaskets.

Inspect for scale and sediment on the water side

(A 1 mm thick scale (deposit) on the water side could increase fuel consumption by 5 to 8%).

Inspect for soot, flyash, and slag on the fire side (A 3 mm thick soot deposition on the heat transfer surface can cause an increase in fuel consumption to the tune of 2.5%.)

Optimize boiler water treatment.

Add an economizer to preheat boiler feedwater using exhaust heat.

Recycle steam condensate.

Study part-load characteristics and cycling costs to determine the most-efficient mode for operating multiple boilers.

Consider multiple or modular boiler units instead of one or two large boilers.

Establish a boiler efficiency-maintenance program.

Start with an energy audit and follow-up, then make a boiler efficiency-maintenance program a part of your continuous energy management program.

Steam System

Fix steam leaks and condensate leaks (A 3 mm diameter hole on a pipe line carrying 7 kg/cm2 steam would waste 33 kilo litres of fuel oil per year).

Accumulate work orders for repair of steam leaks that can't be fixed during the heating season due to system shutdown requirements. Tag each such leak with a durable tag with a good description.

Use back pressure steam turbines to produce lower steam pressures.

Use more-efficient steam desuperheating methods.

Ensure process temperatures are correctly controlled.

Maintain lowest acceptable process steam pressures.

Reduce hot water wastage to drain .

Steam System

Remove or blank off all redundant steam piping.

Ensure condensate is returned or re-used in the process

(6 0C raise in feed water temperature by economiser/condensate recovery corresponds to a 1% saving in fuel consumption, in boiler).

Preheat boiler feed-water.

Recover boiler blowdown.

Check operation of steam traps.

Remove air from indirect steam using equipment

(0.25 mm thick air film offers the same resistance to heat transfer as a 330 mm thick copper wall.)

Steam System

Inspect steam traps regularly and repair malfunctioning traps promptly.

Consider recovery of vent steam (e.g. -- on large flash tanks).

Use waste steam for water heating.

Use an absorption chiller to condense exhaust steam before returning the condensate to the boiler.

Use electric pumps instead of steam ejectors when cost benefits permit

Establish a steam efficiency-maintenance program.

Start with an energy audit and follow-up, then make a steam efficiency-maintenance program a part of your continuous energy management program.

Furnaces

Check against infiltration of air: Use doors or air curtains.

Monitor O2 /CO2/CO and control excess air to the optimum level.

Improve burner design, combustion control and instrumentation.

Ensure that the furnace combustion chamber is under slight positive pressure.

Use ceramic fibres in the case of batch operations.

Match the load to the furnace capacity.

Retrofit with heat recovery device.

Investigate cycle times and reduce.

Provide temperature controllers.

Ensure that flame does not touch the stock.

Insulation

Repair damaged insulation (A bare steam pipe of 150 mm diameter and 100 m length, carrying saturated steam at 8 kg/cm2 would waste 25,000 litres furnace oil in a year.)

Insulate any hot or cold metal or insulation.

Replace wet insulation.

Use an infrared gun to check for cold wall areas during cold weather or hot wall areas during hot weather.

Ensure that all insulated surfaces are cladded with aluminum

Insulate all flanges, valves and couplings

Insulate open tanks

(70% heat losses can be reduced by floating a layer of 45 mm diameter polypropylene (plastic) balls on the surface of 90 0C hot liquid/condensate).

Waste Heat Recovery

Recover heat from flue gas, engine cooling water, engine exhaust, low pressure waste steam, drying oven exhaust, boiler blowdown, etc.

Recover heat from incinerator off-gas.

Use waste heat for fuel oil heating, boiler feed-water heating, outside air heating, etc.

Use chiller waste heat to preheat hot water.

Use heat pumps.

Use absorption refrigeration.

Use thermal wheels, run-around systems, heat pipe systems, and air-to-air exchangers.

Buildings

Seal exterior cracks/openings/gaps with caulk, gasketing, weather stripping, etc.

Consider new thermal doors, thermal windows, roofing insulation, etc.

Install windbreaks near exterior doors.

Replace single-pane glass with insulating glass.

Consider covering some window and skylight areas with insulated wall panels inside the building.

If visibility is not required but light is required, consider replacing exterior windows with insulated glass block.

Consider tinted glass, reflective glass, coatings, awnings, overhangs, draperies, blinds, and shades for sunlit exterior windows.

Buildings

Use landscaping to advantage.

Add vestibules or revolving doors to primary exterior personnel doors.

Consider automatic doors, air curtains, strip doors, etc. at high-traffic passages between conditioned and nonconditioned spaces. Use self-closing doors if possible.

Use intermediate doors in stairways and vertical passages to minimize building stack effect.

Use dock seals at shipping and receiving doors.

Bring cleaning personnel in during the working day or as soon after as possible to minimize lighting and HVAC costs.

Water & Wastewater

Recycle water, particularly for uses with less-critical quality requirements.

Recycle water, especially if sewer costs are based on water consumption.

Balance closed systems to minimize flows and reduce pump power requirements.

Eliminate once-through cooling with water.

Use the least expensive type of water that will satisfy the requirement.

Fix water leaks.

Test for underground water leaks. (It's easy to do over a holiday shutdown.)

Check water overflow pipes for proper operating level.

Automate blowdown to minimize it.

Provide proper tools for wash down -- especially self-closing nozzles.

Install efficient irrigation.

Reduce flows at water sampling stations.

Eliminate continuous overflow at water tanks.

Promptly repair leaking toilets and faucets.

Use water restrictors on faucets, showers, etc.

Use self-closing type faucets in restrooms.

Use the lowest possible hot water temperature.

Do not use a central heating system hot water boiler to provide service hot water during the cooling season -- install a smaller, more-efficient system for the cooling season service hot water.

Consider the installation of a thermal solar system for warm water.

If water must be heated electrically, consider accumulation in a large insulated storage tank to minimize heating at on-peak electric rates

Use multiple, distributed, small water heaters to minimize thermal losses in large piping systems.

Use freeze protection valves rather than manual bleeding of lines.

Consider leased and mobile water treatment systems, especially for de-ionized water.

Seal sumps to prevent seepage inward from necessitating extra sump pump operation.

Install pretreatment to reduce TOC and BOD surcharges.

Verify the water meter readings. (You'd be amazed how long a meter reading can be estimated after the meter breaks or the meter pit fills with water!)

Verify the sewer flows if the sewer bills are based on them

DG sets

Optimize loading

Use waste heat to generate steam/hot water /power an absorption chiller or preheat process or utility feeds.

Use jacket and head cooling water for process needs

Clean air filters regularly

Insulate exhaust pipes to reduce DG set room temperatures

Use cheaper heavy fuel oil for capacities more than 1MW

Miscellaneous

Meter any un-metered utilities. Know what is normal efficient use. Track down causes of deviations.

Shut down spare, idling, or unneeded equipment.

Make sure that all of the utilities to redundant areas are turned off -- including utilities like compressed air and cooling water.

Install automatic control to efficiently coordinate multiple air compressors, chillers, cooling tower cells, boilers, etc.

Renegotiate utilities contracts to reflect current loads and variations.

Consider buying utilities from neighbors, particularly to handle peaks.

Leased space often has low-bid inefficient equipment.

Consider upgrades if your lease will continue for several more years.

Adjust fluid temperatures within acceptable limits to minimize undesirable heat transfer in long pipelines.

Minimize use of flow bypasses and minimize bypass flow rates.

Provide restriction orifices in purges (nitrogen, steam, etc.).

Eliminate unnecessary flow measurement orifices.

Consider alternatives to high pressure drops across valves.

Turn off winter heat tracing that is on in summer