Powerpoint Guidelines

advertisement

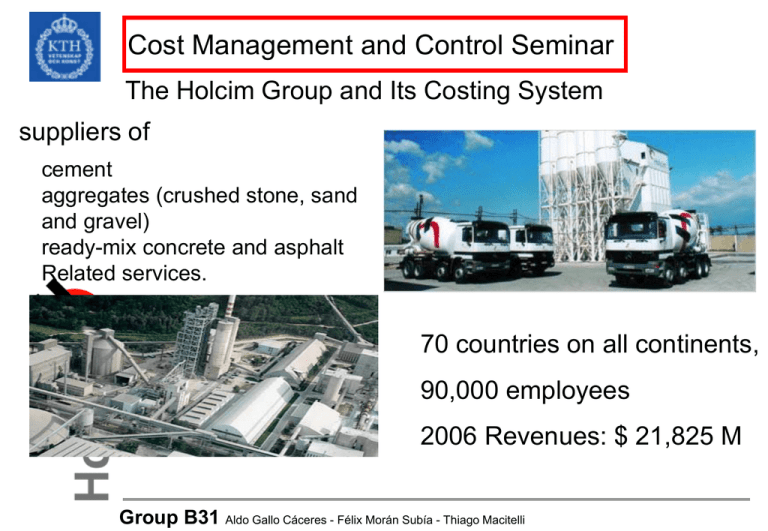

Cost Management and Control Seminar The Holcim Group and Its Costing System suppliers of cement aggregates (crushed stone, sand and gravel) ready-mix concrete and asphalt Related services. 70 countries on all continents, 90,000 employees 2006 Revenues: $ 21,825 M Group B31 Aldo Gallo Cáceres - Félix Morán Subía - Thiago Macitelli Holcim Group Figures and Value Chain Established Markets Emergent Markets + 480% + 1050% 1980 Employees 18734 1980 Revenues $ 2,209 M 2006 Revenues: $ 21,825 M 2006 Employees 90000 2 Cost Management and Control Cement Production Process Main Cost Center Classification Main Cost Accounts Corporate Corporate Marketing Manufacturing Logistics & Sales Administration Code: 100 RM Extraction Code: 500 Code: 300 Cement Grinding RM Preparation 2 Code: 200 Code: 400 Code: 600 RM Preparation 1 Clinker Production Dispatching (no main) Pre-process Cost Centers: Auxiliary Cost Centers: Correctives. Alternative Raw Materials. Gypsum and additives. Alternative Fuels. Mineral Components. Power Generation. Cost Management and Control 3 Costing System Process Costing Major Guides of the Costing System: Employee`s input: Cost Centers. Accounts codification. General required description of the movement. The accounting software (SAP): It has an internal assignation process, accounts are already internally tagged as: variable cash cost, Fixed cash cost, and others related. Key Issue: (Employee's Main Role for the success of the Costing System) Right Assignation of accounts and cost centers. 4 Cost Management and Control Cost Drivers $20,000,000 Main Information Behind $15,000,000 Cost center’s $10,000,000 impacts on total cost Relevant costs $5,000,000 Main opportunities for cost reductions. $- Raw eria Ma t t rac l Ex tion Raw eria Ma t n ati o par e r ls P M Raw eal ke Clin Depreciation odu r pr Fixed cost n ctio ing r ind g t en Cem Variable cost 5 Cost Management and Control How to Choose a Costing System An accounting system established to monitor a company's costs, providing management with information on operations and performance. Process costing Job Order costing High volume Are identical identical amount of direct labor Repetitive operations typically low volume Tend to be unique (custom order) different amount of direct material different amount of direct labor Work in Progress Work in Progress Process A Process B Process C Finished Goods Stock Process A Process B Process C Finished Goods Stock 6 Cost Management and Control Decision making planning and control process 1. Identify objectives 2. Search for alternatives courses of action Cost drivers Planning process 3. Gather data about alternatives 4. Select alternative courses of action e.g. Process improvement, change raw materials, etc. 5. Implement the decisions Control Process 6. Compare actual and planned outcomes 7. Respond to divergences from plan Performance indicators Adjust the plans From: Drury (2004). Management and cost accounting. 6th edition. ISBN 978-1-84480-703-1 7 Cost Management and Control Decisions Making Process Using Costing System 8 Cost Management and Control Decisions Making Process Using Costing System 9 Cost Management and Control Possible decisions Process improvement (e.g. reduce the number of stops by increasing preventive maintenance) Change fuel supplier to reduce costs After selecting and implementing the decisions they performance has to be monitored in the same way The new performance indicators could be compared with the previous period If necessary, corrective action plans could be taken 10 Cost Management and Control