File

advertisement

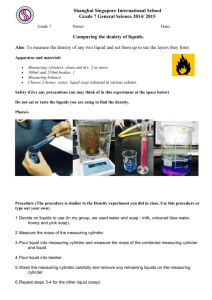

PART 4 Industrial Chemistry 2015 1 2 Overview Focus Experiment Dot Point number 2 22 identify data, plan and perform a first-hand investigation to model an equilibrium reaction 23 choose equipment and perform a first-hand investigation to gather information and qualitatively analyse an equilibrium reaction Perform first-hand investigations to observe the reactions of sulfuric acid acting as an oxidising agent and a dehydrating agent 3 24 4 25 identify, plan and perform a first-hand investigation to identify the products of the electrolysis of an aqueous solution of sodium chloride 5 26 perform a first-hand investigation to gather information and describe the properties of a named emulsion and relate these properties to its uses 27 perform a first-hand investigation to carry out saponification and test the product 28 perform a first-hand investigation to demonstrate the effect of soap as an emulsifier perform a first-hand investigation to assess risk factors and then carry out a chemical step involved in the Solvay process, identifying any difficulties associated with the laboratory modelling of the step 6 29 3 Experiment 22 Identify data, plan and perform a first-hand investigation to model an equilibrium reaction MODELLING EQUILIBRIUM INTRODUCTION Many chemical reactions go to completion so the reactants have been completely consumed, for example burning a match. Some chemical reactions are reversible and so the products react to form the reactants again. The relationship between reactants and products can be investigated through modelling. AIM To plan and perform an investigation to model an equilibrium reaction. EQUIPMENT 2 x 500 mL 1 x 250 mL, 1 x 100 mL beakers 2 rulers 2 large containers with vertical sides such as tote boxes to hold water 2 different coloured food dyes CHEMICALS Nil RISK ASSESSMENT Nil METHOD 1 Remember for equilibrium to be established you need to have a closed system. 2 You can use the beakers to transfer water between two tote boxes so representing the forward and reverse reactions. Use two different dyes to colour the water in the boxes—one to represent reactants and the other products. (red and blue work well) 3 Fill the tote boxes with different amounts of water, e.g. 5 L in one and 8 L in the other and label them 1 and 2. 4 The amount of water in each tote box can be compared by measuring the depth of water. 5 Start by using two 500 mL beakers. Lie the beakers on their sides in the water (see diagram) simultaneously dip one into tote box 1 and the other into tote box 2 then pour the contents of each of the beakers into the opposite bowl. Mix the colours in each box well. 6 Note the change in the colour of the water in each of the boxes and make regular measurements of the depth of water in each box, e.g. every 10 transfers. 7 Consider how you will determine when equilibrium has been reached (note the colour and depth of the water in the boxes). 8 Refill the bowls and repeat using two different sized beakers. 9 Draw up a results table to record the number of dips, the colour of the water and the depth of the water. 4 RESULTS CONCLUSION QUESTIONS 1 How did you determine that equilibrium had been reached? 2 What did you notice about the colour of water in each of the boxes? 3 What do you think the results would have been if all the water had been in one box at the beginning—would the results have been different? 4 What effect did using two different sized beakers have on the equilibrium? 5 What do using two different beakers represent in terms of rate of forward and reverse reaction? 6 Discuss any limitations of this model. 5 EXPERIMENT 23 EQUILIBRIUM IN GASES INTRODUCTION Many reactions proceed almost to completion. In reactions that do not proceed to completion the products of the reaction begin to react to reform the reactants until the rates of the forward and backward reaction are equal. When such a situation exists a state of chemical equilibrium has been achieved. In fact all chemical reactions are reversible to some extent, but in many cases the reactions go to completion. With a reversible reaction it is possible to alter the relative proportions of products and reactants by altering one of the factors which affect the state of equilibrium. The effect of such changes can be predicted using le Chatelier’s Principle. In this experiment the equilibrium that occurs between the brown gas nitrogen dioxide and the colourless gas dinitrogen tetroxide will be investigated 2NO2 (g) N2O4 (g) + Brown colourless 57kJ Because NO2 (g) is brown and N2O4 (g) is colourless it is possible to observe qualitatively the effect of various changes on the relative proportions of reactants and products EQUIPMENT 3 Large transparent glass syringes with sealed ends Hot tap water bath at about 60oC Ice bath CHEMICALS Gas mixture of NO2/N2O4 in glass syringes RISK ASSESSMENT What is the risk Why is it a risk? How will you minimise the risk? METHOD This experiment will be carried out as a demonstration. a. Effect of pressure or volume on equilibrium 1. Observe the colour intensity of the gas mixture in the syringe 2. Push the gas syringe quickly so that the volume occupied by the gas mixture is instantaneously reduced. Note the immediate change in colour of the gas mixture. 6 3. Carefully observe the change in colour intensity which occurs over several seconds after the immediate colour change. Record your results in a table. Remember the relationship between pressure and volume . b. Effect of temperature on the equilibrium 1. Compare the colour of the two flasks containing the NO2 (g)/ N2O4 (g) mixtures 2. Place one of the flasks in the ice bath, leave for a few seconds and compare this flask with the flask at room temperature 3. Remove the flask from the ice bath and place it in hot water. Leave a few seconds and compare with the flask at room temperature. Draw up a table to record your results OBSERVATIONS AND RESULTS a. Effect of pressure or volume on equilibrium b. Effect of temperature on the equilibrium QUESTIONS 1. What happened to the concentration of the two gases immediately after the volume was reduced but before the system adjusted to re-establish equilibrium? Explain your observation. 7 2. Explain what happened to the colour as the system re-established equilibrium. Use the equation in your answer. 3. If the volume of the gas mixture was increased predict the effect this would have on the equilibrium and thus on the colour of the mixture. 4. Temperature had an effect on equilibrium. Explain this effect using the equation for the reaction. Remember it is an exothermic reaction in the forward direction. 8 EXPERIMENT 24 Choose equipment and perform a first-hand investigation to gather information and qualitatively analyse an equilibrium reaction INVESTIGATING AN EQUILIBRIUM REACTION INTRODUCTION A reversible chemical reaction is one in which both the forward and reverse reactions occur. When these two reactions are occurring at the same rate there is no change in the macroscopic properties (e.g. colour) of the system and it is described as being at equilibrium. A common example of a reversible reaction is the reaction between iron(III) ions and thiocyanate 2+ ions (SCN–) to produce iron(III) thiocyanate ions (FeSCN ) . The equilibrium reaction is given below: 3+ 2+ Fe + SCN– FeSCN The iron(III) thiocyanate ions are a blood red colour. When changes are made to a system in equilibrium the system reacts according to Le Chatelier’s principle. Changes in the above system can be detected by a corresponding change in colour intensity. AIM To observe the effect of a change in conditions to system at equilibrium and to explain this in terms of Le Chatelier’s principle. EQUIPMENT 1 X 50mL beaker 2 x 100mL beakers Semi micro test tubes and rack 50mL measuring cylinder Graduated plastic pipettes Thermometer Ice CHEMICALS 0.1M iron (III) nitrate 0.9M sodium hydroxide 0.1M potassium thiocyanate 0.05M silver nitrate RISK ASSESSMENT SAFETY: Wear safety glasses. Sodium hydroxide is corrosive so avoid contact with skin. If contact occurs wash thoroughly with water. WHAT IS THE RISK WHY IT IS THE RISK (Risk to self and risk to environment) 9 HOW YOU MIGHT MINIMISE THE RISK METHOD: 1 Measure 25 mL of distilled water into the 50 mL beaker. 2 Using a clean pipette for each, to the beaker add 1.0 mL of 0.1 mol/L iron(III) nitrate (Fe(NO3)3) solution and 1.0 mL of 0.1 mol/L potassium thiocyanate (KSCN) solution. Mix thoroughly. Record your observations. 3 Pipette 2 mL of the mixture into each of seven semi micro test tubes and label them A–G. 4 A is the control. To B add 5 drops of the Fe(NO3)3 solution. 5 To C add 5 drops of the KSCN solution. 6 To D add 5 drops of 0.9 mol/L NaOH solution. 7 To E add 5 drops of silver nitrate. 8 Place F in a beaker of ice 9 Place G in a beaker of water at 80○C 10 Record your observations of the seven beakers. Note any change in colour by comparing each test tube with the control. To compare colours hold the test tubes over a piece of white paper and look through them. RESULTS CHEMICALS Iron (III) nitrate (Fe(NO3)3 solution OBSERVATIONS (COLOUR) Potassium thiocyanate (KSCN) solution A Fe(NO3)3 + KSCN B Fe(NO3)3 + KSCN + additional Fe C Fe(NO3)3 + KSCN + additional SCN– D Fe(NO3)3 + KSCN + NaOH solution E Fe(NO3)3 + KSCN + AgNO3 F Fe(NO3)3 + KSCN in ice bath G Fe(NO3)3 + KSCN in water bath at 80○C 3+ In order to help us understand more clearly the changes that are taking place in the chemical system in this investigation, we can draw diagrams representing the way the concentrations of the reactants and products change with time. For example, here is a diagram to represent what happens when the drops of 0.1mol/L iron(III) nitrate solution were added to the equilibrium mixture. concentration in mol/L Key concentration of Fe3+ concentration of SCNconcentration of FeSCN2+ time 5 drops of 0.1 mol/L iron(III) nitrate solution are added at this point 10 When the drops of 0.1mol/L iron(III) nitrate solution are added, the concentration of Fe3+ rises suddenly. After this the system responds in order to re-establish the equilibrium. It does so by favouring the forward reaction for a while which uses up some of the excess Fe3+ ions. This also uses up some of the SCN- ions and increases the concentration of the FeSCN2+ ions as shown on the diagram. Equilibrium is once again established at the point where the concentrations of the reactants and the product no longer change. Complete the following diagrams in a similar way to the above to indicate the effects of imposed changes concentration in mol/L concentration in mol/L time time 5 drops of 0.9mol/L sodium hydroxide solution are added at this point 5 drops of 0.1mol/L potassium thiocyanate solution are added at this point concentration in mol/L concentration in mol/L time time the equilibrium mixture is cooled at this point 5 drops of 0.05M silver nitrate solution are added at this point concentration in mol/L time the equilibrium mixture is warmed at this point 11 QUESTIONS Explain each of the following in terms of Le Chatelier’s principle. 3+ 1 What effect did the addition of Fe have on the system? _____________________________________________________________________________ _____________________________________________________________________________ 2 What effect did the addition of SCN– have on the system? _____________________________________________________________________________ _____________________________________________________________________________ 3 What effect did the addition of NaOH solution have on the system? _____________________________________________________________________________ _____________________________________________________________________________ 4 What effect did the addition of AgNO3 have on the system? _____________________________________________________________________________ DO YOU NEED THESE QUESTIONS AS WELL? Aim states to explain in terms of Le Chatelier’s principle 12 EXPERIMENT 25 Perform first-hand investigations to observe the reactions of sulfuric acid acting as an oxidising agent and a dehydrating agent INTRODUCTION Worldwide, more sulfuric acid is produced than any other chemical. It is used in a diverse variety of industries including the manufacture of fertiliser, detergents, synthetic fibres, pigments and explosives. This diversity of uses stems from the variety of chemical reactions sulfuric acid undergoes. It can be used as an oxidising agent, a catalyst, an electrolyte, a precipitating agent and a dehydrating agent. In this experiment you will explore the action of sulfuric acid as an oxidising agent and a dehydrating agent. AIM To observe the reactions of sulfuric acid as an oxidising agent and as a dehydrating agent. EQUIPMENT Test tubes and rack 100mL beaker Glass petri dish CHEMICALS Conc sulfuric acid 2M sulfuric acid Zinc Iron Sucrose Wood Copper sulfate RISK ASSESSMENT SAFETY: Concentrated sulfuric acid is highly corrosive. Wear safety glasses, protective clothing (apron or laboratory coat) and gloves. Avoid contact with skin. If contact occurs wash under cool running water for at least 15 minutes. Have sodium bicarbonate available to neutralize spills and clean up spills immediately. Follow instructions for disposal of materials and chemicals WHAT IS THE RISK WHY IT IS THE RISK (Risk to self and risk to environment) 13 HOW YOU MIGHT MINIMISE THE RISK METHOD: FUME CUPBOARD DEMONSTRATIONS Part A—Sulfuric acid as an oxidising agent Perform this reaction in a fume cupboard 1 Clean each of the pieces of metal with steel wool or sandpaper to remove any oxide coating. 2 Add a piece of each metal to a separate test tube. 3 Stand these test tubes in a test tube rack and place them in a fume cupboard. 4 Add 5 mL of concentrated sulfuric acid to each of these test tubes. 5 Record your observations in the results table Part B—Sulfuric acid as a dehydrating agent Perform these reactions in a fume cupboard 1 Place 1 g of sugar in a 100 mL beaker. Carefully add 1–2 mL of concentrated sulfuric acid. Do not handle the material produced. Feel the outside of the beaker once the reaction is complete. Record your observations. 2 Place a couple of drops of concentrated acid on a paddle pop stick. Record your observations. 3 Place about a gram of copper sulfate pentahydrate in a beaker and add a few drops of concentrated sulfuric acid. Record your observations 4 In a sealed container a sample of copper sulfate pentahydrate has been set up with a separate sample of concentrated sulfuric acid and left for several days. Record your observations STUDENT EXPERIMENTS 1 Add a clean piece of each metal to separate test tubes in a test tube rack and add 5 mL of 2 mol/L sulfuric acid to each. Record your observations in the results table. 2 Place about 1g of sugar in a 100mL beaker and add 1-2 mL of 2M sulfuric acid. Record your observations RESULTS OBSERVATIONS 2 M SULFURIC ACID CONCENTRATED SULFURIC ACID Zinc Iron Sugar Wood Copper sulfate Direct: *** Indirect: 14 CONCLUSION QUESTIONS 1 Compare the reactivity of concentrated and dilute sulfuric acid. _____________________________________________________________________ _____________________________________________________________________ 2 Write balanced equations for the reactions which occurred between concentrated sulfuric acid and metals. _________________________________________________________________________ _________________________________________________________________________ _________________________________________________________________________ _________________________________________________________________________ _________________________________________________________________________ 3 a What gas is produced in the reactions between dilute sulfuric acid and metals? ____________________________________________________________________ b Write the net ionic equation for any reactions. ____________________________________________________________________ 4 Write a balanced equation for the reaction of sugar (C12H22O11) with concentrated sulfuric acid. _____________________________________________________________________ 15 EXPERIMENT 26 Identify, plan and perform a first-hand investigation to identify the products of the electrolysis of an aqueous solution of sodium chloride ELECTROLYSIS OF SODIUM CHLORIDE INTRODUCTION Electrolytic cells have many applications. In the chemical industry electrolysis is used in the manufacture of metals such as sodium, magnesium and aluminium, as well as in the production of chlorine gas and sodium hydroxide. It is also used in electroplating metals. In this experiment you will electrolyse a concentrated aqueous solution of sodium chloride and a dilute aqueous solution of sodium chloride, examine the chemistry involved and identify the products formed at the electrodes. AIM To investigate the chemistry involved in electrolysing different aqueous solutions of sodium chloride. EQUIPMENT 2 Voltameters 2 20V power packs Red and blue litmus paper CHEMICALS Saturated NaCl Universal Indicator 0.1M NaCl RISK ASSESSMENT SAFETY: Wear safety goggles and protective clothing. Make sure power source is turned off when connecting and disconnecting electrodes. Chlorine gas is poisonous so work in fume cupboard and avoid breathing the vapour. WHAT IS THE RISK WHY IT IS THE RISK (Risk to self and risk to environment) 16 HOW YOU MIGHT MINIMISE THE RISK METHOD: Part A - DEM in FUME CUPBOARD - Electrolysis of saturated sodium chloride solution with inert electrodes 1. Clamp a voltameter to a retort stand. Fill with saturated NaCl at 55oC. 2. Set the power supply to 20 V and switch on the power. Electrolyse the solution. 3. Observe and record any changes in the results table, such as colour of the solution or electrode, evolution of a gas or deposition of a solid, at each electrode. Caution: Do not try to smell any gas being produced. 4. Switch off the power. Remove the gas. To show the presence of chlorine, allow some gas into a test tube containing wet litmus paper. The litmus paper will be decolourised in the presence of chlorine 5. To determine the pH of the solution at each electrode introduce the universal indicator into the hole in the glass tap. You can see the initial colour before it is bleached by the chlorine. 6. Record your observations and pH results in a table. Part B - DEM - Electrolysis of 0.1 M sodium chloride solution. 1 Repeat steps 1–6 as for Part A using a dilute solution of sodium chloride (0.1M). RESULTS Observations (e.g. colour change, gas or solid production, pH) ANODE CATHODE Part A Electrolysis of saturated NaCl solution Part B Electrolysis of dilute NaCl solution CONCLUSION 17 QUESTIONS 1. Complete the following table giving all possible electrode reactions. ELECTRODE REACTIONS ANODE CATHODE Concentrated solution Dilute solution 2. From the possible electrode reactions for each electrolyte cell use your experimental results to decide which of the reactions which actually took place. ________________________________________________________________________________ ________________________________________________________________________________ 3. Write the overall reaction for each cell. ________________________________________________________________________________ ________________________________________________________________________________ 5. Suggest possible differences in the solution and electrodes in parts A and B after both solutions had been electrolysed for 30 minutes. Give reasons for these differences. 18 EXPERIMENT 27 MAKING AN EMULSION Perform a first-hand investigation to gather information and describe the properties of a named emulsion and relate these properties to its uses INTRODUCTION An emulsion consists of a mixture in which small drops of one liquid are suspended throughout another liquid. There are two kinds of emulsion involving oil and water. One is a mixture of oil in water where small droplets of oil are spread throughout the water. Mayonnaise, thickened cream and moisturisers are examples of this type of emulsion. The other kind of emulsion is a mixture of water in oil, where tiny drops of water are spread throughout the oil. Butter, margarine, salad dressings and lipsticks are all examples of water-in-oil emulsions. The emulsions tend to feel like the main component so a water-in-oil emulsion will usually feel greasy or oily while oil-in-water emulsions like hand creams and moisturisers will feel ‘lighter’ or less greasy and will dry on the skin as the water evaporates. All emulsions need a surfactant to stabilise them. This can be a naturally occurring compound (such as casein in milk or lecithin from egg yolk in mayonnaise) or can be a synthetic surfactant (such as those used in cosmetics). AIM To prepare an oil-in-water emulsion (mayonnaise) and investigate its properties. EQUIPMENT 50mL measuring cylinder 25 mL measuring cylinder A stick mixer CHEMICALS 40 mL salad oil (e.g. olive oil) 2 egg yolks 50 mL vinegar METHOD: Dem 1. Add 40 mL oil and 50mL of vinegar to the mixing container. 2. Mix for approximately 30 seconds. Observe 3. Leave for a short time. Observe. 4. Add 2 egg yolks and process for approximately 2 minutes. Observe 5. Describe the properties (e.g. colour, texture, feel, appearance) of this mixture. Do not taste! 19 RESULTS Property Colour Observation Texture Feel Appearance CONCLUSION QUESTIONS What changes were observed after the oil and vinegar were first mixed? _____________________________________________________________________ ______________________________________________________________________ How long did these changes last? _____________________________________________________________________ _____________________________________________________________________ What was the emulsifying agent in this experiment? _____________________________________________________________________ What changes were observed when the oil, vinegar and egg yolks were mixed and how long did they last? _____________________________________________________________________ _____________________________________________________________________ 20 Compare the properties of the final mixture to those of the individual components. _____________________________________________________________________ _____________________________________________________________________ _____________________________________________________________________ _____________________________________________________________________ _____________________________________________________________________ _____________________________________________________________________ 6 Consider the following properties of the emulsion—colour, texture (smooth or grainy), feel (oily, sticky, greasy), appearance, and relate these to the purpose for which this emulsion is used. _____________________________________________________________________ _____________________________________________________________________ _____________________________________________________________________ _____________________________________________________________________ _____________________________________________________________________ _____________________________________________________________________ 21 EXPERIMENT 28 SAPONIFICATION Perform a first-hand investigation to carry out saponification INTRODUCTION Soap has been in use for a long time and it is thought to have been discovered accidentally around 3000 BC. For centuries it was made from animal fats and lye (NaOH) which was obtained by pouring water through wood ashes. The processes of manufacturing soap have been refined over time. Soap is now made commercially by heating various vegetable oils or animal fats with about 30% sodium hydroxide. Sodium chloride is added to the mixture to precipitate the sodium salts of the fatty acids as a thick layer of crude soap, which is purified, coloured and perfumed. In this experiment you will saponify a vegetable oil. The product will be tested in Expt 28. AIM To make soap from a vegetable oil and compare the properties of the product with a commercially produced soap. EQUIPMENT Hotplate 600mL water bath 250 mL beaker (reaction vessel) 100 mL measuring cylinder 10 mL measuring cylinder Beaker tongs and rubber band Small sieve Stirring rod CHEMICALS 25 mL 3M Sodium hydroxide soln in 50% ethanol/water 8mL rice bran oil 150 mL saturated sodium chloride solution RISK ASSESSMENT SAFETY: Wear safety goggles and protective clothing. WHAT IS THE RISK WHY IT IS THE RISK (Risk to self and risk to environment) 22 HOW YOU MIGHT MINIMISE THE RISK METHOD: Part A—Making soap 1. Set up a water bath by placing a 600 mL beaker half filled with water on hot plate. 2. Pour 8 mL rice bran oil into a 250 mL beaker. Slowly add 25mL of the NaOH solution to the vegetable oil, stirring continuously during the addition. (The ethanol does not take part in the reaction but assists the reaction between the oil and sodium hydroxide.) 3. Using beaker tongs and a rubber band place the beaker containing the reaction mixture in the water bath and boil gently, stirring frequently. Caution: if it is overheated the mixture may spit out of the beaker. Keep your face away from the beaker and make sure it is stirred frequently to prevent spattering. Wear Goggles at all times 4. After about 30 minutes of heating and stirring the oil should be dissolved and the mixture should look thick and creamy. 5. Add 25 mL water to the hot solution and stir. 6. Pour this mixture into a 250 mL beaker containing 150 mL saturated sodium chloride solution and stir. Allow to cool. (This separates the glycerol from the soap) 7. Remove the soap layer and place in a 50 mL beaker. 8. Rinse a couple of times with distilled water to remove excess NaOH. 9. Place the rinsed soap on some paper towel to dry. Keep for Experiment 28. OBSERVATIONS _____________________________________________________________________ _____________________________________________________________________ _____________________________________________________________________ QUESTIONS Write the reaction for saponification of a typical oil with sodium hydroxide. 23 EXPERIMENT 29 Perform a first-hand investigation to demonstrate the effect of soap as an emulsifier SOAP AS AN EMULSIFYING AGENT INTRODUCTION A soap molecule has dual properties based on its structure. One end of the molecule is hydrophobic and is therefore attracted to non-polar substances like grease and oil while the other end is hydrophilic and is attracted to polar substances such as water. Soap is able to create an emulsion by attaching to both grease and water. When soap is added to a greasy substance the hydrophobic end is embedded in the grease. When this substance is then washed in water the hydrophilic ends are attracted to the water and eventually the greasy material is rinsed away. AIM Aim: To investigate the effectiveness of soap as an emulsifier. EQUIPMENT 4 x 50 mL beakers 10 x test tubes with stoppers Measuring cylinder or graduated dropper CHEMICALS Hard water Your own soap Soap flakes shaved from a bar of laundry or bath soap 5 mL liquid hand wash 5 mL washing-up detergent 5 mL cooking oil Distilled water 0.1M HCl Universal indicator RISK ASSESSMENT SAFETY: Wear safety glasses, as soap can sting if it gets in the eyes METHOD: 1. Make a soap solution by half filling a 50 mL beaker with distilled water, then add some soap flakes (approx. ½ tsp), stirring until they are dissolved. 2. Make up similar solutions using the liquid hand wash, detergent and your own soap Part A – Comparing different emulsifying agents 3. Place 2mL of each solution in separate test tubes and determine the pH of each solution with universal indicator 4. Place 5mL of each solution in separate test tubes, stopper and shake vigorously. Measure the amount of lather produced 24 Part B - Comparing the effect of different emulsifying agents on other substances 5. In one test tube place 10 mL distilled water and 2 mL of oil. Stopper and shake well to mix. Record your observations immediately after shaking. Place the test tube in a test tube rack and record your observations once the mixture has settled. ( Note this sample has no emulsifying agent and can be used as a comparison) 6. Add 2mL of oil to each of four test tubes. Then add 10 mL of the soap solution to one of the test tubes, 10 mL of the liquid hand wash solution to the second, 10 mL of detergent solution to the third test tube and 10mL of your soap solution to the fourth. Stopper each test tube and shake vigorously. Record your observations. 7. Add 5 mL 0.1M HCl to each of four fresh test tubes. Then add 5 mL of the soap solution to one of the test tubes, 5 mL of the liquid hand wash solution to the second, 5 mL of detergent solution to the third test tube and 5mL of your soap solution to the fourth. Stopper each test tube and shake vigorously Record your observations. 8. Add 2mL of oil to each of the test tubes from step 7. Stopper and shake vigorously. Record your observations. 9. Repeat steps 7 and 8 using the hard water instead of 0.1M HCl. Record your observations. RESULTS Test tube with oil and water only (observations) ________________________________________________________________________ ________________________________________________________________________ Part A – Comparing different emulsifying agents SOAP FLAKE LIQUID HAND DETERGENT YOUR SOAP SOLUTION WASH SOLUTION SOLUTION SOLUTION pH Height of lather produced on shaking 25 Part B - Comparing the effect of different emulsifying agents on other substances SUBSTANCE SOAP FLAKE LIQUID HAND DETERGENT YOUR SOAP ADDED SOLUTION WASH SOLUTION SOLUTION SOLUTION Oil 0.1M HCL 0.1M HCl and oil Hard water Hard water and oil CONCLUSION QUESTIONS 1 Compare the appearance of the oil and water mixture with the oil and soap solution mixture. Did soap act as an emulsifier? _____________________________________________________________________ _____________________________________________________________________ _____________________________________________________________________ 2 Did acid affect the action of soap or detergent as an emulsifier? How could you tell? ______________________________________________________________________ ______________________________________________________________________ ______________________________________________________________________ 26 3 What effect, if any, did the hard water have on the actions of soap and detergent? _____________________________________________________________________ ______________________________________________________________________ _____________________________________________________________________ 4 Explain why detergents are more commonly used than soaps. ______________________________________________________________________ ______________________________________________________________________ 27 EXPERIMENT 30 Perform a first-hand investigation to assess risk factors and then carry out a chemical step involved in the Solvay process, identifying any difficulties associated with the laboratory modelling of the step MODELLING THE SOLVAY PROCESS INTRODUCTION Perform a first-hand investigation to assess risk factors and then carry out a chemical step involved in the Solvay process, identifying any difficulties associated with the laboratory modelling of the step Sodium carbonate is a very useful chemical. It is used as an intermediate in the production of other chemicals and in the manufacture of glass, detergents and soaps, metals and mining, paper and textiles. Synthetic sodium carbonate is produced in South Australia at Penrice Soda Products using the Solvay process. AIM To model steps in the Solvay process and compare the laboratory modelling with the industrial process. EQUIPMENT Gas generator Filter funnel and stand Filter paper 150 mL conical flask 1 large test tube 20 mL measuring cylinder 2 x 100 mL beakers CHEMICALS 10 g NaCl 10 mL 0.1 mol/L Na2CO3 solution 1 g MgCl2 5 mL 1.0 mol/L NaOH solution 0.5 g CaCl2 5 g NaHCO3 20 mL ammonia/ammonium chloride solution (10g ammonium chloride dissolved in 20mL 25% ammonia) 30 mL limewater (saturated Ca(OH)2 solution) Red litmus paper 28 RISK ASSESSMENT Safety: Wear glasses and protective clothing. Check the material safety data sheet for ammonia. Carry out hydrogen carbonate formation and ammonia recovery steps in a fume cupboard. WHAT IS THE RISK WHY IT IS THE RISK (Risk to self and risk to environment) HOW YOU MIGHT MINIMISE THE RISK METHOD: Step A Brine purification 1. To make a seawater solution, measure 20 mL distilled water into a 100 mL beaker. Add 7 g NaCl, 0.8 g MgCl2 and 0.2 g CaCl2 to the distilled water, stir well to ensure all salts are dissolved. 2+ 2. Add 2 mL 0.1 mol/L Na2CO3 to precipitate the Ca ions. 2+ 3. Add 1 mL 0.9 mol/L NaOH solution to precipitate the Mg ions. 4. The solution should now be filtered to remove the precipitates and the solid residue discarded. Step B DEM - Hydrogen carbonate formation 1. Add 20 mL of ammonia solution to a prepared brine filtrate (similar to that from Step A) and stir. 2. Pour the solution into a conical flask ensuring any solid remains in the beaker. 3. Bubble carbon dioxide through the solution from a gas generator or gas cylinder. (Carbon dioxide is readily generated by dripping hydrochloric acid onto marble chips in a gas generator.) 4. Allow the CO2 to bubble through the mixture for approximately 10 minutes. A white precipitate of sodium hydrogen carbonate should form. 5. Try to separate the precipitate by filtering the solution. 6. If filtering did not work allow the precipitate to settle and decant the liquid into a clean 100 mL beaker. 29 Step C Sodium carbonate formation 1. Place 2 g NaHCO3 in a large test tube and fit with a gas delivery tube and stopper. Clamp the test tube in a stand as shown in the diagram below. 2. Half fill another test tube with limewater and place the gas delivery tube in it. 3. Heat the NaHCO3 strongly to convert it to Na2CO3. Record your observations. Caution: remove the limewater tube before removing the Bunsen burner. Step D DEM Ammonia recovery 1. Transfer 5 mL of the filtrate from Step B into a clean test tube. 2. Add 5 mL limewater and heat gently. Hold moist red litmus paper near the mouth of the test tube to check for the presence of ammonia. Record your observations. CONCLUSION QUESTIONS 1 2+ 2+ Why do the Ca and Mg ions need to be removed from the brine solution? ______________________________________________________________________ ______________________________________________________________________ 2 How are the precipitates removed in the industrial process? ______________________________________________________________________ ______________________________________________________________________ 30 3 In the Solvay process CO2 is obtained by heating limestone in a kiln. Why could this not be done in the school laboratory? ______________________________________________________________________ ______________________________________________________________________ In industry the temperature of Solvay tower (carbonator) is carefully controlled to give sodium bicarbonate crystals of the required size to facilitate filtration. Compare this with the school laboratory filtration in Step B. ______________________________________________________________________ 4 ______________________________________________________________________ What other products are present in the reaction in Step B? How are these removed in the industrial process? ______________________________________________________________________ 5 ______________________________________________________________________ 6 Write the chemical equation for the reaction occurring in Step D. ______________________________________________________________________ ______________________________________________________________________ 31