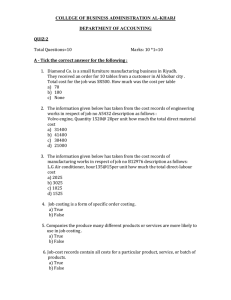

process costing

advertisement

INTRODUCTION : Process costing is the type of costing applied in industries where there is continuous or mass production. The necessity for compilation of the costs of a process or a department for a given period, as distinct from the cost of a whole job or a specific batch of production units, has given rise to the concept of process cost accounting. There are many industries engaged in continuous processing in which the end products are the results of a number of operations performed in sequence. In such industries, it is necessary to apply process costing. Process costing is suitable for a large number of mining, manufacturing and public utility industries like mines and quarries, cotton, wool and jute textiles, chemicals, soap making, paper, plastics, distillation processes, e.g. alcohol, tanning, oil refining, screws, bolts and rivets, canning, food products, dairy, and electricity and gas undertakings. 1) 2) 3) 4) The production is continuous and the end product is the result of a sequence of processes. The product is homogeneous and the units product are identical and standardized. The sequence of operations for processing the product is specific and predetermined. The finished products of one process works as raw material for the next or process until completion. A comparison of the basic principles of process costing with those of job costing, given below, will assist in appreciating process costing procedures. Job Costing 1.) Production is by specify orders. Process Costing 1.) Production is in continuous flow, the products being homogeneous 2.) Costs are determined by jobs or 2.) Cost are compiled on time basis, batches of products i.e. for production for a given accounting period, for each process or departments 3.) The various jobs are separate and 3.) Being manufactured in a independent of each other continuous flow, products lose their individual entity 4.) Unit cost of a job is calculated by 4.) The unit cost of a process, which is dividing the total cost incurred computed by dividing the total into the units produced in the lot cost for the period (after or batch adjustment of the opening and closing work-in-process), is an average cost for the period 5.) Costs are calculated when a job is 5.) Costs are calculated at the end of completed the cost period 6.) There may or may not be any 6.) Production being continuous 1. 2. 3. 4. 5. 6. Process cost may be determined periodically at short intervals. When predetermined overhead rates are in use, it may be possible to complete unit cost weekly or even daily. This not always so under the job costing system, particularly when jobs run for long periods and there are no significant units of completed production during the various accounting periods, falling between the total period of run of the jobs. It involves less efforts and less clerical expenses as the accounting method is simpler than that in job costing. Detailed cost, budgeted as well as actual, are made available for each possible by evaluating the performance of each process etc. Allocation of overhead to departments and processes can be made fairly accurately on definite bases. Since the material consumption ass the various operations are more or less standardized, more accurate cost estimates are available for price quotations. It is easier to set effective and fairly stable standards in case of mass production or continuous repetitive production. Process costing situations are, therefore, more adaptable for installing standard costing procedures. 1) 2) 3) 4) Being only average costs for the accounting period, process cost cannot be considered to be very accurate for the purpose of detailed analysis, evaluation, and control of individual performance efficiency on a day-to-day basis. Costs obtained at the end of the accounting period are only historical and are not of much use for effective control unless standard process cost are used. This is, no doubt, true in respect of all other historical systems but the nature of process accounting with its departmental divisions makes this disadvantage more prominent. When different products come out of one and the same process, the common costs are prorated to the various products. Such cost of individual products are not reliable as they may, at best, be taken to be only approximations. For the purpose of calculation of unit costs of continuous processes, work-in-process is required to be determined at the end of an accounting period. This is done mostly on estimated basis which introduces further inaccuracies in costs. The cost accounting system used by a company depends upon the nature of its products or services. Process costing is more efficient for companies that produce large quantities of homogenous product in a continuous process. 1.- Summarize the physical flow of the units to produce. 2.- Calculate production in terms of equivalent units. 3.- Calculate equivalent unit costs. 4.- Summarize total costs to account for 5.- Assign total costs to the units already completed and to units in ending work in process inventory (WIP). • Normal losses cannot be avoided –Cost is absorbed by good production. • Abnormal losses are avoidable –Cost is recorded separately and treated as a period cost. Example Input = 1 200 litres at a cost of £1 200 Normal loss = 1/6 of input Actual output = 900 litres CPU = £1 200/Expected output (1 000 litres) = 1.20 Cost of completed production = £1 080 (900 ×£1.20) Cost of abnormal loss = £120 (100 × £1.20) Sale proceeds from normal losses Sale proceeds (normal and abnormal losses) Example 2 As example 1 but output CPU as example 1 = 900 litres (abnormal loss = 100 litres) = £1.10 per litre The sales value of the abnormal loss should be offset against the cost of the abnormal loss. Abnormal gains Example Input Output Normal loss Scrap value = 1 200 litres at a cost of £1 200 = 1 100 litres = 1/6 of input = £0.50 per litre CPU = Cost of production less scrap value of normal loss Expected output = £1 100 /1 000 = £1.10 per litre Equivalent Units: Measure the resources used in partially completed units relative to the resources needed to complete the units. Equivalent Units Depend on the Pattern of Cost Flow: Direct Materials: * Added at the beginning of the process * Added during the process Conversion Costs: * Incurred uniformly throughout the process * Incurred non-uniformly Chapter 6 Weighted Average Method: Costs from beginning WIP (performed last period) are averaged with costs incurred during the current period and then allocated to all units completed and ending WIP. Chapter 6 Equivalent production & closing WIP Partly completed units are expressed as fully completed equivalent units in order to compute CPU (e.g. 1000 units 50% complete equls 500 equivalent production. Example Opening WIP Nil Units introduced into the process 14 000 Units completed and trasferred to next process 10 000 Closing WIP (50% complete) 4 000 Materials cost (introduced at start) £70 000 Conversion cost £48 000 Note that materials are 100% complete. Equivalent production and closing WIP Previous process cost Inclusion of inter-process profit creates complications in the accounts. As the internal profits remain merged in process stock, work-in-progress, and finished stock suitable adjustment is required to be made in the Balance Sheet in order to exclude such unrealized profit. When inter-process profit is included in the accounts, it is advisable to have three columns in the ledger to indicate the cost, profit, and the total. This facilitates the calculation of the profit to be provided for inclusion in closing stock in each process and in the final finished stock.