mix proportioning - gozips.uakron.edu

MIX

PROPORTIONING

Prepared by Marcia C. Belcher

Construction Engineering Technology

Design Consideration: Obtaining

Good Workability

Design Consideration: Obtaining

Good Workability

Obtaining Good Workability

Obtaining Good Workability

Design Consideration: Prevent

Segregation & Bleeding

Well Graded Aggregates Will Reduce

Segregation & Bleeding

Well Graded Poorly Graded

Measuring Workability: Slump

The Slump Cone

Approximate Required Slump

Values (PCA)

Concrete

Construction

Reinforced foundation walls/footings

Plain footings and substructure walls

Beams & reinforced walls

Slump (Max.)

3 in

3 in

4 in

Building columns

Pavement & slabs

Mass concrete

4 in

3 in

2 in

Slump

(Min.)

1 in

1 in

1 in

1 in

1 in

1 in

Economics of Mix Design

Goals:

Maximize strength

= minimize water

= control bleeding & segregation

Reduce Cost

= use largest gravel possible for the job

= minimize paste requirement

Provide good durability

= use well graded aggregates

= maximize void packing

= reduced segregation

Cost Comparison of Constituents

Guidelines We Use For Mix Design

PCA Manual

• Tables for w/c ratio based on compressive strength requirement & slump (workability)

• Volume of stone required based on max. agg. size and sand fineness.

• Water required based on max. agg. size, slump & w/c ratio (compressive strength)

Design Method We Will Use:

Absolute Volume Method

Assumes no air voids in concrete

Amount of concrete is sum of solid volumes:

1 CUBIC YARD

• Cement

• Sand

• Coarse aggregate

• Water

• Air

WATER CORRECTION

Any water content in aggregates above SSD water content must be subtracted from the water requirements

Any water requirement of aggregates

(below the SSD water content) must be added to the water requirements

Material Values & Constants

Needed For Design:

SSD (Absorption) of Sand

Unit Weight & SG of Sand

SSD (Absorption) of Stone

Unit Weight & SG of Stone

Density of Cement = 195 pcf

SG Cement = 3.15

Density of Water = 62.4 pcf

1 Cubic Foot Water = 7.48 gal

1 Gal. Water = 8.34 lbs

ACI Standard Mix Design

Method

The standard ACI mix design procedure can be divided up into 8 basic steps:

1.

Choice of slump

2.

Maximum aggregate size selection

3.

Mixing water and air content selection

4.

Water-cement ratio

5.

Cement content

6.

Coarse aggregate content

7.

Fine aggregate content

8.

Adjustments for aggregate moisture

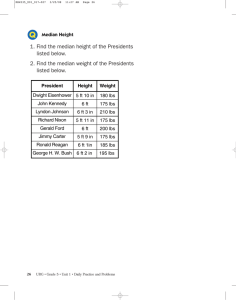

Step #1: Select Slump

Table 9.6

Step #2: Determine Mixing Water and Air Content

Table 9.5

Step #3: Max. Agg. Size Check

DEFINITION: Nominal maximum aggregate size is the largest sieve that retains some of the aggregate particles.

ACI Limits:

1/3 of the slab depth

3/4 of the minimum clear space between bars/form

1/5 minimum dimension of non-reinforced member

Aggregate larger than these dimensions may be difficult to consolidate and compact resulting in a honeycombed structure or large air pockets

.

Step #4: Select W/C Ratio

Table 9.3

Step #5: Cement Content

The calculated cement amount is based on the selected mixing water content and water-cement ratio.

W/C= Wt. of Water

Wt. of Cement

Step #6: Coarse Agg. Content

Table 9.4

Step #7: Fine Agg. Content

Step #8: Batch Weight & Water Adjustment

Aggregate weights .

Aggregate volumes are calculated based on oven dry unit weights, but aggregate is batched in the field by actual weight.

Any moisture in the stockpiled aggregate will increase its weight.

Without correcting for this, the batched aggregate volumes will be incorrect.

Amount of mixing water.

If the batched aggregate is anything but saturated surface dry it will absorb water

(if dry) or give up water (if wet) to the cement paste.

This causes a net change in the amount of water available in the mix and must be compensated for by adjusting the amount of mixing water added.

Mix Design Example:

10” Thick Unreinforced Pavement Slab

Properties of Concrete

Specified By Engineer:

Slump =1.0 inch

28-day strength of 5000 psi

Air content: 4.5 - 6.5 percent

Information About Materials:

Coarse aggregate we are using (ODOT #467):

• nominal maximum size = 1.5 inch (see Agg. Size Table)

• dry-rodded weight = 100 lb/ft 3

• specific gravity = 2.68

• moisture content = 1.0 percent

• absorption = 0.5 percent

Fine aggregate:

• fineness modulus = 2.80

• specific gravity = 2.64

• moisture content = 5 percent

• absorption = 0.7 percent

Step #1: Select Slump

Engineer Specified 1” (correlates w/table)

Table 9.6

Step #2: Determine Mixing Water and Air Content

1.5” Stone

Table 9.5

1” Slump

Step #2: Determine Mixing Water and Air Content

Weight of Water = 250 lbs/yd 3

Volume of Water = 250 lbs/yd 3 = 4 ft 3

62.4 lbs/ft 3

Volume of Water = 4 ft 3 per cubic yard of concrete

Step #3: Max. Agg. Size Check

ACI Limits:

1/3 of the slab depth

10”/3 = 3.33 inches > 1.5” OK

Step #4: Select W/C Ratio

Table 9.3

Step #5: Cement Content

W/C= Wt. of Water

Wt. of Cement

Wt. of Cement = 250 lbs/yd 3

.40

=625 lbs/yd 3

Volume of Cement = 625 lbs/yd 3 (Concrete)

3.15 x 62.4 lbs/ft 3

SG Cement

Volume of Cement = 3.18 ft 3 per cubic yard of concrete

Step #6: Coarse Agg. Content

Table 9.4

Step #6: Coarse Agg. Content

Weight (Dry) =.71 x 27 ft 3 /yd 3 x 100 lb/ft 3 = 1,917 lbs

Dry Rodded Unit Wt of Stone

Volume = 1,917 lbs = 11.46 ft 3

2.68 x 62.4 lbs/ft 3

SG Stone

Step #7: Fine Agg. Content

27 ft 3

4 ft 3

Cubic Yard of Concrete

Water

1.49 ft 3 Air (.055 x 27 ft 3 )

3.18 ft 3 Cement

11.46 ft 3 Stone

6.87 ft 3 Sand

Wt of Sand (Dry) = 6.87 ft 3 x 2.64 x 62.4 lbs/ft 3 = 1,131.7 lbs.

SG Sand

Step #8: Aggregate Batch Weights & Water Adjustment

Wt of Stone (Wet) = 1,917 lbs x 1.01= 1,936.2 lbs

1% Moisture

Wt of Sand (Wet) =1,131.7 lbs x 1.05= 1,188.3 lbs

5% Moisture

Step #8: Aggregate Batch Weights & Water Adjustment

Mixing water needs to be adjusted. Both the coarse and fine aggregate are wet of SSD and will contribute water to the cement paste.

Water from Stone = 1,917 lbs. x (.01-.005) = 9.59 lbs

Dry Wt.

Moisture Absorption

Water from Sand= 1,131.7 lbs x (.05-.007) = 48.66 lbs

Dry Wt.

Moisture Absorption

Water = 250 lbs – 9.59 lbs – 48.66 lbs = 191.75 lbs

Final Batch Wts. (1 Cubic Yard)

Water

Cement

Stone

Sand

191.75 lbs = 23 gallons

625 lbs

1,936.2 lbs

1,188.3 lbs