Integration and Test in a CMMI Level 5

advertisement

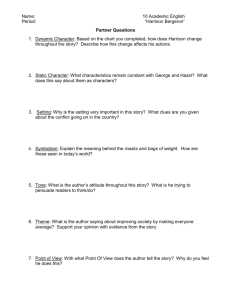

Integration and Test in a CMMI Level 5 Environment AIAA Space 2009 Conference 14–17 September 2009 Cecilia Harrison Warren Scheinin Northrop Grumman Corporation AIAA Space 2009, Harrison and Scheinin The Steps to Success: An Agenda in Reverse Order Success The Result: Managed Integration The Details: How it is Done The Solution: Engineering for Integration The Problem: Some Assembly Required The Environment: CMMI Level 5 The Set Up 2 AIAA Space 2009, Harrison and Scheinin The Set Up • Some products were not being delivered in as timely a manner or within budget as planned • Defects injected early in the product life cycle were not being detected until late in the life cycle • Components did not always plug together as easily as hoped • Unanticipated and unwanted outputs needed to be eliminated • Project personnel often experienced stress as milestones drew near • Smooth running processes often hit bumps when external stakeholders provided inputs We knew we could be more efficient 3 AIAA Space 2009, Harrison and Scheinin The Environment: CMMI Level 5 • Institutionalized processes, tools and stakeholder involvement are focused on success factors • Selected processes are optimized using results based, quantitative methods • Early life cycle processes are not allowed to crowd out later life cycle processes at project start-up and early execution • Staged representation lifts all process areas in parallel • Continually improving performance through incremental and innovative changes 4 AIAA Space 2009, Harrison and Scheinin Climbing the CMMI Level 5 Ladder • Each CMMI Level is a step to Higher Project Maturity – – – – Starts with the foundations for a maintainable system Gets your head above water Clears the fog of fighting fires Engages the supercharger Level 3 Defined Level 2 Managed Level 1 Initial 5 The Ad Hoc Sink Hole AIAA Space 2009, Harrison and Scheinin Level 5 Optimizing Level 4 Quantitatively Managed Level 4: Understand Your Processes and Subprocesses • Targets defined processes for quantitative control • Take advantage of organizational knowledge – Identify the implementations of processes which perform best – Know that processes are performing within natural bounds that are consistent across teams – Surgical precision of Six Sigma methods Defect Detection Profile – Co-ordinate with other projects • Better understanding and use of Level 3 metrics 160.00 140.00 120.00 Defects/KSLOC – Goal setting becomes more important for Levels 4 and 5 – Need better definitions of the measures and measurement processes – Lower level metrics of subprocesses Process Capability Metric 180.00 100.00 All Projec New Proc 80.00 60.00 40.00 20.00 0.00 Req'mts Design Code Unit Test 6 AIAA Space 2009, Harrison and Scheinin Integrate Life Cycle Phase Phase Sys Test Del 90 Days Level 5: Adding the Edge • Get ahead of the curve by catching problems before they attack the project • Reduce the variation – Initiate late cycle processes early – Create procedures/checklists – Strengthen process audits • Increase the effectiveness (increase the mean) – – – – Train people Create checklists Reduce waste and re-work Replicate best practices Revolutionary Process Capability Improvement 7 AIAA Space 2009, Harrison and Scheinin The Problem: Some Assembly Required • Things do not always work as intended • Needed two-pronged attack on the classical weakness of integration: surprise and delay • Many projects disempowered integration and test until it is too late • Major flaws are generally “baked into the cake” before integration efforts even start • Integration and Test teams are often brought onto the project far too late to influence and/or contribute to the system design • I&T Team can have negative affect on the dynamics of the project team if not on board from “Day One” • Risks need to be identified before they become problems • Let software do it is not a good answer 8 AIAA Space 2009, Harrison and Scheinin Worse Case Scenario • Early Defects Cause Late Term Problems • Need eyes of Integration and Test Managers and leads early in product life cycle Requirements Acquisition Defect s Process Development Design Product Development Test and Evaluation Operations Program Failure 9 Missed defect in early product realization processes provide opportunities for potential failure modes to be created and propagated, causing Mission failure AIAA Space 2009, Harrison and Scheinin Experience at NGIS • Lessons Learned show that as the product development life proceeds, the more positive the impact of early integration and test management Integration Management Impact on Success 10 9 Risk Management 8 7 6 Tech Perform Management 5 4 3 2 Schedule Management 1 0 Scope Management Subcontract Management Pre-Proposal Program Initiation Program Execution Business Acquisition Phase High leverage points 10 AIAA Space 2009, Harrison and Scheinin Cost Management Communications Management Quality Management Issue Management The Solution: Engineering for Integration • Focuses on managing the integration and test efforts • Mechanism to assess and improve system reliability starting from “Day One” • Empowers the Integration and Test team by involving them at the earliest part of the project lifecycle • Supports performance analysis to optimize throughput, capacity, and product quality • Proactively make demands of the system design to suit Managed Integration and Performance Analysis needs • Implemented in parallel to the System Development effort Byproducts are satisfied customers and users 11 AIAA Space 2009, Harrison and Scheinin The Details: Managed Integration • Process of integrating hardware and software products in frequent, small, additive steps into a full system environment • Typically characterized by: – Deliberately conceived architectures that enable parallel, component-level integration – Test tools sufficient to analyze weaknesses in submitted products, so as to enable their rapid correction/improvement – Emphasis on evaluation of both internal and external interfaces – Concentration on a meaningful set of basic functionality (Core Function and Long Mission Threads) – Early capacity for full operational stress conditions – Potential for rapid turnaround of products and tasks in integration, such as in “continuous integration” approaches 12 AIAA Space 2009, Harrison and Scheinin 10 General Elements of Managed Integration • Early Infrastructure Selection • System Architecture Skeleton Strategy • Layered Service Provisioning • Long Mission Threads Emphasis • Strategic Component Selection • Minimize Interdependencies • Specify, Organize, and Control System States • Automate Regression Testing • Design for Performance Tuning • Control Configurations and Versions 13 AIAA Space 2009, Harrison and Scheinin The Details: Performance Analysis • Targets details of implementation and obscure characteristics of complex systems that can have extraordinary impact on overall performance • Solve issues that could become major factors impacting delivery timelines • Ensures that flow down of general performance requirements into specific requirements are realistic and testable • Uses system architecture skeleton to analytically extrapolates overall understand of components on the system collectively to mitigate overall performance risk • Allows focusing of limited resources to components of the system which will experience the greatest performance stress 14 AIAA Space 2009, Harrison and Scheinin 4 General Elements of Program for Performance Analysis “Program for Performance Analysis” is a well-planned effort to examine performance and apply a variety of strategies to gain appropriate, timely understanding of the system. • Component Benchmarking • Communication Channel Characterization • Long Mission Thread Exercise • Interface performance Description 15 AIAA Space 2009, Harrison and Scheinin The Result: Managed Integration From Day One 16 • Integration and Test managers and leads working side by side with System Engineers and Architects to define scenarios that will drive a design that meets the required performance • Early establishment of systems engineering and architecture elements which most directly pertain to and predict integration success • Proactively exploiting the emerging system in integration to achieve higher quality, higher confidence results AIAA Space 2009, Harrison and Scheinin Indicators of Success • More up front thinking means less work later • More value-added products produced with reduced effort and time – Instead of overrunning budgets and schedules, products are delivered early and on budget – Extra deliveries are possible without strain • Less “help” from senior management but more resources available • Lots of new work pours in • Communications with other groups is easier Systems • Safety • Reliability • Availability • Maintainability Program Quality • Quality Assurance • Software Assurance • Hardware Assurance Mission Assurance Supplier AIAA Space 2009, Harrison and Scheinin Reviews and Assessments • Risk Management • Qualification • Selection • Assessment 17 • Independent A Level 5 Organization is Never Satisfied…. More stakeholder involvemen t A family of integratio n strategies Add more subprocesse s 18 Better metrics More efficient statusing AIAA Space 2009, Harrison and Scheinin 19 AIAA Space 2009, Harrison and Scheinin