ATEX Products

advertisement

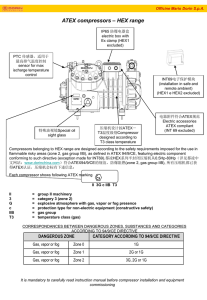

Explosion Proof Cameras What is Explosion Proof (EX)? Electric Powered Industrial Equipment, used in areas containing explosive or flammable materials, must be designed to prevent any operation of the equipment from igniting the atmosphere. The design and construction of EX Equipment permit their classification as Explosion Proof (EX) and enable their use in explosive and hazardous atmospheres. EXPLOSION PROOF ENCLOSERES An EX Enclosure is a case or housing that has been tested and approved to contain electrical components. The strength of the enclosures must contain any internal explosion. The enclosures have been hydrostatically tested for internal explosive resistance to pressures in excess of UL requirements without failure. Explosion Proof Enclosures protect all cabling, wiring, and electrical components. What is ATEX Explosion Proof (ATEX EX)? ATEX EX (also referred to as Flameproof) is European Explosion Proof equipment certified to ATEX standards. Equipment and protective systems intended for use in potentially explosive atmospheres must enclose all ignition sources. ATEX EX is equipment that complies with ATEX (94/9/EC Directive) (Definition in the following slide). Approved by Internationally Recognized Testing Laboratories, ATEX EX Equipment can be used in designated explosive and hazardous atmospheres. • What is the actual differences in Stainless Steel between the 316L or 304 housing? • What are advantages of each housing type? The main difference is on the percentage of nickel (Ni), the Ni in 316L is much more than in the 304, so the 316L is much better suitable for corrosion proof capability. All products are for Class 1, Division 1. Class 1 : means the explosive gas area Division 1 : means the explosive gas always exist. 316L Stainless Steel is with Mo (molybdenum) inside and can withstand the corrosion better than 304ss. Example: For marine use, the 316L is recommended. 316L delivery time is rather longer than 304ss. Abbreviation Example: The ATEX certificate for SVEX-Q18 is II 2G EExd tD II B +H2 T6 II 2G: Equipment group II (Equipment intended for use in areas other than mines (above ground). In Places which explosive atmospheres caused by gas, vapors and liquid) zone 1 (gas), equal US standard Class 1, Division 1. EEx: EX mark d: Flame proof structure tD:Dust Explosion Proof II: Equipment group II (Equipment intended for use in other areas than mines (above ground) in areas which have explosive atmospheres, which is caused by gases, vapors and liquids) B+H2: gas group B plus hydrogen. T6: Max surface temperature 85 degree. • Group I – Electrical apparatus for mines susceptible to firedamp (for use underground) • Group II – Electrical apparatus for places with a potentially explosive atmosphere, other than mines susceptible to firedamp General information According to 94/9/EC, a device that is to be used in an environment at risk of explosion may only be brought into the market if it satisfies the standards specified in the norm. Compared with the previous directives, it must be noted that the specification refers not only to electrical but also to mechanical equipment Ex: PTZs. Devices are divided into categories and groups to accurately define the conditions of use. This definition is marked on the device and may appear as follows: Example: II 2G EEx IIC T6 Device group Category Identifier Explosion group Temperature class Device group II , There are 2 groups of devices. Devices of Group I, Category M are for use in underground mines and their above ground equipment, which are at risk from firedamp and/or inflammable dusts. (This is not given further coverage in this document). All other areas at risk of explosion are combined in Device Group II. Identifier EEx defines that this is an electrical device. d: Flame proof structure tD: Dust Explosion Proof Category The categories define which zones the devices may be used in. The classification states how frequently and in what concentration the ignitable mixture occurs. Furthermore, differentiation is made as to whether the hazard is due to gases, vapors and mists or due to dust. Category 1 For devices, which guarantee a very high level of safety. Intended for the case where an atmosphere at risk of explosion is to be expected frequently or continuously. Devices in this category can also be used in Category 2 and 3. Inflammable gases, vapors or mists Zone 0 equivalent to Category 1G Area in which an atmosphere at risk of explosion as a mixture of air and inflammable gases, vapors or mists is continuously or frequently present or present for long periods. Inflammable dusts Zone 20 equivalent to Category 1D Area in which an atmosphere at risk of explosion in the form of a cloud of inflammable dust contained in the air is continuously or frequently present or present for long periods. Category 2 For devices, which guarantee a high level of safety. Intended for the case where an atmosphere at risk of explosion is to be expected. Devices in this category can also be used in Category 3. Inflammable gases, vapors or mists Zone 1 equivalent to Category 2G Area in which an atmosphere at risk of explosion as a mixture of air and inflammable gases, vapors or mists can form occasionally during normal operation. Inflammable dusts Zone 21 equivalent to Category 2D Area in which an atmosphere at risk of explosion in the form of a cloud of inflammable dust contained in the air can form occasionally during normal operation. Category 3 For devices, which guarantee a normal level of safety. Intended for the case where an atmosphere at risk of explosion is to be expected rather infrequently and, if so, for only short periods. Inflammable gases, vapors or mists Zone 2 equivalent to Category 3G Area in which an atmosphere at risk of explosion as a mixture of air and inflammable gases, vapors or mists does not normally occur at all or only for short periods during normal operation. Inflammable dusts Zone 22 equivalent to Category 3D Area in which an atmosphere at risk of explosion in the form of a cloud of inflammable dust contained in the air does not normally occur at all or only for short periods during normal operation. Explosion group Device group II is sub-divided into Explosion Groups A, B or C. This classification is dependent on the typical material properties of the gases and vapors that occur. The hazard level of materials increases from Explosion Group IIA to IIC. The requirements for the devices increase accordingly. If a device is approved for IIC, it can be used for all other explosion groups. Alternatively, the chemical formula or the name of the material can be stated here. Temperature class It must be ensured that the ignition temperature of an inflammable material is not reached during operation. Forthis purpose, the maximum surface temperature of a device must be less than the minimum ignition temperature. For this reason, the maximum surface temperature of equipment for use with inflammable gases, vapors or mists is specified in temperature classes. For dusty environments, the maximum surface temperature is specified in °C. Temperature class Maximum permissible surface temperature of the equipment (°C) T1 450 T2 300 T3 200 T4 135 T5 100 T6 85 Explosion Proof Zone Summary Explosion Proof Explanation Gas Dust I.E.C. N.E.C. Zone 0 Class I, Division I Zone 1 Class I, Division I Zone 2 Class I, Division II Zone 10 Class II, Division I Zone 11 Class II, Division II I.E.C.: International Electrotechnical Commission N.E.C.: National Electrical Code, U.S.A. Explosion Proof Explanation Temperature in Celsius and Fahrenheit Products Applications • On-shore Applications 1. Oil Refinery 2. Gas Station 3. Chemical Plant 4. Coal Mining 5. Military • Off-shore Applications 1. Drilling Platform 2. Marine Vessels Applications Applications Typical Analog System Connection Typical Digital System Connection Now several models of Veilux EX products are with ATEX certificate and a complete product line is formed. ATEX certificate Products List: 1. SVEX-HIR7 EX PTZ Camera 2. SVEX-Q18 EX Dome Camera 3. SVEX-W1301 EX PTZ Camera 4. SVEX-W125 EX Pan Tilt with Camera Housing 5. SVEX-T100A EX Camera Housing 6. SVEX-2028E EX Control Box ATEX Products SVEX-HIR7 SVEX-W1301 EX PTZ CAMERA ATEX Certificate: Nemko 08ATEX1100 ATEX Standard: EN 60079-0: 2006, EN 60079-1: 2004, EN61241-0: 2006;EN61241-1: 2004 EX Mark: +60℃ II 2 GD Ex d IIC T6, Ta : -40℃ to Ex tD A21 T80℃ 27 ATEX Products SVEX-HIR7 SVEX-1301 EX PTZ CAMERA Main Features: 1. Integrated with pan/tilt, camera, camera housing, telemetry board(receiver), sunshield, wiper, auto heating system etc. 2. IR illuminator or laser can be optional for different distance requirement on night vision conditions. 3. 128 presets, 360°continuous pan and +/-90°tilt rotation. 4. IP68 5. Variable rotation speed from 0~30°per second. 6. -40℃ to +60℃ working temperature. Dimensions 28 ATEX Products SVEX-Q18 EX DOME CAMERA ATEX Certificate: Nemko 11ATEX1022 ATEX Standard: EN 60079-0: 2009, EN 60079-1: 2007, EN60079-31: 2009 EX Mark: II 2 GD Ex d IIC T6 Gb, Ta : -15℃ to +60℃ Ex t IIIC T80℃ Db 29 SVEX-Q18 EX DOME CAMERA Key Features: 1. Unique dome structure design, easy for maintenance. 2. On-screen-display function. 3. IP67 4. Available for both ceiling mounting and stand mounting. 5. 128 presets, 360°continuous pan and +90~-30°tilt rotation. 6. Support Pelco P/D protocols and multiple baud rate. 7. 100~240VAC power supply. 8. IR illuminator can be optional. Dimensions 30 ATEX Products SVEX-W125 EX PT & CAMERA HOUSING ATEX Certificate: Nemko 05ATEX1190 ATEX Standard: EN 50014: 1997 + A1: 1999 + A2:1999 and CENELEC EN 50018: 2000 EX Mark: II 2 G EEx d IIC T6, Ta : -25℃ to +60℃ 31 ATEX Products SVEX-125 EX PT & CAMERA HOUSING Key Features: 1. Integration with P/T and camera housing. 2. Flexible design for camera housing, available for both block camera as well as box camera and zoom lens. 3. Wiper, sunshield and auto heating optional. 4. 24VAC or 220VAC power supply. 5. 350°pan and +/-90°tilt rotation. Yellow part means available room for inner camera. 。 32 ATEX Products SVEX-T100A EX CAMERA HOUSING ATEX Certificate: Nemko 05ATEX1209 ATEX Standard: EN 50014: 1997 + A1: 1999 + A2:1999 and CENELEC EN 50018: 2000 EX Mark: +60℃ II 2 G EEx d IIC T6, Ta : -25℃ to 33 ATEX Products SVEX-100A EX CAMERA HOUSING Key Features: 1. Two versions design for camera housing, available for both block camera as well as box camera and zoom lens. 2. Sunshield and auto heating optional. 3. Electro-polish or corrosion proof painting finish. 4. Thermal camera version available. Yellow part means available room for inner camera. 34 ATEX Products EX CONTROL BOX ATEX Certificate: Nemko 08ATEX1089 ATEX Standard: EN 60079-0: 2006 EN 60079-1: 2004 EX Mark: II 2 G Ex d IIB+H2 T6 35 ATEX Products EX CONTROL BOX Key Features: 1. Six cable entry for wiring. 2. Widely applications to install telemetry board, power supply, web server, optic fiber T/R etc.. 3. Electro-polish or corrosion proof painting finish. 4. Inner size: 240(L) x 210(W) x 100(H) mm. 36 ATEX Products EX MONITOR 15 or 17 inch monitor to work with the video display in EX site. BNC or VGA video signal can be optional for monitors . 37 Non ATEX Products SVEX-300A EX CAMERA HOUSING Key Features: 1. Two versions design for camera housing, available for both block camera as well as box camera and zoom lens. 2. Sunshield, wiper and auto heating available. 3. Electro-polish or corrosion proof painting finish. 38 Non ATEX Products SVEX-HSF WATER COOLING HOUSING Key Features: 1. SVEX-HSF is a Water Cooling Camera Housing that is designed for special environments, available for block camera as well as box camera. 2. This product can be used under dusty and high temperature conditions. 3. Environmental Temperature≤+250°C 4. Water Pump is required but not included 39 Non ATEX Products EX JUNCTION BOX Junction Box to connect the pipes 40 Non ATEX Products EX Controller EX QUAD 1. Control 4 pan/tilts, camera and wiper system separately 2. Voltage control or RS485 control 3. Up/down/left/right, zoom, focus, iris and wiper functions can be used by buttons 1. 4-channel video signal input/1channel video output 2. 1/2/3/4 channel video display 41 REFERANCES