Case Study Agile Auto Architecture GM's Autonomy and the i

advertisement

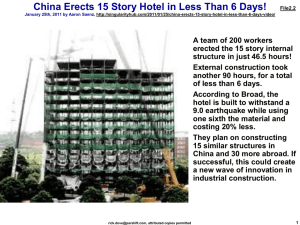

Case Study Agile Auto Architecture GM's Autonomy and the i-Solo/Duo rick.dove@stevens.edu, attributed copies permitted 1 AUTOnomy is the “Reinvention of the Automobile” and is the first vehicle to be designed from the ground up around a fuel cell propulsion system and combining drive-by-wire control technology and electric wheel hub motors. The GM AUTOnomy is a powerful vision of what the future of auto-mobility may become and as such offers an endless variety of all-wheel-drive vehicles built from a limited number of common “skateboard” chassis with unlimited plug-andplay body styles. The skateboards include all of the essential systems: a fuel cell stack, an electronic network, electric drive motors, and an on-board hydrogen storage system. The result is a vision of a future based on hydrogen fuel, a future where the only emission from the tailpipe is water. rick.dove@stevens.edu, attributed copies permitted 2 rick.dove@stevens.edu, attributed copies permitted 3 With AUTOnomy, an almost endless variety of affordable, all-wheel-drive vehicles could be built from a limited number of common chassis - possibly as few as two or three - emitting only water from the tailpipe and using renewable energy. rick.dove@stevens.edu, attributed copies permitted 4 rick.dove@stevens.edu, attributed copies permitted 5 rick.dove@stevens.edu, attributed copies permitted 6 POWER: Fuel Cells combine hydrogen and oxygen to produce electricity, with water and heat as the only by-products. Hydrogen is the most abundant element in the universe. CONTROL: Drive-by-wire allows steering, braking, and other vehicle systems to be controlled by electrical signals rather than mechanical joints and linkages. SKATEBOARD: A six-inch thick chassis with the entire propulsion system housed within; wheel hub motors at the wheels enable four-wheel drive and four-wheel independent steering, acceleration, and braking; four electrical mechanical body attachment mounts to lock the body in place onto the skateboard; pre-configured and validated perimeter structural impact zones; external side mounted optimized cooling fins; a smart single access docking port to connect and link power, control, heating and cooling systems to the body from the skateboard; a refueling port for hydrogen, and an exhaust outlet dispersing water in the form of vapor. MANUFACTURING: By decoupling the body and skateboard in the manufacturing process and using modular assembly and accelerated vehicle development techniques, millions of skateboards can be manufactured at one location to achieve economies of scale. The various bodies and body styles would then be built and customized at satellite assembly plants around the world for both emerging and established markets. This freedom and flexibility allows the vehicle to adapt to the needs of unique global markets, changing lifestyles, and various customer requirements around the world. BODY INTERCHANGEABILITY: The body of an AUTOnomy vehicle can be tailored to a manufacturer type, to a desired interior vocabulary, and to any exterior form or desired style. SOFTWARE CUSTOMIZATION: The body and skateboard are programable and customizable and can learn from and adapt to the user. Software--in combination with hardware--can adapt to a user or be pre-conditioned for certain driving characteristics, such as braking, cornering and acceleration. UNVEILING: Revealed January 2002 at the North American International Auto Show (NAIAS). The General Motors AUTOnomy body has a futuristic two-seat roadster body (one of many possible interchangeable body styles) inspired by motorcycle and fighter jet designs. 7 rick.dove@stevens.edu, attributed copies permitted It looks like an ordinary Opel Astra, one of Europe’s most popular compact sedans. But slip into the driver’s seat and you quickly realize there’s something a bit unusual about this high-tech prototype. The oddly shaped steering wheel is probably the first clue, though the lack of foot pedals is a definite giveaway. The particular Astra TheCarConnection had the chance to drive at California’s Buttonwood racetrack uses the latest in so-called “drive-by-wire” technology, and could very well be a sign of things to come. rick.dove@stevens.edu, attributed copies permitted 8 Named for its combination of hydrogen fuel cell and drive-by-wire technology, the Hy-wire incorporates the features envisioned in the AUTOnomy concept vehicle. All of its propulsion and control systems are contained within an 11-inch-thick skateboard-like chassis, maximizing the interior space for five occupants and their cargo. rick.dove@stevens.edu, attributed copies permitted 9 Hy-wire specifications Vehicle: Fuel cell and by-wire technology; front-wheel drive, new luxury sedan Seating capacity: 5 Fuel storage system: Three cylindrical high-pressure tanks of carbon composite material, mounted in the middle of the skateboard chassis Length/diameter: 1,161/241 mm (45.7/9.5 inches) Total capacity: 2 kg (4.4 pounds) Total weight: 75 kg (165 pounds) Fuel cell stack: 200 single fuel cells; connected in a series Voltage:125-200 Volt Length/width/height:472/251/496 mm Pressure:1.5-2.7 bars Continuous rating: 94 kW, peak of 129 kW Power density: 1.60 kW/l, 0.94 kW/kg Electrical traction system: Three-phase asynchronous electric motor with integrated power electronics and planetary gear Operating voltage: 250-380 Volt Maximum rating: 60 kW Maximum torque: 215 Nm (159 lb-ft) Maximum rpm: 12,000 Transmission ratio: 8.67:1 Total weight: 92 kg (203 pounds) Skateboard chassis: Length/width/height: 4,357/1,670/ 279 mm (171.5/65.7/11 inches - taller in the back) Aluminum frame Body: Steel and fiberglass Length: 5 meters (195 inches) Vehicle size/weight: Mass: 1,900 kg (4,185 pounds) Wheel base: 3,114 mm (122.6 inches) rick.dove@stevens.edu, attributed copies permitted 10 Overview: The Sequel, about the size of a Cadillac SRX, is the first fuel cell vehicle that achieves 0-60 mph in under 10 seconds and has a 300-mile range. Unequaled control on snow and ice, or uneven terrain. 42-percent more torque for unparalleled acceleration. Shorter braking distance than an equal size vehicle Sequel’s sophisticated by-wire system replaces the mechanical and hydraulic linkages of conventional vehicles with electrical wires and actuators. This means fewer parts to wear out, and because by-wire systems work like a fast computer, Sequel has enhanced accelerating, braking and overall handling. Jan, 2005 - The New York Times G.M. unveiled the Chevrolet Sequel, that runs on a hydrogen fuel cell, and employs the Platform architecture Larry Burns has been spearheading. rick.dove@stevens.edu, attributed copies permitted 11 I+Solo / I+Duo http://www.solo-duo.hu/main.php?category=126 Hungarian Car project rick.dove@stevens.edu, attributed copies permitted 12 “The Antro Solo concept is a three-passenger car, with a hybrid drive and solar cells on its roof that the company says could generate enough electricity for up to 20km a day at city speeds. Antro intends to allow users to be able to connect two Antro Solos to form a six-passenger Antro Duo. Or, owners of a Duo could split the car into two smaller Solos should Mum have different weekend plans to Dad." The Group’s view of the future • responses with a perspective in rapidly changing circumstances • relationships based on human values • an economy based on satisfying needs • rapid, flexible and decentralised networks • synergies emerging from cooperation rick.dove@stevens.edu, attributed copies permitted 13 • • • • the large family car (DUO) can be separated to two identical minicars (SOLO) the SOLO seats three passengers the DUO seats six passengers hybrid drive with renewable energies, running on vegetable oil and alcohol + electric motor • solar cells on roof for charging the batteries • supplementary drive by pedal-generator, the option of exercise during travel (fitnessmobile) • use of only the electric motor + pedal drive at low speed, within residential areas (silent, 0 emissions) rick.dove@stevens.edu, attributed copies permitted 14 2006-2008 – Creation of an operational “concept car” 2009-2010 – Creation of the Solo+Duo prototype 2010-2012 – Production design, prep for manufacture 2012-2013 – Launch of large-scale serial production 15 rick.dove@stevens.edu, attributed copies permitted The SOLO-DUO will need only one quarter of the fuel required by current cars. When burning vegetable oil, alcohol, or synthetic, renewable fuels, the amount of carbon dioxide released is equal to the amount the plant already absorbed during its growth. Its hybrid drive will be as dynamic and quick as that of traditional cars, so it will fit perfectly into public road traffic. rick.dove@stevens.edu, attributed copies permitted 16 rick.dove@stevens.edu, attributed copies permitted 17 Autos as Mobile Complex Computer Systems Film-5:20 Feb 2010 email from recognized auto-expert academic/consultant http://spectrum.ieee.org/riskfactor/computing/it/us-national-highway-traffic-safety-administration-has-no-ees-or-sw-engineers-working-for-it http://abcnews.go.com/Nightline/video/auto-professor-pinpoints-car-flaw-9916379 As the industry switches to drive-by-wire, the number of lines of code in a vehicle these days exceeds those in aircraft. The statements made by Toyota executives suggest that the top command failed to realize what kind of new world the company had entered. On the other hand Ford in July implemented a new record system designed by Siemens. It starts a record of each vehicle at line off, including all the software and updates to it. No two vehicles may be identical, so when one comes in for service, you have to know what's in it to diagnose. And updates and patches can be downloaded from Ford, same as for computer software. Vehicles are becoming computers and have to be managed as such. Biggest problem in automotive advance that I see today is lack of engineering software talent to integrate all this stuff. If you could multiply that, you could retrofit much of the existing vehicle fleet to quickly pump up fuel efficiency by 10-25%. Nonetheless, I suspect that is coming fairly soon, and it will drastically change the business model of the industry. Out of the last four automotive development projects I have seen, on three, 75% of development staff were software. You can no longer design one of these things without constant simulations to see which combination "works better" (or has unacceptable characteristics). rick.dove@stevens.edu, attributed copies permitted 18