Schottky Defects

advertisement

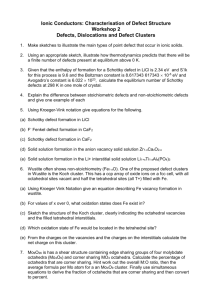

Ionic Conductors: Characterisation of Defect Structure Lectures 5-6 Defects in Crystalline Solids Dr. I. Abrahams Queen Mary University of London Lectures co-financed by the European Union in scope of the European Social Fund Thermal Defects Crystalline solids are those that show a regular repeating structure, e.g. NaCl. However all crystals are imperfect above 0 K, i.e, atoms are missing or displaced from their normal lattice positions. e.g. NaCl ccp Cl– ions with Na+ in every octahedral site At room temperature a small number of Cl– and Na+ ions are missing (ca.1 in 1015 atoms missing). Defects have important effects on the properties of materials. In ionic conductors it is the presence of defects that facilitates ionic conduction. Where the influence of the defect (apart from elastic strains) extends for just a few Angstroms this is called a point defect. Where the defect invoves a number of point defects extending over longer distances then it may be described as an extended defect. Lectures co-financed by the European Union in scope of the European Social Fund Classical Point Defects Point defects are the simplest cases, where a single atom/ion or pair of ions (in ionic AB structures) is missing or displaced. Sites where an atom is missing are known as vacancies. Atoms or ions displaced into a part of the structure that is normally vacant are called interstitials. Three main types of point defect will be considered: Schottky Defects Frenkel Defects Colour Centres Lectures co-financed by the European Union in scope of the European Social Fund Schottky Defects A Schottky defect in a metal consist of a single vacancy. In ionic crystals of the type AB the Schottky defect consists of a pair of missing ions. e.g. NaCl One Na+ and one Cl– absent from their normal lattice sites. These absent positions are described as vacancies. Electroneutrality is maintained Lectures co-financed by the European Union in scope of the European Social Fund HF of a Schottky defect in NaCl is ca. 220 kJ mol-1 Therefore the heat of formation is high and explains why only 1 in 1015 Na+ and Cl– ions are missing at room temperature. However despite the low concentration this can have an important influence on properties. For example the presence of defects can lead to ionic conduction (small in NaCl). Ionic conduction occurs as a result of Na+ ions moving into a vacancy. Many ionic solids exhibit Schottky defects e.g. NaCl, LiCl, MgO etc. Lectures co-financed by the European Union in scope of the European Social Fund Frenkel Defects Frenkel defects consist of anions or cations displaced from their normal lattice sites into interstitial sites. Interstitial sites are ones which are not normally occupied in the perfect crystal. e.g. AgCl (rocksalt) Ag+ ion displaced from it normal octahedral position to an interstitial tetrahedral site. Lectures co-financed by the European Union in scope of the European Social Fund HF for a Frenkel defect in AgCl ca. 130 kJ mol-1. Therefore again only a very small number of defects are present at room temperature. NaCl and AgCl both have the rocksalt structure, but have different point defects. In any compound the defect with the lowest HF will form. Frenkel defects have lower HF in AgCl. Schottky defects have lower HF in NaCl. NaCl is more ionic than AgCl. Interstitial Ag+ is more stable than interstitial Na+. Lectures co-financed by the European Union in scope of the European Social Fund Colour Centres The F– centre is the best known colour centre (F for farbenzentre). F – centres occur when an electron becomes trapped on an anion vacancy. If NaCl is heated in Na vapour, Na ionises at the surface. Na+ remains at the surface, but e- migrates into the bulk, where it becomes trapped on an anion vacancy. The resulting solid is greenish-yellow in colour and is non-stoichiometric. Na1+Cl (<<1) Colour centres can also be created by irradiation (e.g. X-rays). Because the e – is unpaired, ESR (electron spin resonance) can be used to study colour centres. Lectures co-financed by the European Union in scope of the European Social Fund Energetics of defect formation Unlike extended defects such as dislocations and grain boundaries, point defects are present in relatively high concentrations at thermodynamic equilibrium. Consider a perfect crystal. Introducing a single defect results in a greater degree of disorder i.e. a gain in entropy due to the number of possible sites at which the vacancy may be located. This configurational entropy S is given by: S k ln W where k is the Boltzman constant and W is the number of possible configurations of locating n defects over N sites and is given by: W N! N n !n! Lectures co-financed by the European Union in scope of the European Social Fund The driving force behind defect formation is a lowering of the Gibbs’ free energy (G), where: G = H – TS Starting with the perfect crystal, the more defects created, the more energy required (H increases). The more defects created the greater the disorder (S increases). Initially TS >> H – ve G As more defects are created H increases, but disorder decreases and therefore the TS term becomes small. Later H >> TS + ve G Therefore no more defects are spontaneously created. Lectures co-financed by the European Union in scope of the European Social Fund The number of defects increases until G becomes +ve, corresponding to a minimum in the G curve. This is therefore the equilibrium defect concentration. At higher temperatures the TS term becomes larger and therefore we see a larger equilibrium defect concentration. Lectures co-financed by the European Union in scope of the European Social Fund Thus if the enthalpy of formation of a single defect is HF and the additional entropy associated with the addition of this defect is S. Then for n defects the change in free energy will be: G nH F T S nS ' The equilibrium defect concentration of defects ne corresponds to the minimum in the G curve and can be found by differentiating G with respect to n, i.e. dG/dn = 0 S' ne H exp exp F N ne kT k where N is the total number of atoms. Since ne << N: S' ne H exp exp F N kT k Lectures co-financed by the European Union in scope of the European Social Fund Non-Stoichiometric Defects Schottky defects in NaCl and Frenkel defects in AgCl are termed stoichiometric defects as they leave the stoichiometry of the crystal unchanged. The F-centre in NaCl is an example of a non-stoichiometric defect since the stoichiometry is changed with respect to the pure crystal. Another example of a non-stoichiometric defect occurs in wustite (FeO). This compound exhibits the rocksalt structure and like NaCl shows Schottky defects. However in this case: No of cation vacanies > No of anion vacancies i.e. a stoichiometry of Fe1-xO Electroneutrality is maintained by oxidation of Fe(II) to Fe(III) and so the formula may be more correctly written as: Fe(II)1- yFe(III)2y/3Vy/3O (y = x/3) Lectures co-financed by the European Union in scope of the European Social Fund Defect Notation The IUPAC accepted notation for defect formulae is the Kröger-Vink notation. Symbols are of the form: A c s A is the species and can be: an element symbol, e.g. Li e for electrons V for vacancy h for hole. C is the effective charge and can be: for an effective negative charge for an effective positive charge x for an effective neutral charge. S is the site of the species and can be: the element symbol for the atom that normally resides in that site, e.g. Li i for interstitial F.A. Kröger and H.J. Vink, in" Solid State Physics, vol. 3, editors: F. Seitz, D. Turnbull, p.273-301, (1956) Lectures co-financed by the European Union in scope of the European Social Fund Defect Equations An atom in its normal lattice site is assumed to be neutral. Vacancies and interstitials are assumed to have an effective charge. Similarly aliovalent substitution introduces an effective charge. As in normal chemical equations the charges should balance. e.g. Schottky defect in NaCl NaNax + ClClx VNa + VCl Frenkel defect in AgCl AgAgx Agi + VAg Solid solution formation in YSZ 2ZrZrx + OOx 2YZr + VO Lectures co-financed by the European Union in scope of the European Social Fund Defect Clusters Simple point defects i.e. interstitial/vacancies in some cases can cluster together in a solid to minimise energy. Consider a vacancy in a ccp metal. The energy of defect formation will involve contributions arising from breaking bonds. To place a second defect next to the first will involve lower energy since less bonds have to be broken. The difference in energy between two isolated defects and two paired defects is termed the binding enthalpy, HB: H F (pair ) 2 H F (isolated ) H B where HF is the enthalpy of formation. The number of vacancy pairs np is given by: 2 H F (isolated) H B n p exp kT Lectures co-financed by the European Union in scope of the European Social Fund Since: S' ne HF exp exp N kT k Then if ni is the number of isolated vacancies: ni2 HB q exp np N kT where q is factor dependent on the entropy of defect formation and the number of possible positions for the vacancy pair over N atom sites. The ratio of isolated vacancies and vacancy pairs at equilibrium is given by: S' 2 H F (isolated) H B n1 q exp exp n2 kT k This means that the number of vacancy pairs at equilibrium increases with increasing temperature. Lectures co-financed by the European Union in scope of the European Social Fund Defect Clusters in Ionic Conductors Defect clusters in ionic conductors can be important when considering possible conduction mechanisms: e.g. LISICON Lithium SuperIonic CONductor LISICON is a solid electrolyte, which shows high Li+ ion conductivity. It is a solid solution between Li4GeO4 and Li2ZnGeO4 and has a general formula: Li2+xZn1-xGeO4 Li2ZnGeO4 has hcp O2– ions with Li+, Zn2+ and Ge4+ in half of the available tetrahedral sites. The octahedral sites are vacant. As Li4GeO4 is introduced in the solid solution, some of the Li+ directly replaces Zn2+ on the tetrahedral sites. However, in order to maintain electroneutrality, extra Li+ is required, which enters the vacant octahedral sites. Lectures co-financed by the European Union in scope of the European Social Fund The octahedral sites share faces with filled tetrahedral sites. This is energetically unfavourable and so Li+ ions in the tetrahedral sites are displaced into vacant tetrahedra. This results in the formation of defect clusters Lectures co-financed by the European Union in scope of the European Social Fund Extended Defects We have seen how individual point defects can come together in crystalline solids to minimise free energy. Extended defects occur over much larger scales. These include: Crystallographic shear structures Stacking faults Antiphase grain boundaries Dislocations Low angle grain boundaries Lectures co-financed by the European Union in scope of the European Social Fund Crystallographic Shear Structures Crystallographic shear is the term given, when one or more parts of a structure are translated with respect to the remainder of the structure. This results in complex structures where the ideal structure may be limited to columns, blocks or layers separated by planes of different structure/composition. This type of structure is common in certain transition metal oxides that show variable oxidation state of the metal. e.g. MoO3 MoO3 exhibits the ReO3 type structure with corner sharing MoO6 octahedra. O:Mo ratio = 3 Lectures co-financed by the European Union in scope of the European Social Fund MoVI is readily reduced to lower oxidation states such as MoIV In partially reduced molybdenum oxides such as M9O26 the average oxidation state is 5.78. In this structure there is less oxygen per Mo: O:Mo = 2.889. This means that in order to maintain an octahedral geometry, some of the Mo octahedra must share edges. These are arranged in groups of four edge sharing octahedra which are distributed at regular intervals in the structure to give a shear plane. Ref: W.H. McCarroll, K.V. Ramanujachary, Encyclopaedia of Inorganic Chemistry, J. Wiley and Sons. Lectures co-financed by the European Union in scope of the European Social Fund This leaves the ReO3 type blocks separated from each other by the shear planes. In fact Mo9O26 is part of a homologous series of MonO3n-1 oxides (n = 8, 12-14). In all the ReO3 block extended infinitely in 2 dimensions, but their length in the third dimension varies with n. Similar series are seen in Ti oxides TinO2n-1 (n = 4 to 10) and Nb oxides. In H-Nb2O5 shear planes occur without change in oxidation state. A double shear occurs resulting in a very complex structure containing different size blocks of ReO3 units. Lectures co-financed by the European Union in scope of the European Social Fund Stacking Faults Stacking faults tend to occur in layered structures. Essentially these involve an interruption of the normal layer sequence. e.g. Co Co can crystallise in hcp or ccp forms. These forms differ only in their stacking sequence i.e. hcp ABABAB ccp ABCABC So for example stacking faults can occur in the hcp arrangement as: ABABACABAABABACABABAB Similarly in ccp metals a stacking fault can occur in the (111) plane. ABCABCBABCABCABCBABCABC Lectures co-financed by the European Union in scope of the European Social Fund Antiphase Boundaries Closely related to stacking faults are anitiphase boundaries. They involve a translation of one part of the structure to another such that like parts of the structure face each other across the antiphase boundary. Thus the periodicity changes phase from to -. Lectures co-financed by the European Union in scope of the European Social Fund Dislocations Dislocations occur where many individual point defects come together. They are created by thermal energy and rapid crystal growth. They can occur in all types of solid, but are very important in metals where they greatly affect their properties. There are two important classes: (1) Edge dislocations This is where a line of vacancies split a plane of atoms into two half-planes. Atoms are perturbed around the ends of the half-planes resulting in a stressed region. Lectures co-financed by the European Union in scope of the European Social Fund (2) Screw dislocations This is where an extra half plane of atoms becomes attached to the surface. The step eventually propagates on the surface resulting in a full step. It is called a screw dislocation because when viewed perpendicular to the step, the atoms appear to spiral through the crystal. Under applied stress or heat dislocations will migrate. This allows for the hardening and softening of metals. Lectures co-financed by the European Union in scope of the European Social Fund Berger’s Vector Dislocations are characterised by the Burger’s vector. e.g. Consider the atoms around a perfect part of a crystal Travelling from atom to atom a circuit of the perfect part of the crystal arrives at the starting atom in the upper plane In contrast a circuit around an edge dislocation arrives at a different atom in the upper plane. The Burger’s vector is defined as the vector between the starting atom and the last atom. Lectures co-financed by the European Union in scope of the European Social Fund Grain Boundaries Most materials are not single crystals, but polycrystalline, i.e. a mosaic of small crystals (crystallites) held together in a ‘jig-saw’ like pattern. The regions where the individual crystallites are held together are called grain boundaries. In some cases, there is a very small angle (1<<) between domains. The region separating the domains is called a sub-grain boundary. Lectures co-financed by the European Union in scope of the European Social Fund Low Angle Grain Boundaries Low angle grain boundaries can be formed by collections of dislocations. When several edge dislocations come together with the same orientation, the accumulated distortions caused in the lower planes results in a re-alignment of these lower planes at an angle to the upper planes. This is known as a low angle grain boundary. Grain boundaries act as barriers to movement of defects and dislocations. They are very important in ionic conductors where they can lower the total conductivity. Lectures co-financed by the European Union in scope of the European Social Fund Locking of dislocations Adding a second component can often lock or trap a defect or dislocation. Forming a solid solution can achieve this. For example this is used in steel manufacture where carbon or boron are added to iron. Lectures co-financed by the European Union in scope of the European Social Fund