TOC Measurement of Pharma Waters

advertisement

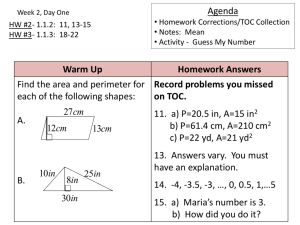

TOC MEASUREMENT OF PHARMA WATERS Sheesh Gulati Monitoring Total Organic Carbon in Pharmaceutical High-Purity Water Systems …How to Meet USP <643> and EP 2.2.44 TOC and USP <645> and EP 2.2.38 Conductivity Requirements TOC -- HISTORY • TOC analysis techniques were developed back in the 1960s as a means of better understanding the contents of potable water and also f a c t o r y w a s t e w a t e r . • As these waters typically contained high levels of TOC (up to 1,000PPM), the analysis techniques were not suitable f o r U l t r a P u r e Wa t e r. • With advances in technology , newer, more sophisticated methods of measuring TOC were developed . EVOLUTION OF TOC LIMITS PHARMACEUTICAL GRADE WATER USP Standard TOC Limit ppb (1998) Water for Injection 500 SEMICONDUCTOR GRADE WATER SEMI Guidelines 1992 ppb TOC attainable <1 ppb TOC acceptable <2 ppb TOC alert 5 ppb TOC critical 19 Introduction and Background • TOC is an acronym for total oxidisable carbon, more commonly referred to as total organic carbon. • Original laboratory TOC methods were developed to help correlate Chemical Oxygen Demand (COD) and Biological Oxygen Demand (BOD) in drinking and waste waters. • BOD test requires five days (5-day BOD) and provides little information for detecting fast changes or excursions of organics. Also the 5-day BOD test is totally manual and no official on-line method is available. • The COD test uses significant amounts of hazardous chemicals and mercury compounds. TOC Total organic carbon analysis is a determination of organic carbon in a sample regardless of its oxidation state or biodegradability. Other measures of total organic matter (e.g., COD, BOD) may respond differently to solutions of equal carbon concentration depending on the oxygen content or the bidegradation kinetics. Definition of Carbon in Water Sources of Total Organic Carbon • Organic carbon, especially at ppb levels, is pervasive in water purification systems. It is a very dynamic contaminant to measure, if not carefully controlled. – Feedwater - municipal, surface, and/or wells influenced by fertilizers, pesticides, vegetation, dumping of waste – The High-Purity Treatment Process - ion exchange resins, RO and filtration membranes, softeners, carbon beds, chemical additions – Distribution System - plumbing, pumps, valves, joints, fittings, storage tanks, biofilms, use points On Line & Off Line TOC • TOC can be measured both on- and off-line. Off-line measurements (laboratory methods) are typically used for high concentrations (>1 ppm). On-line measurements are typically used for sub-ppm (<1000ppb) detection and quicker response than the laboratory methods. Most industries particularly pharmaceutical and semiconductor manufacturing, now use on-line measurements due to the faster response which is required for process control. ON-LINE vs.LAB TOC • A debate has always existed concerning which is better, on-line analysis or laboratory testing. Today, many parameters that can affect the drug manufacturing process are being measured on-line. It is important to be able to develop trending information for these parameters in order to determine that the process is in control. On-line measurements can provide real-time data without having to wait for analytical results from the laboratory and help avoid major upsets in the manufacturing process. • As soon as you remove a high-purity water sample from its environment, the sample is no longer representative of the high-purity water in the system. On-line Methods Continuous data Real time data Trending information Low cost- ofownership No sample handling No sample contamination Measure in own environment data becomes valuable information for efficient operation of a water system Laboratory Methods infrequent results delayed data no trending information high cost-ofownership sample tracking protocols grab sample contamination measure foreign environments ISSUE Operating Personnel Required Sampling Personnel Required Auto Sampler Required Computer required for Operation PC required for Data Storage Sample Containers required Glassware Washers Required Syringes Required Oxidant required for operation Acid required for operation ON-LINE LABORATORY UNITS 0 0 No No No No No No No No 1 1 Yes Yes Yes Yes Yes Yes Yes Yes ON-LINE vs. LABORATORY TOC ANALYSERS Gas required for operation Sample Time Sampling Difficulty Sample Purging Required Transportation of sample required Quality of Data Measuring Purgeable Organics Minimum Measurable Range Weight Size Hot DI water Networkable No Few Seconds Automatic No No High Accurate 1 ppb Under 8 lbs. Compact Yes Yes Yes Several Minutes Difficult Yes Yes Low Not accurate 4 ppb 100 lbs. Large No No ON-LINE vs. LAB TOC Very similar to a movie with continuous frames, an on- line analyser does not miss a frame or a TOC excursion. However, a laboratory method is like a single frame (still) photograph that takes a "snapshot" of the system. With "snapshots", TOC excursions can be measured wrongly or may be missed completely. TOC analysers Components The two basic components of any TOC analyzer are: 1. The Oxidation Reactor, which converts the organic carbon in the water to CO2 gas, either by thermal, chemical or ultraviolet radiation. Oxidation efficiency, assuring complete conversion of the organic carbon to CO2, is critical. 2. The CO2 Detector, which measures the concentration of the CO2 gas generated in the oxidation chamber. This component is critical for precise analytical results, since it directly correlates to the organic carbon content of the analysed water. BASIC TOC ANALYZER The Oxidation Reactor For ultra-pure water analysis, two techniques are in common use: • High Temperature Catalytic Oxidation • UV Oxidation, with/without the addition of chemical reagents (persulphate) High Temperature Oxidation • This method uses a high temperature furnace into which a water sample is injected . The furnace normally contains a platinum or cobalt catalyst. The process oxidises all the carbon materials to CO2, the quantity of which is directly proportional to organics in the sample. The actual measurement is of Total Carbon (TC) • A later variation on this method is based on the use of two furnaces. A sample of water is equally divided and put into the furnace chambers, one at 150°C and the other at 950°C. The lower temperature furnace measures Organic Carbon (TIC), while the high temperature furnace measures Total Carbon (TC). The TOC can be calculated by subtracting the TIC value from the TC value i.e. TOC=TC-TIC. UV/Chemical Oxidation • This method offers a low maintenance, high sensitivity method but must demonstrate its efficiency to fully oxidise the organic carbon to CO2 in the particular application. • To compensate for oxidation limitations of some UV reactors, the addition of an oxidising reagent (usually a persulphate) aids in the conversion of the organic carbon to CO2 gas. • Limitations of this method include inaccuracies associated with the addition of any foreign substance into the analyte. “Blanking” of chemical additions help but still contribute error to the analysis in levels below 50 ppb TOC. DISADVANTAGES OF COMBUSTION & PERSULPHATE METHODS Each of the above mentioned methods has requirements of acids, reagents and gases. This adds to the complexity of measurement and also requires the skill of a trained person, normally a technician or scientist. In most cases the water sample must be removed from the DI plant, this making it susceptible to contamination. DISADVANTAGES OF COMBUSTION & PERSULPHATE METHODS Additional drawbacks of this technique are the routine maintenance required and frequent calibrations to maintain accurate results. With rare exceptions the methods that employ acidification and persulfate addition lose the volatile organics which can be significant contaminants in very low level TOC, high purity water systems. In general, operating costs are high especially as the reagents and gases have a finite shelf-life CO2 Detector Two basic methods are in common use: • CONDUCTIVITY AND • NON-DISPERSIVE INFRARED (NDIR) • THE CONDUCTIVITY method measures the conductivity of the sample before and after it is oxidised, attributing this differential measurement to the TOC of the sample. During the sample oxidisation phase, CO2 (directly related to the TOC in the sample) and other gases are formed. Definition of Pharmaceutical Water • The exercise was to address compendial waters: “any water intended for use in a final dosage form.” • Examples of compendial waters include: – – – – – – – – Water for Injection(s) (WFI) Bacteriostatic Water for Injection Sterile Water for Inhalation Sterile water for Injection Sterile Water for Irrigation Purified Water (PW) Highly Purified Water (EP only) Sterile Purified Water Bulk Water Packaged Water USP <643> TOC Method Requirements (1) • Nominal TOC limit of 500 ppb as determined by the Standard Solution results, or Limit Response • Instrument must completely oxidise the sample • Instrument detection limit of 50 ppb • On-line or laboratory test • Use a calibrated instrument • Perform a System Suitability test on a calibrated instrument with recovery levels of 85 -115% USP <643> TOC Method Requirements (2) Defining the commonly used terms in the <643> method: • Standard Solution (500 ppb C by sucrose RS) = rs • Standard Solution or Limit Response = rs - rw and establishes the PW & WFI pass/fail limit • Reagent Control Water = rw • System Suitability Solution (500 ppb C by 1,4-benzoquinone RS) = rss • System Suitability Solution response = rss - rw • Response Efficiency = [(rss - rw ) / (rs - rw)] x 100 What is System Suitability? • System suitability is not calibration! • System suitability is “the process of validating whether your system (i.e. TOC analyser) is acceptable for providing useful analytical data without any bias.” • This is typically done by: analysing a material that is easy-to-oxidise (sucrose) analysing a material that is difficult-tooxidise (1,4 -benzoquinone) calculating the ratio of the responses Frequency of System Suitability • • • • • • USP <643> specifies “periodically” and EP 2.2.44 specifies at “suitable intervals” ?? Water system dependent Instrument dependent Quality system and company protocol dependent Measure a validation check standard for verification of calibration Re-calibration suggests new system suitability Frequency of system suitability should be determined systematically, using historical data Meeting the USP <645> Conductivity Requirements There are 3 basic requirements that the conductivity equipment must meet: – “The conductivity cell constant… must be known within ±2%. – “The instrument must have a minimum resolution of 0.1 µS/cm…” – “…the instrument accuracy must be ±0.1 µS/cm.” Conductivity/Resistivity & Temperature Compensation • Typically high-purity water is specified as resistivity. M-cm = 1/µS/cm (temperature compensated) • Conductivity increases as a function of temperature. • Temperature compensation algorithms calculate what the conductivity would be at 25 °C • Pharmaceutical nomenclature is conductivity and <645> is temperature uncompensated. Common Locations for Online TOC Sensors • Supply – After the final purification component and prior to distribution to the use points • Return – After the use points as the water is recirculating to a storage tank • Before and after any storage tank • Before and after distillation • Before and after deionization • Before and after UV sterilizing or TOC destruct units • After reverse osmosis ON-LINE + OFF-LINE TOC ANALYZER Model DI 1000 ON-LINE + OFF-LINE TOC ANALYZER Model DI 1000 DI 1000 TOC analyzer is a patented product, it can detect total organic carbon (TOC) contained in the water, by calculating it from total inorganic carbon (TIC) and total carbon (TC). DI 1000 analyzer operation principle is to oxidize microorganisms by UV lamp and convert organic carbon into carbon dioxide. Then TOC analyzer adopts direct conductance method to detect the concentration of carbon dioxide and report. During testing procedure, TC and TIC are detected and TOC is equal to TC- TIC (TOC = TC-TIC) MODEL DI 1000 TOC ANALYZER • • • • • • • • • FEATURES: Low power consumption, no consumables. Professional design for highly purified water test, monitoring on line. Memory of the last six months' records automatically, able to look up the record for every day and print the test results. Test speed is fast and time of flushing piping is short. Small, light, portable and easy to move. Designed with buzzer alarm for upper limit. Easy to test according to USP. Large 320x234 color screen and personalized interface. RS232 digital interface and micro-printer interface. MODEL DI 1000 SPECIFICATIONS Power supply: 220V, 50Hz, AC Rated output: 100W Dimension: 44cmx18cmx26cm Measuring limit: 0.001mg/L Measuring range: 0.001mg/L ~ 1.000mg/L, also display in 1 to 1000 ppb Analysis time: 4min • Sample temperature: 1-95 deg C Sample flow rate: 0.5ml/min Mini Printer included Heat exchanger included