TOPSAW presentation - Louisiana State University

advertisement

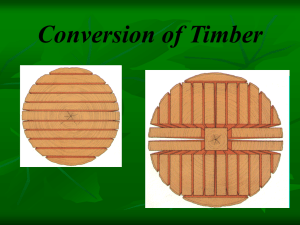

A Training and OPtimization System for Log SAWing Sun Joseph Chang School of Renewable Natural Resources Louisiana State University Agricultural Center Baton Rouge, LA 70803 Defect Identification on Cross-sectional Views Heart Rot ___________ Decay Inside a Knot Sap Wood ______I Sound Knot __________| Heart Check ____________________ Heart_______________ Wood Decay __________| Results of Replication of Log #3 Board Sawmill Results ID Board Size BF A1 6.25”x 12’ A2 TOPSAW Results Grade Value Board Size BF Grade Value 6 FAS $6.34 6.3”x 12’ 6 1C $3.72 10”x 12’ 10 1C $6.20 9.8”x 12’ 10 1C $6.20 A3 6.25”x 9.15’ 5 FAS $5.20 6.95”x 9.15’ 5 FAS $5.20 A4 8.25”x 12’ 8 FAS $8.32 8.4”x 12’ 12 FAS $8.32 A5 10.25”x 8’ 7 FAS $7.28 10”x 8’ 7 FAS $7.28 A6 5.25”x 12’ 5 SEL $4.00 6.2”x 12’ 6 SEL $4.80 A7 7.25”x 12’ 7 FAS $7.28 7.3”x 12’ 7 FAS $7.28 A8 6.75’x 12’ 7 F1F $6.93 7.2”x 12’ 7 F1F $6.93 A9 7.25”x12’ 7 1C $4.34 7.3”x 12’ 7 1C $4.34 7”x 6”x 12’ 42 NA $10.50 7”x 6”x 12’ 42 NA $10.50 Cant Total $66.29 $64.57 Details of the seven red oak logs scanned Log # Grade Large End Diameter (Inches) 1 1 17.50 Small End Diameter (Inches) 14.13 Length (Feet) 11.75 Board Feet (BF) 69 2 3 5 1 1 2 17.50 14.25 14.00 12.75 13.75 13.00 11.92 11.92 12.67 44 56 61 6 7 8 2 2 2 11.62 14.75 14.88 11.00 13.88 14.13 12.42 12.25 12.25 37 61 75 Comparison between sawmill and simulation results Comparison 1 Simulation Results Sawmill Results Percent Gain Comparison 2 Comparison 3 $479.05 $497.26 $356.62 $422.06 $422.06 $278.42 13.5% 17.8% 28.1% Challenges for the Internal Defect Based Sawing Optimization System • Hardware: A fast, more powerful, strong, durable, and low cost scanner • Software: A fast optimization software • With a fast solution algorithm and smart programming, a real time optimization software has been developed Optimal Cutting Sequence • Cut No. • • • • • • • • • Thickness (in inches) 1 2 3 4 5 6 7 8 9 4/4 5/4 6/4 8/4 6/4 6/4 5/4 6/4 4/4 Volume (in board feet) 6.5 12.9 17.4 26.0 20.0 18.8 14.3 13.4 5.4 Grade Value ($) 1C FAS 1C 1C 1C 1C FAS FAS 1C 4.00 12.77 14.09 21.73 16.26 15.21 15.54 15.31 3.31 » » Total Volume 134.8 BF Total Value $118.22 Results related to Log #3 • Sawmill production: $66.29 • TOPSAW replication: $64.57 • TOPSAW simulation: $91.32 (+ 37.8% over sawmill production) • TOPSAW optimization: $118.22 (+29.5% over simulation, +78.3% over sawmill production) A comparison between live sawing optimization and sawmill production • • • • • • • • • • Log Log 1 Log 2 Log 3 Log 5 Log 6 Log 7 Log 8 Live sawing Sawmill Optimization Production $92.35 $84.20 $94.97 $69.91 $118.22 $66.29 $100.48 $64.81 $74.25 $32.42 $45.23 $59.44 $63.23 $41.81 Average Gain 40.5% A Comparison between Live Sawing and Bi-directional Sawing Optimization • • • • • • • • • • Log Live Sawing Bi-directional Sawing Optimization Optimization Log 1 $92.35 $93.94 Log 2 $94.97 $107.7 Log 3 $118.22 $122.73 Log 5 $100.48 $107.9 Log 6 $74.25 $74.8 Log 7 $45.23 $53.6 Log 8 $63.23 $71.3 Average gain of bi-directional over live sawing 7.3% Why we need TOPSAW • Log cost accounts for about 60% of the hardwood lumber production cost based on the data of the 1997 Census of Manufactures State Cost of Value of log cost as a % Materials Shipments of shipments IN 119395 211461 0.56 KY 221508 391409 0.57 MO 148512 241356 0.62 OH 154080 260451 0.59 PA 432503 720675 0.60 WV 255149 422082 0.60 mean= 0.59 std= 0.02 • increasing log conversion efficiency, therefore, produces a significant gain in lumber revenue and mill profit • It holds the key to the competitive advantage in the future. Only the Paranoid survives • Our competitors also recognize that, particularly our Canadian friends up north. Only the Paranoid Survives • Canadian softwood sawmills already have an edge over their U.S. counterparts. • Despite a 27% import tariff, Canadian softwood sawmills can still undercut domestic producers in the US market. • In terms of hardwoods, over the last 10 years, US hardwood log exports doubled and Canada’s share of the export increased from 59% to 70%. As a result, more than ever US hardwood logs are sawn into lumber in Canada. • Forintek Canada has embarked on a sawing optimization project similar to TOPSAW to establish firmly the competitive edge for the Canadian hardwood sawmill industry. • It is time to establish a Hardwood Sawing Technology Center, make TOPSAW a reality, and regain the competitive edge. Hardwood Sawing Technology Center Goal: To commercialize TOPSAW in 3-4 years Objectives: 1. Develop a $5-600,000 per unit CT log scanner 2. Refine the optimization software 3. Develop a log set-up system to accurately and quickly orient and position the log for sawing • Cost over 4 years • With sawmill equipments $3.5 million • Without sawmill equipments $2.5 million TOPSAW Benefits Individual Sawmills Sawmill Industry Nation Consumers Increased Profit Strengthened Global Competitiveness Enhanced Resource Conservation Improved Lumber Quality