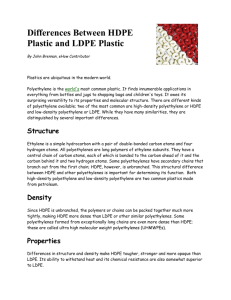

90º Peel Test

advertisement

3.042 Materials Project Laboratory Design Review Team No-Drip Tania Chan Michele Dufalla Jacqueline Greene 3.042 Materials Project Laboratory Design Review Team No-Drip Tania Chan Michele Dufalla Jacqueline Greene New Goal + http://www1.istockphoto.com/file_thumbview_approve/1168596/2/istockphoto_116859 6_plastic_can_container.jpg, http://www.baproducts.com/spigot.jpg Plastic Joining • • • • • • • • • • • • • • • • Fasteners Hinges Hot Die Fusion and Hot Wire/Resistance Welding Hot Gas Welding Induction/Electromagnetic Welding Press Fits/Shrink Fits Snap Fits Spin Welding Staking/Cold Forming Threads Ultrasonic Welding Vibration Welding Lasers Adhesives Solvents **List from Joining of Plastics by Jordan Rotheiser (2nd ed.) Plastic Joining • • • • • • • • • • • • • • • • Fasteners Hinges Hot Die Fusion and Hot Wire/Resistance Welding Hot Gas Welding Induction/Electromagnetic Welding Press Fits/Shrink Fits Snap Fits Spin Welding Staking/Cold Forming Threads Ultrasonic Welding Vibration Welding Lasers Adhesives Solvents **List from Joining of Plastics by Jordan Rotheiser (2nd ed.) Hot Plate Welding (from Joining of Plastics by Jordan Rotheiser (2nd ed.) HDPE vs. LDPE • Max Temp = 120°C • Melt Temp = 130°C • Max Temp = 80°C • Melt Temp = 120°C http://www.dynalabcorp.com/technical_info_hd_polyethylene.asp http://www.dynalabcorp.com/technical_info_ld_polyethylene.asp Method http://www.cooking.com/images/products/shprodde/743196.jpg, http://www.flagstaff.az.gov/images/pages/SC581/plastic%20bag.JPG Extrusion http://www.flagstaff.az.gov/images/pages/SC581/plastic%20bag.JPG http://www.midi-classics.com/i/p19228.gif Sample prep • Plastic (HDPE, LDPE) was cut in 1x6 in strips • Samples were welded together with a clothes iron, pressed together and allowed to cool at room temperature • Last week tested initial control samples of varying thicknesses, as well as ability of LDPE to bond with HDPE. 90º Peel Test INSTRON 1/16” LDPE 3x1 in contact area 1 in wide 1/8” HDPE Free-moving stage Shear Test 1/8” HDPE 4 layers of clear LDPE film (0.0006”) 1/8” HDPE 3x1 in contact area Results of Peel Test • 1/16 in LDPE was non-uniformly bonded to the 1/8 HDPE (due to greater thickness, more difficult to melt with iron) • Maximum Load: 0.020 kN • Could not test LDPE film:1/8 HDPE because strength of adhesion > than the tensile strength of LDPE which is 1700psi (22kN, http://www.mcmaster.com/) Results of Shear Test • The bond between the LDPE film and the 1/8 HDPE was greater than the tensile strength of the 1/8 HDPE! (4400psi / 30 MPa/ 58 kN, www.mcmaster.com). We could tell because the HDPE started necking rather than breaking the adhesive bond • Max load = 2.070 kN, Stress at Peak 55 MPa Shear Force 1/8 HDPE: LDPE film necking Immediate Next Steps… • Continue 90o Peel Test and Shear Test 3 Sets of Control Samples: 1/8” HDPE Substrate -White LDPE Film 1/16” HDPE Substrate 1/8” LDPE Substrate -White LDPE Film -Black LDPE Film -White LDPE Film -Black LDPE Film -1/16” LDPE Sheet -Black LDPE Film -1/16” LDPE Sheet -1/16” HDPE Sheet -1/16” LDPE Sheet -1/16” HDPE Sheet Goals of the Materials Testing Control Samples are Pure Polyethylene -no contaminations, impurities -effects of thickness, colors, processing temperature and material density on polyethylene adhesion Materials Testing Using Post-Consumer Polyethylene -ink, dye, processing agents -nonuniform density Ultimate Goal -Establish a range of temperature, pressure, time and processing condition optimal for polyethylene welding Design of the Tap Basic Pop Rivet Design to Attach Pinch Tube at the Lid of Jerrycans Design Considerations: – Simple design, reduce production and materials costs Materials Considerations: – Tube to be made from recycled polyethylene – Sealing between the flange and the containers surface Tube Production Continue with the idea of post-consumer polyethylene recycling – Melt plastic bags and extrude melt into tubes – Questions to be answered: • Is the process plausible? • How durable is the resultant products? • Can the procedure be done in the field? Tap Production and Plastic Welding • Plastic Welding Will Be Used to Attach Tap onto Jerrycans Lids • Using the welding parameters (temperature, time and processing conditions) to attach tube to containers • Challenges: – Tricky interface between tube and containers, how to apply plastic welding? – Is plastic welding a water proof seal? – Can plastic welding withstand the chlorination in the water? Revised Gantt Chart 2/6/07 2/16/07 2/26/07 3/8/07 3/18/07 3/28/07 4/7/07 4/17/07 4/27/07 5/7/07 5/17/07 Background Research Recycling Processing Cost Material Cost Target User Materials Economic Analysis Polyethylene Properties Research Polyethylene Recycling Research Plastic Welding Testings 90 Degree Peel Tests Shear Tests Production of Prototype #1 Extrusion of Plastic Tubes from Recycled Polyethylene Design of Prototype #1 on SolidWorks Designing Interface betw een Tab and Containers Testing Plastic Welding Adhesion between Tab and Container Production of Final Product Increase Efficiency and Decrease Cost of Production Troubleshoot Defects in Final Product Preparation for Final Presentation Completed Remaining