Experiment #4 Momentum Deficit Behind a Cylinder

advertisement

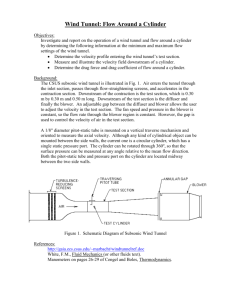

Experiment #5 Momentum Deficit Behind a Cylinder Problem Statement Water, 40 °F • Find the drag force on the rod located in a 2.0 mph 40 °F water stream • Use analogy with air flow normal to a model cylinder in a wind tunnel • Estimate the error in the drag force 2.0 mph 0.5” rod Available Major Equipment • 6 x 6 inch in cross section wind tunnel • Hot film anemometer to measure air speed • Model cylinder to place in the wind tunnel Approach • Measure the drag on a model cylinder in the wind tunnel • Use results from dimensional analysis to establish the conditions for similarity between the flow around the model and the prototype (the rod in the water stream) • Use the non-dimensional numbers derived from dimensional analysis to estimate the drag force on the rod • Estimate the error in the drag force on the model and the prototype Results from Dimensional Analysis (consult a fluids text) Drag Coefficient, CD, of a cylinder in cross-flow F D C f(Re), D 1 DwU2 1 2 where FD = drag force on the cylinder = air density D = cylinder diameter w = cylinder length U1 = approach velocity of air stream = kinematic viscosity of air Similarity between model and prototype requires that CDmodel = CDprototype= f(Remodel) = f(Reprototype) or that Remodel = Reprototype UD Re = 1 Equality of Reynolds Numbers implies equality of the Drag Coefficients Experimental Approach for the Drag Force • Estimate the Reynolds number for the prototype (rod in water), and compute the wind tunnel air speed necessary for similarity with the model cylinder – Note: account for the fact that the pressure in the wind tunnel is less than atmospheric • Find the drag force on the model cylinder from measurements carried out in the wind tunnel • Compute the model Reynolds number and Drag coefficient. – • Compare with the values from the previously shown CD vs. Re curve. Assuming similarity (check this) use the magnitude of the experimental drag coefficient on the model cylinder to find the drag force on the prototype stack Static pressure inside the wind tunnel • P1, V1 Po, Vo = 0 • • Use Bernoulli’s equation between points o (outside the tunnel) and 1 (inside the tunnel) Note that at point o the pressure is the atmospheric level, and that the velocity at point o is zero. Using the known wind tunnel speed, V1 find the pressure p1. Control Volume Force and Mass Balances ( = constant) Force balance L L -L -L m )U F w U U dy w u (y)u (y)dy (m D 2 3 4 1 1 1 2 Surface 1, rate of momentum in Surface 2,rate of momentum out Surfaces 3 and 4, rate of momentum out Mass balance -L -L -L -L m ) 0 w U dy w u (y)dy (m 2 3 4 1 Surface 1, rate of mass in Surface 1, rate of mass out Surfaces 3 and 4, rate of mass out Multiplying the second eq. by U1 and substituting in the first eq, results in: L F w u yU u ydy 1 D 2 L 2 Drag force on the Model Cylinder L F w u yU u ydy 1 D 2 L 2 • Measure the velocity profile U1 without the cylinder • Measure the velocity profile u2 with the cylinder at two location downstream from the cylinder • Compute FD for each of the two profiles using the experimental data (numerical integration needed) • Take the mean of the two FD values Drag force on the Rod in the Water 1 DwU2 F 1 prototype Dmodel 2 1 2 F C DwU Dprototype Dmodel 2 1 prototype 1 DwU2 1 model 2 Error Estimation Find the error in FD of the model assuming that the only measuring error is a ±1% in the measurement of velocity. Use the RSS method. (Consult your 650:350 Measurements Book) L F w u yU u ydy 1 D 2 L 2 Error in FD where 2 F FD D u u u u u2 U U F 2 D F L D w U 2u ydy u 2 L 1 2 1 and uu2 and uU1 are the ± errors in the velocity measurement. Use ±1% of measured values Numerical integration is needed to evaluate the integrals 1 1/2 2 F L D w u ydy U L 2 1 Error Estimation (continued) The error in the FD of the prototype rod is then found in a similar way from: 1 DwU2 F 1 Dmodel 2 prototype 1 2 DwU F C Dprototype Dmodel 2 1 prototype 1 DwU2 1 model 2 1/2 2 2 F F Dprototype u u Dprototype u U F F U F Dprototype Dmodel 1model Dmodel 1model F Dprototype F Dmodel DwU 2 1 prototype DwU 2 1 model 1 DwU 2 F 1 prototype Dprototype Dmodel 2 1 DwU 3 U 1model 1 model 4 F