Controlling Food Cost in Production

7

Controlling Food Cost in Production

Controlling Foodservice Costs

OH 7-2

Chapter Learning Objectives

Develop a food production chart.

Describe how a waste report helps control food costs.

Use a conversion factor to calculate a new yield for an existing recipe.

Determine a recipe’s yield and the number of portions it will produce.

OH 7-3

Monitoring Standards

Tasting foods regularly is one way to ensure standards are met. The use of standardized recipes is another.

OH 7-4

Food That Does Not Meet the Restaurant’s Standards

Should not be served

Should be salvaged (all or part), if possible

Should be discarded if not salvageable

Increase costs

Reduce profits

OH 7-5

Questions to Ask When Food

Fails to Meet Standards

Is the recipe clearly written?

Did the cook understand the recipe?

OH 7-6

Questions to Ask When Food

Fails to Meet Standards continued

Are ingredients used in the recipe clearly labeled?

Are the appropriate ingredients in the proper containers? (Do ingredients in containers match the containers’ labels?)

OH 7-6

OH 7-7

Determining Quantity to Produce

Accurate food production schedules are important because

Overproduction causes excessive leftovers and waste.

Underproduction causes production shortages and unhappy customers.

Both situations reduce profits!

Determining Quantity to Produce continued

OH 7-8

To maximize guest satisfaction, managers help their production staff know how much to prepare on the proper day and at the proper time.

OH 7-9

To Ensure Proper Production

Professional managers always use food production charts!

OH 7-10

Sample Production Chart

OH 7-11

Food Production Charts

Created by studying past sales (sales histories)

Generally, the best predictor of what guests will buy in the future is what they purchased in the past.

Created based upon management’s estimate of future sales

OH 7-12

When Using Production Charts

Prepare an estimate of the number of guests to be served.

Indicate the actual number of items to be produced.

Post the production chart where it can be seen easily.

OH 7-13

When Using Production Charts continued

Ensure the required standardized recipes are readily available.

Periodically check the actual recipe yield against that listed on the standardized recipe.

OH 7-14

Waste Reports

Critical to food cost control

Easily completed

Should be maintained for each shift

May indicate

Where training is needed

Production concerns that require attention

OH 7-15

Sample Waste Report

OH 7-16

Analysis of Waste Reports

Determine why each item had to be discarded.

Develop a strategy to prevent similar future losses.

Share findings with those who need to know.

OH 7-17

Recipe Conversions

Step 1 – Compute the conversion factor.

Desired yield

÷

Current recipe

= Conversion factor yield

OH 7-18

Recipe Conversions continued

Step 1 – Example

Current yield, fifty portions

Desired yield, forty portions

Desired yield

40 ÷ 50

= Conversion factor

= 0.80

OH 7-19

Recipe Conversions continued

Step 2 – Convert ingredients into units that can be easily multiplied or divided.

Convert weights to ounces.

Convert cups, pints, and quarts to fluid ounces.

OH 7-20

Recipe Conversions continued

Step 3 – Multiply each ingredient by the conversion factor.

Example

96 oz x 0.80

= 76.8 oz

OH 7-21

Recipe Conversions continued

Step 4 – Convert ingredient amounts back to normally used units.

Example

76.8 oz ÷ 8 oz = 9.6 c; or 2 qt, 1½ c

OH 7-22

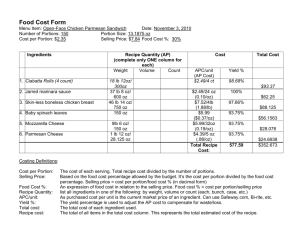

Recipe Yields

Recipe yields must be known.

Accurate costing of menu items is not possible without known and consistent yields from standardized recipes.

Effective production planning is also impossible without known recipe yields.

OH 7-23

Recipe Yields continued

To calculate a recipe yield, compute the total volume of the recipe by

Weight—for those recipes where portion size is determined by weight.

Volume—for those recipes where portion size is determined by volume.

OH 7-24

Calculating Recipe Yield

Weigh or measure only the major ingredients.

Account for cooking loss, especially for

Meats

Vegetables

Fruit

OH 7-25

How Would You Answer the Following Questions?

1.

2.

3.

4.

It (is/is not) possible for a cook using a standardized recipe to create a substandard menu item.

Waste reports indicate when employees overportion and waste food. (True/False)

How many steps does the recipe conversion process have?

A.

B.

Three

Four

C.

D.

Five

Six

A recipe (yield/portion conversion) test is a calculation of the number of portions produced by a standardized recipe.

OH 7-26

Key Term Review

Conversion factor

Food production chart

Recipe conversion

Recipe yield

Taste test

Waste report

OH 7-27

Chapter Learning Objectives—

What Did You Learn?

Develop a food production chart.

Describe how a waste report helps control food costs.

Use a conversion factor to calculate a new yield for an existing recipe.

Determine a recipe’s yield and the number of portions it will produce.