Plantwide control: Towards a systematic procedure

advertisement

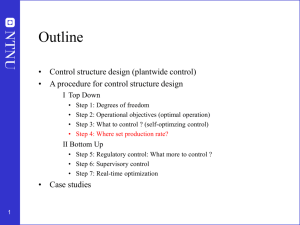

Plantwide control: Towards a systematic procedure Sigurd Skogestad Department of Chemical Engineering Norwegian University of Science and Tecnology (NTNU) Trondheim, Norway Based om: Plenary Presentation at ESCAPE’12, , May 2002 Updated: August 2002 (for use in Advanced process control) 1 • Alan Foss (“Critique of chemical process control theory”, AIChE Journal,1973): The central issue to be resolved ... is the determination of control system structure. Which variables should be measured, which inputs should be manipulated and which links should be made between the two sets? There is more than a suspicion that the work of a genius is needed here, for without it the control configuration problem will likely remain in a primitive, hazily stated and wholly unmanageable form. The gap is present indeed, but contrary to the views of many, it is the theoretician who must close it. • Carl Nett (1989): Minimize control system complexity subject to the achievement of accuracy specifications in the face of uncertainty. 2 Outline • Introduction • Plantwide control procedure – Top-down – Bottom-up • • • • 3 What to control I: Primary controlled variables Inventory control - where set production rate What to control II: Secondary controlled variables Decentralized versus multivariable control Related work • Page Buckley (1964) - Chapter on “Overall process control” (still industrial practice) • Alan Foss (1973) - control system structure • George Stephanopoulos and Manfred Morari (1980) • Bill Luyben and coworkers (1975- ) - “snowball effect” • Ruel Shinnar (1981- ) - “dominant variables” • Jim Douglas and Alex Zheng (Umass) (1985- ) • Jim Downs (1991) - Tennessee Eastman process • Larsson and Skogestad (2000): Review of plantwide control 4 Idealized view of control (“Ph.D. control”) 5 Practice I: Tennessee Eastman challenge problem (Downs, 1991) 6 Practice II: Typical P&ID diagram (PID control) 7 Practice III: Hierarchical structure 8 Plantwide control • Not the tuning and behavior of each control loop, • But rather the control philosophy of the overall plant with emphasis on the structural decisions: – – – – Selection of controlled variables (“outputs”) Selection of manipulated variables (“inputs”) Selection of (extra) measurements Selection of control configuration (structure of overall controller that interconnects the controlled, manipulated and measured variables) – Selection of controller type (PID, decoupler, MPC etc.). • That is: All the decisions made before we get to “Ph.D” control 9 Stepwise procedure plantwide control I. TOP-DOWN Step 1. DEFN. OF OPERATIONAL OBJECTIVES Step 2. MANIPULATED VARIABLES and DEGREE OF FREEDOM ANALYSIS Step 3. WHAT TO CONTROL? (primary variables) Step 4. PRODUCTION RATE 10 II. BOTTOM-UP (structure control system): Step 5. REGULATORY CONTROL LAYER 5.1 Stabilization (including level control) 5.2 Local disturbance rejection (inner cascades) What more to control? (secondary variables) Step 6. SUPERVISORY CONTROL LAYER Decentralized or multivariable control (MPC)? Pairing? Step 7. OPTIMIZATION LAYER (RTO) 11 I. Top-down • Step 1: Define operational objectives • Step 2: Identify degrees of freedom • Step 3: Identify primary controlled variables (look for selfoptimizing variables) • Step 4: Determine where to set the production rate 12 Step 2. Manipulated variables and DOFs Manipulated variables: • Usually given by design (“valves”) Degrees of freedom (DOFs): • Nm : no. of dynamic (control) DOFs (valves) • Nss = Nm- N0 : steady-state DOFs • N0 : liquid levels with no steady-state effect (N0y)+ purely dynamic control DOFs (N0m) • Cost J depends normally only on steady-state DOFs 13 Table 2. Typical number of steady-state degrees of freedom for some process units • • • • • • • • • 14 each external feedstream: 1 (feedrate) splitter: n-1 (split fractions) where n is the number of exit streams mixer: 0 compressor, turbine, pump: 1 (work) adiabatic flash tank: 1 (0 with fixed pressure) liquid phase reactor: 1 (volume) gas phase reactor: 1 (0 with fixed pressure) heat exchanger: 1 (duty or net area) distillation column excluding heat exchangers: 1 (0 with fixed pressure) + number of sidestreams ……. • Check that there are enough manipulated variables (DOFs) - both dynamically and at steady-state (step 2) • Otherwise: Need to add equipment – extra heat exchanger – bypass – surge tank 15 Distillation column with given feed Nm = 5, N0y = 2, Nss = 5 - 2 = 3 (2 with given pressure) 16 Heat-integrated distillation process Nm = 11 (w/feed), N0y = 4 (levels), Nss = 11 – 4 = 7 17 Heat exchanger with bypasses CW Nm = 3, N0m = 2 (of 3), Nss = 3 – 2 = 1 18 Alternatives structures for optimizing control Step 3: What should we control? 19 Step 3. What should we control? (primary controlled variables) • Intuition: “Dominant variables” (Shinnar) • Systematic: Define cost J and minimize w.r.t. DOFs – Control active constraints (constant setpoint is optimal) – Remaining DOFs: Control variables c for which constant setpoints give small (economic) loss Loss = J - Jopt(d) when disturbances d occurs 20 Loss with constant setpoints 21 Self-optimizing control (Skogestad, 2000) Loss L = J - Jopt (d) Self-optimizing control is achieved when a constant setpoint policy results in an acceptable loss L (without the need to reoptimize when disturbances occur) 22 Effect of implementation error on cost 23 Tennessee Eastman plant J Oopss.. bends backwards c = Purge rate Nominal optimum setpoint is infeasible with disturbance 2 Conclusion: Do not use purge rate as controlled variable 24 Example sharp optimum. High-purity distillation : c = Temperature top of column Ttop Water (L) - acetic acid (H) Max 100 ppm acetic acid 100% water: 100 C 99.99 % water: 100.01C Temperature 25 Procedure for selecting (primary) controlled variables (Skogestad, 2000) • • • • • • • Step 3.1 Determine DOFs for optimization Step 3.2 Definition of optimal operation J (cost and constraints) Step 3.3 Identification of important disturbances Step 3.4 Optimization (nominally and with disturbances) Step 3.5 Identification of candidate controlled variables Step 3.6 Evaluation of loss with constant setpoints for alternative controlled variables Step 3.7 Evaluation and selection (including controllability analysis) Case studies: Tenneessee-Eastman, Propane-propylene splitter, recycle process, heat-integrated distillation 26 Application: Recycle process J = V (minimize energy) 5 4 1 Given feedrate F0 and column pressure: Nm = 5 N0y = 2 Nss = 5 - 2 = 3 27 2 3 Recycle process: Selection of controlled variables • • • • Step 3.1 DOFs for optimization: Nss = 3 Step 3.2 J=V (minimize energy with given feed) Step 3.3 Most important disturbance: Feedrate F0 Step 3.4 Optimization: Constraints on Mr and xB always active (so Luybens structure is not optimal) • • 28 Step 3.5 1 DOF left, candidate controlled variables: F, D, L, xD, ... Step 3.6 Loss with constant setpoints. Good: xD, L/F. Poor: F, D, L Recycle process: Loss with constant setpoint, cs Large loss with c = F (Luyben rule) Negligible loss with c = L/F 29 Recycle process: Proposed control structure for case with J = V (minimize energy) Active constraint Mr = Mrmax Active constraint xB = xBmin 30 Recycle systems: Do not recommend Luyben’s rule of fixing a flow in each recycle loop (even to avoid “snowballing”) 31 Good candidate controlled variables c (for self-optimizing control) Requirements: • The optimal value of c should be insensitive to disturbances • c should be easy to measure and control • The value of c should be sensitive to changes in the steady-state degrees of freedom (Equivalently, J as a function of c should be flat) • For cases with more than one unconstrained degrees of freedom, the selected controlled variables should be independent. Singular value rule (Skogestad and Postlethwaite, 1996): Look for variables that maximize the minimum singular value of the appropriately scaled steady-state gain matrix G from u to c 32 Step 4. Where set production rate? • • • • 33 Very important! Determines structure of remaining inventory (level) control system Set production rate at (dynamic) bottleneck Link between Top-down and Bottom-up parts Production rate set at inlet : Inventory control in direction of flow 34 Production rate set at outlet: Inventory control opposite flow 35 Production rate set inside process 36 Definition of bottleneck A unit (or more precisely, an extensive variable E within this unit) is a bottleneck (with respect to the flow F) if - With the flow F as a degree of freedom, the variable E is optimally at its maximum constraint (i.e., E= Emax at the optimum) - The flow F is increased by increasing this constraint (i.e., dF/dEmax > 0 at the optimum). A variable E is a dynamic( control) bottleneck if in addition - The optimal value of E is unconstrained when F is fixed at a sufficiently low value Otherwise E is a steady-state (design) bottleneck. 37 Reactor-recycle process: Given feedrate with production rate set at inlet 38 Reactor-recycle process: Reconfiguration required when reach bottleneck (max. vapor rate in column) MAX 39 Reactor-recycle process: Given feedrate with production rate set at bottleneck (column) F0s 40 II. Bottom-up • Determine secondary controlled variables and structure (configuration) of control system (pairing) • A good control configuration is insensitive to parameter changes 41 Step 5. Regulatory control layer • Purpose: “Stabilize” the plant using local SISO PID controllers to enable manual operation (by operators) • Main structural issues: • What more should we control? (secondary cv’s, y2) • Pairing with manipulated variables (mv’s) y1 = c y2 = ? 42 Selection of secondary controlled variables (y2) • The variable is easy to measure and control • For stabilization: Unstable mode is “quickly” detected in the measurement (Tool: pole vector analysis) • For local disturbance rejection: The variable is located “close” to an important disturbance (Tool: partial control analysis). 43 Partial control Primary controlled variable y1 = c (supervisory control layer) Local control of y2 using u2 (regulatory control layer) Setpoint y2s : new DOF for supervisory control y1 = P1 u1 + Pr1 (y2s-n2) + Pd1 d P1 = G11 – G12 G22-1 G21 Pd1 = Gd1 – G12 G22-1 Gd2 - WANT SMALL Pr1 = G12 G22-1 44 Step 6. Supervisory control layer • Purpose: Keep primary controlled outputs c=y1 at optimal setpoints cs • Degrees of freedom: Setpoints y2s in reg.control layer • Main structural issue: Decentralized or multivariable? 45 Decentralized control (single-loop controllers) Use for: Noninteracting process and no change in active constraints + Tuning may be done on-line + No or minimal model requirements + Easy to fix and change - Need to determine pairing - Performance loss compared to multivariable control - Complicated logic required for reconfiguration when active constraints move 46 Multivariable control (with explicit constraint handling - MPC) Use for: Interacting process and changes in active constraints + Easy handling of feedforward control + Easy handling of changing constraints • no need for logic • smooth transition - 47 Requires multivariable dynamic model Tuning may be difficult Less transparent “Everything goes down at the same time” Step 7. Optimization layer (RTO) • Purpose: Identify active constraints and compute optimal setpoints (to be implemented by supervisory control layer) • Main structural issue: Do we need RTO? (or is process selfoptimizing) 48 Conclusion Procedure plantwide control: I. Top-down analysis to identify degrees of freedom and primary controlled variables (look for self-optimizing variables) II. Bottom-up analysis to determine secondary controlled variables and structure of control system (pairing). 49 References • • • • • • Skogestad, S. (2000), “Plantwide control -towards a systematic procedure”, Proc. ESCAPE’12 Symposium, Haag, Netherlands, May 2002. Larsson, T., 2000. Studies on plantwide control, Ph.D. Thesis, Norwegian University of Science and Technology, Trondheim. Larsson, T. and S. Skogestad, 2000, “Plantwide control: A review and a new design procedure”, Modeling, Identification and Control, 21, 209-240. Larsson, T., K. Hestetun, E. Hovland and S. Skogestad, 2001, “Self-optimizing control of a large-scale plant: The Tennessee Eastman process’’, Ind.Eng.Chem.Res., 40, 4889-4901. Larsson, T., M.S. Govatsmark, S. Skogestad and C.C. Yu, 2002, “Control of reactor, separator and recycle process’’, Submitted to Ind.Eng.Chem.Res. Skogestad, S. (2000). “Plantwide control: The search for the self-optimizing control structure”. J. Proc. Control 10, 487-507. See also the home page of S. Skogestad: http://www.chembio.ntnu.no/users/skoge/ 50