Pipe clamp - Teacher guide

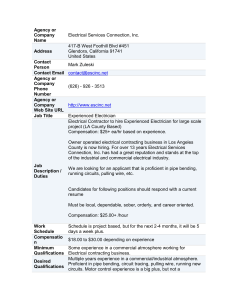

advertisement

The pipe clamp – teacher guide Abstract How can you install a doorway pull-up bar? A simple and common way to do this is to use pipe clamps. But how are pipe clamps produced? In this task, students not only think about this question - they actually produce their own pipe clamp. Which group of students is able to produce a pipe clamp exact enough to secure the pull-up bar in a doorway? Discipline: Mathematics/mechanical engineering Duration: 4 lessons Target Group: lower secondary school Age range: 11 - 15 WoW context: Mechanical engineering Use the PowerPoint presentation ‘Introduction’ to give your students a general idea of the task. Then show them a pipe clamp. Student task: You want to install a pull-up bar with a diameter of 37mm between two doorposts and plan to secure the bar with two pipe clamps. Make your own pipe clamps out of 1mm thick sheet metal. The difficulty is: once you have bent the sheet metal, you can no longer cut it. This means you have to calculate the total length of the strip of sheet metal needed in advance. Proceed with this task just like a real mechanical engineer would: First, prepare a sketch that includes all the specifications and then make a prototype. Prepare a presentation for your classmates that includes your sketch, work process steps and results. Calculating the flat length (length before bending): For classes with younger students, you could ignore some parts of the task, for example, the bending radii of the 90° angle and/or the observation of the neutral fibres. With older students, you can deepen the task by having the class include other aspects (such as those described in the background information). Further, you could have students consider the aspect of metal extension in the bending process, i. e. the so-called bending allowance. Students can look up the bending allowance on a table und include it in their calculations. Author: mascil team Freiburg, Germany in cooperation with SSS Siedle company CC BY-SA mascil consortium 2014 The mascil project has received funding from the European Union’s Seventh Framework Programme for research, technological development and demonstration under grant agreement no 320 693 Equipment: 3 vices 3 bending cylinders (37mm circumference) 3 rectangular bending blocks (2.5mm radius) Note: You can order the bending forms from, for example, the German company Siedle. 3 plastic-faced hammers (you can order these online) paper strips, carton strips pieces of flexible (sheet) metal circa 2cm wide and 20 cm long, and non-flexible metal (1mm thick, 2cm wide) Note: They can be purchased, for example, at a construction supply shop. Lesson plan example: 15 min Acquaint your students with the task by using the PowerPoint presentation ‘Introduction’. Then give your students the worksheet to look at so they have the actual task in front of them. 30 min Students work in groups to try to find out the exact flat length of the sheet metal. To do this, provide them with strips of paper, carton and flexible metal. Students should show the results of their planning stage to the instructor. The instructor must give their okay before students begin making the actual product. 30 min Students make their prototype and when doing so, can use the instructions for bending a pipe clamp found on the back of their worksheet. Alternatively, let students watch the PowerPoint presentation about the procedure for producing a pipe clamp. 15 min A feedback session in the form of a plenary includes desired improvements and suggestions for achieving the optimal product. 30 min Students produce their pipe clamps. 15 min Groups prepare their presentations. 45 min In a plenary session, students present their flat length calculations and pipe clamps. Author: mascil team Freiburg, Germany in cooperation with SSS Siedle company CC BY-SA mascil consortium 2014 The mascil project has received funding from the European Union’s Seventh Framework Programme for research, technological development and demonstration under grant agreement no 320 693