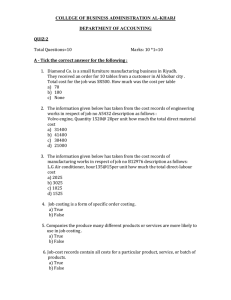

A History of the Allocation of Common Costs in France between

advertisement