Measuring Level

advertisement

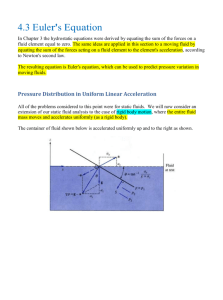

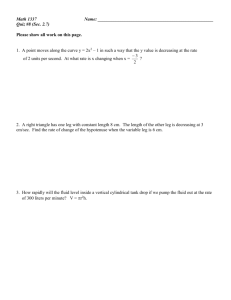

ACADs (08-006) Covered 5.4.1.7 Keywords Calibrate, direct, inferred, transmitter calibration, gravity correction, density correction, hydrostatic head detector, float. Description Supporting Material Measuring Level Terminal Objective: Given the appropriate equipment and procedures the I&C Technician will calibrate and maintain level instrumentation. Mastery will be demonstrated by successful completion of Lab Performance Exercises and written Exam. • Contrast direct and inferred methods of measuring level, giving an example of each • Describe the theory of operation of a given level measuring device • Given an example of a hydrostatic head detector, calculate the transmitter calibration input pressure for a dry reference leg system using specific gravity and density corrections • Given an example of a hydrostatic head detector, calculate the transmitter calibration input pressure for a dry reference leg with zero suppression • Given an example of a hydrostatic head detector, calculate the transmitter calibration input pressure for a wet reference leg system Direct versus Indirect • Direct: Level is measured by direct contact with the fluid surface. Either the fluid surface is visible to be compared directly to a scale, or direct contact is made with the fluid surface. • Indirect: Level is inferred by means other than direct contact with the Fluid surface. Fluid level is inferred by its effect on some type of device. Classify as Direct or Indirect • • • • • • Dipstick Float Sightglass Float & chain Bubbler tube Capacitance • Pressure or DP transmitter • Ultrasonic • HJTC • Warrick Conductivity Level • Magnetrol Ways to measure level • • • • • • • • • • • • Antenna level sensor Bubbler Capacitance probe Conductivity probe Diaphragm detector Differential Pressure Dipstick Displacer Float Impedance probe Level gauge Magnetic Follower • • • • • • • • • Optical level Radiation level sensor Resistance tapes Rotating paddles Sightglass Slip tubes Tape level devices Thermal level sensor Time domain reflectometry • Ultrasonic level detectors • Vibrating reed switches Considerations in level measurement • • • • • • • • Atmospheric vs. pressurized vessel Conductive vs. non-conductive fluid Temperature, specific gravity of the fluid Turbulance, foam, fog, dust, or a mixed layer at fluid surface Open flow channels Head correction, range suppression or elevation Mixed fluids, fluid boundaries, slurries, solids Continuous monitoring or point level detection Dipstick Dipsticks Pneumatic Dipstick • Combines a dipstick and a bubbler tube Float & mechanical linkage Archimides Principle • A body wholly or partly immersed in a fluid is buoyed up with a force equal to the weight of the fluid displace by the body What is the difference between a float and a displacer? Chain Float Bubbler Tube Capacitive-Type Transducers Measuring level with pressure differential Reference to Atmosphere Level Instruments Calculating Dry Reference Leg Calibration Values Calculate zero and span calibration values for the following example: • Vented tank (at atmospheric pressure) • The tank is full when it has 12’ of water at room temperature • Pressure tap located 2’ above the bottom of the tank • Transmitter 2’ below the bottom of the tank Dry Leg Level Instrument Calculating Dry Reference Leg Calibration Values Calculate zero and span calibration values for the following example: • Tank pressurized with 2 psi Nitrogen • The tank is full when it has 30’ of water at room temperature • Pressure tap located 1’ above the bottom of the tank • Transmitter 4’ below the bottom of the tank Wet Reference Leg Level Instrument Specific Gravity Water in our pressurizer is xxx degrees but the water in the reference leg is only xxx degrees. How does this effect differential pressure seen at the level transmitter? Compare indicated to actual level. What can be done to compensate? Wet Reference Leg Calibration Factors • • • • • Tank level Reference leg level Specific Gravity Pressure Temperature • The ASME steam tables can be used to determine specific gravity for pure water or steam • http://www.higgins.ucdavis.edu/webMathematica/ MSP/Examples/SteamTable Pressure = H x Sg x D • H = height of fluid column • Sg = Specific Gravity of the fluid • D = Density Calculating Wet Reference Leg Calibration Values Calculate zero and span calibration values for the following example: • Tank pressurized at 2250 pounds with 800 degree F water and steam mixture • The tank is full when it has 40’ of water at 800o F • The tank is empty when it has 12’ of water • Pressure tap located 1’ above the bottom of the tank • Transmitter 8’ below the bottom of the tank Ultrasonic Level Measurement How does it work? • Ultrasonic sound waves are pulsed from the transducer about 3 times per second • The sound waves reflect against the process medium and return to the transducer • The microprocessor based electronics measure the time of flight between sound generation and receipt • This time is translated into the distance between the transducer and the process medium below Conductivity Probe Method Capacitance Level Sensor • Also called RF level sensors • Uses the process material as the dielectric of a capacitor • As the dielectric (level) changes, capacitance changes • This change (picofarads) is conveted to a level signal. • We use these on RCP oil levels. Radar Level Instruments • Sometimes called microwave • Similar to ultrasonic, but uses 1MHz+ RF • Can be used in high temperature steam environments (FW heaters) • Mist, steam, dust and foam can be ignored • Non-contact surface level measurement • Low power (2 wire) On to Flow Measurement