Design Process - Mechanical & Materials Engineering

Design process is a collection of procedures and habits that help teams design better products

Designing is the process of making many decisions that converts a need into a hardware reality.

Need Product

1.

Product Design Specifications ( PDS )

2.

External Search ( Research )

3.

Internal Search ( Brainstorming )

4.

Concept Evaluation and Selection

5.

Detail Design ( Engineering )

6.

Prototyping and Testing

7.

Documentation

Step

Product Design Specifications

External Search ( Research )

Outcome

PDS Document

List of existing related products and technologies

Internal Search ( Brainstorming ) A lot of solution ideas

Concept Evaluation / Selection Pros and Cons / Decision Matrix

Selection of one idea to implement

Detail Design ( Engineering ) Determination of all details needed to build the product

Prototyping and Testing

Documentation

Comparisons to PDS target

Improvement recommendations

Final Design Report

BOM + Production Drawings

All other reports

Nail Driver

Rope Climber

Climbs fast

Affordable as a birthday present

Fully assembled

Uses batteries for power

No small parts – is safe

Looks good

Plays music as it climbs

Glows in the dark

Lasts a long time

Would not violate any patents

START

Slow

Patents

No Glow

Silent

Expensive

Unsafe Indoors Only

Battery

Life

Desired Boundary

Retail < $45

Acceptable Boundary

Retail < $50

High Priority

Plays Music

Low Priority

Glow in the dark

Cannot be taken apart

Has no small parts or sharp edges

Only to be used indoors

It is light and compact

Does not use toxic materials

Fits into a small box for shipping

Has attractive packaging

Design and testing finished in 4 months

Quantity 1 Million

Climbs at 1 ft/s or faster

Retail cost is to be less than $45

Uses 2 AA batteries

Has 0 removable small parts

Music loudness between 20-30 db

Luminosity is to be more than 5 C

Works for minimum 3 hours on 2 AA

Level-I

◦

Rope climbing toys / machines

◦

Rope climbers (sports or circus)

◦

Nature (spiders, bats, etc)

Level-II (friction wheels selected)

Hoists

Trolleys

Ski Lifts

Brainstorming

◦

Generate many ideas

◦

Evaluate against PDS

◦

Evaluate risks

◦

Select one to engineer

More Abstract

Lift and Drag Coefficients

(as effected by ground promimity)

0.35

0.3

0.25

0.2

0.15

0.1

0.05

0

0 0.05

h/L

0.1

0.15

Drag Coefficient

Lift Coefficient

Engineering Less Abstract

Applies to Top-level decisions

Applies to lower levels decisions

◦ Define requirements

◦ Search for existing ideas/technologies

◦ Brainstorm for solutions

◦ Pick a candidate

◦ Determine the details

Candidate Design

Detail Design

Prototyping

Release for Production

PDS

Concept Synthesis

Concept Evaluation

Candidate Design

Candidate Design

Components

No Numbers

System-Level Design

Numbers Parameter Design

Prototype Testing

Release for Production

Complexities of Developing a PDS

Document

• Level-I:

– Goal is clear, “Design a X to do Y”

– specifications are known,

– priorities are known,

– no mass production concerns,

– IP issues not important,

– limited customer base

– Example: one-of-a-kind equipment.

Complexities of Developing a PDS

Document

• Level-II:

– Goal is specific “Design a X to do Y”,

– Specifications are unknown,

– Priorities are unknown,

– Mass production concerns,

– IP issues are important,

– expanded customer base

– Example: Most consumer products

Complexities of Developing a PDS

Document

• Level-III:

– Goal is unclear, “Design ? To do ?

– There is a general statement of need

– Not easy to get to: “Design X to do Y”

– Example: Oceans are rising

People who define the PDS

People who influence product success

People you cannot ignore

Globe

(External)

Team

Company

(Internal)

A successful product:

1) Sells well and makes a lot of profit

2) Would not violate any laws/regulations

What about:

◦ Safer than law requires?

◦ Solves some problems of humanity?

◦ Is green (energy efficient, recycles, etc)?

◦ Lasts more than warranty period?

◦ Perform better than required?

Only when they relate to 1) or 2)

Customers

The design team and its members are not customers

Every PDS statement must be associated with at least one customer

Internal customers are within the organization (management, marketing)

External customers are outside the organization(end users)

Retailer

Maintenance

Society

(Marketing)

EXTERNAL

Company

Buyers

End

Users

Government

&

Standards

Manufacturing

&

Procurement

Marketing

Legal

Internal

Management

Shipping

Packaging

What Do They Want?

• End users want

– Performance & Functionality

– Affordability

– Ease of use including ergonomics

– Reliability and Long life

– Robustness

– Versatility

– Safety

– Low maintenance and easy assembly

– Esthetics

External Customers

• Buying managers want

– Low Cost/Performance

– Safety

– Ruggedness ( abuse resistance )

– Ergonomics

– Long warrantees

– Reliable with Low downtime

– Low operating cost

External Customers

• Retailers want

– Small and attractive packaging

– Long shelf life

– Low cost high profit

– Exciting features

• Maintenance wants

– Ease of maintenance

– Low cost of maintenance

External Customers

• Government wants

– Conformance to laws and regulations

• Standards want

– Conformance to industry standards

– Conformance to codes

Internal Customers

• Management wants

– Make $$$

– On time delivery

– Low risk of financial failure

– Proper Documentation

– Process: Conformance to company product development process

Internal Customers

• Marketing wants

– Attractive features to target buyers

– Low retail price

– Esthetics

– Attractive packaging

– Ease of user assembly/maintenance

– On time delivery

– Long Warrantees

Internal Customers

• Manufacturing / Purchasing want

– Available materials

– Manufacture-able at low cost.

– Conformance to company documentation formats.

– Use of products from preferred vendors.

Internal Customers

• Legal wants

– No patent infringements

– Safety

• All required safety warnings and labels

• Protection against reasonable abuse

• Safety manual

– Conformance to laws and regulations

Internal Customers

• Shipping and Packaging

– Small (standard) package sizes

– Ability of locking or fixing sensitive components

– Resistance against damage due to dropping, vibrations, moisture, heat, and cold.

Product Design

Specification

• Is this a PDS item?

– Is there a customer associated with it?

– Does the information limit the design selections and choices?

– Can the requirement be designed into the product?

• High resale value

• Win a Prize

Product Design

Specification

• Elements of PDS

– Performance

(Primary customer: End User)

• Speed,

• Capacity,

• Power,

• Efficiency,

• Accuracy,

• Return on investment

• etc.

Elements of PDS

– Environment:

(User)

• Temperature range, rain, humidity, dust.

– Life in service:

(User

)

• 10 years, 5000 cycles, etc.

– Maintenance:

(User)

• The market policy, what customers accept

– Retail/Production cost:

(User)

• Consistent with comparable products

• Rule of thumb 4:1

Elements of PDS

• Shipping/packaging:

– Package sizes + Weights

– Damage resistance

Elements of PDS

• Quantity

(Marketing)

– Determined by marketing

• Manufacturing facility

(Management)

– Does the company policy dictate certain facilities?

Element of PDS

• Size and shape

(Marketing)

• Weight

(Marketing)

– What is the desired weight?

– Handles for lifting points?

– Modular?

• Aesthetics

(Marketing)

– Color, shape, form, texture, finish.

– Market research.

Elements of PDS

• Materials

(Marketing, Codes, Regulations)

– Left to designers unless company guidelines or regulations restrict certain materials (asbestos, lead).

• Product life span

(Marketing)

– Designed life

Elements of PDS

• Laws, Codes, and standards

(Government)

• Ergonomics

(User + Marketing + buyers)

Elements of PDS

• Quality and reliability

(Marketing)

– Company policy regarding warranties

– Failure rate during warrantee period

• Testing

(Marketing)

– Tests to perform to verify performance and other PDS requirements

– Industry standard tests

Elements of PDS

• Shelf life (storage) -

Retail

– Possibility of rust, decay, deterioration

• Processes

(Mangement)

– Conformance to certain standards

(GD&T or ISO 9000 for example)

– Use of company procedures

• Time-scales (deadlines) -

Management

– Whole design project, milestones

Elements of PDS

• Safety

(User, Government, Legal)

– Safety requirements mandated by government

– Professional society's codes and standards

– Need for warning labels

– Design against acceptable degrees of abuse

Elements of PDS

• Company constraints

(Management)

– Compatibility with other products

• Documentation

(Management – Legal)

– Full documentation (Guard against possible litigation)

– Safety, Operation, and Service documents.

Elements of PDS

• Legal

(Lawyers)

– Product liability law suits associated with similar products and why.

– Relevant patents

Element of PDS

• Installation

(Installers)

– Connection geometry.

– Various models to install

• Disposal

(Marketing)

– Recyclable?

– bio-degradable?

– Green

Other Element of PDS

• Other possible PDS items to include

– Rugged

– Easy to use

– Reliable

– Quiet

– Portable

– Source of energy

Before you Interview

Sponsors

• Prepare your questions (PDS)

• Let them do most of the talking

• Take notes

• Ask for clarification

• Do not be annoying

(you can always ask more questions later if deemed important)

Wording of the PDS

Document

• Format of most statements in PDS:

– The device must ……..

– The device is to ……

– The device is desired to ….

• Avoid mixing requirements.

– One sentence per requirement.

• Cast PDS statements in a positive format

PDS is a Dynamic

Document

• A design statement usually begins as a vague statement

– The device is to be easy to use

– The device is to be safe

– The device is to be inexpensive

– The device is to be rugged and reliable

– The device is to be portable

Wording of the PDS

Document

• Example: ESCO’s Pin Remover

– The pin-remover is to be light.

– The pin-remover must work in a wet, cold, and dusty environment.

– The Pin-remover must be safe

– The Pin-remover must have a 3-year warranty .

PDS Example

• The Pin Remover is to be rugged.

• must work with air pressure.

• is to be easy to use.

• is to pass “ASME standard” tests.

• is to last 5 years in normal usage.

• is to be easy to carry.

PDS Example

• is to sell for less than $150.

• is to cost less than $50 to make.

• is to have low maintenance needs.

• is to be difficult to use as a hammer.

• must not infringe patented devices.

• Production volume is 3000 per year

PDS Example

• is to be tested by June 2013.

• is to be released by Sep. 2013.

• is to be usable with all Dredge models.

• is to work faster than a hammer

Engineering

Specifications

• Engineers cannot design for vague criteria

– “Fast, accurate, high-performing”

– “Light, Small, portable”

– “Easy to use”

– “Safe”

– “Stylish” (maybe)

Engineering Specifications

– Verifiable PDS statements

– Developed for important PDS statements

– Have associated target numbers

• BUT

– Do not push the customer for numbers

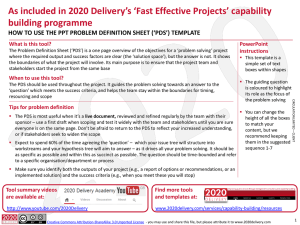

A Typical PDS Page

• Requirement: PR is to be easy to maintain

– Primary customer: End users

– Priority: High

– Metrics and Targets

• Daily maintenance: None

• Weekly maintenance: < 10 minutes – field

• Yearly maintenance: < 1 hour – Shop

• Cost of weekly maintenance < 10c

• Cost of yearly maintenance < $10

Methods of setting targets

Some targets are specified by:

• Marketing

• Management

• Regulations /standards

• Users / buyers / retailers

• etc

Methods of setting targets

• Benchmarking + parametric Studies

• Technology capability

• Field experts

• Experimentation

• Educated guesses

• Select ranges for targets from

Barely acceptable to highly desirable

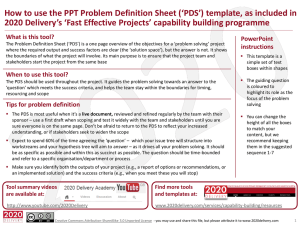

HoQ

Customer

Needs

PDS

Statements

T

A

N

C

I

M

P

O

R

E

Engineering Requirements

Competition

Relation Between

Engineering and

Customer Needs

Competition

Target