5 S training

advertisement

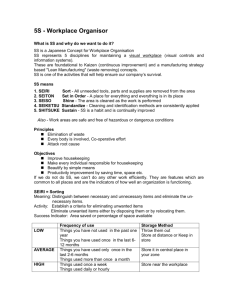

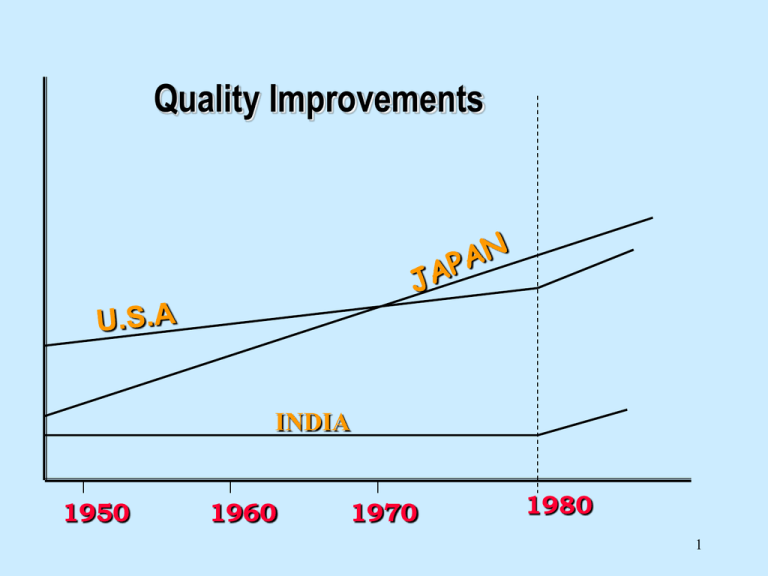

Quality Improvements INDIA 1950 1960 1970 1980 1 1. 5S Principles Elimination of waste Every body is involved, Cooperative effort Attack root cause Human being is not infalliable 2 2. Objectives Improve housekeeping Make every individual responsible for housekeeping Beautify by simple means Productivity improvement by saving time, space etc. 3 3. 5S’s • Seiri • Seiton • Seiso - Sorting - Systematic arrangement - Cleaning Inspection while cleaning • Seiketsu - Standardization • Shitsuke - Self Discipline 4 5S If we do not do 5S, we can’t do any other work efficiently. They are features which are common to all places and are the indicators of how well an organization is functioning. 5 SEIRI = Sorting Meaning Distinguish between necessary and unnecessary items and eliminate the unnecessary items Activity Establish a criteria for eliminating unwanted items Eliminate unwanted items either by disposing them or by relocating them. Success Indicator Area saved or percentage of space available 6 SEIRI = Sorting Japanese Meaning : The Japanese meaning of “Seiri” is to straighten and contain. - Get rid of waste and put it in order according to rules OTHER JAPANESE MEANINGS farmland cultivation, Make an orderly system and straighten 7 Seiri = Sorting What is unnecessary 1. Item is not needed 2. Item is needed however quantity in stock is more than what is needed for consumption in near future 3. Contingency Parts Critically decide the quantity of contingency parts to be retained and criteria for such parts 8 Organization Frequency of use LOW Storage Method *Things you have not used Throw them out in the past one year *Things you have used once Store at distance OR in the last 6-12 months Keep in store *Things you have used only Store it in central place once in the last 2-6 months in your zone *Things used more than once Store it in central place a month in your zone HIGH *Things used once a week Store near the workplace *Things used daily or hourly Store near the workplace 9 Seiri = Sorting Identifying unnecessary 1. Parts & Work in Process (WIP) • Things fallen back behind the machine or rolled under it • Broken items inside the machine • Things under the racks/ platform • Extra WIP • Stock of rejected items • Items accumulated over period for rework • Material awaiting disposal decision • Material brought for some trial, still lying even after trial • Small qty of material no longer in use Contd.. 10 Seiri = Sorting Identifying unnecessary 2. Tools, Toolings, Measuring devices • Old jigs, tools not in use are lying • Modified tools, tooling for trial, are lying after trial • Worn out items like bushes, liners, toggles etc. lying • Broken tools, bits, etc. may be lying • Measuring equipment not required for the operation being performed , is lying 3. Contingency Parts • Many times storage place for contingency parts become a last refuge for broken parts, surplus items and things nobody is likely to use Contd.. 11 Seiri = Sorting Identifying unnecessary 4. Shelves and Lockers • Shelves and lockers tends to collect things that nobody ever uses , like surplus, broken items etc. 5. Passages and Corners • Dust, material not required seem to gather in corner 6. Besides Pillars and under the stairs • These places tends to collect junk, spittoon etc. 7. Walls and Bulletin Boards • Old out dated notices which have lost their relevance • Posters or bulletins on wall • Dust, remains of torn notices, cell tape pieces Contd.. 12 Seiri = Sorting Identifying unnecessary 8.Floor, Pits, Partitions • Defective parts • Protection caps, covers • Packing material • Hardware items , small items • Even tools, tooling Items dropped on the floor are never picked 9.Computer Hard Disk • Many unwanted, outdated, temporary files pile up 13 Seiri = Sorting Improvement methods 1. Flow Process Chart (Procedural Analysis) Drawing a process flow chart for the system eg. How to make and use category wise grouping 2. Operational Analysis Preparing the sequence of operations for system eg. How to perform Seiri (sorting) 3. Check List A check sheet is used to decide what sort of main system and sub system are necessary. 14 Seiri = Sorting Dealing with papers How to reduce papers on your table ? 1. Make a single pile of papers 2. Go through them and sort in following categories a) Immediate action b) Low priority c) Pending d) Reading material e) For information 15 Seiri = Sorting Dealing with papers How to reduce papers on your table ? 4 D Principle DO DELEGATE DELAY DUMP 16 SEITION = Systematic Arrangement Meaning Activity To determine type of storage and layout that will ensure easy accessibility for everyone . - Functional storage - Creating place for everything and putting everything in its place Success - Time saved in searching Indicator - Time saved in material handling 17 SEITION = Systematic Arrangement Japanese Meaning: Dictionary meaning of Seiton is “to be correctly prepared”and “to prepare correctly”. In short these means : (a) arrange correctly in accordance with the correct method of doing activities and (b) make thorough preparations so that activities can be done even if they occur abruptly 18 SEITION = Systematic Arrangement The main target areas for Seri-Seiton improvement are : Tool-setting and preparation operations, line balancing and process planning, parts supply to assembly line, peak time problems etc. Improvement Methods Kit Method / Assembly box method / Outside tool setting Cassettisation / Parallel operations / Changes in assignment method 19 Seiton = Systematic Arrangement How to achieve Systematic Arrangement ? • Decide where things belong • Decide how things should be put away • Obey the Put away rules 20 Seiton = Systematic Arrangement How to achieve Systematic Arrangement ? • Decide where things belong - Standardize Nomenclature - Determine an analytical method of storage • Decide how things should be put away - Name & locations to everything. Label both item and location - Store material functionally - Prevent mistakes with coding by shapes & colour contd.. 21 Seiton = Systematic Arrangement How to achieve Systematic Arrangement ? • Decide how things should be put away - Follow first in first out rule - If two identical items are to be located, then store them separately, colour code them. • Obey the rules - Put the things back to their location after their use 22 Seiton = Systematic Arrangement USE : 1 ) Signboards 2) Colour codes 3) Outline markings 4) Labels 23 Seiton = Systematic Arrangement Functional Storage 24 Seiton = Systematic Arrangement Usage • Store frequently used material Frequency near the workplace and less frequently at some distance Weight & Shape of the Material • Heavy material should be stored at lower levels/layers Place directly on the material handling device for ease of handling Functional Storage 25 Seiton = Systematic Arrangement Category Operation Wise • Same category of material may be stored in one location. Eg. Allen Screws, Oil Seals • All items required for an operation may be stored in one location. Eg. Allen key, spanner etc hand tools required for setting m/c Functional Storage 26 Seiton = Systematic Arrangement • Outlining and Placement Marks - Mark boundaries of dept., aisles, Machines - Follow straight line, right angle rule - Nothing shall be kept outside the boundaries • Stands and shelves - Keep only required number of stands and shelves - Standardize height, size - Provide casters where necessary so that it can be moved 27 Seiton = Systematic Arrangement • Wires and Ducts - Colour code - When there are multiple connections - bundle the wires, label them and make sure that they are in straight line /right angle and firmly anchored • Machine-tools & Tools - Put the tools in the order you need them - Location of the tool should be such that it can be put away with one hand - Try to eliminate some hand tools by permanently attaching it to the bolt head 28 Seiton = Systematic Arrangement • Blades, Dies, Other important consumables - Store them in the protected place - Maintain these things regularly by applying rust preventive, oiling etc. • WIP- Work In Process - Designate a place for each component/part - Decide on how much quantity to be stored - Ensure that there is no damage to good part during transit, they do not get rusty and they are not mislabeled 29 Seiton = Systematic Arrangement • Oils - Reduce number of oils used (Standardize) - Colour code for oil - Safety aspects - fire prevention, pollution, leak, spillage • Instrumentation & Measuring Devices - Label them, show direction of flow 30 SEISO = Cleaning Meaning Cleaning trash, filth, dust and other foreign matter. Cleaning as a form of Inspection Activity - Keep workplace spotlessly clean - Inspection while cleaning - Finding minor problems with cleaning inspection Success Indicator - Reduction in machine down time - Reduction in no. of accidents 31 SEISO = Cleaning Japanese Meaning : Dictionary meaning “to clean up” and “getting rid of dirt and unclean items” While cleaning potential defects such as abrasion, damage, loose parts, deformities, leaks temp., vibration, abnormal sound etc. are revealed hence Seiso is Inspection 32 Seiso = Cleaning • Here cleaning means more than just keeping things clean. Cleaning should be viewed as a form of Visual Inspection • Preventive measures should be taken to tackle problems of dust, grim, burrs, leakage etc. Root cause of the problem should be identified and it should be eliminated 33 Seiso = Cleaning Various Minor Defects = Trash = Dirt =Knocking = Loose parts = Leaks =Scattering =Skips =Curvature =Abrasion =Rust =Scratches =Eccentricity =Lurching =Abnormal =Vibration Movements =Abnormal =Heat =Abnormal Sounds smells =Faded colour =Hisses 34 Seiso = Cleaning 5 Minutes Every day for cleaning • Devote 5 minutes everyday for cleaning your work area • Participation of everyone is required • Attack hard to clean places regularly 35 Seiso = Cleaning Cleaning-Inspection points for most equipment Grime, clogging, dust balls, rust, Cleaning leakage etc. Oils No oil, Low oil, leakage, filter clogging, dirty oil, dirty or bent oil lines, clogged drainage, oil spillage, worn& torn ports etc. 36 Seiso = Cleaning Cleaning-Inspection points for most equipment Tightening Heat Loose bolts, welding detachment, loose parts, vibration or bumping noise, friction Oil tanks, motors, heater, axles, control panels, washing/ cleaning water, bearing, wiring etc. 37 Seiso = Cleaning Cleaning-Inspection points for most equipment Breakage, Cracks Breakage, cracks, dent on sliding parts, handle has come off, broken switches, wire joints come off, wires are broken or crack, crack dial of various pre. gauges, meters etc. 38 Seiso = Cleaning Function wise Cleaning check list of equipment Pneumatics Compressed Air lines, air valves, connections, meters, filters, reservoirs etc. Hydraulics Hydraulic oil tank, oil valves, filters, pumps, hoses, gauges, cylinders etc. 39 Seiso = Cleaning Function wise Cleaning check list of equipment Motor fan, fan belt, couplings, Mech & Joints, pulleys, chains, pump Power Train bearings etc. Electrical Control panel, lamps, light, switch, sensors, wiring, ducts, fuses etc. 40 Seiso = Cleaning Function wise Cleaning check list of equipment Toolings Equipment Specific Tools, fixtures, gauges, dies, measuring instruments, etc. Furnaces, rollers, chutes, CNC machines, etc. 41 SEIKETSU = Standardization Meaning Setting up standards / Norms for a neat, clean, workplace and details of how to maintain the norm (Procedure) Activity - Innovative visual management - Colour coding - Early detection of problem and early action Success Indicator Increase in 5S indicator 42 SEIKETSU = Standardization Japanese Meaning : Dictionary meaning “unsoiled things, purity and cleanliness” Clean manners , Clean cloths, clean politician It is the proof that 3 S’s are being faithfully carried out. 43 SEIKETSU = Standardization Tools used for analysis : MTTR MTBF OEE 44 Seiketsu = Standardization • Regularizing 5S activities so that abnormalities are revealed • Make it easy for everyone to identify the state of normal or abnormal condition • For maintaining previous 3S, deploy visual management 45 Seiketsu = Standardization • It has been estimated by scientific study that 60% of all human activities starts with sight • 5S is easy to do once.It is consistency that is difficult. That is why Visual Management is so important, so that everybody will know that there is some problem. Visual Management 46 Seiketsu = Standardization What visual control communicates ? It grabs one or more of our senses in order to • • • • Alert us to an abnormality Help us recover quickly Promote adherence and prevention Enable successful self management 47 Seiketsu = Standardization Some methods for visual communication Colour coding Use of Labels Danger alerts Indication where things should be put Directional arrows/ marks Transparent covers Performance indicators 48 Seiketsu = Standardization Some methods for visual communication Labels Precision management labels Inspection labels Temperature labels Responsibility labels 49 Seiketsu = Standardization Points to remember in making visual c control tools 1. Make them easy to see from distance 2. Put the display on the things 3. Everyone can tell what is right and what is wrong 4. Anybody can follow them and make necessary corrections easily 5. Work place should look brighter & orderly 50 Seiketsu = Standardization Some everyday visual management examples Traffic signal Zebra crossing In car - Petrol indicator - Speed indicator Direction arrows Electric danger sign etc. 51 Seiketsu = Standardization Some visual communication signs 52 SHITSUKE = Self Discipline Meaning Every one sticks to the rule and makes it a habit Activity - Participation of everyone in developing good habits - Regular audits and aiming for higher level Success Indicator High employee morale Involvement of all people 53 SHITSUKE = Self Discipline Japanese Meaning : Dictionary meaning is “learning of the manners” “having manners, dressing neatly” OR “training children for good customs” 54 SHITSUKE = Self Discipline Activities : 5S Committee 5S Training 5S Competition / evaluation 5S Month Posters , Literature etc. 55 Shitsuke = Self Discipline We need everyone to maintain 5S guidelines. To maintain DISCIPLINE, we need to practice and repeat until it becomes a way of life. Discipline is the Core of 5S 56 Shitsuke = Self Discipline Discipline means making a steady habit of properly maintaining correct procedure. Time and effort involved in establishing proper arrangement and orderliness will be in vain if we do not have discipline to maintain it. 57 Shitsuke = Self Discipline Pledge It shall be my constant effort to maintain my workplace in good order by Assigning a place for everything & keeping everything in its place Sorting out unwanted material periodically & discarding them Keeping my work area neat & clean everyday 58 Organization • • • • • Departments into areas Coordinators at department level Coordinator at each area level Training for all Audit each area and make action check list • Implement actions • Audit and evaluation on continuous basis 59 Implementation Target • TOTAL FACTORY • 400 people/month to be trained • Every 3 month 25% area will be covered 60